Preparation method of poly(3,4-ethylenedioxythiophene) (PEDOT)-coated carbon nanotube composite material

A technology of carbon nanotubes and dioxyethyl, which is applied in the field of carbon materials and conductive polymer composite materials, can solve the problems of unfavorable large-scale production, difficult control of repeatability, small reaction area, etc., to achieve large-scale synthesis, The method is simple and the effect of good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

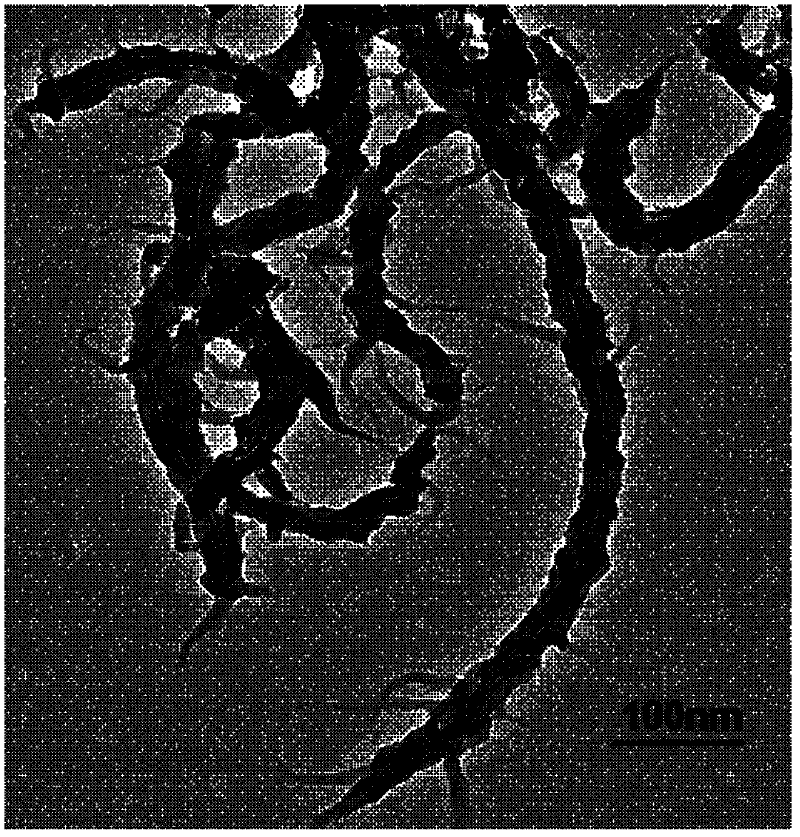

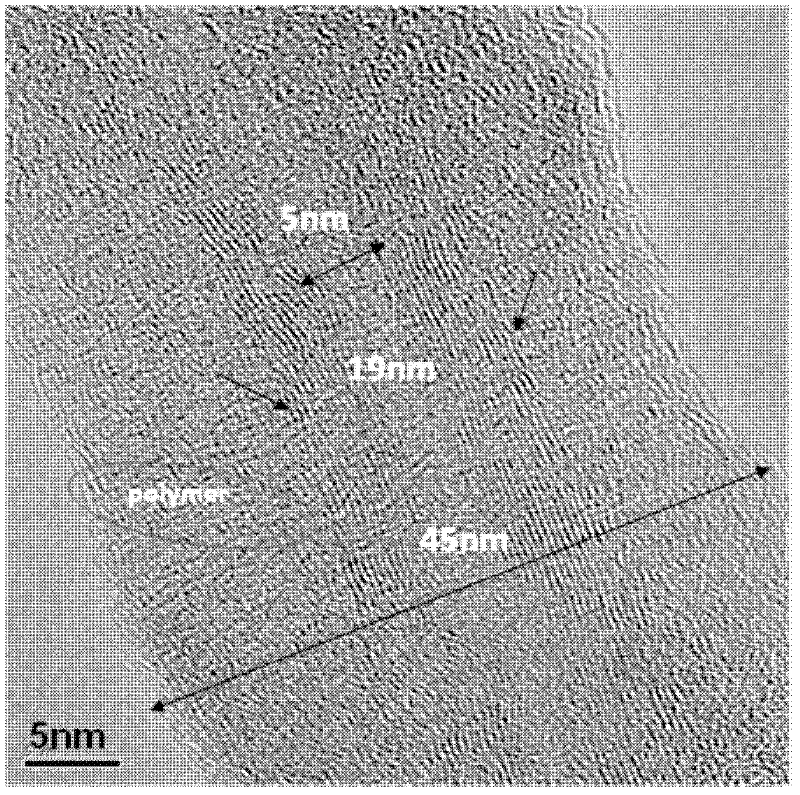

[0019] a) ultrasonically dispersing carboxy-functionalized multi-walled carbon nanotubes (COOH-MWCNTs) in deionized water to obtain a multi-walled carbon nanotube dispersion with a solid content of 0.3 wt %;

[0020] b) Iron trichloride (FeCl 3 ) was dissolved in deionized water, stirred and dissolved to obtain an orange-yellow aqueous solution containing a concentration of 16mol / L ferric chloride;

[0021] c) Using p-xylene as a solvent, take the surfactant di(2-ethylhexyl) sodium succinate sulfonate (AOT) and dissolve it in p-xylene, and dissolve it by ultrasonication and continuous stirring to obtain the surfactant A solution with an AOT concentration of 1.3mol / L;

[0022] d) Add the multi-walled carbon nanotube dispersion obtained in step a) to the solution obtained in step c), and ultrasonically disperse and stir until the multi-walled carbon nanotubes are uniformly dispersed in the mixed system; under stirring conditions, add The obtained orange-yellow aqueous solution...

Embodiment 2

[0026] a) ultrasonically dispersing carboxy-functionalized multi-walled carbon nanotubes (COOH-MWCNTs) in deionized water to obtain a multi-walled carbon nanotube dispersion with a solid content of 1.5 wt %;

[0027] b) Iron trichloride (FeCl 3) was dissolved in deionized water, stirred and dissolved to obtain an orange-yellow aqueous solution that contained a concentration of 13mol / L ferric chloride;

[0028] c) Using p-xylene as a solvent, take the surfactant AOT and dissolve it in p-xylene, ultrasonically and continuously stir to dissolve it, to obtain a solution with a concentration of the surfactant AOT of 1.4mol / L;

[0029] d) Add the multi-walled carbon nanotube dispersion obtained in step a) to the solution obtained in step c), and ultrasonically disperse and stir until the multi-walled carbon nanotubes are uniformly dispersed in the mixed system; under stirring conditions, add The obtained orange-yellow aqueous solution containing ferric chloride in step b) is fully ...

Embodiment 3

[0033] a) ultrasonically dispersing carboxy-functionalized multi-walled carbon nanotubes (COOH-MWCNTs) in deionized water to obtain a multi-walled carbon nanotube dispersion with a solid content of 3 wt %;

[0034] b) Iron trichloride (FeCl 3 ) was dissolved in deionized water, stirred and dissolved to obtain an orange-yellow aqueous solution that contained a concentration of 12mol / L ferric chloride;

[0035] c) Using p-xylene as a solvent, take the surfactant AOT and dissolve it in p-xylene, ultrasonically and continuously stir to dissolve it, to obtain a solution with a concentration of the surfactant AOT of 1.6mol / L;

[0036] d) Add the multi-walled carbon nanotube dispersion obtained in step a) to the solution obtained in step c), and ultrasonically disperse and stir until the multi-walled carbon nanotubes are uniformly dispersed in the mixed system; under stirring conditions, add The obtained orange-yellow aqueous solution containing ferric chloride in step b) is fully s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com