High-strength, solvent-resistant and anti-pollution hollow fiber reverse osmosis membrane and preparation method thereof

A reverse osmosis membrane and solvent-resistant technology, which is applied in the field of membrane separation, can solve the problems of small quantity, pressure resistance, and structural damage of the desalination layer, and achieve the effects of low cost, improved acid and alkali hydrolysis resistance, and improved solvent resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

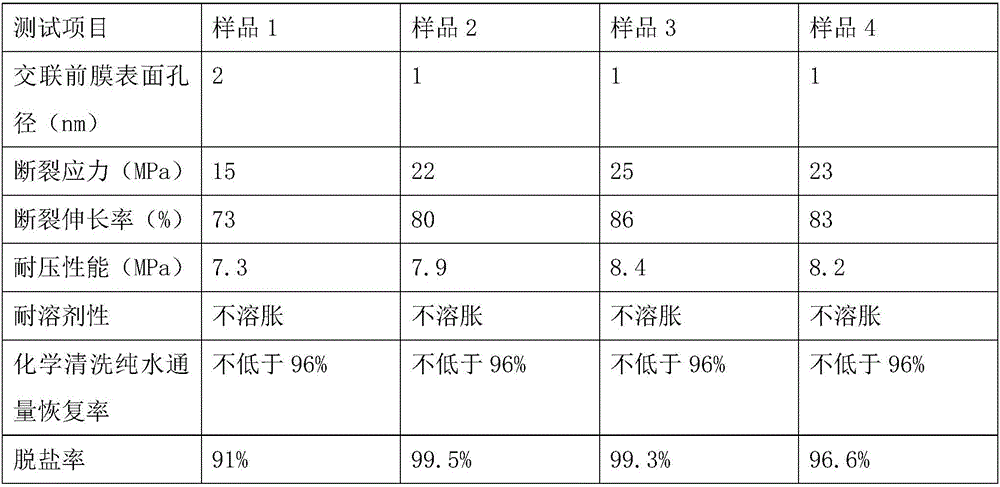

Examples

Embodiment 1

[0036] The high-strength solvent-resistant and anti-fouling anti-pollution hollow fiber reverse osmosis membrane is prepared from the following components in parts by weight: 65 parts of hydroxyl-containing polymers, 4.9 parts of hydrophilic inorganic nanoparticles containing hydroxyl groups, 0.2 parts of antioxidants and plasticizers 15 doses. Wherein, the hydroxyl-containing polymer is an ethylene-vinyl alcohol copolymer with a vinyl mass fraction of 29%. The hydrophilic inorganic nanoparticles containing hydroxyl are graphene oxide; the particle size of the hydrophilic inorganic nanoparticles containing hydroxyl is 5nm. The plasticizer adopts polyethylene glycol 200. The antioxidant was octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate.

Embodiment 2

[0038] The high-strength solvent-resistant and anti-fouling anti-pollution hollow fiber reverse osmosis membrane is prepared from the following components in parts by weight: 70 parts of hydroxyl-containing polymers, 9.9 parts of hydrophilic inorganic nanoparticles containing hydroxyl groups, 0.3 parts of antioxidants and plasticizers 30 doses. Wherein, the hydroxyl-containing polymer is an ethylene-vinyl alcohol copolymer with a vinyl mass fraction of 44%. The hydrophilic inorganic nanoparticles containing hydroxyl are titanium dioxide; the particle size of the hydrophilic inorganic nanoparticles containing hydroxyl is 40nm. The plasticizer adopts polyethylene glycol 300. The antioxidant was octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate.

Embodiment 3

[0040] The high-strength solvent-resistant and anti-fouling anti-pollution hollow fiber reverse osmosis membrane is prepared from the following components in parts by weight: 68 parts of hydroxyl-containing polymers, 7.5 parts of hydrophilic inorganic nanoparticles containing hydroxyl groups, 0.1 parts of antioxidants and plasticizers 20 doses. Wherein, the hydroxyl-containing polymer is an ethylene-vinyl alcohol copolymer with a vinyl mass fraction of 36%. The hydrophilic inorganic nanoparticles containing hydroxyl are zirconium dioxide; the particle size of the hydrophilic inorganic nanoparticles containing hydroxyl is 22nm. The plasticizer adopts diethylene glycol. The antioxidant was octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com