hair winding device

A hair winding and hair silk technology, applied in wigs, applications, clothing, etc., can solve the problems of small amount of hair silk, cumbersome operation, low efficiency, etc., and achieve the effect of improving production efficiency and simple feeding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

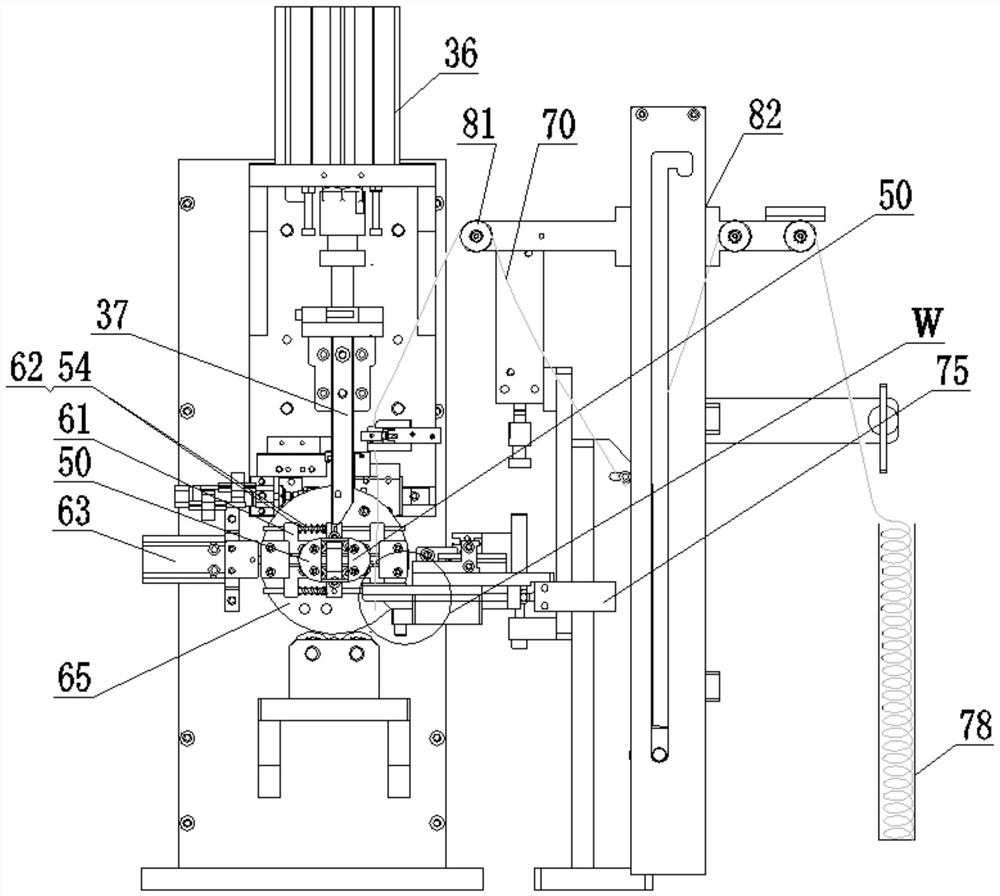

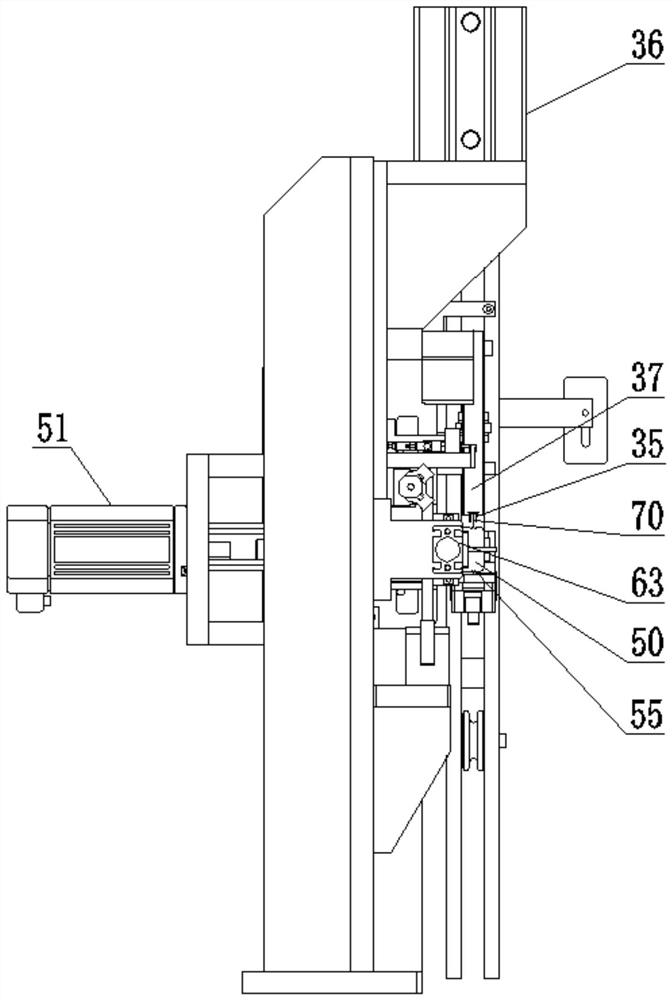

[0044] See Figure 1 to Figure 16 .

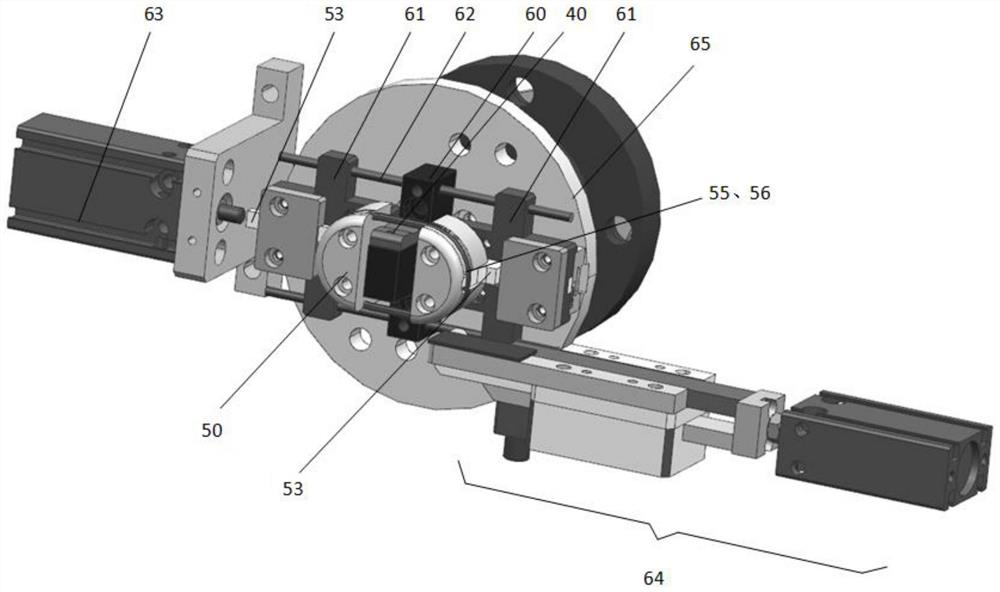

[0045] A hair-winding device, comprising a hair-winding disc 50, the hair-winding disc 50 is connected to a drive system, and the drive system is used to drive the hair-winding disc 50 to rotate, specifically, the hair-winding disc 50 is arranged on a base disc 65, and the back side of the base disc 65 A motor 51 is provided as a driving system, the output shaft of the motor 51 is connected to the base plate 65, and the hair winding plate 50 adopts a split structure, including two semicircular split bodies, and a middle is provided between the two semicircular split bodies. The body, the split body and the intermediate body are fixed on the base plate 65; a laterally movable wire head pressing member 53 is arranged on the hair plate 50, and the movable rod 58 of the wire head pressing member 53 is perpendicular to the pressing portion 57. , the wire head pressing member 53 can rotate synchronously with the hair winding reel 50. When the e...

Embodiment 2

[0051] A hair winding device, the structure of which refers to Embodiment 1, Figure 17 and Figure 18 , the main difference between it and Embodiment 1 is: the movable rod 58 of the wire head pressing member 53 passes through the inner hole of the hair winding plate 50 laterally, and a spring 54 is sleeved on the movable rod 58, and one end of the spring 54 passes through the coil. The limit platform 66 inside the hair plate 50 is limited, and the other end is limited by the convex edge on the movable rod 58; such as Figure 17 As shown, before coiling the hair 70, the wire pressing member 53 is driven to the left by external force, and then the end of the hair 70 is sent to the left side of the pressing part 57 of the wire pressing member 53 through the clipping device 64 Then, the external force is withdrawn, and the wire head pressing member 53 that is laterally away from the winding disc 50 is driven by the spring 54 to reset, so that the end of the hair wire 70 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com