Bending forming die tool for bus roof through beam

A technology for buses and forming molds, applied in beams, structural elements, building components, etc., can solve problems such as low production efficiency, twisted beams, low efficiency, etc., and achieve stable and reliable installation, stable product size, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

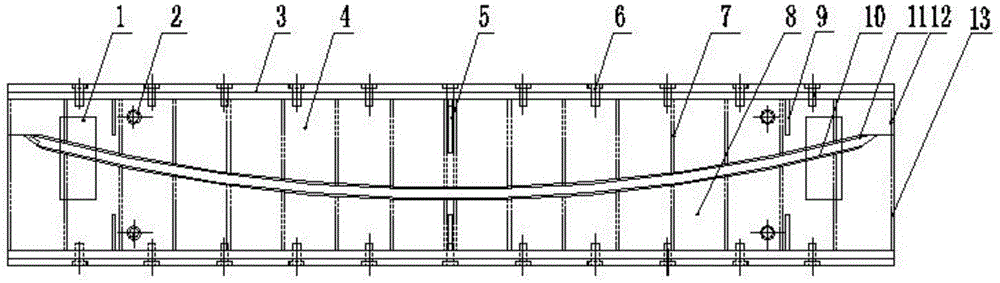

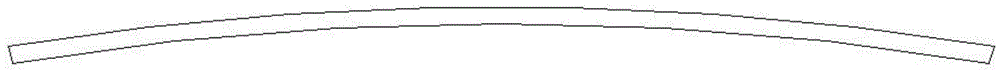

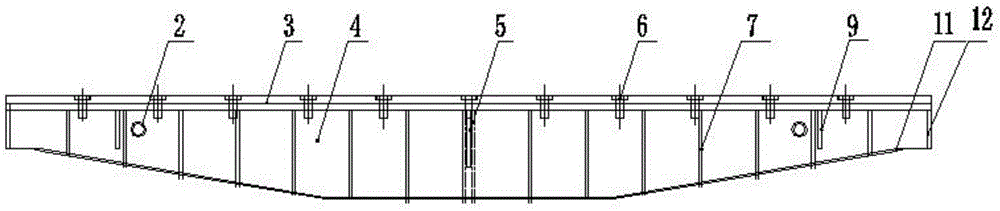

[0018] The tooling of the bus large roof penetrating beam bending forming die, such as figure 1 As shown, the tooling is composed of an upper mold and a lower mold that cooperate with each other, and is used to press and form the large top curved beam of the bus;

[0019] see image 3 , Figure 4 , the upper mold includes a bottom plate 3, and the bottom plate is provided with two rows of relative bolts 6, the bottom plate and the bolts are used to support the upper mold body and position it on the hydraulic press; a row of sixteen upper reinforcement plates 7 are welded on the bottom plate 3, and the upper The reinforcing plate is located between two rows of bolts, and a connecting plate 14 is provided between adjacent upper reinforcing plates; an upper mold arc plate 4 is welded on both sides of the upper reinforcing plate 7, and the outer sides of the two upper mold arc plates pass through the middle reinforcing rib 5 and the end reinforcing ribs 9 are fixed on the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com