DLED liquid crystal display television backplane without hardware forming mould and preparation method thereof

A technology for LCD TVs and forming molds, which is applied to TVs, color TVs, and parts of color TVs. It can solve the problems of large size deviation, expensive mold costs, and high development costs, and achieve accurate dimensions, cheap mold costs, and economical The effect of mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

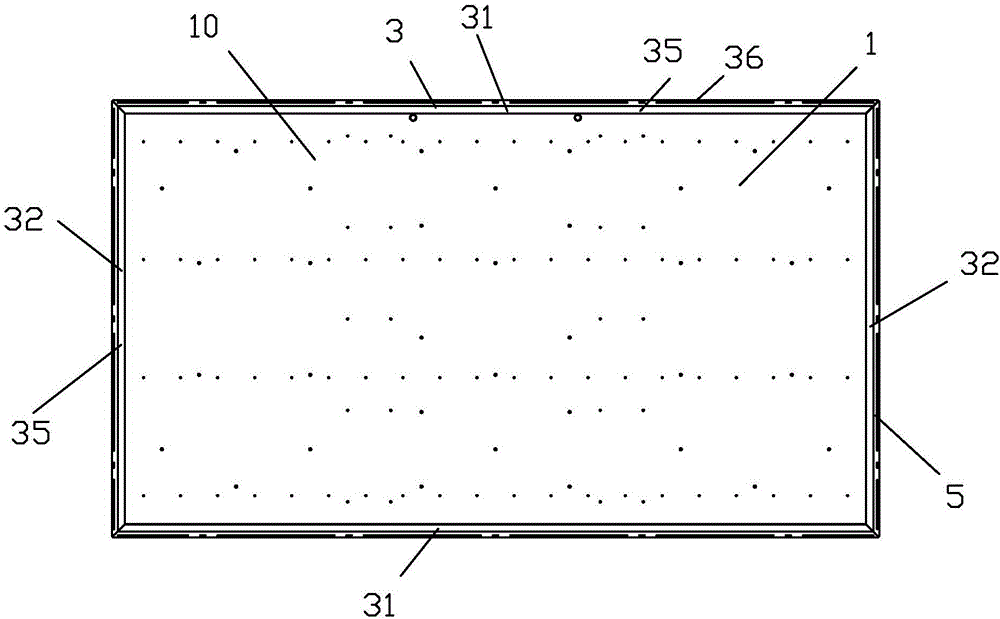

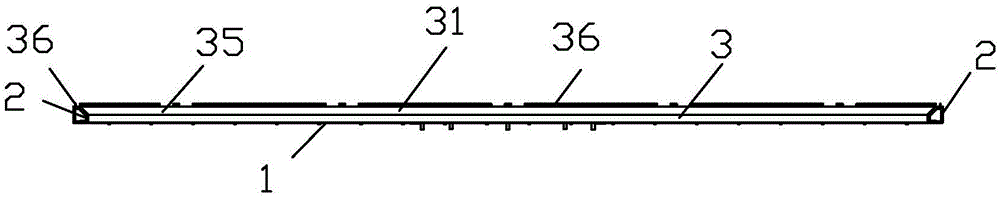

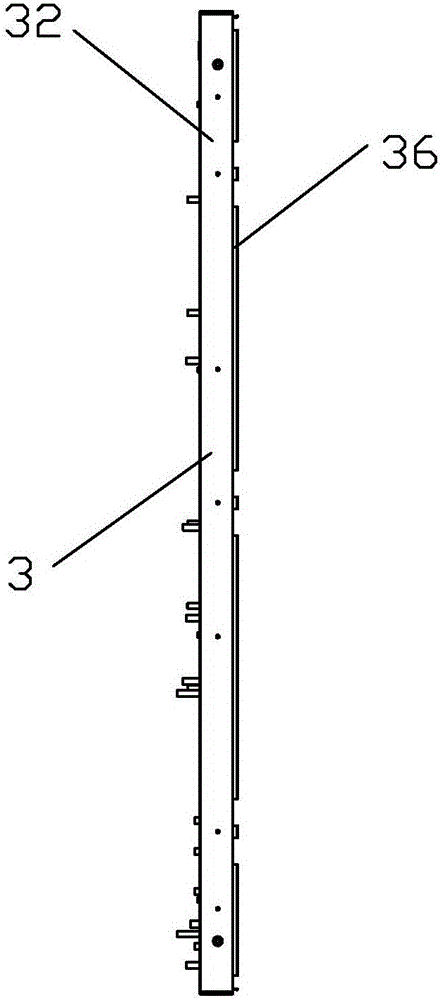

[0035] see Figure 1 to Figure 13 As shown, a DLED LCD TV backplane without metal forming molds of the present invention includes: four aluminum profiles 3, four die-cast aluminum corner fittings 2 and a flat steel plate 1; the four aluminum profiles 3 are sequentially head to tail After being assembled vertically, a rectangular frame is formed; the four die-casting aluminum corner fittings 2 are L-shaped, and the four die-casting aluminum corner fittings 2 are respectively inserted into the cavities of two adjacent aluminum profiles 3 , and screwed 41 Locked between the die-casting aluminum corner fittings 2 and the corresponding aluminum profiles 3, two adjacent aluminum profiles 3 are fixed to form a rectangular aluminum frame 5; The four aluminum profiles 3 and the flat steel plate 1 encircle a concave cavity 10 capable of accommodating electronic devices corresponding to the DLED LCD TV.

[0036] In this embodiment, the two ends of the four aluminum profiles 3 are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com