Preparation method of photo-Fenton self-cleaning film and application thereof

A technology of self-cleaning film and polyvinylidene fluoride film is applied in the field of preparation of optical Fenton self-cleaning film, which can solve problems such as hindering the application of film, and achieve the effects of strong self-cleaning, efficient separation and enhanced stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Surface modification of commercially available polyvinylidene fluoride membranes: first pre-wet a piece of commercially available polyvinylidene fluoride membranes with ethanol, and then soak the polyvinylidene fluoride membranes in an aqueous solution of 2 mg / mL tannic acid for 5 min. Then rinse the polyvinylidene fluoride membrane with tannic acid with deionized water, denoted as PVDF / TA membrane, and then transfer to FeCl with a concentration of 2mg / mL 3 ·6H 2 O aqueous solution for 5min, after rinsing with deionized water, dry at room temperature to obtain PVDF / TA-Fe(III) membrane;

[0030] (2) Preparation of self-cleaning membrane: a piece of PVDF / TA-Fe(III) membrane immersed in a concentration of 0.4wt% FeCl 3 ·6H 2 O aqueous solution was incubated at 60°C for 24 hours in a water bath, the membrane was taken out, rinsed with deionized water, and dried at 40°C to obtain a self-cleaning membrane, denoted as PVDF / TA / β-FeOOH.

Embodiment 2

[0032] (1) Surface modification of commercially available polyvinylidene fluoride membranes: first pre-wet the polyvinylidene fluoride membranes with ethanol, then soak the polyvinylidene fluoride membranes in 3.5 mg / mL tannic acid aqueous solution for 8 min, and then use Rinse the polyvinylidene fluoride membrane with tannic acid in deionized water, denoted as PVDF / TA membrane, and then transfer to FeCl with a concentration of 3.5mg / mL 3 ·6H 2 O aqueous solution for 8min, after rinsing with deionized water, dry at room temperature to obtain PVDF / TA-Fe(III) membrane;

[0033] (2) Preparation of self-cleaning membrane: the PVDF / TA-Fe(III) membrane is immersed in 0.2wt% FeCl 3 ·6H 2 O aqueous solution was incubated at 75°C for 18 hours in a water bath, the membrane was taken out, rinsed with deionized water, and dried at 40°C to obtain a self-cleaning membrane, which was designated as PVDF / TA / β-FeOOH.

Embodiment 3

[0035] (1) Surface modification of commercially available polyvinylidene fluoride membranes: first pre-wet the polyvinylidene fluoride membranes with ethanol, then soak the polyvinylidene fluoride membranes in 5 mg / mL tannic acid aqueous solution for 10 min, and then use The polyvinylidene fluoride membrane with tannic acid was rinsed with ion water, denoted as PVDF / TA membrane, and then transferred to FeCl with a concentration of 5mg / mL 3 ·6H 2 O aqueous solution for 10min, after washing with deionized water, dry at room temperature to obtain PVDF / TA-Fe(III) membrane;

[0036] (2) Preparation of self-cleaning membrane: the PVDF / TA-Fe(III) membrane is immersed in 0.6wt% FeCl 3 ·6H 2 O aqueous solution was incubated at 90°C for 12 h in a water bath, the membrane was taken out, rinsed with deionized water, and dried at 40°C to obtain a self-cleaning membrane, which was denoted as PVDF / TA / β-FeOOH.

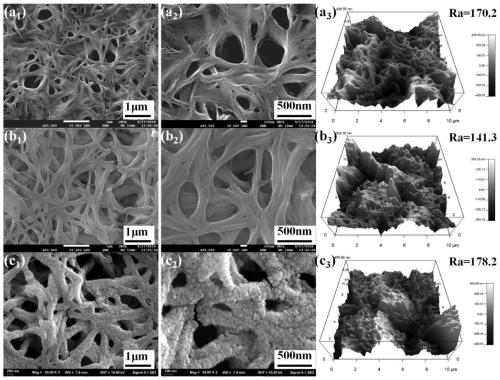

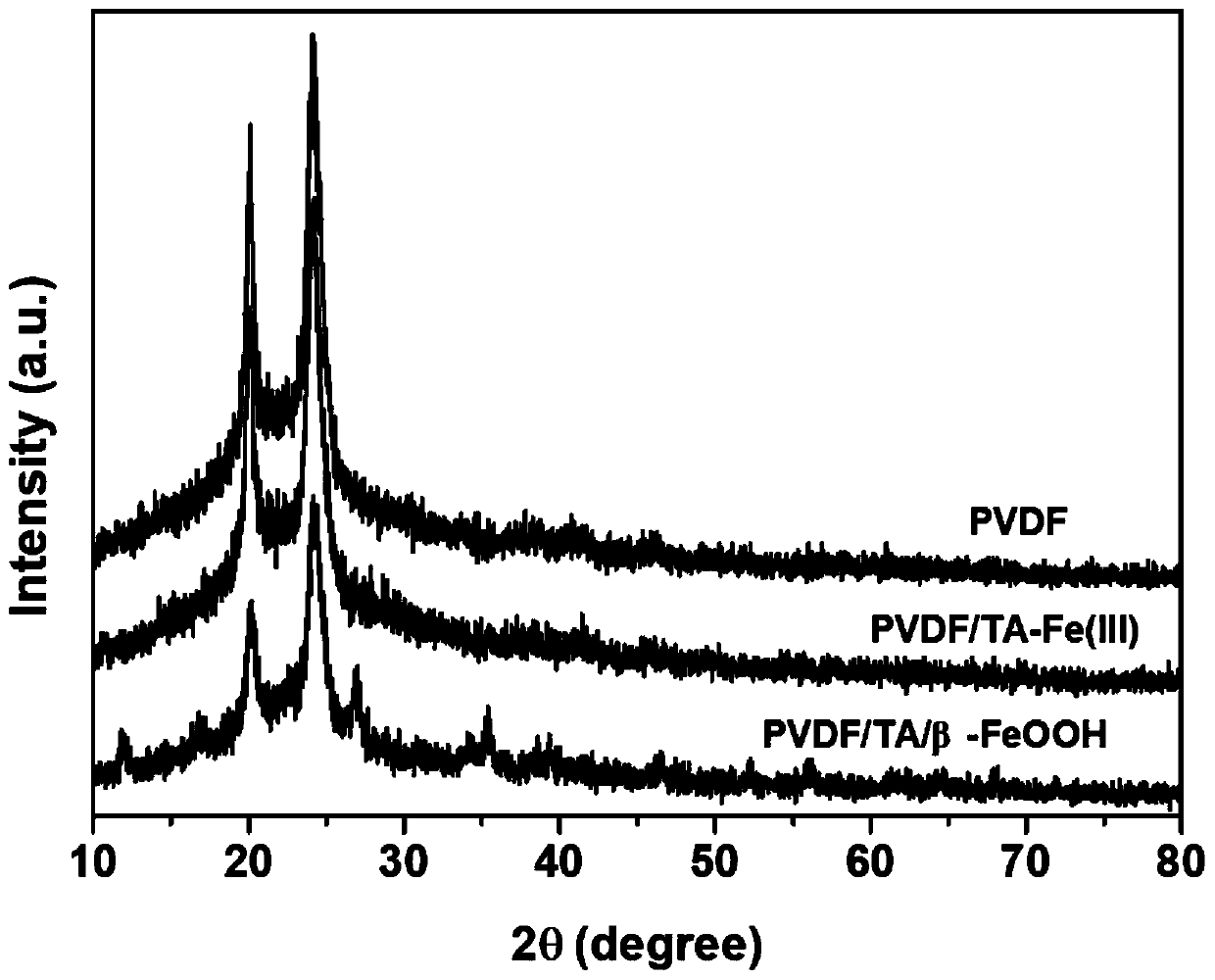

[0037] figure 1 For PVDF, PVDF / TA-Fe(III) and the scanning electron microscop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com