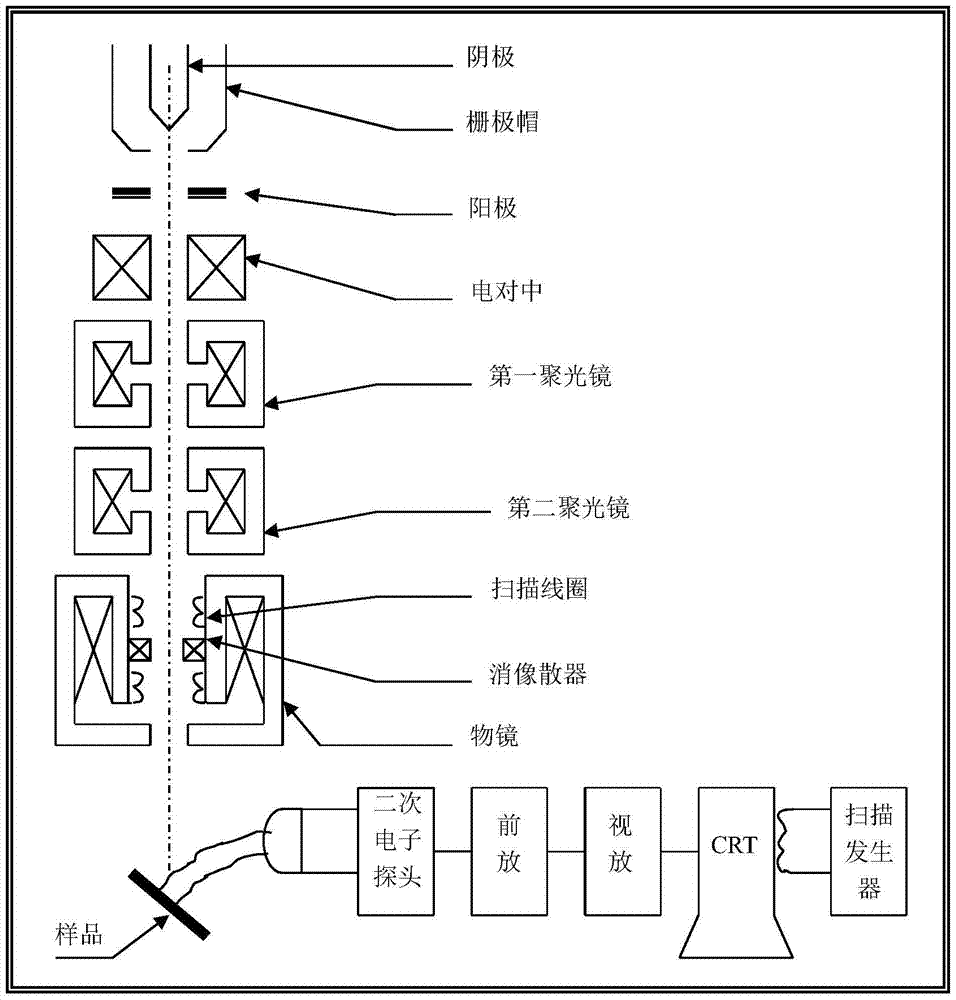

A method for measuring electron beam spot size of scanning electron microscope

An electron microscope and electron beam technology, applied in the field of electronics, can solve the problems of imprecise imaging measurement error, complex production process, measurement error and troublesome operation process, and achieve the effect of improving contrast, simple operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

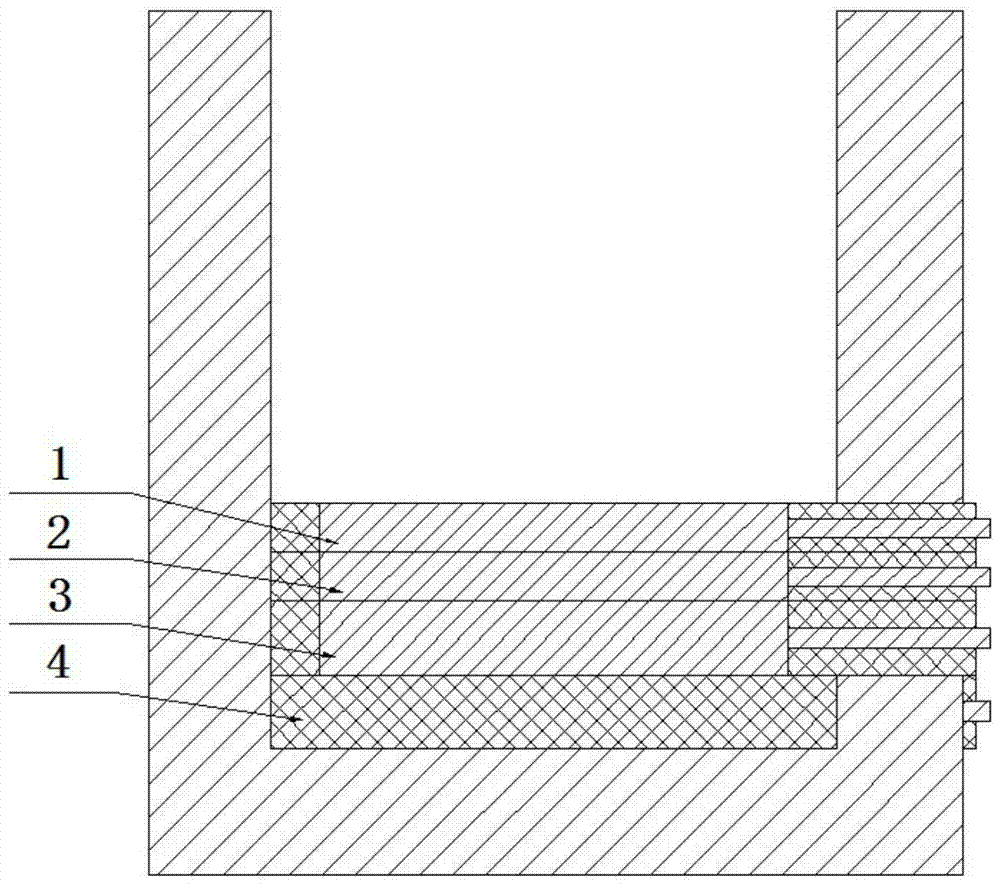

[0021] refer to figure 2 The schematic diagram of the structure of the Faraday cup is shown. The Faraday cup with a grid is designed and manufactured. The purpose of adding the grid is to intercept the secondary electrons generated by the electron beam hitting the inner plate of the Faraday cup, thereby effectively enhancing the force at the edge of the blade sample. contrast.

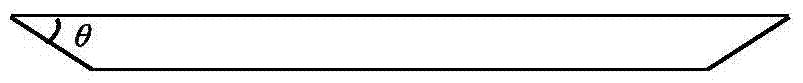

[0022] refer to image 3 The metal flake shown is a metal blade. The blade sample has a wide top and a bottom narrow section. At the same time, it is necessary to ensure that the surface smoothness and finish of the blade sample are as high as possible.

[0023] refer to Figure 4 The measurement device and sample placement diagram shown in the diagram place the Faraday ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com