Cleaning system and method for decolorizing membrane in membrane-process sugar making system

A cleaning system and decolorization technology, which is applied in the field of cleaning systems for decolorization membranes in membrane sugar production systems, can solve problems such as decolorization membrane pollution, and achieve the effects of reducing operating costs and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

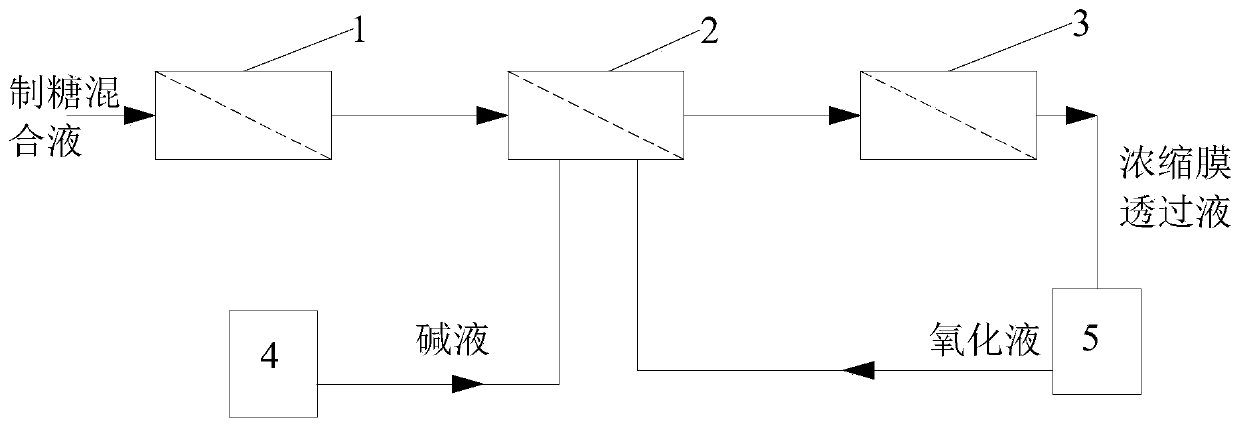

[0060] This embodiment provides a cleaning system for the decolorization membrane in the membrane sugar production system, the structural diagram is as follows figure 1 As shown, it includes a clarification membrane filtration unit 1 , a decolorization membrane filtration unit 2 and a concentration membrane filtration unit 3 connected in sequence, and also includes an alkali cleaning unit 4 and an enzyme-catalyzed oxidation unit 5 .

[0061] The alkali cleaning unit 4 includes an lye storage device and an lye delivery device; the lye delivery device is used to deliver the lye in the lye storage device to the decolorization membrane filter unit 2 .

[0062] The enzyme-catalyzed oxidation unit 5 includes an enzyme-catalyzed oxidation reactor carrying glucose oxidase and an oxidation liquid delivery device; the liquid inlet of the enzyme-catalyzed oxidation reactor is connected to the permeate outlet of the concentrated membrane filtration unit 3; The oxidation liquid delivery de...

Embodiment 2

[0066] This embodiment provides a cleaning system for the decolorization membrane in the membrane sugar system, including a clarification membrane filtration unit 1, a decolorization membrane filtration unit 2, and a concentration membrane filtration unit 3 connected in sequence, and also includes an alkali cleaning unit 4 and enzyme-catalyzed oxidation Unit 5.

[0067] The alkali cleaning unit 4 includes an lye storage device and an lye delivery device; the lye delivery device is used to deliver the lye in the lye storage device to the decolorization membrane filter unit 2 .

[0068] The enzyme-catalyzed oxidation unit 5 includes an enzyme-catalyzed oxidation reactor carrying glucose oxidase and an oxidation liquid delivery device; the liquid inlet of the enzyme-catalyzed oxidation reactor is connected to the permeate outlet of the concentrated membrane filtration unit 3; The oxidation liquid delivery device is used to transport the oxidation liquid produced by the enzyme-cat...

Embodiment 3

[0072] This embodiment provides a cleaning system for the decolorization membrane in the membrane sugar system, including a clarification membrane filtration unit 1, a decolorization membrane filtration unit 2, and a concentration membrane filtration unit 3 connected in sequence, and also includes an alkali cleaning unit 4 and enzyme-catalyzed oxidation Unit 5.

[0073] The alkali cleaning unit 4 includes an lye storage device and an lye delivery device; the lye delivery device is used to deliver the lye in the lye storage device to the decolorization membrane filter unit 2 .

[0074] The enzyme-catalyzed oxidation unit 5 includes an enzyme-catalyzed oxidation reactor carrying glucose oxidase and an oxidation liquid delivery device; the liquid inlet of the enzyme-catalyzed oxidation reactor is connected to the permeate outlet of the concentrated membrane filtration unit 3; The oxidation liquid delivery device is used to transport the oxidation liquid produced by the enzyme-cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com