Device and method for machining reinforcing steel bar shaped like the Arabic number 8

A technology for steel bar processing and equipment, applied in the field of tunnels, can solve the problems of large material loss, low product output, low product qualification rate, etc., and achieve the effect of ensuring safety and reliability, simple installation and production, and improving the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following non-limiting examples illustrate the invention.

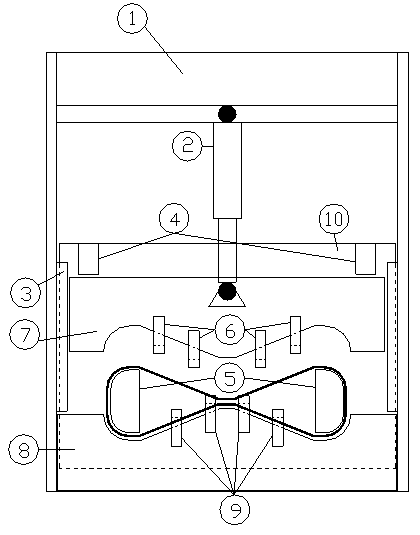

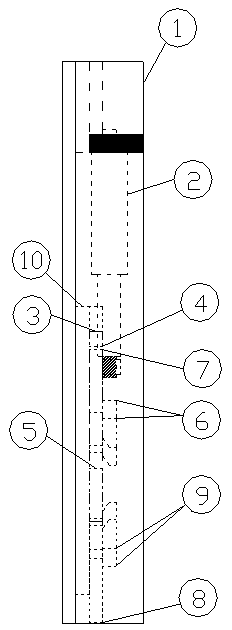

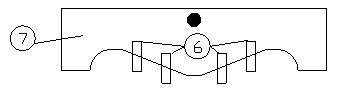

[0036] Such as Figures 1 to 10 As shown, an 8-shaped steel bar processing equipment is composed of 8-shaped forming equipment and bow-back forming equipment. Formed inner mold 5, limit anti-floating clamps 6, 9, sliding forming outer formwork A7, sliding forming outer formwork B8 and sliding inner mold base plate 10; Figures 1 to 6 As shown, the workbench 1 is located at the bottom as a support, and the limit plate 3 is fixed on it. The sliding inner mold base plate 10 is placed between the workbench 1 and the limit plate 3, and the limit plate 3 limits the sliding inner mold base. The seat plate 10 can only slide on the surface of the workbench 1, and the workbench 1 is also fixed with a sliding forming outer formwork B8, and the sliding inner mold base plate 10 is fixed with a telescopic clamping plate 4 and a sliding 8-shaped inner mold 5. One end of the hydraulic arm 2 is fixed on the worktable 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com