Supporting limiting structure for use in production of automobile dashboard beams

A technology of automobile instrument panel and limit structure, which is applied in the directions of supports, positioning devices, vehicle parts, etc., can solve the problems of inability to adjust the size of U-shaped supports, difficulty in taking parts, etc., and achieves safe and reliable automobile performance and improved production efficiency. , the effect of easy pickup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the drawings.

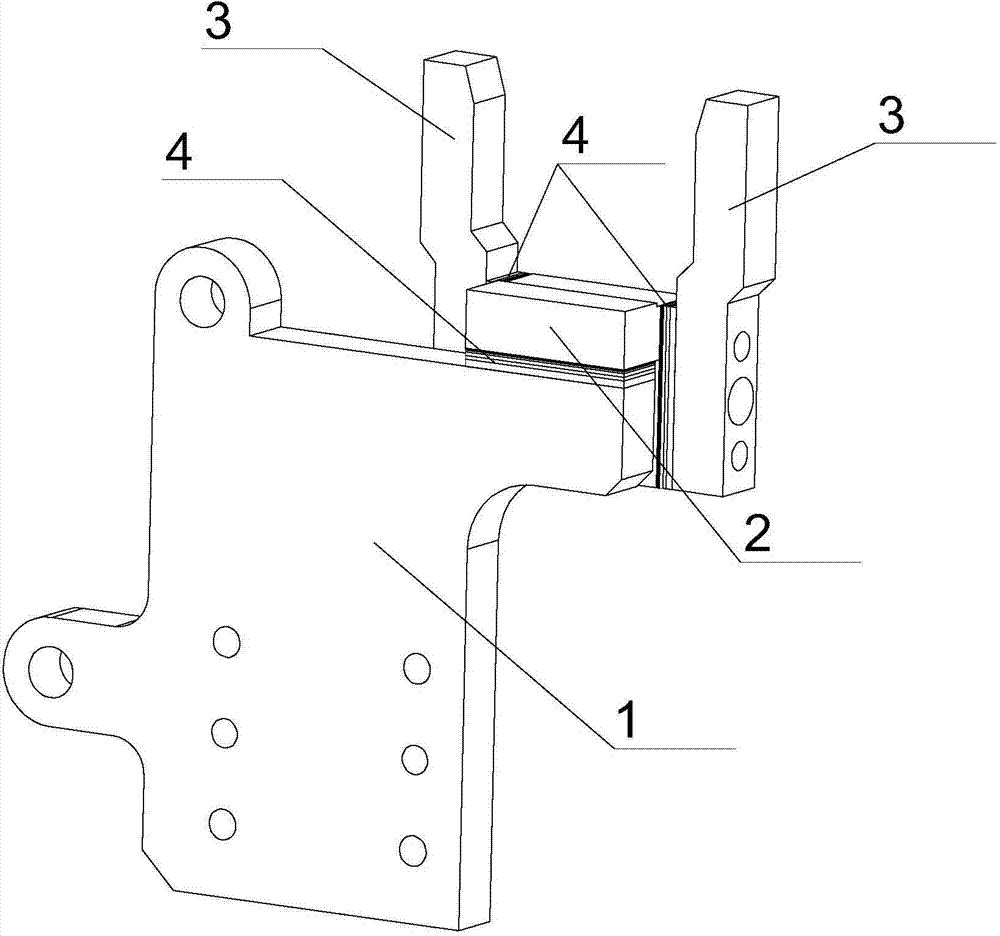

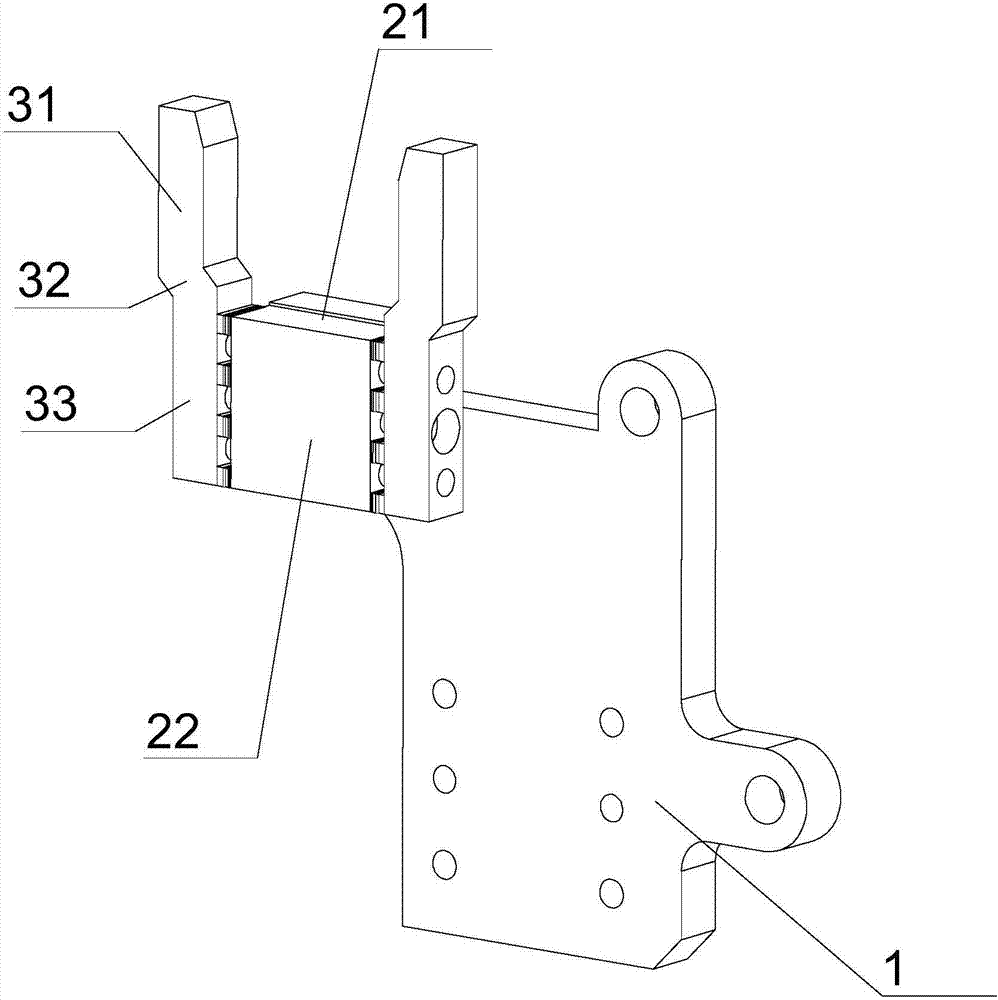

[0015] See figure 1 with figure 2 , The figure shows the supporting and limiting structure of the present invention used in the production of automobile instrument panel beams, including supporting block 2 and limiting block 3. The supporting block 2 is L-shaped, including the transverse member 21 and the vertical connection and An integrally formed vertical member 22 and a transverse member 21 are fixed on the top surface of the vertical plate 1;

[0016] The limiting block 3 is symmetrically arranged on both sides of the vertical member 22 of the supporting block 2;

[0017] A multi-layer 5mm thick gasket 4 is arranged between the limit block 3 and the vertical member 22;

[0018] Between the vertical plate 1 and the transverse member 21, multiple layers of 5 mm thick spacers 4 are arranged.

[0019] The limiting block 3 includes a mounting section 33, a bending section 32, and a limiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com