Amphiphilic fluorine-containing gradient copolymer, and preparation method and application thereof

A gradient copolymer and amphiphilic technology, applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problems of increased membrane adhesion and difficulty in cleaning, to eliminate attenuation, improve resistance Pollution performance and total flux decay rate decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

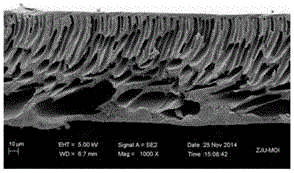

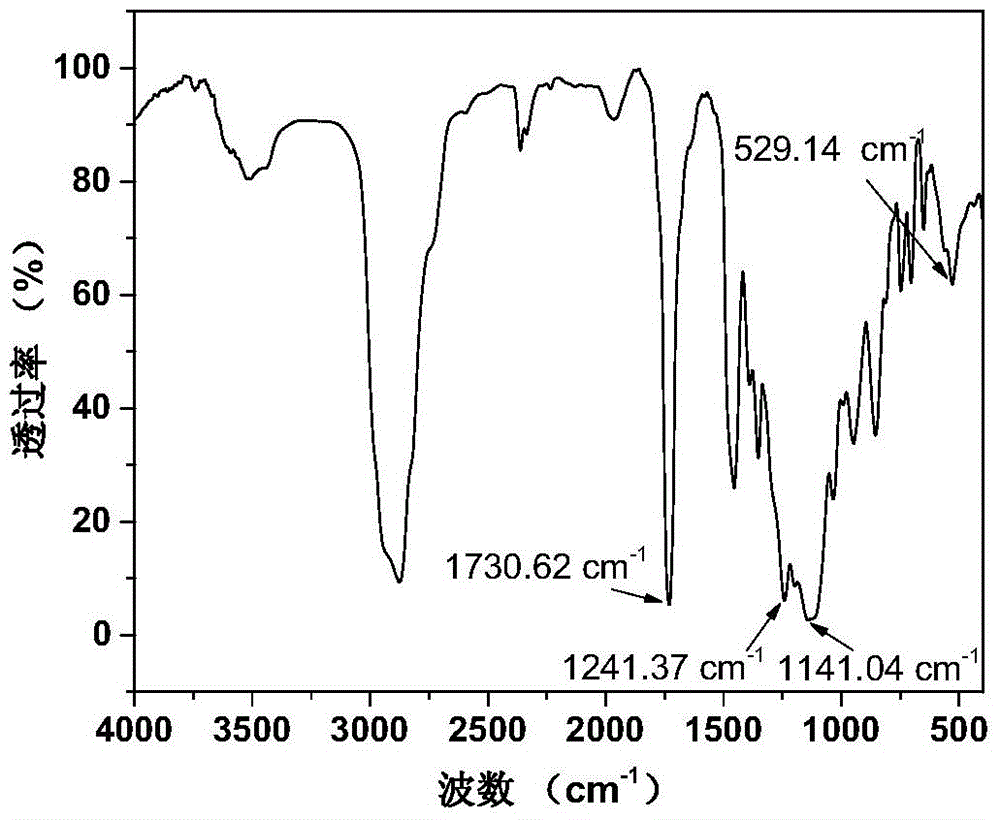

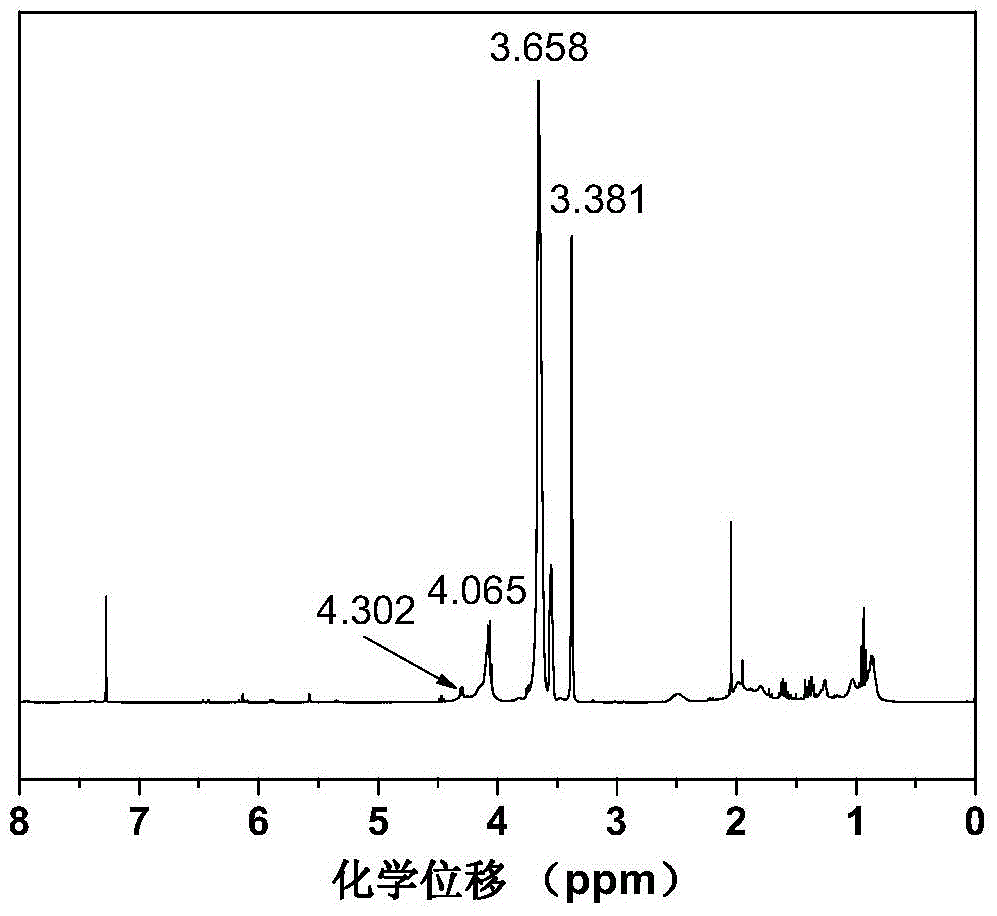

[0029] Example 1: This example prepares amphiphilic fluorine-containing gradient copolymer

[0030] Add 14.46g polyethylene glycol methacrylate, 0.422g RAFT reagent CPDB, 0.096g initiator AIBN and 33.72g butyl acetate into a 100mL three-necked flask (A), the three-necked flask is equipped with mechanical stirring and reflux condenser . Before the reaction started, the inside of the flask was replaced with nitrogen for 30 minutes to remove the oxygen inside, and then the flask was placed in an oil bath at 75°C. 9.71g fluorine-containing monomer perfluorohexyl ethyl acrylate C 6 A and 22.64 g of butyl acetate were placed in another flask, and the oxygen in the solution system was replaced by three freeze-wash-thaw cycles. Then it was placed in the syringe pump (B), and was added dropwise to the three-necked flask A at a constant rate (the dropping time was 4h), the whole reaction was carried out under the atmosphere of nitrogen protection, and the reaction was continued for 12...

Embodiment 2

[0032] Embodiment 2: This embodiment prepares amphiphilic fluorine-containing gradient copolymer

[0033] Add 14.46g polyethylene glycol acrylate, 0.422g RAFT reagent CPDB, 0.096g initiator AIBN and 33.72g butyl acetate into a 100mL three-necked flask (A). The three-necked flask is equipped with mechanical stirring and a reflux condenser. Before the reaction started, the inside of the flask was replaced with nitrogen for 30 minutes to remove the oxygen inside, and then the flask was placed in an oil bath at 75°C. Put 9.71g of perfluorohexylethyl methacrylate and 22.64g of butyl acetate in another flask, and replace the oxygen in the solution system through three freeze-wash-thaw cycles. Then it was placed in the syringe pump (B), and was added dropwise to the three-necked flask A at a constant rate (the dropping time was 6h), the whole reaction was carried out under the atmosphere of nitrogen protection, and the reaction was continued for 18h after the dropwise addition The r...

Embodiment 3

[0034] Embodiment 3: This embodiment prepares amphiphilic fluorine-containing gradient copolymer

[0035] Add 14.46g polyethylene glycol acrylate, 0.422g RAFT reagent CPDB, 0.096g initiator AIBN and 33.72g butyl acetate into a 100mL three-necked flask (A). The three-necked flask is equipped with mechanical stirring and a reflux condenser. Before the reaction started, the inside of the flask was replaced with nitrogen for 30 minutes to remove the oxygen inside, and then the flask was placed in an oil bath at 75°C. Put 9.71g of (N-methylperfluorohexanesulfonamido)ethyl methacrylate and 22.64g of butyl acetate in another flask, and replace the oxygen in the solution system by three freeze-wash-thaw cycles . Then it was placed in the syringe pump (B), and was added dropwise to the three-necked flask A at a constant rate (the dropping time was 5h), the whole reaction was carried out under the atmosphere of nitrogen protection, and the reaction was continued for 15h after the dropw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com