Positioning clamp for Macpherson suspension body and tower body welding

A Macpherson suspension tower and positioning fixture technology, applied in the field of welding and fixtures, can solve the problems of opening dimensional accuracy and shape and position accuracy not meeting the requirements, poor coaxiality, unqualified four-wheel calibration, etc., to achieve product size Stable and reliable, improved offline qualification rate, and high production energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention, in order to understand the technical solutions of the present invention more clearly. Obviously, the described embodiments are only a part of the present invention Examples, but should not be used to limit the protection scope of the present invention.

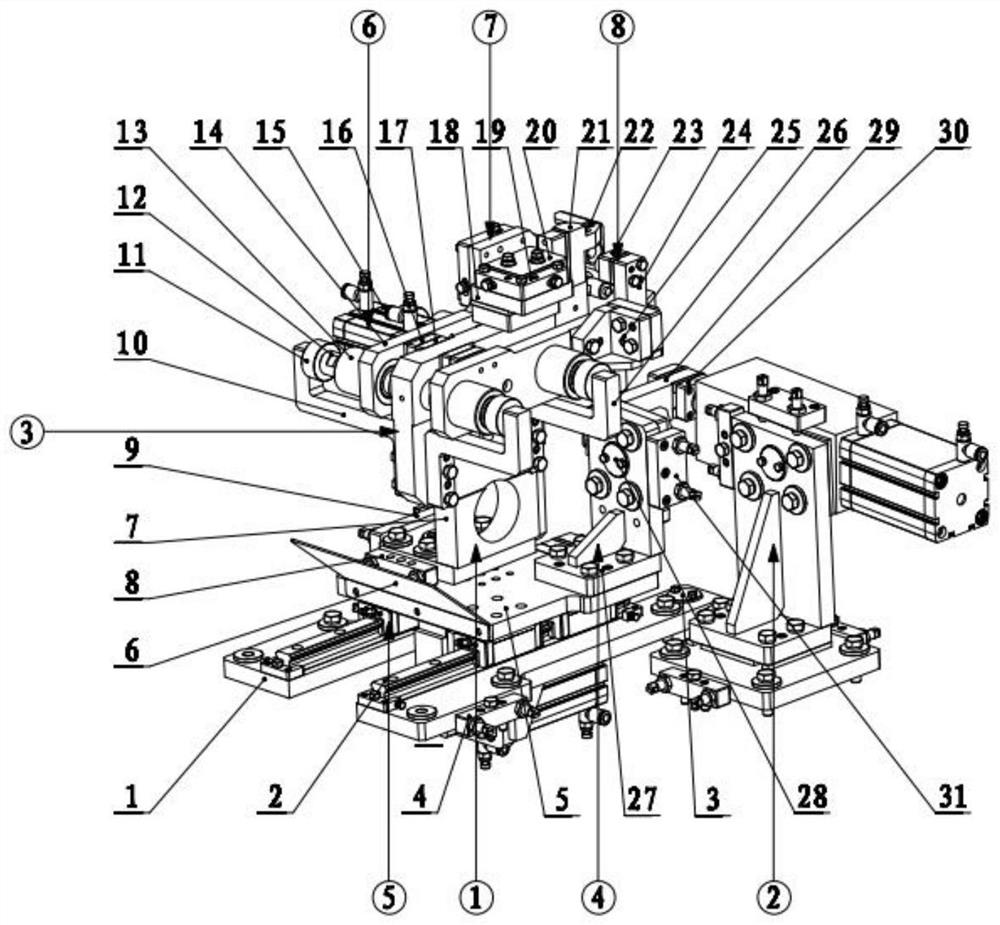

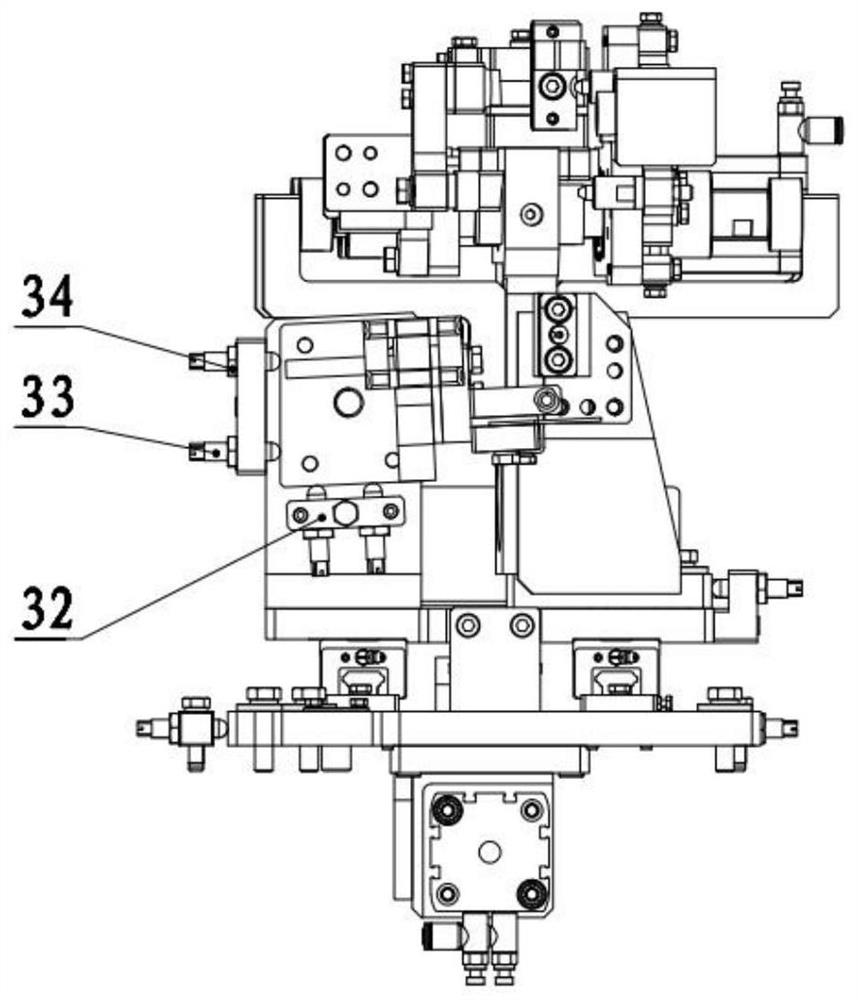

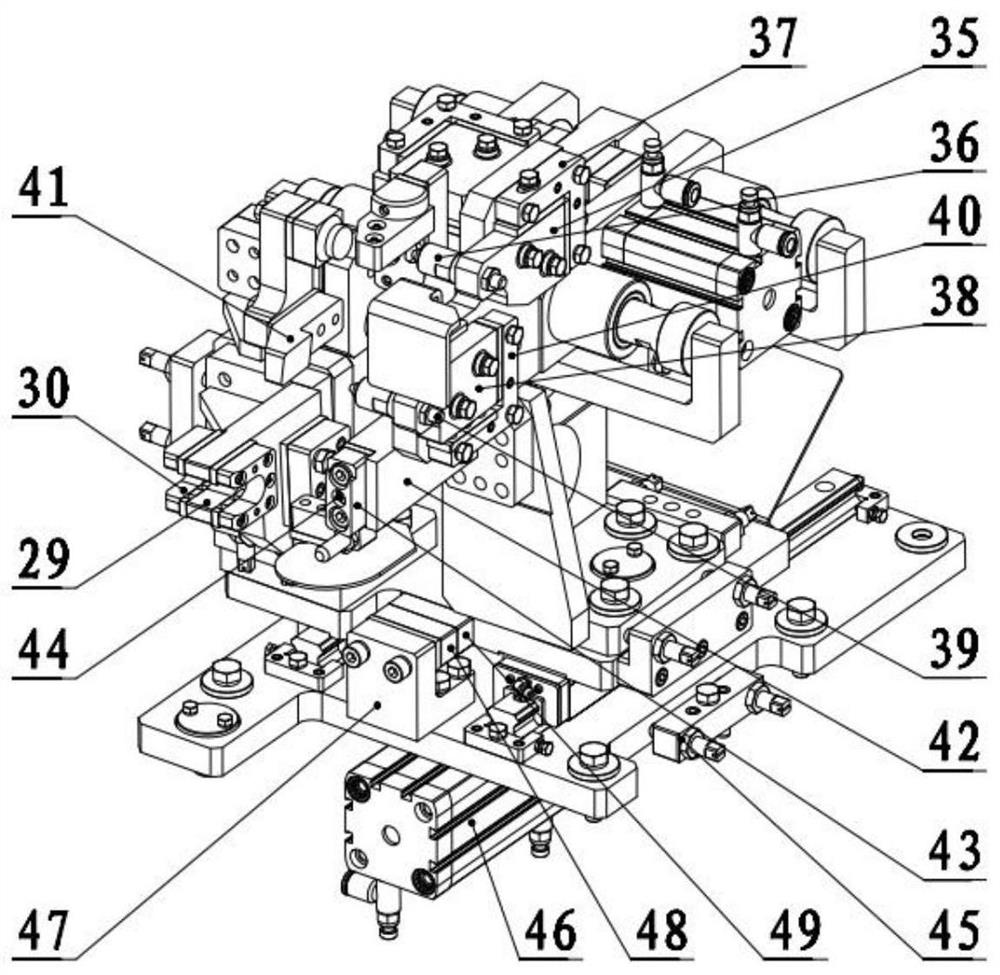

[0030] see Figure 1-4, the present invention provides a technical solution: a positioning fixture welded between the MacPherson suspension tower and the main body, including the tower body positioning mechanism ① and the suspension main body positioning mechanism ②, the tower body positioning mechanism ① and the suspension The main body positioning mechanism ② is fixedly installed on the fixture table. The tower body positioning mechanism ① is equipped with a tower body positioning and clamping unit ③, a tower body auxiliary support un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com