Silent variable frequency generator

A generator, silent technology, applied in the direction of engine components, machine/engine, engine cooling, etc., can solve the problems of high production cost, unfavorable generator assembly, fire, etc., achieve reliable use, ingenious structural design, reduce manufacturing and the effect of assembly cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

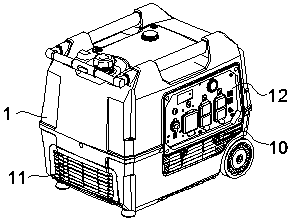

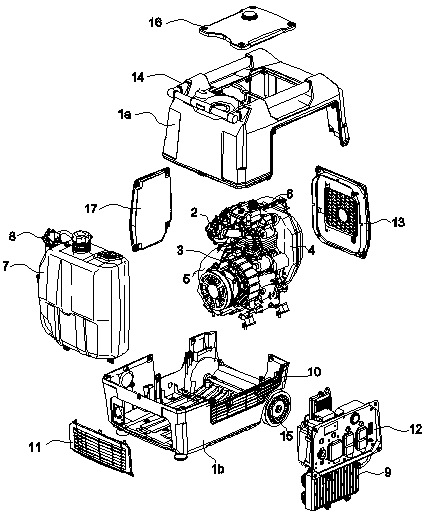

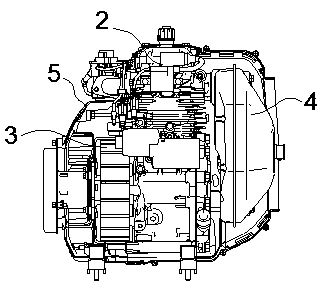

[0027] Embodiment 1: as figure 1 , 2 , 3, 4, 5, and 6, a silent frequency conversion generator, the generator includes a housing assembly 1 composed of an upper housing 1a and a lower housing 1b, and is set in the lower housing 1b There is an engine 2, and a muffler 4 and a stator-rotor assembly 3 with a cooling fan are distributed on both sides of the engine; a wind deflector 5 and a wind deflector 6 are arranged in the housing assembly 1, and the wind deflector 5 surrounds the stator-rotor assembly 3, and the shroud 6 surrounds the engine 2 and the muffler 4; a fuel tank 7, a fuel delivery unit 8 and an inverter unit are also arranged in the housing assembly 1 9. The fuel tank 7 and the fuel delivery unit 8 are arranged on one side of the engine 2 and away from the inverter unit 9 .

[0028] In the present invention, the wind deflector 6 surrounds the engine 2 and the muffler 4, and combines with the wind deflector 5 to form a cooling air flow passage for cooling the stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com