Anti-pollution composite reverse osmosis membrane and preparation method thereof

A reverse osmosis membrane, anti-pollution technology, applied in semi-permeable membrane separation, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc., can solve problems such as short travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

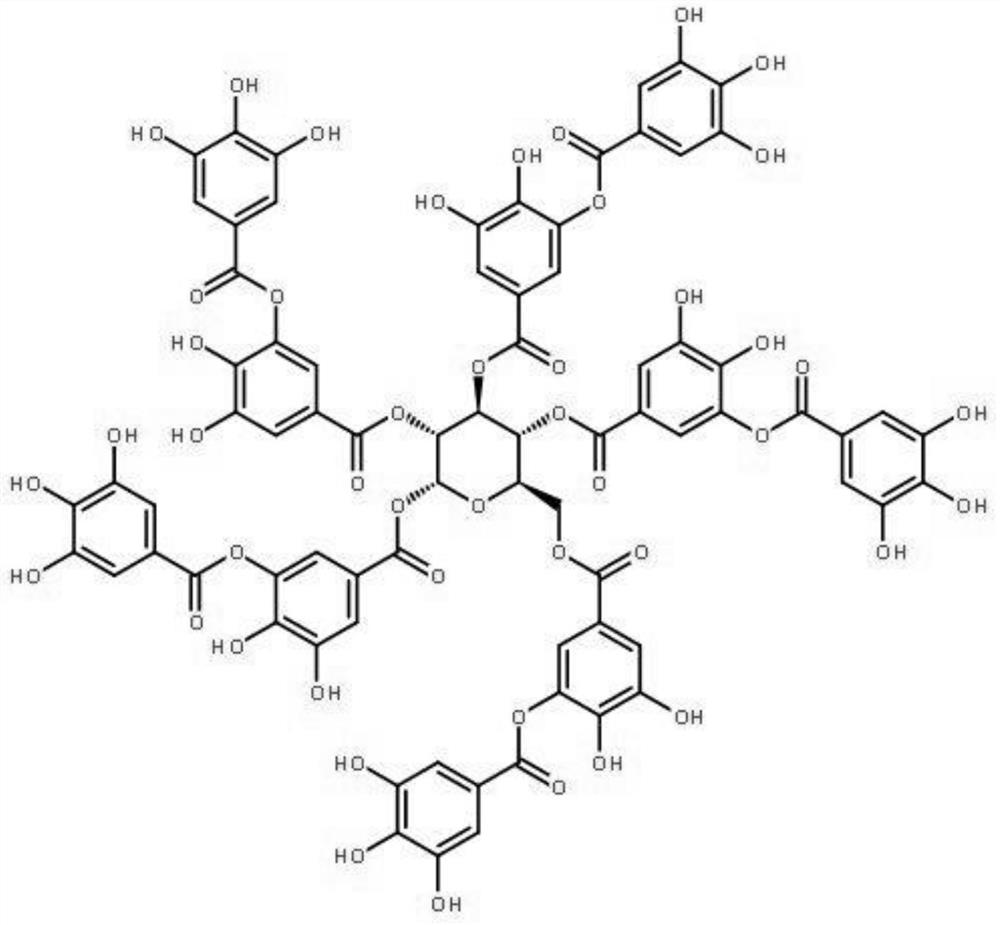

Image

Examples

preparation example Construction

[0082] In some embodiments, the preparation method of the composite reverse osmosis membrane of the present invention comprises the following steps:

[0083] (1) Add polyvinyl alcohol or its aqueous solution to the tannic acid aqueous solution, stir evenly, optionally adjust the pH to 3-6, and obtain the mass ratio of polyvinyl alcohol and tannic acid as (5-500): 1 coating solution;

[0084] (2) The polyamide reverse osmosis membrane is contacted with the coating solution, and then heat-treated to obtain a composite reverse osmosis membrane.

[0085] In a preferred embodiment, the preparation method of the composite reverse osmosis membrane of the present invention comprises the following steps:

[0086] (1) Add polyvinyl alcohol or its aqueous solution to the tannic acid aqueous solution, stir evenly, and optionally adjust the pH to 3-6 to obtain polyvinyl alcohol with a mass fraction of 0.1-8%, polyvinyl alcohol and tannic acid The mass ratio is (5-500): 1 coating solution...

Embodiment 1

[0111] Add tannic acid to the water, stir evenly, then add polyvinyl alcohol aqueous solution, stir evenly, adjust the pH with dilute hydrochloric acid, and obtain a mass fraction of polyvinyl alcohol of 0.8%, and a mass ratio of polyvinyl alcohol to tannic acid of 30:1. A coating solution with a pH of 5.36; soak the surface of the aromatic polyamide reverse osmosis membrane after rinsing in the coating solution, contact it at 25°C for 10 seconds, air-dry it, transfer it to an oven for drying treatment, and dry it at 100°C for 1 minute to obtain The anti-pollution polyamide composite reverse osmosis membrane has a hydrophilic and smooth surface without adhesion.

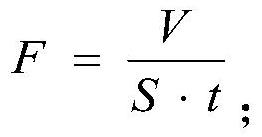

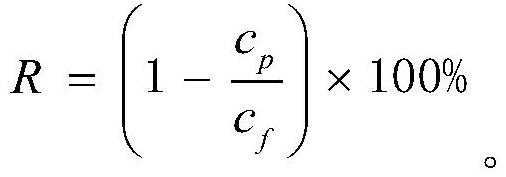

[0112] The prepared composite reverse osmosis membrane has a surface chemical structure with a C / O ratio of 62.8 / 37.2 and an N / O ratio of 0 / 100. The initial performance was measured at 25°C, 2000ppm NaCl feed liquid, and 1.55MPa for 30 minutes, and the flux was 54.78L / (m 2 *h), the desalination rate is 99.71%; the r...

Embodiment 2

[0114] Add tannic acid to the water, stir evenly, then add polyvinyl alcohol aqueous solution, stir evenly, adjust the pH with dilute hydrochloric acid, and obtain a mass fraction of polyvinyl alcohol of 1.5%, and a mass ratio of polyvinyl alcohol to tannic acid of 15:1. A coating solution with a pH of 5.94; apply the coating solution on the surface of the rinsed aromatic polyamide reverse osmosis membrane, transfer it to an oven for drying treatment, and dry it at 120°C for 2 minutes to obtain an anti-pollution polyamide composite reverse osmosis membrane , the appearance showed a hydrophilic smooth surface, showing no adhesion.

[0115] The prepared composite reverse osmosis membrane has a surface chemical structure with a C / O ratio of 62.2 / 37.8 and an N / O ratio of 0 / 100. The initial performance was measured at 25°C, 2000ppm NaCl feed liquid, and 1.55MPa for 30 minutes, and the flux was 50.12L / (m 2 *h), the desalination rate is 99.63%; the replacement raw material solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com