Patents

Literature

43results about How to "Eliminate the risk of leaks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

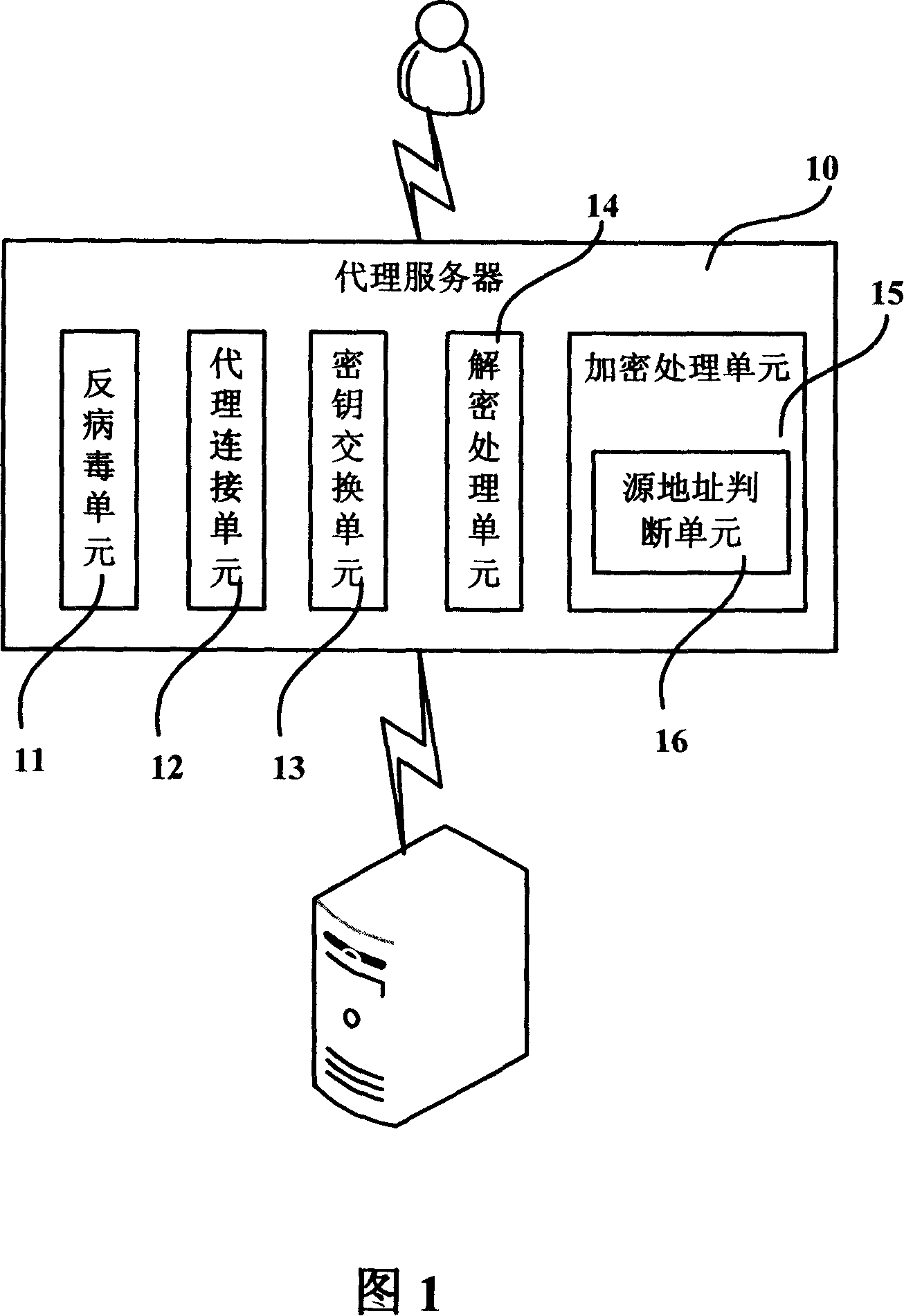

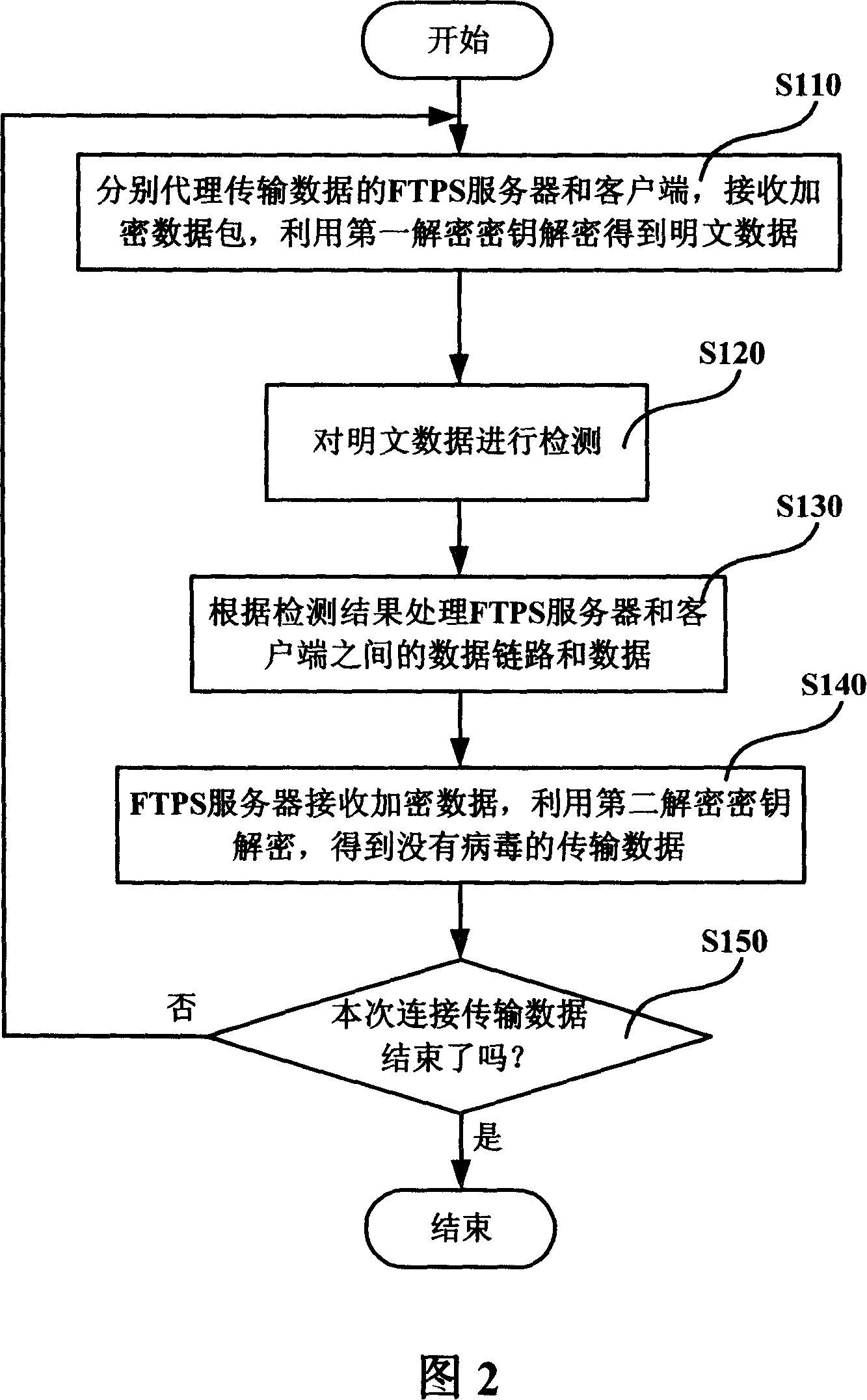

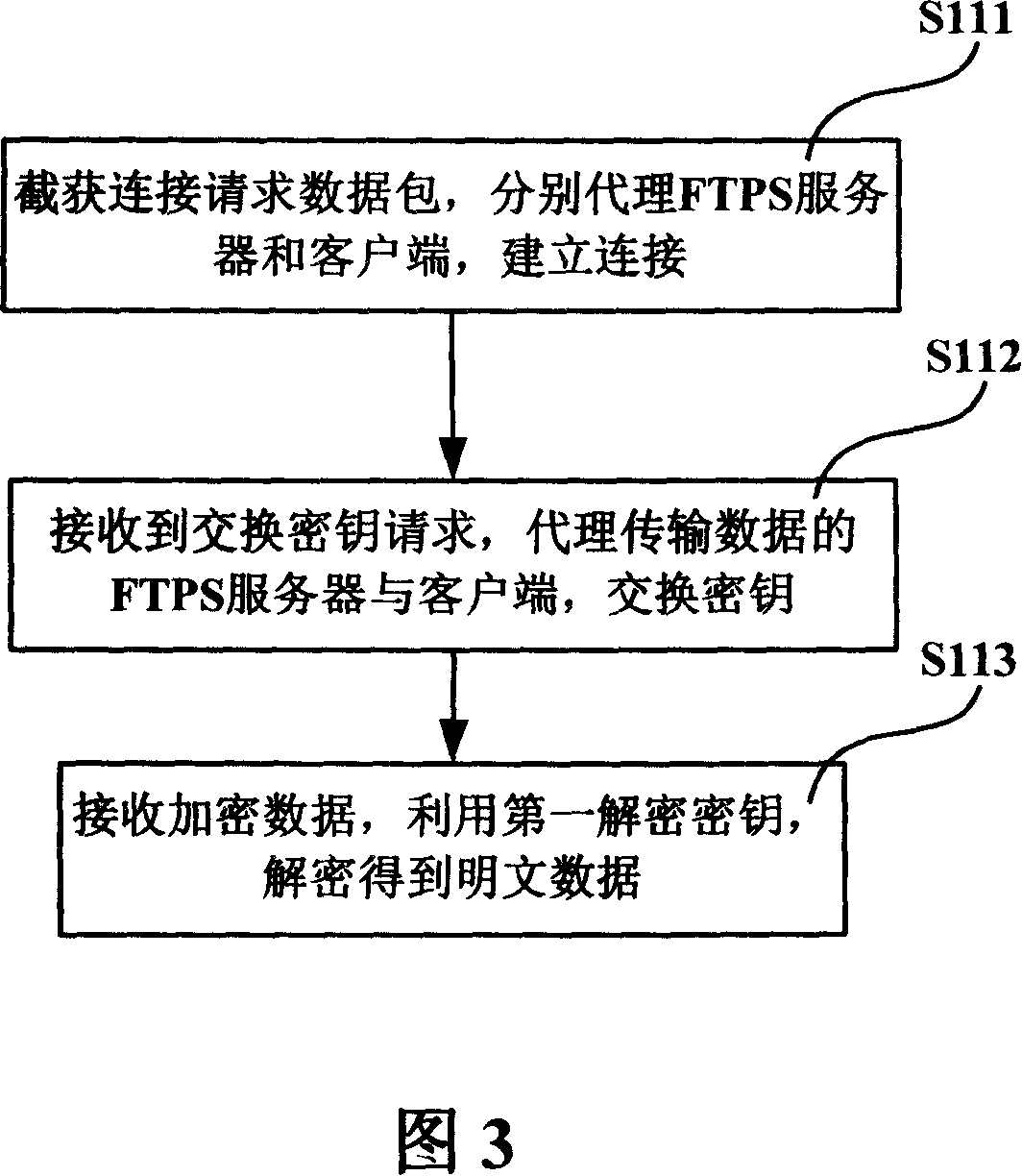

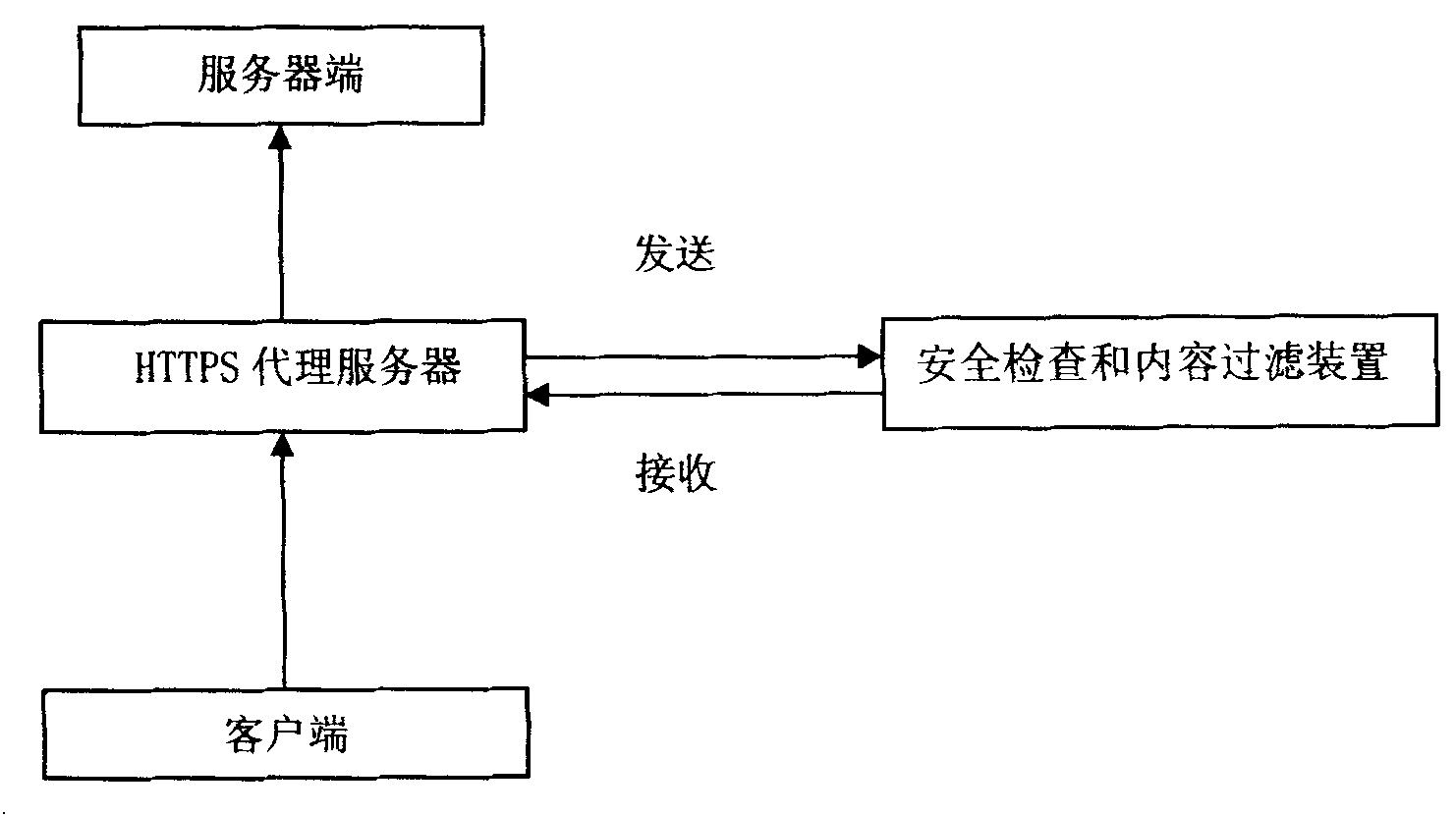

Network enciphered data virus detection and elimination system and proxy server and method

ActiveCN101141244AEliminate transmissionEliminate the risk of leaksSecuring communicationAnti virusPlaintext

The utility model discloses a virus-detection and removing system, proxy server and method used for network encryption data. The system comprises a client, a server, a proxy server and a anti-virus unit, among which when the proxy server encrypts the data communication between the client and the server, the proxy client and the server will receive the transmitted data pack which is decrypted to the plaintext data and then sent to the anti-virus unit for virus examination and removing, so that the safety plaintext data are re-encrypted and then sent to the server. The anti-virus unit can detect and remove the virus from the plaintext data and inform the examining and removing results to the proxy sever, so as to reduce or even remove the network viral transmission via SSL / TLS cryptographic protocol.

Owner:FORTINET

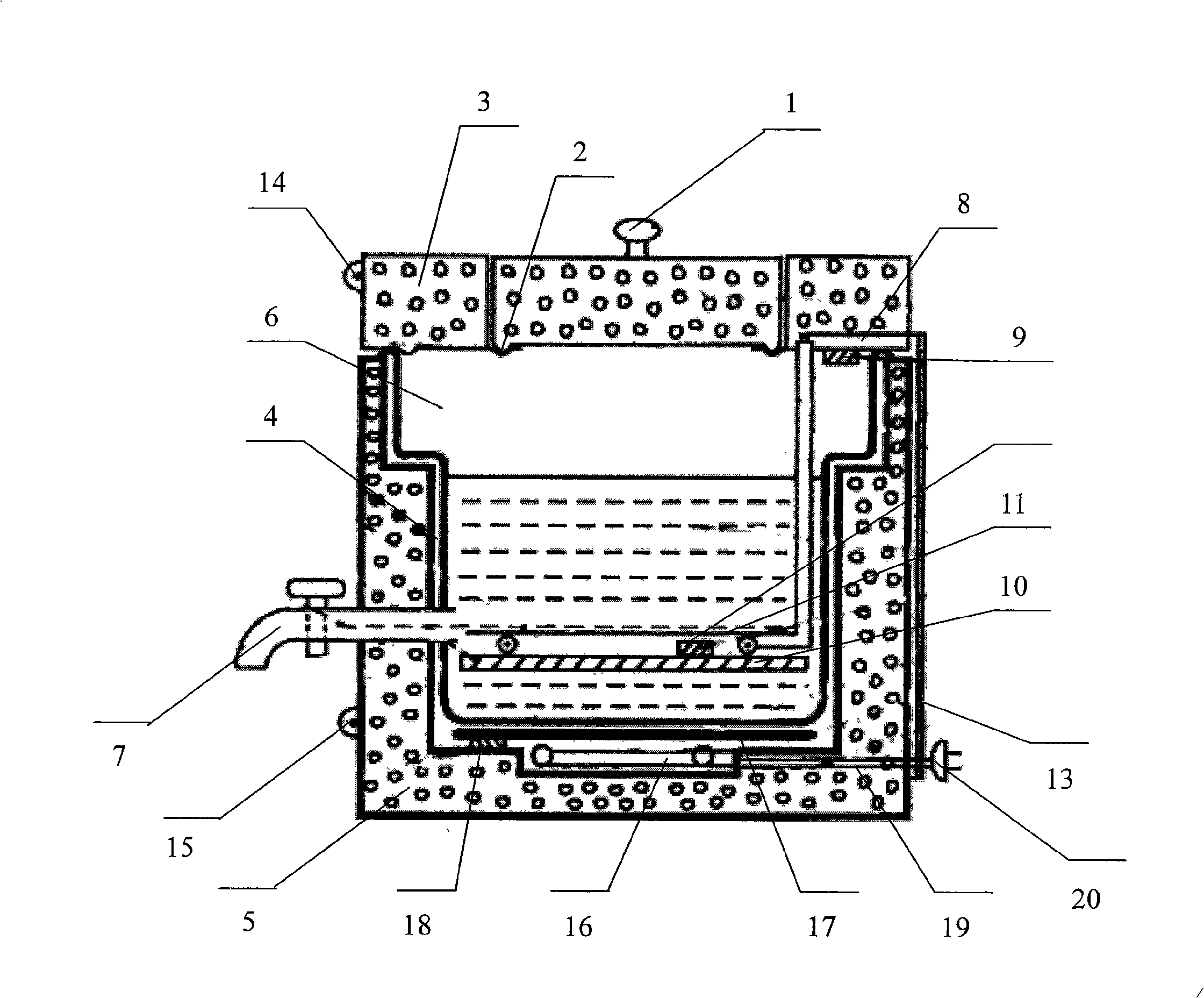

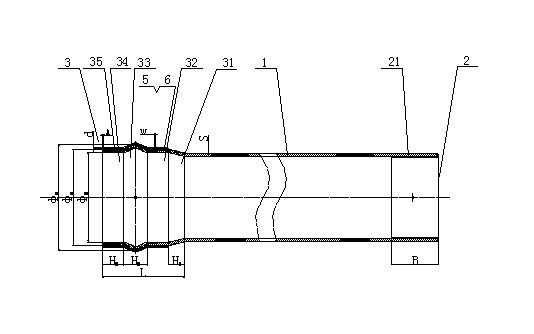

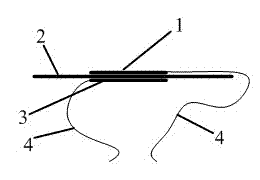

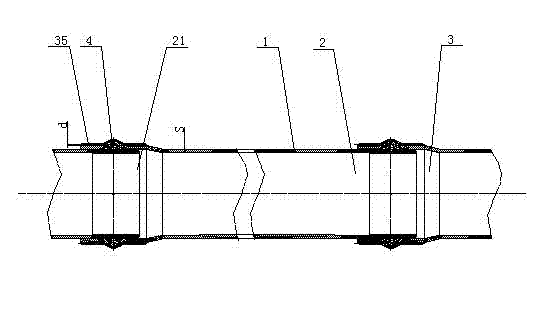

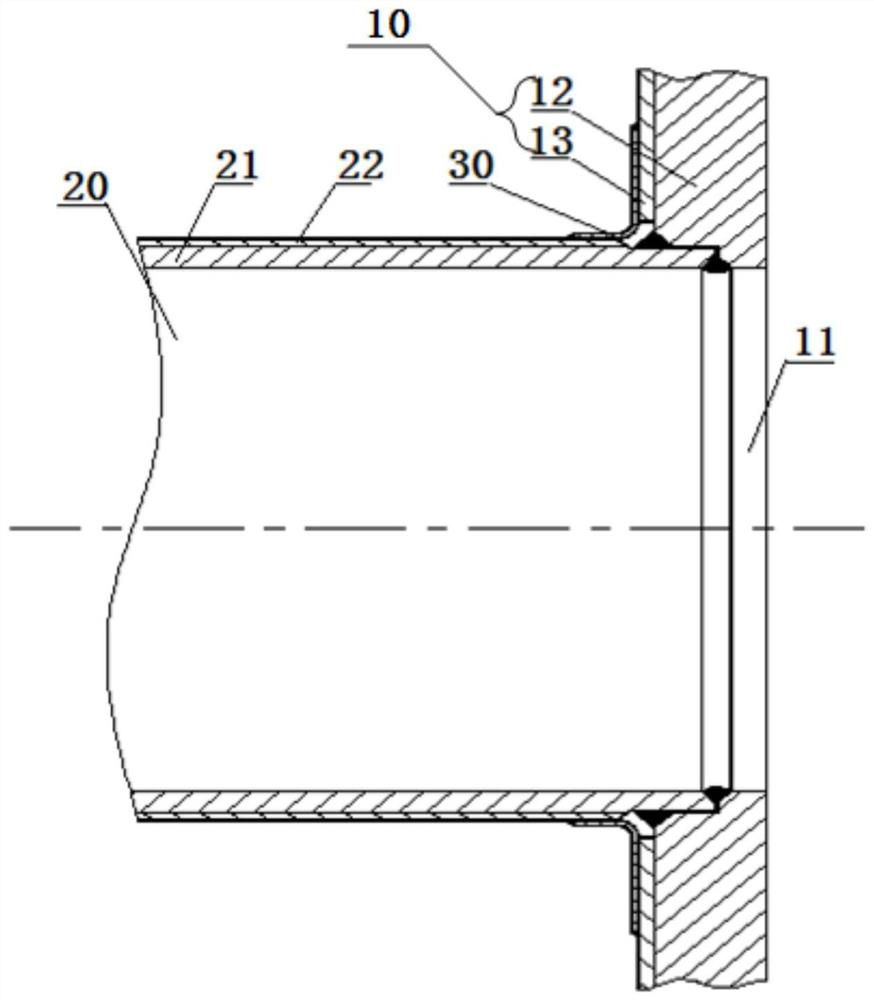

Dual-seal filling rotary compensator

InactiveCN102829278ADouble seal structure is simpleEasy to manufacturePipeline expansion-compensationEngineeringFastener

The invention discloses a dual-seal filling rotary compensator which comprises an inner tube, a fastener, an outer tube, a left packing, filling valves, a right packing, a sealing ring and an adapter tube. The inner tube is sleeved with the outer tube; and the adapter tube is connected with the right end of the outer pipe in a sealed mode to form an axial limiting inner tube. The left packing is plugged into a gap between the left sections of the inner tube and the outer pipe and is locked on a flange edge of the outer tube by a gland and the fastener to form a main sealing structure. The sealing ring and the right packing are sleeved between steps of the inner tube and the outer tube to form an auxiliary sealing structure. 4 to 16 filling valves communicated with a main sealing cavity are uniformly distributed on the outer wall of the outer tube to form an online leakage compensation structure. The dual-seal filling rotary compensator is of a dual-seal structure and has a good sealing effect. Importantly, in the using process of the dual-seal filling rotary compensator, once the main sealing structure is leaked, the left packing can be filled by the filling valves to recover the sealing under the condition that the regulation is invalid. The dual-seal filling rotary compensator is simple to carry out online maintenance and is easy to operate; the shutdown maintenance cost is greatly reduced and the potential safety hazard caused by the leakage is also avoided.

Owner:JIANGSU HUADIAN PIPELINE EQUIP

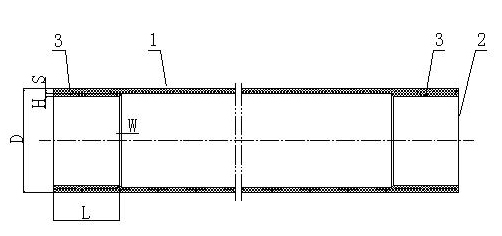

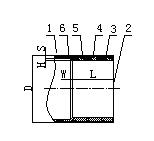

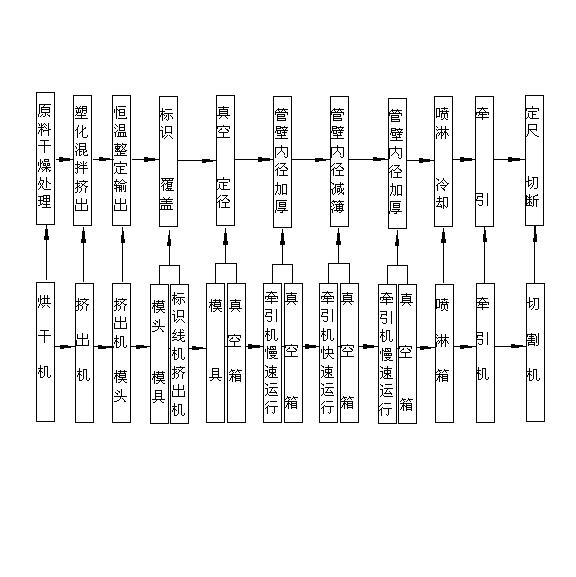

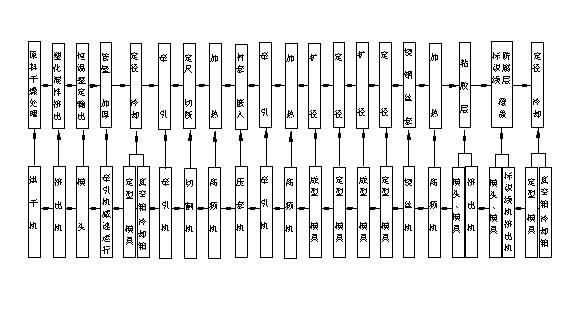

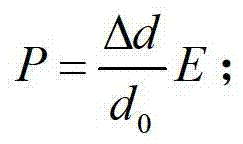

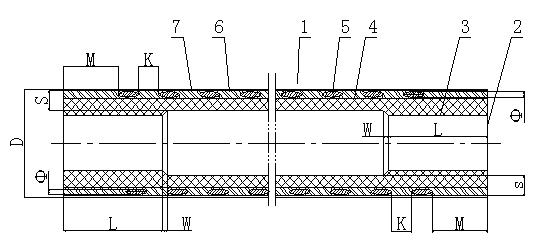

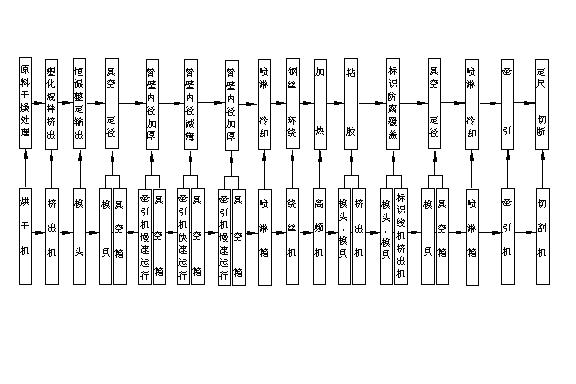

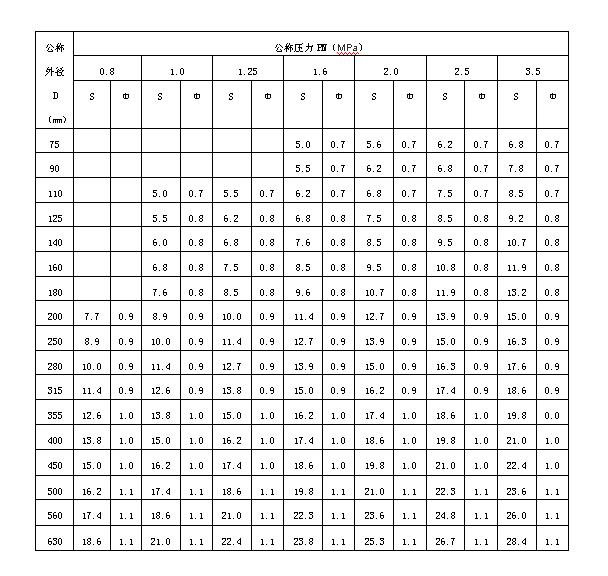

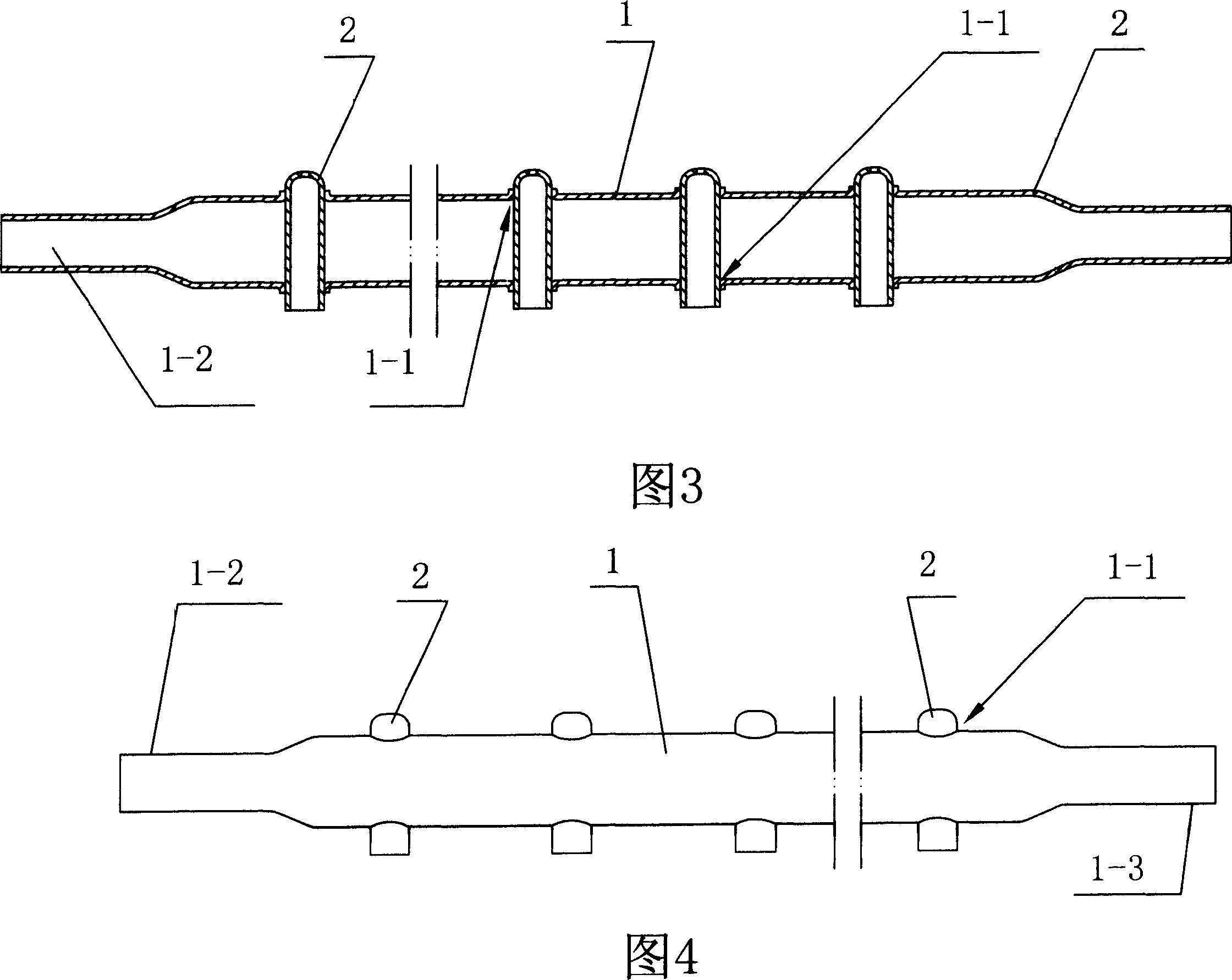

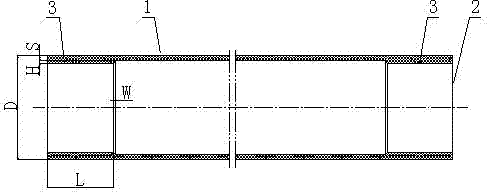

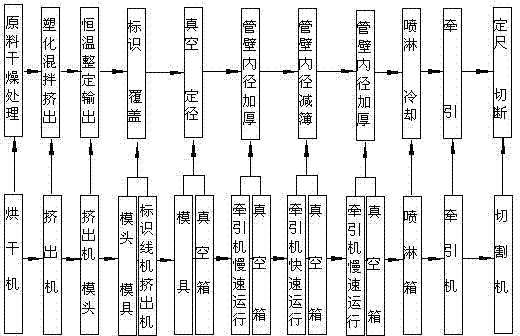

Socket reinforced composite plastic pipe and manufacturing process thereof

ActiveCN101788084ASimple structureSimple manufacturing processRigid pipesProcess engineeringWater leak

The invention relates to a socket reinforced composite plastic pipe and a manufacturing process thereof, and the socket reinforced composite plastic pipe comprises a pipe wall and a socket, wherein a convex ring is arranged at the pipe wall with the inner diameter of L at the end part of the socket, plastics and resin are mixed for being taken as raw materials, and the technical scheme simultaneously produces a product under the synchronous control of a drying machine, an extrusion machine, a mold head, a mold, a vacuum box, a spraying box, a traction machine, a cutting machine and other equipment. The socket reinforced composite plastic pipe can overcome the defects that the strength and the rigidity of the cross section at the butt joint between the pipe and the socket can not bear the internal pressure in the pipe for the existing polyethylene resin composite pipe-PE pipe, thereby causing expansion, deformation and cracking of the pipe wall of a pipe, further resulting in water leakage and gas leakage of a pipeline and causing difficult maintenance of a water supply system, a gas supply system and a liquid supply system, serious loss of resources, environmental pollution caused by gas leakage and the like; and the socket reinforced composite plastic pipe is applicable to being used as connecting pipe for various water transportation projects and gas transportation projects, in particular to socket thickening and reinforcing of PE, PVC-U, PVC-M and other plastic pipes.

Owner:HUNAN ZHENHUI PIPE IND

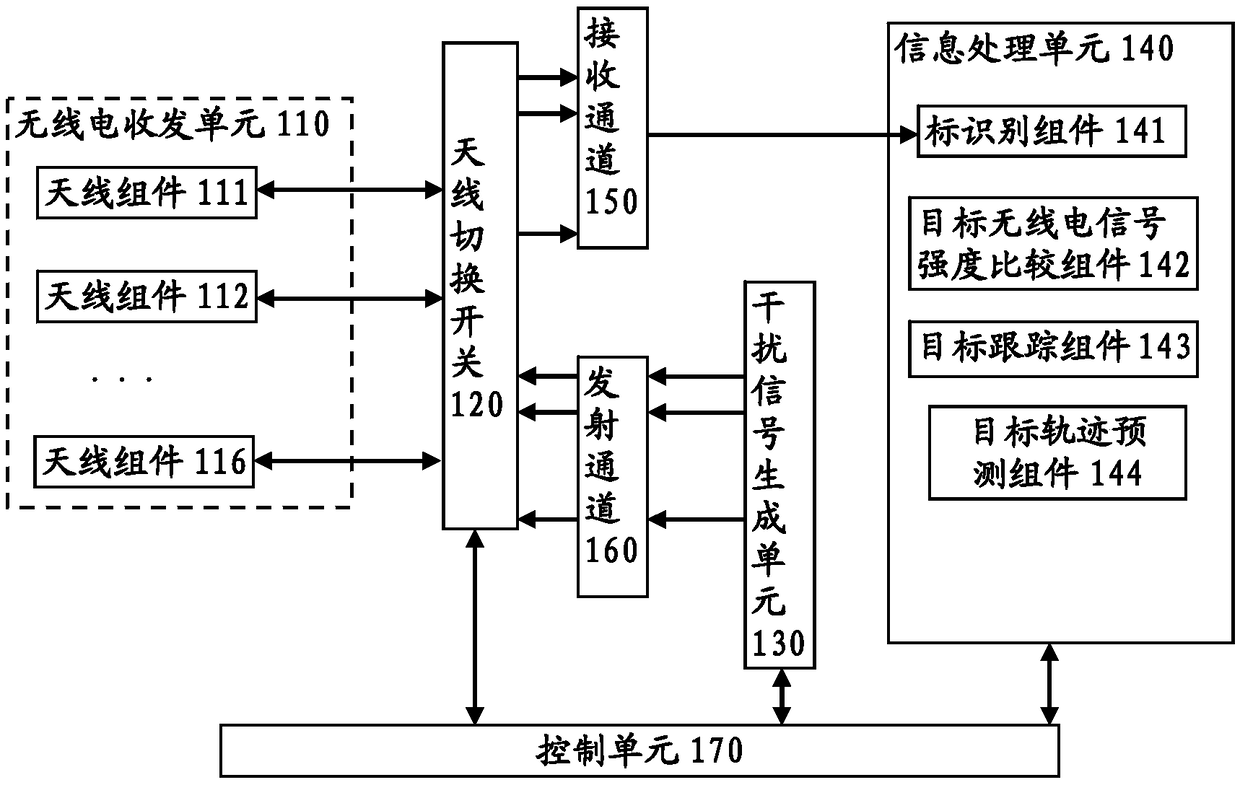

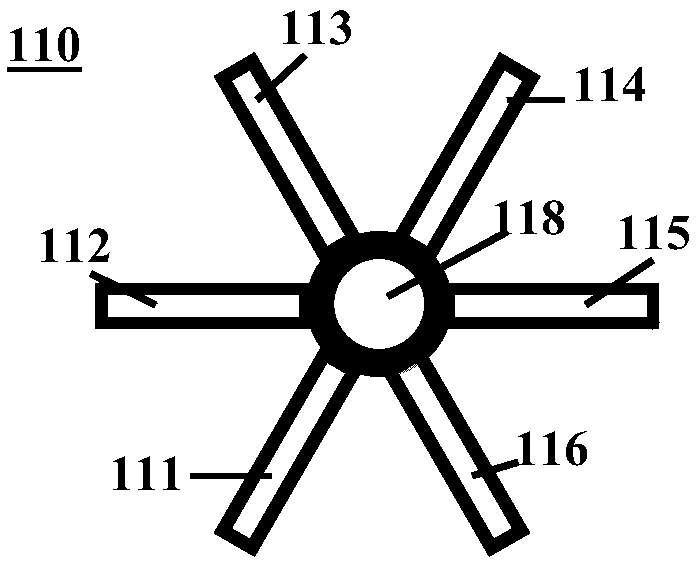

Flying target detection interference system and method

PendingCN109347596ARealize all-round detectionAchieve interferenceCommunication jammingTransceiverEngineering

The invention relates to a flying target detection interference system and method. The system comprises a radio transceiver unit, a signal processing unit, an interference signal generation unit and acontrol unit. The radio transceiver unit is used for receiving a target radio signal transmitted by a flying target or transmitting a radio interference signal to the flying target in a specific airspace. The signal processing unit is used to receive and process the target radio signal from one of radio antenna assemblies, and determine a serial number of the radio antenna assembly closest to theflying target. The interference signal generation unit generates a radio interference signal and transmits the radio interference signal to one of the radio antenna assemblies for performing transmission. The control unit controls the radio antenna assembly corresponding to the serial number to receive the radio interference signal generated by the interference signal generation unit and transmitthe radio interference signal to the flying target.

Owner:BEIJING SHIAN LITIAN TECH DEV CO LTD

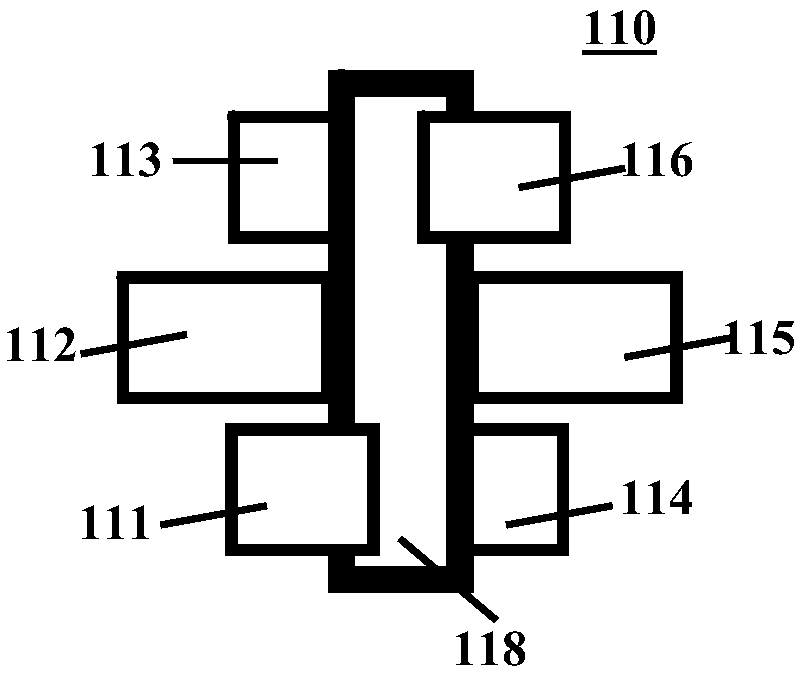

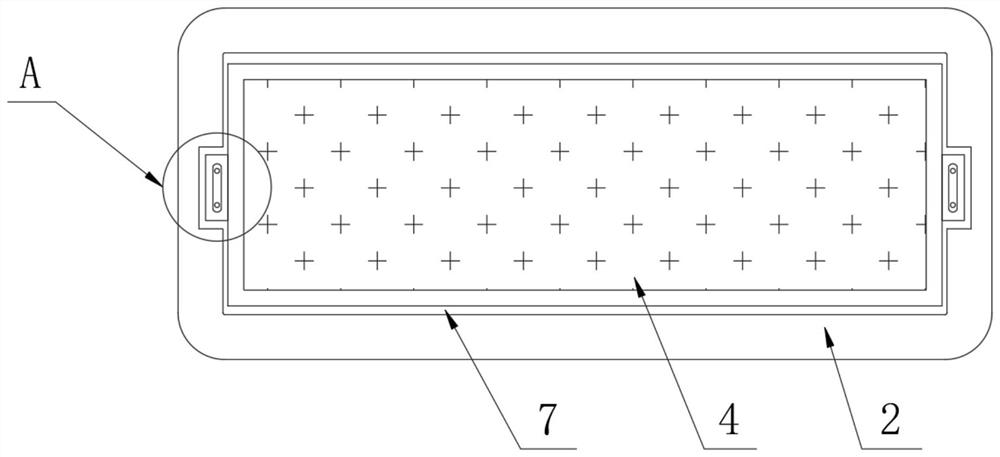

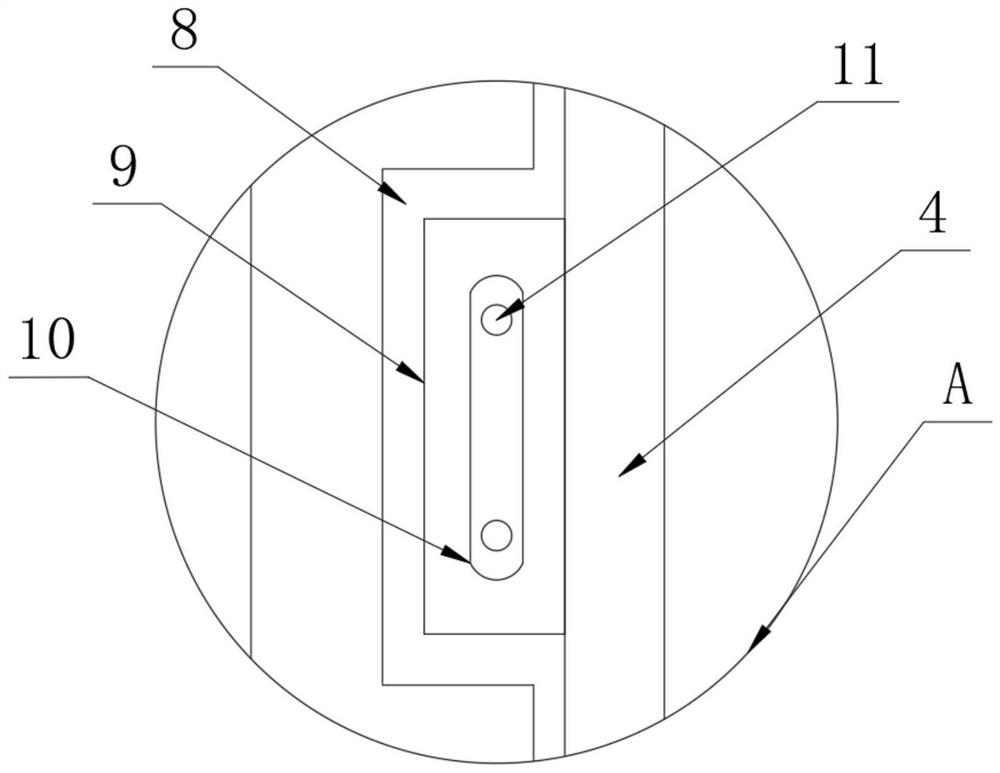

Novel constant-temperature electrical heating water boiler

InactiveCN101268911ASolve the leakReduce security risksBoiling over preventionCooking utensils shields/jacketsElectricityTemperature control

The invention belongs to the electric heater field, in particular relates to a novel constant-temperature electric heating water pot which consists of a carry wrench (1), a pot cover (2), a pot cover insulation layer (3), an inner pot (4), an inner pot insulation layer (5), an inner cover overflow prevention layer (6), a water outlet tap (7), an inner electric heating tube eduction tube (8), an inner electric heating tube eduction tube temperature controller (9), an inner electric heating tube (10), an inner electric heating plate (11), an inner electric heating tube temperature controller (12), an inner electric heating tube connecting line (13), an inner electric heating tube indicator light (14), an external electric heating tube indicator light (15), an external electric heating tube (16), an external electric heating plate (17), an external electric heating tube temperature controller (18), an external electric heating tube connecting line (19) and an attaching plug (20). By improving a heater of the common electric heating water pot, not only the heating efficiency of the constant-temperature electric heating water pot is improved with better insulation effect, what is more important, the disadvantage of uneven heating of water is also solved, so as to lead that the constant temperature of the water temperature can be reached, but also an automatic temperature control device is increased with faster and more convenient use.

Owner:XIANGMING MIDDLE SCHOOL SHANGHAI

Steel wire enhanced bell and spigot composite plastic tube and fabrication process thereof

ActiveCN101881356ASimple structureSave raw materialsCorrosion preventionPipe protection against corrosion/incrustationConical tubePolyvinyl chloride

The invention relates to a steel wire enhanced bell and spigot composite plastic tube and a fabrication process thereof. The steel wire enhanced bell and spigot composite plastic tube is prepared by mainly enhancing an inner bell and spigot and an outer bell and spigot, reasonably configuring each corresponding ratio parameter and adopting the fabrication process. The steel wire enhanced bell and spigot composite plastic tube comprises the inner bell and spigot, a bush, the outer bell and spigot, a sealing ring adapted to the outer bell and spigot, a conical tube, a round tube A, an arc tube, a round tube B and a steel wire sleeve mainly covering the outer wall of the arc tube, wherein the inner bell and spigot and the bush are arranged at one end of the tube wall, the outer bell and spigot and the sealing ring are arranged at the other end of the tube wall, and the conical tube, the round tube A, the arc tube, the round tube B and the steel wire sleeve are sequentially connected to the tube wall. The invention overcomes the defects that in the traditional PE (Polyethylene) tube, a reticular enhancement mode and a bidirectional winding enhancement mode are adopted at the external of the tube wall to cause the axial rigidity of the tube to be too strong and enable the axial flexibility performance at the bell and spigot to be lowered, thereby influencing the geological subsidence resistance performance of a pipeline network system; the connecting part of the bell and spigots is easy to strain to break, thereby enabling maintenance of a water, gas and liquid supply system to be difficult; fuel gas leaks to cause environmental pollution and the like. The invention is suitable for various water conveyance projects and connecting tubes of the water conveyance projects and is particularly suitable for enhancing bell and spigots of PE plastic tubes, PVC-U (Unplasticizied Polyvinyl Chloride) plastic tubes, PVC-M (High Impact Polyvinyl Chloride) plastic tubes and the like.

Owner:HUNAN ZHENHUI PIPE IND

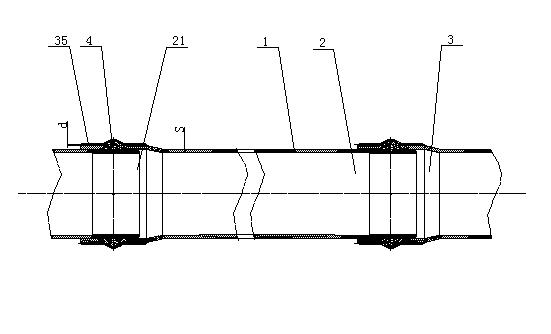

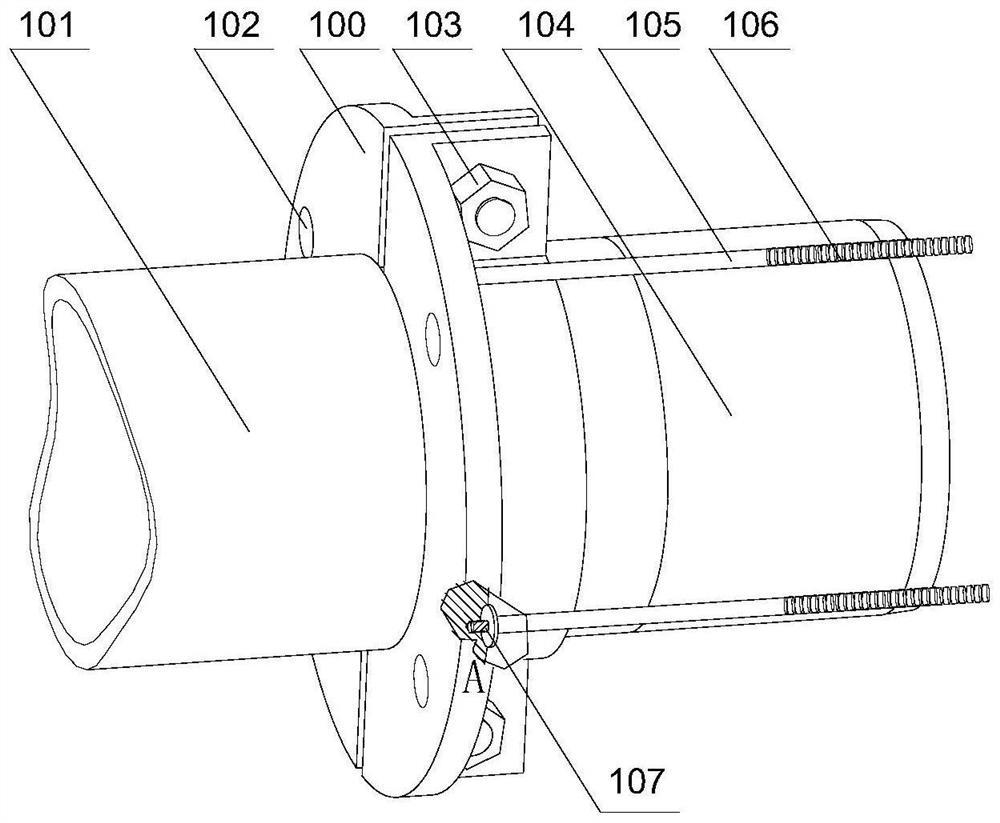

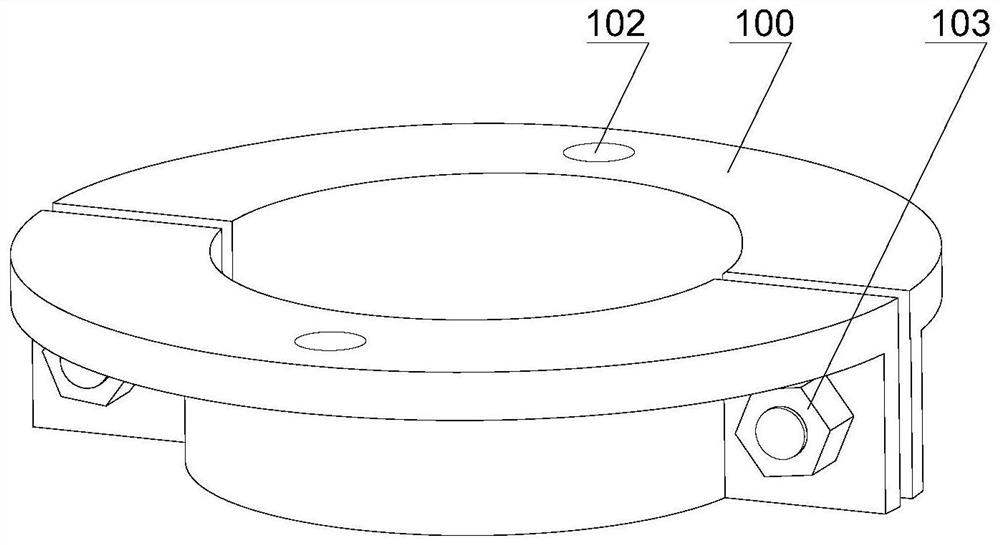

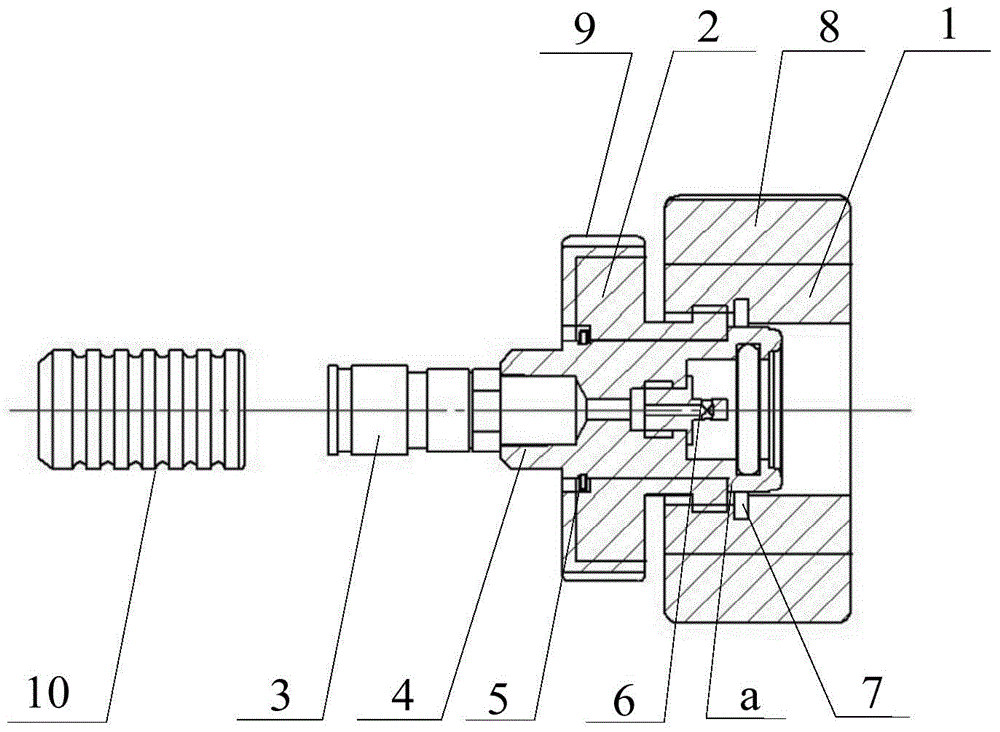

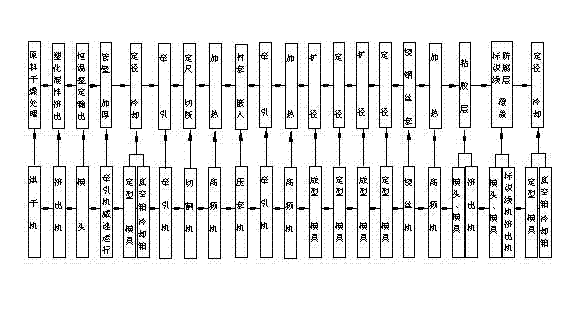

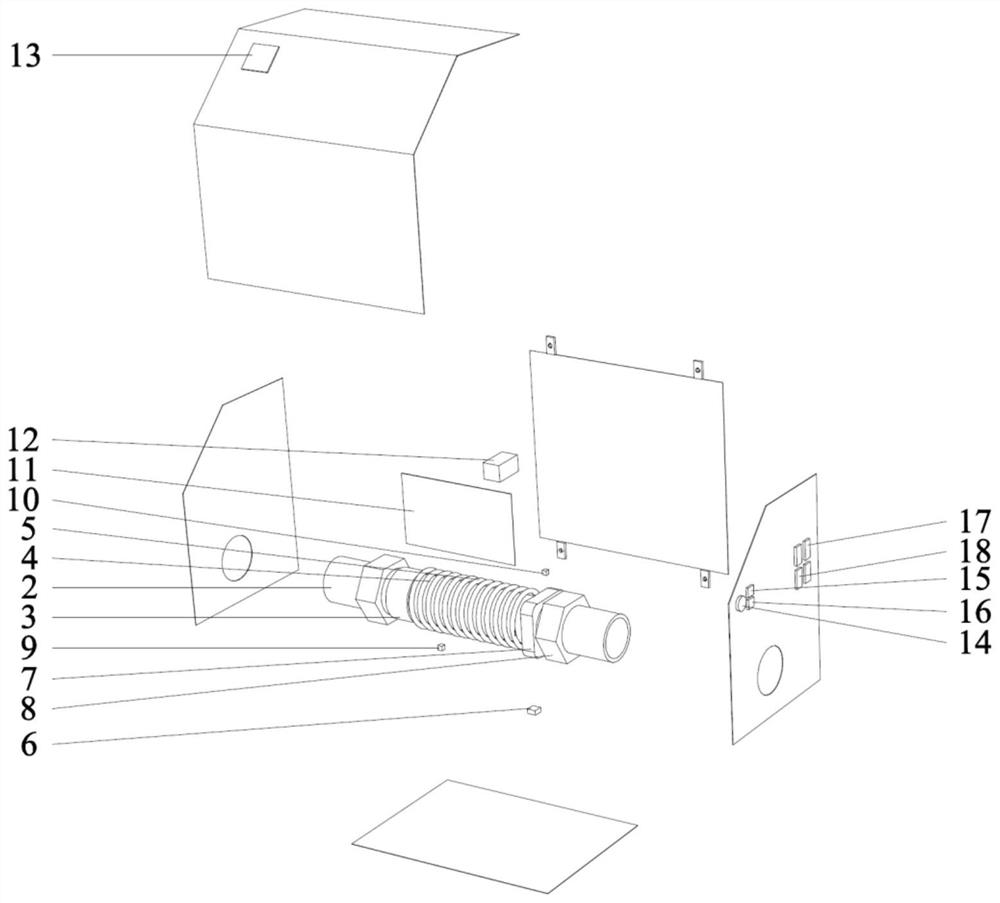

Electric-melted pipeline press-fitting process, press-fitting tool and press-fitting tool manufacturing process

PendingCN113635258ADifficult and easy to affectSize Difficulty AffectedMetal-working hand toolsPipe fittingPipe

An electric-melted pipeline press-fitting process comprises the following steps of performing oxide layer removing and polishing operation on the surface of an electric-melted pipeline inserting part, polishing an extremely thin surface layer, and keeping the cylindricity precision of the polished part basically unchanged; selecting a pressing disc, an electric-melted direct pipe fitting, an elbow pressing frame and a tee pressing frame pressing tool which are matched with the pipeline and the pipe fitting which are to be assembled, and mounting the pipeline and the pipe fitting on the pressing tool; and synchronously rotating a nut, and driving the pipeline and the pipe fitting to move oppositely in a relative spiral rotation mode to finish spiral press-fitting assembly of the pipeline and the pipe fitting. And then electrifying and welding are conducted. The invention further relates to a press-fitting tool and a manufacturing method of the press-fitting tool; after the press-fitting tool is used, the welding quality can be guaranteed through the assembly interference magnitude of the electric-melted pipeline and the pipe fitting, the welding quality cannot be affected by the small interference magnitude, and the threshold value of the interference magnitude is much larger than that of the prior art; and the press-fitting tool has the advantages that the whole device is simple, the operation is convenient, the process is suitable for space-limited and high-altitude environment operation, and the application range is wide.

Owner:江西铜业集团(贵溪)防腐工程有限公司

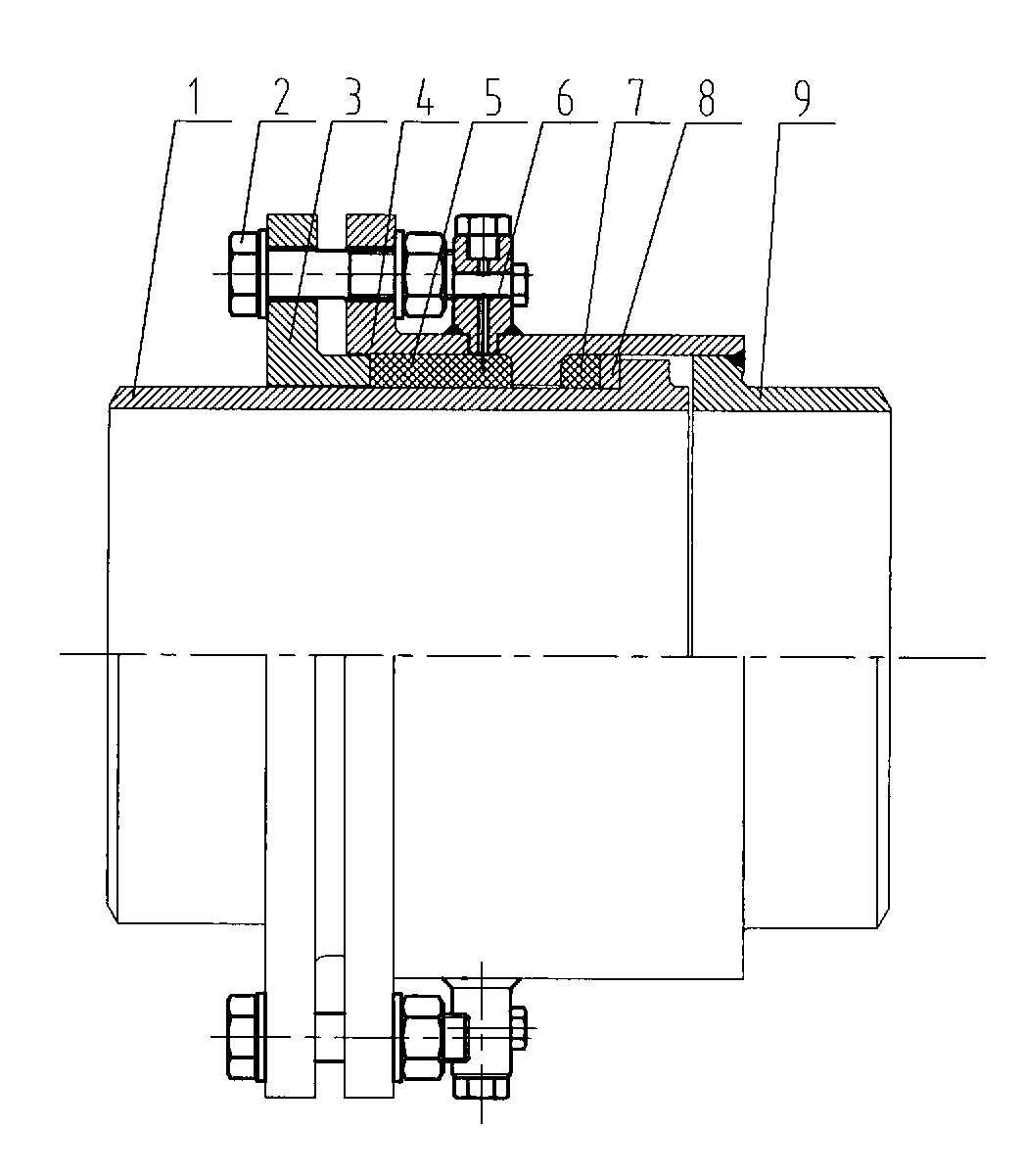

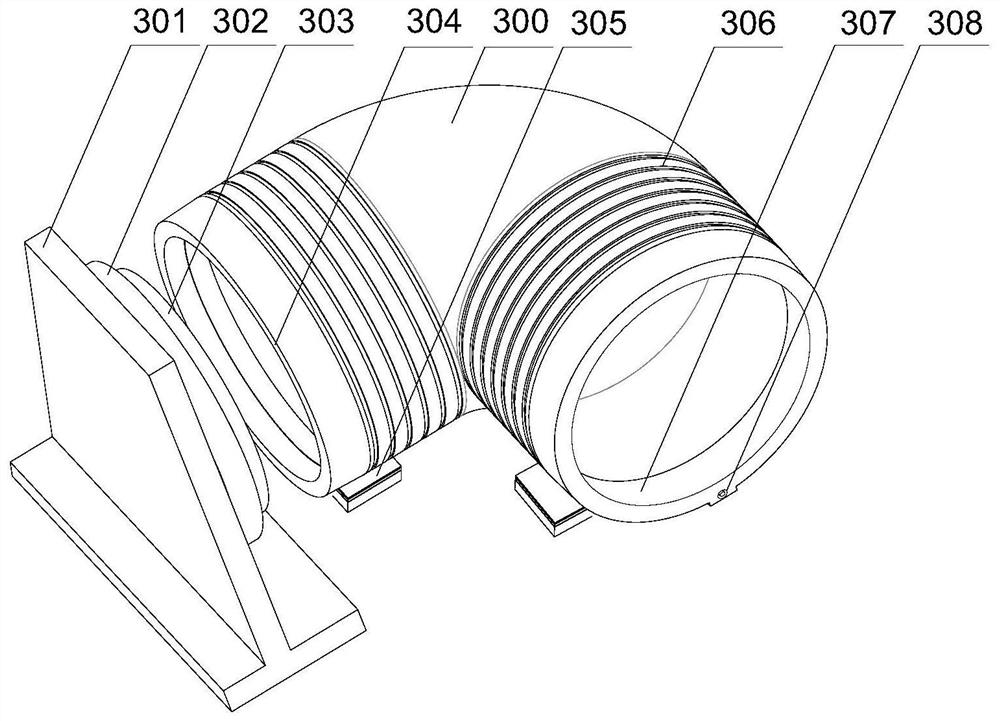

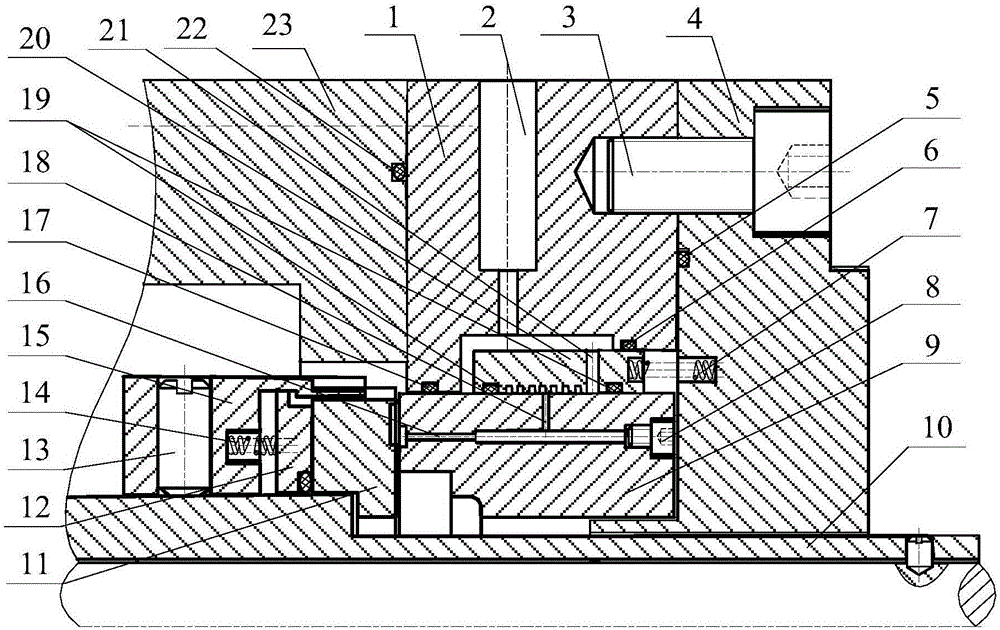

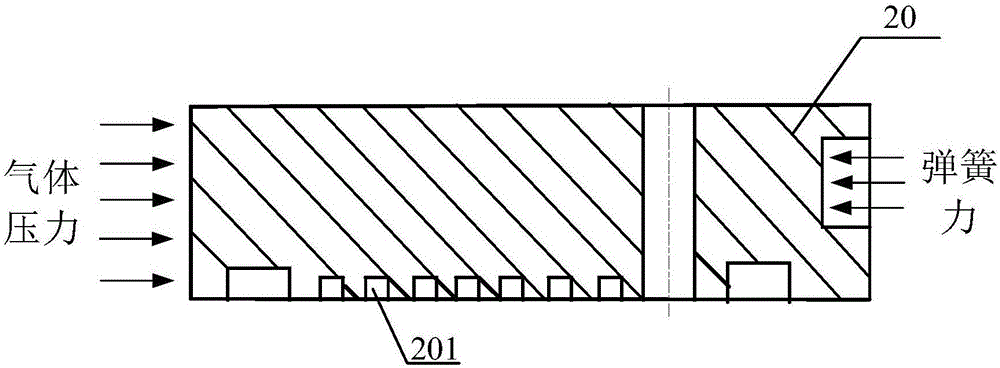

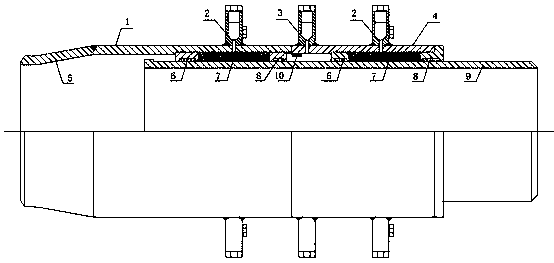

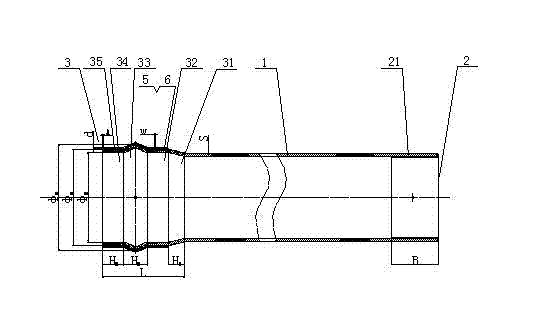

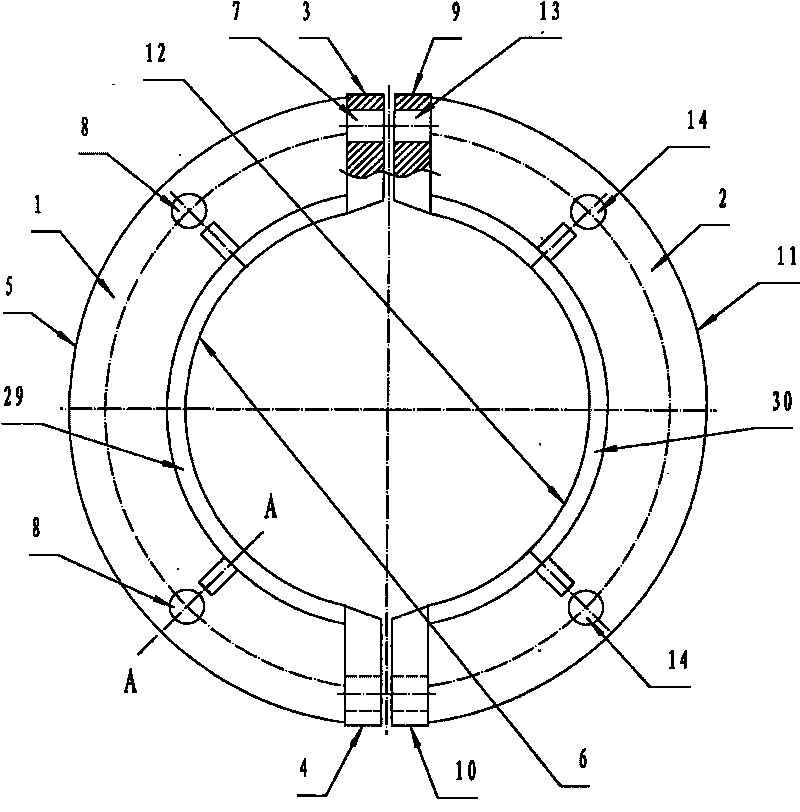

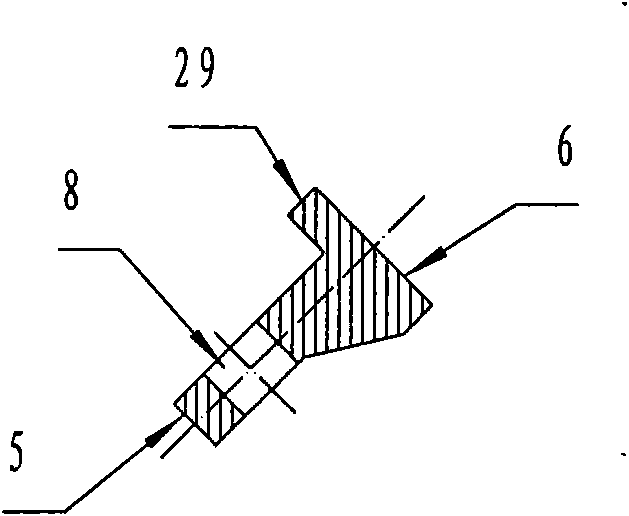

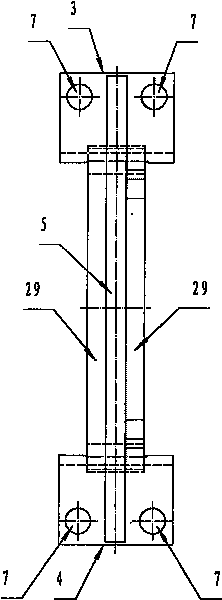

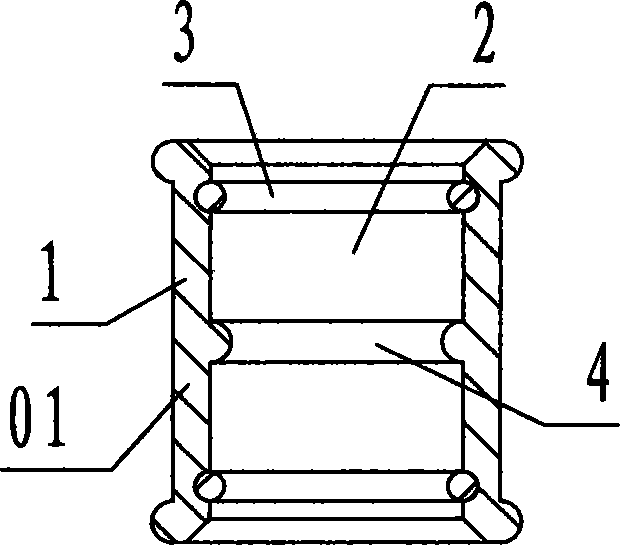

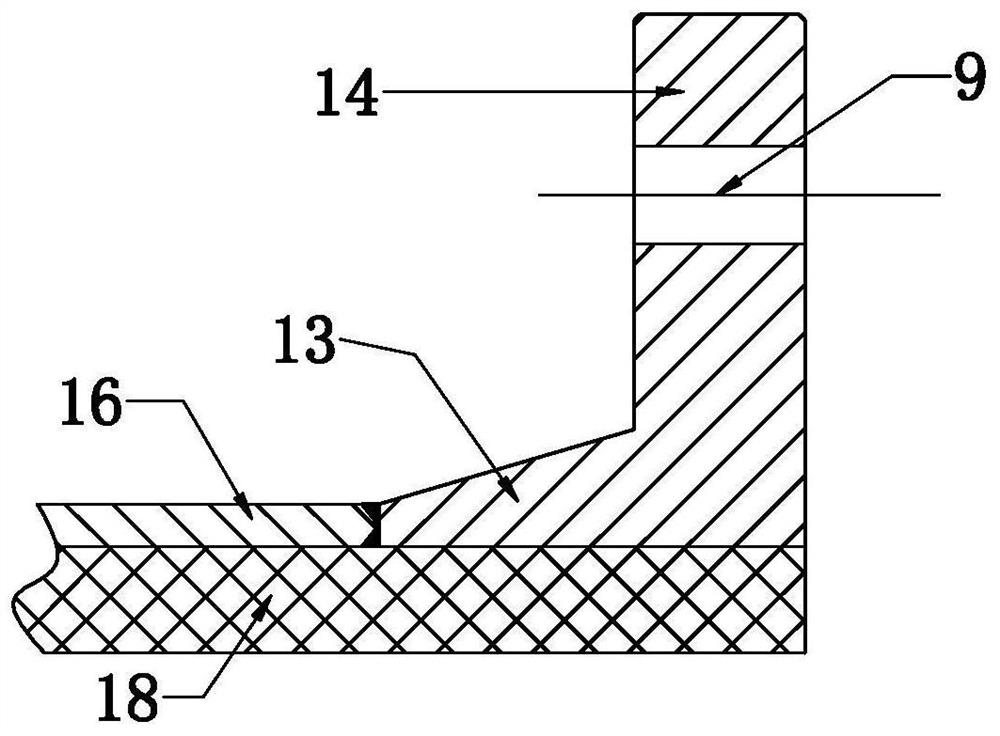

Static pressure gas labyrinth throttling control mechanism for dynamic and static pressure dry gas seal

ActiveCN106352094BReduced number of seal teethGood throttling effectEngine sealsThrottle controlDry gas seal

The invention provides a static pressure gas labyrinth throttle regulating mechanism for both dynamic and static pressure dry gas seals, wherein a third radial air inlet and an axial throttle hole are both formed in a static sealing ring, the third radial air inlet is communicated with a labyrinth seal, and is located at a comb area of the labyrinth seal, the axial throttle hole is communicated with a pressure groove of a seal end surface, the other end is sealed tightly by countersunk bolts; the interior of the labyrinth seal is provided a second radial air inlet by processing, a static pressure gas cavity is formed among the outer circle of the labyrinth seal, an intrinsic pressure cover and a stationary seal ring, a first radial air inlet and a second radial air inlet are both connected with the static pressure gas cavity; the inner circle of the labyrinth seal is provided with two sealing rings, gases entering the labyrinth seal can only flow into the third radial throttle hole, a third sealing ring is arranged between the outer circle of the throttle hole and the intrinsic pressure cover, a first sealing ring is arranged between the static ring and the interior pressing cover; the labyrinth end nearing the exterior press cover is provided with a spring for a regulator. which drives the labyrinth seal to slide along the outer circle of the static ring, thereby achieving the gas static pressure regulating function through the third radial air inlet.

Owner:ZHEJIANG UNIV OF TECH

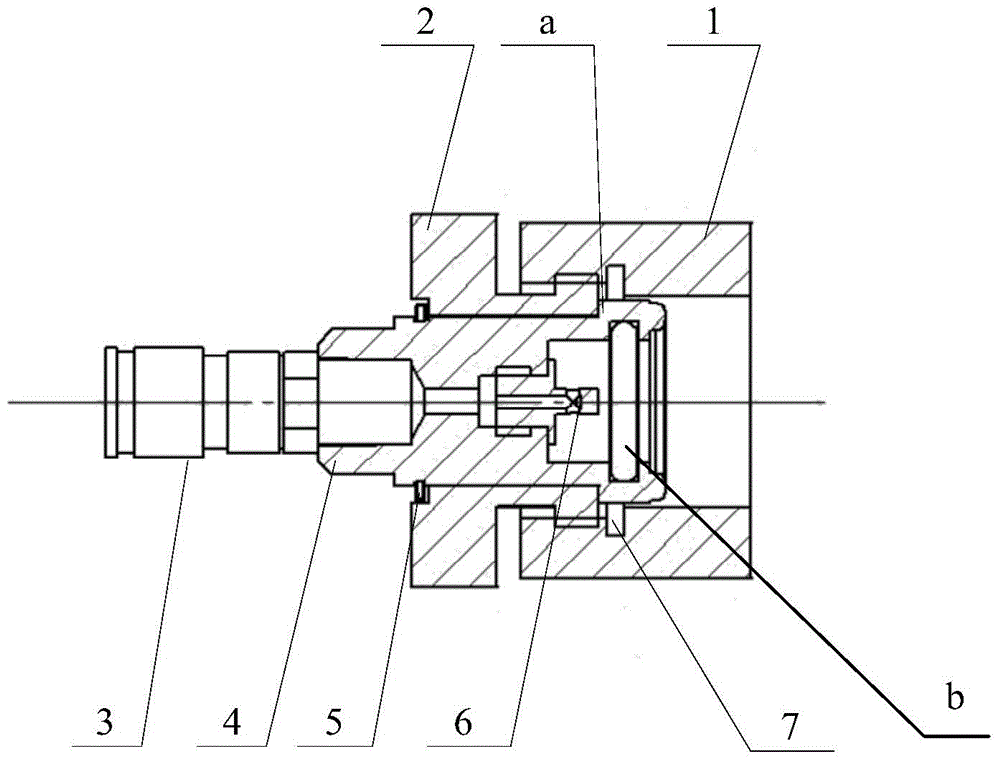

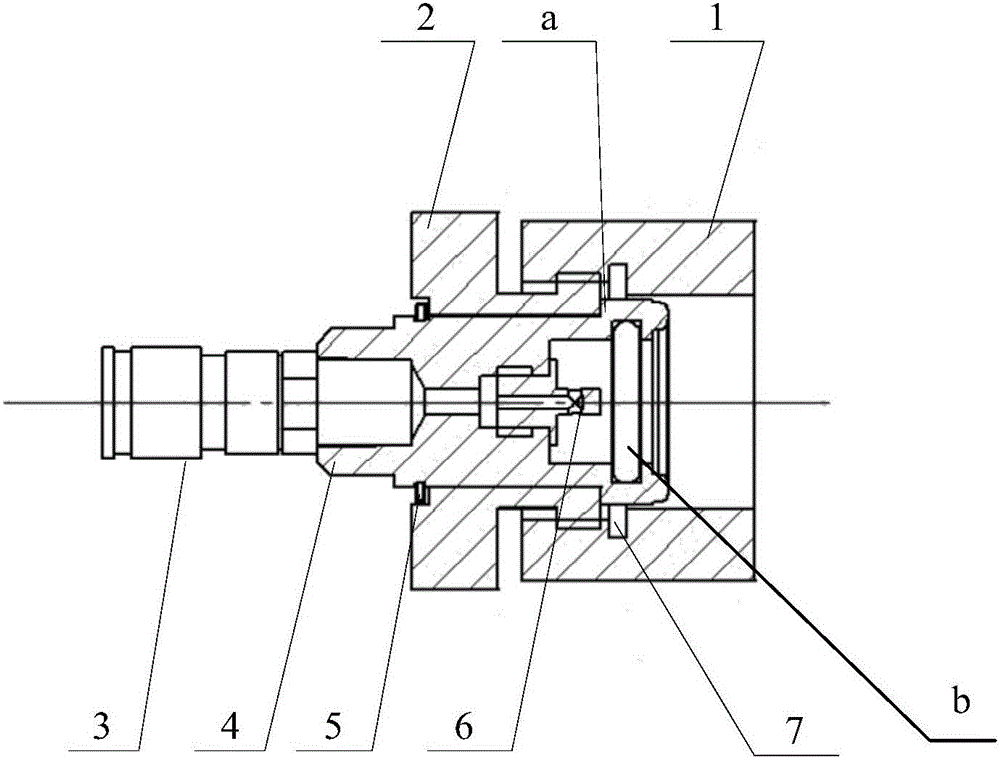

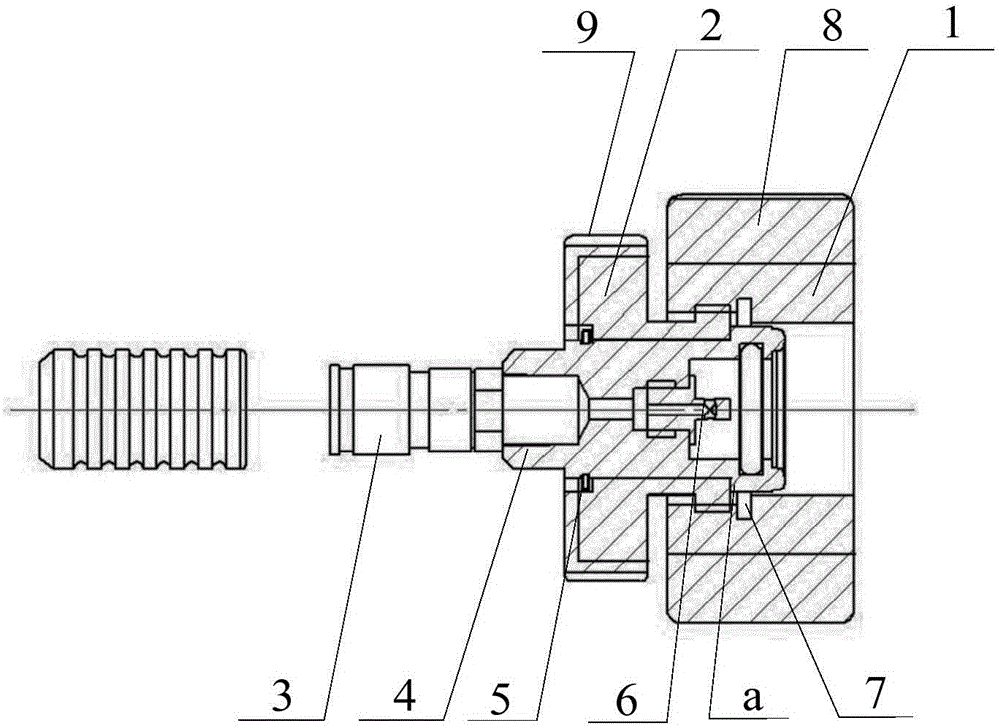

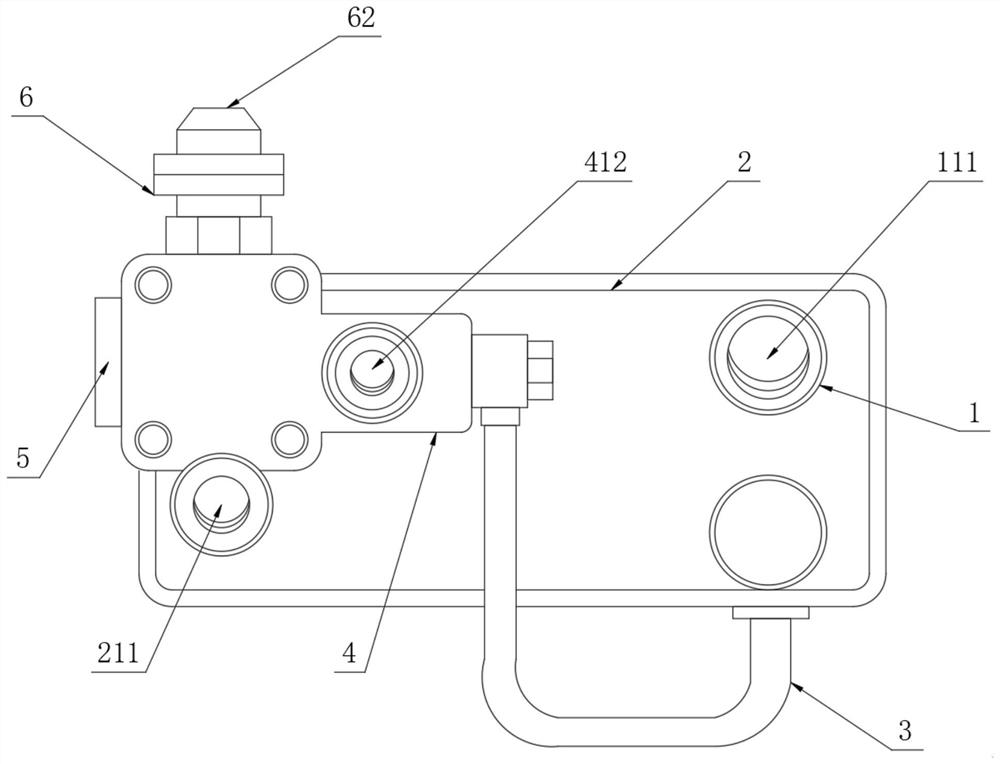

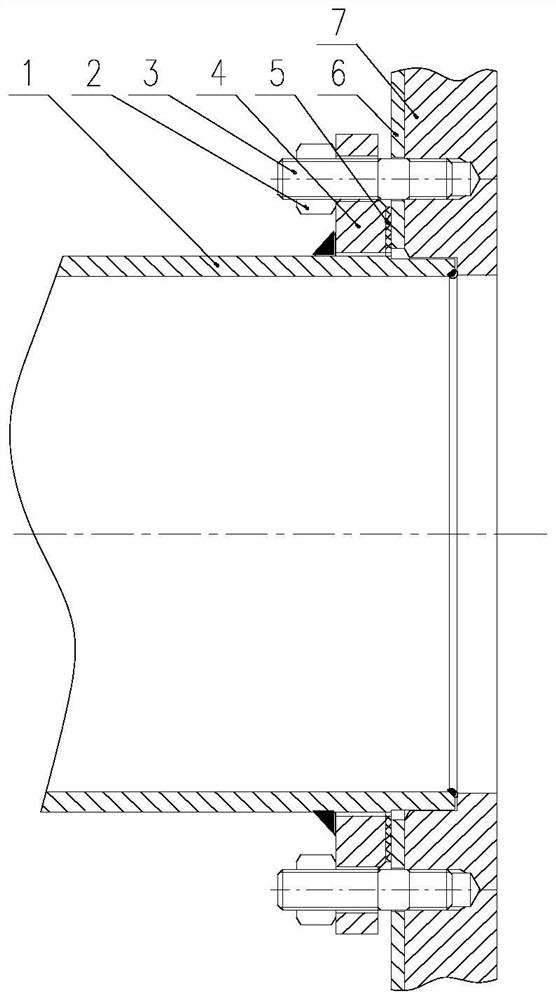

Gas taking connector and online gas taking method

InactiveCN104458345ANo leaksAccurate control of accessWithdrawing sample devicesMechanical engineeringEngineering

The invention relates to a gas taking connector and an online gas taking method. The gas taking connector comprises a fixed nut, a valve core with a gas taking ejector pin, a propelling part and a quick connector with an automatic sealing structure, wherein the gas taking ejector pin is fixed in the valve core, a through air duct is formed along the axial direction of the valve core, a pin head part stretches out of the front end of the valve core, and the front part and the rear part of the valve core are respectively provided with a baffle mechanism; the propelling part is arranged outside the valve core in a sleeving manner and snapped between the baffle mechanisms on the front part and the rear part of the valve core, the periphery of the propelling part is provided with outer threads which are matched with the inner threads of the fixed nut, and the propelling part is also provided with a propelling control part so as to drive the valve core to move in the fixed nut; one end of the quick connector can be connected with the tail end of the valve core in a sealing manner. By adopting the gas taking connector and the online gas taking method, the gas leakage in the gas taking process can be maximally eliminated, and the potential danger caused by the fault operation of people in the detection process can be prevented by virtue of the normalized operation method.

Owner:STATE GRID GANSU ELECTRIC POWER CORP +3

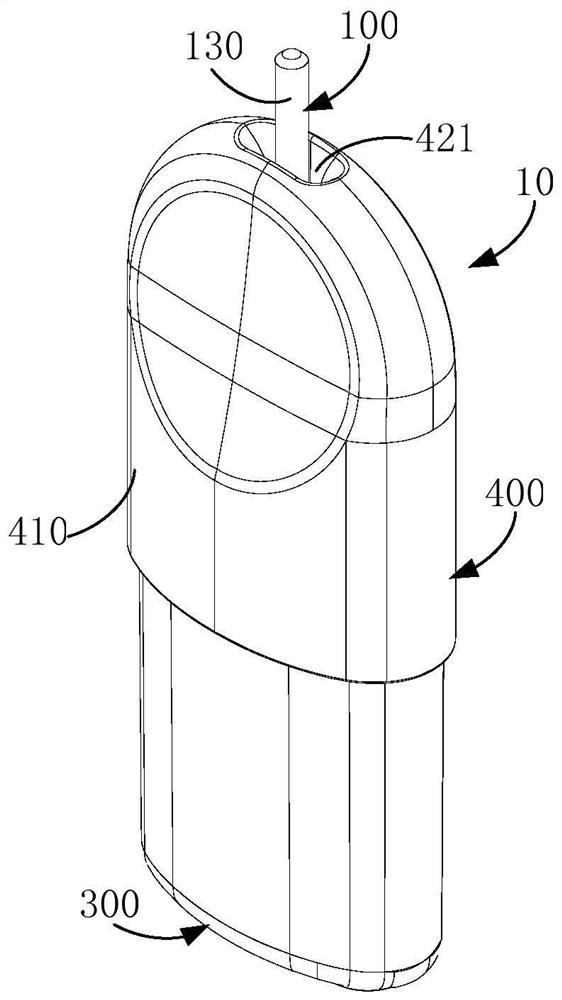

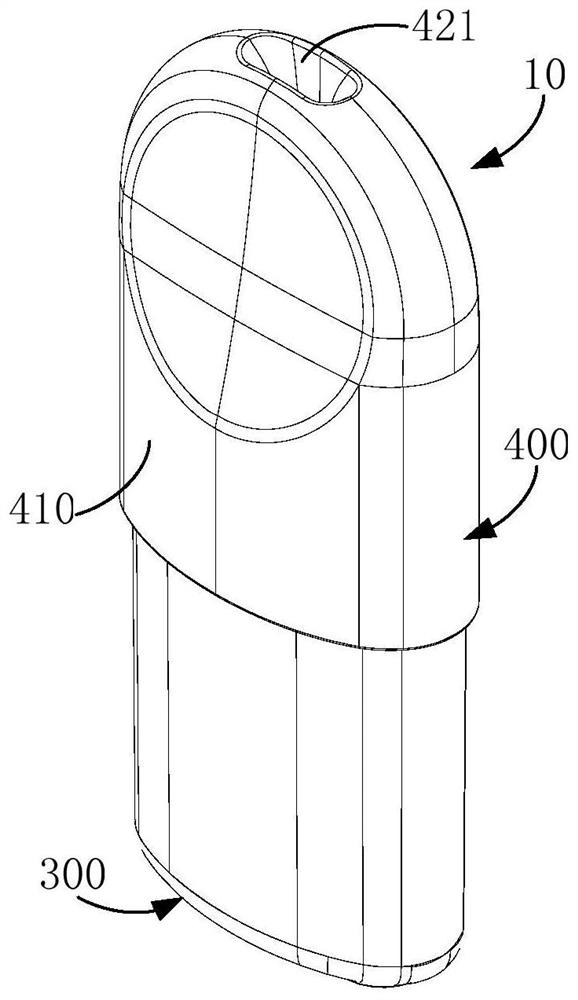

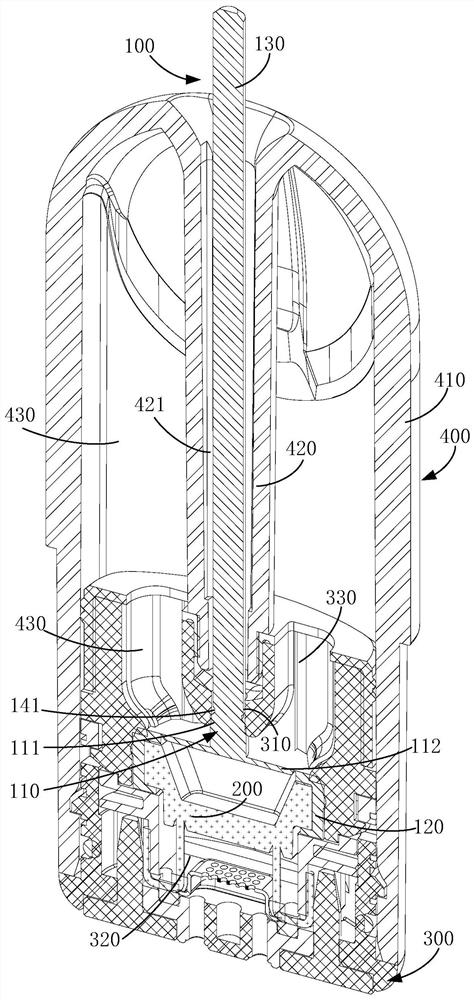

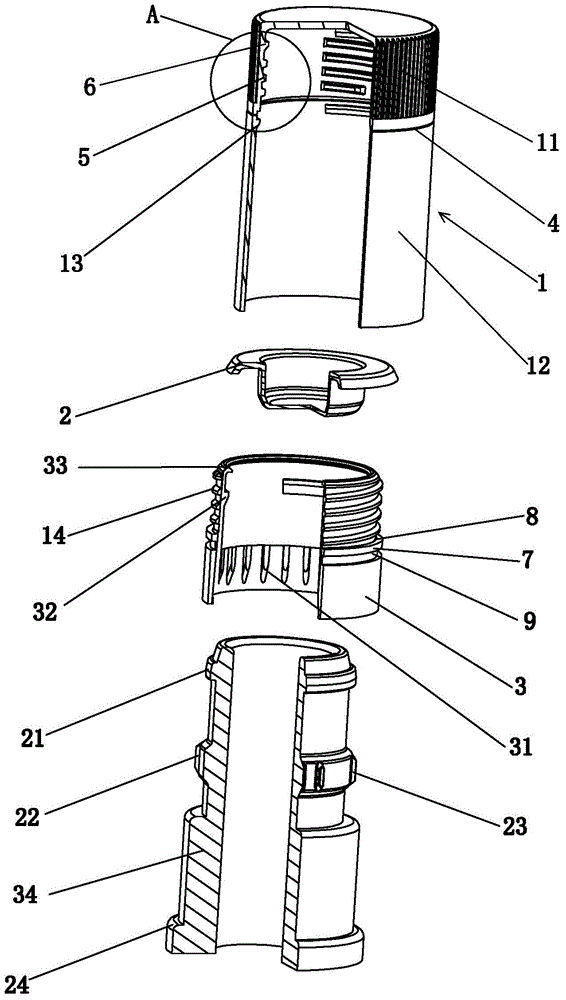

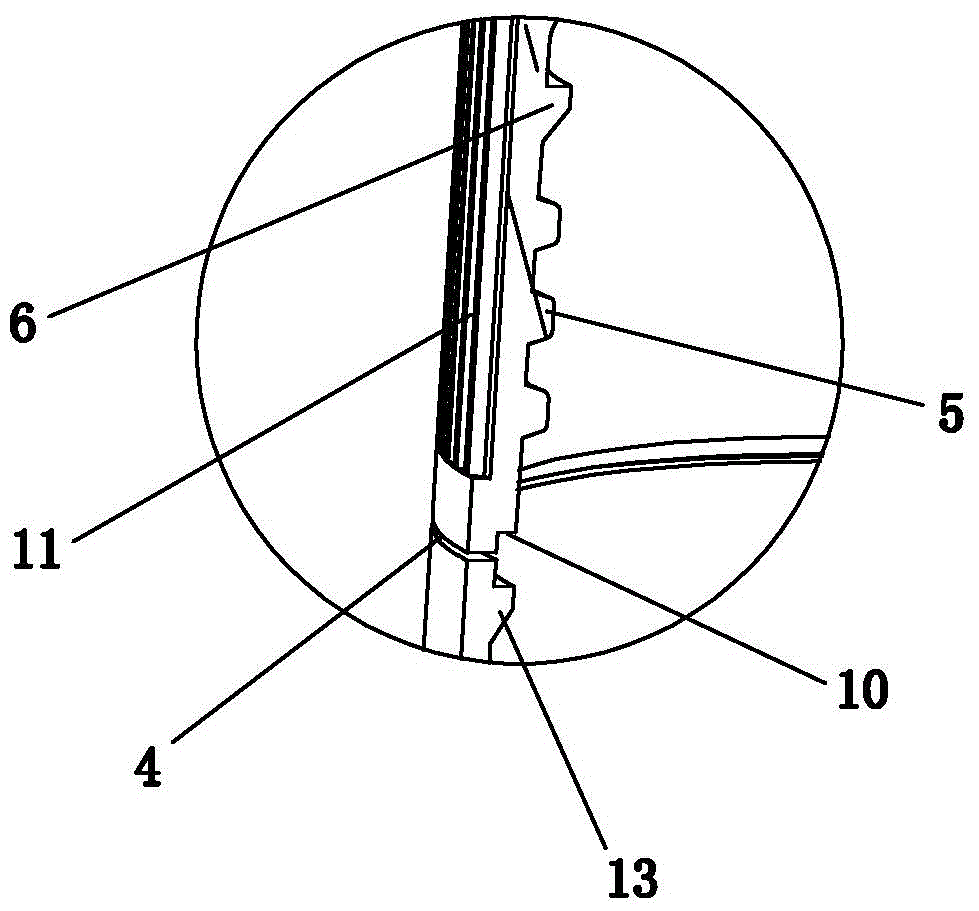

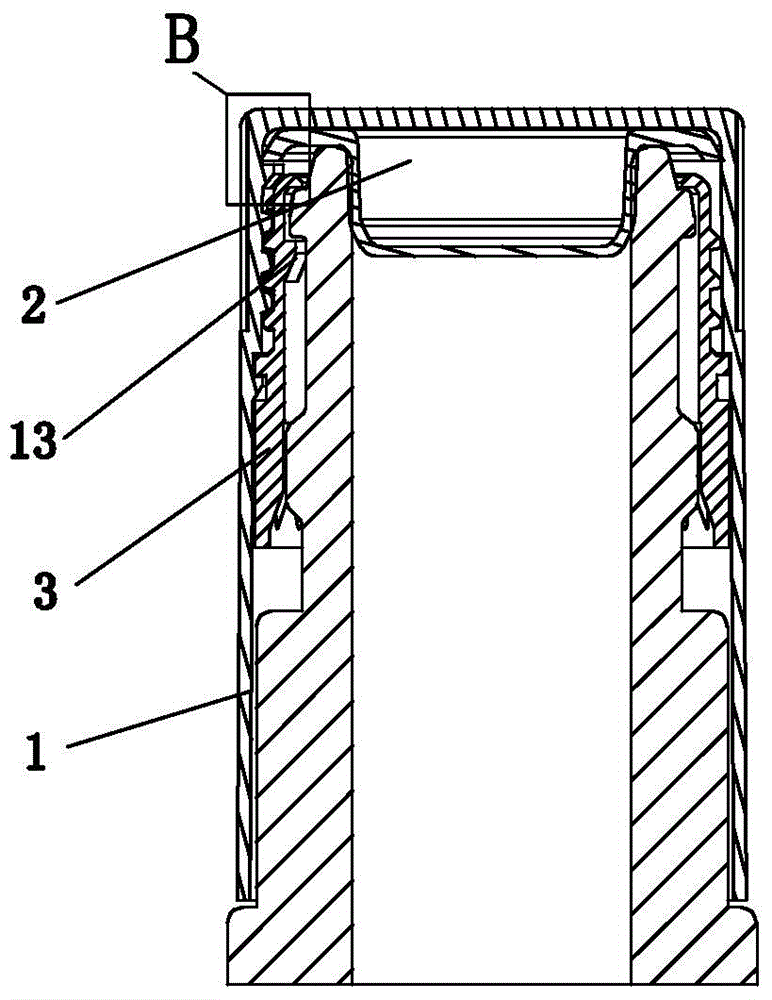

Sealing element, atomizer and electronic atomization device

PendingCN112353008AEliminate the risk of leakageImprove stability and reliabilityTobaccoPhysicsFluid Leak

The invention relates to a sealing element, an atomizer and an electronic atomization device. The atomizer comprises a sealing piece and a fixedly-arranged atomizing core. The atomizer is provided with a liquid storage cavity, a mounting hole and an air suction channel. The sealing piece comprises a pulling part, a first sealing part and a second sealing part, the second sealing part is arranged on the atomizing core, and the pulling part and the first sealing part can move relative to the mounting hole, so that the sealing piece has a sealing state and a using state. In the sealing state, thepulling part, the first sealing part and the second sealing part are connected with one another, and the first sealing part and the second sealing part isolate and seal the air suction channel and the atomization core from the liquid storage cavity. The pulling part is arranged in the air suction channel, and one end of the pulling part protrudes out of the air suction channel. And / or in the using state, the pulling part is separated from the first sealing part and pulled out of the air suction channel, and the air suction channel is opened; and the first sealing part is separated from the second sealing part to communicate the liquid storage cavity with the atomizing core. Therefore, the hidden danger of liquid leakage of the atomizer can be eliminated.

Owner:SHENZHEN SMOORE TECH LTD

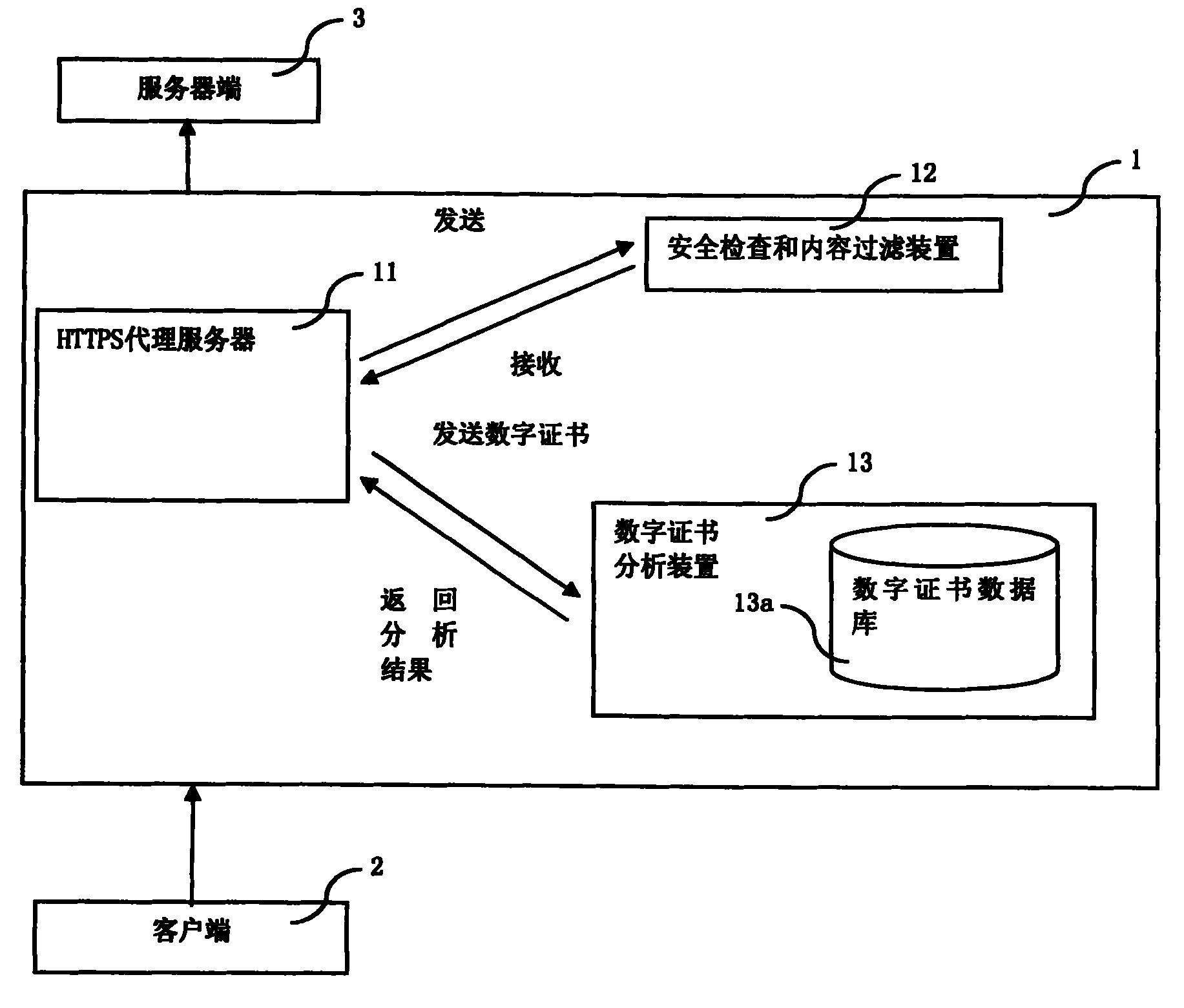

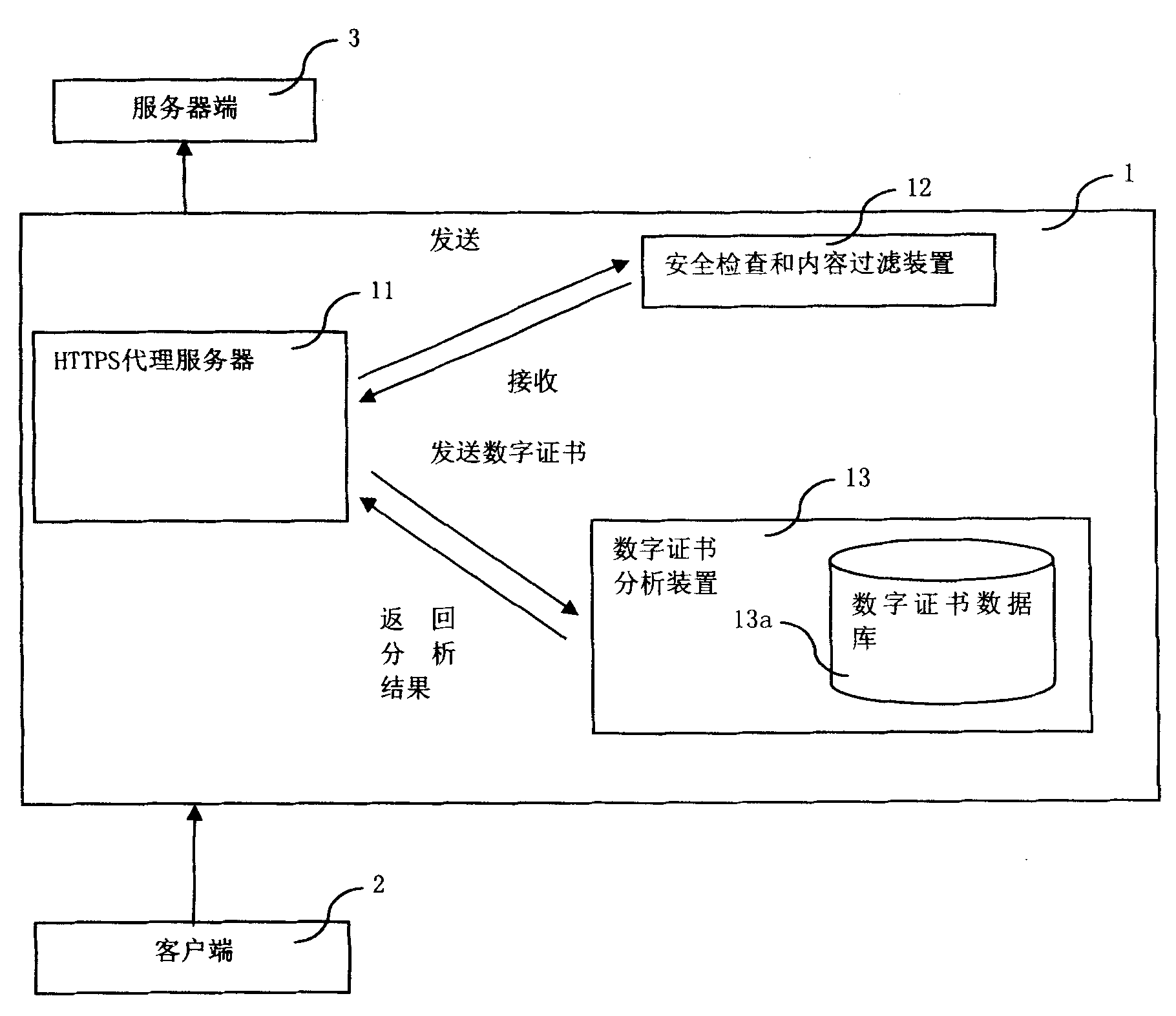

HTTPS communication tunnel safety examination and content filtering system and method

ActiveCN101141447BEliminate the risk of leaksTransmissionTransmission protocolSecure Hypertext Transfer Protocol

The present invention relates to a method and a system for security hypertext transmission protocol communication tunnel security checking and content filtering, which are used to check the security hypertext transmission protocol connection between a client side and a sever side. The method comprises the steps that, step one, a security hypertext transmission protocol proxy server forwards the digital certificate in security hypertext transmission protocol connection data to a digital certificate analysis device; step two, the digital certificate analysis device compares the digital certificate in the security hypertext transmission protocol connection data with the digital certificate stored, if the digital certificate transmitted by the security hypertext transmission protocol proxy server belongs to a digital certificate white list tabulation, step three is performed; step three, the security hypertext transmission protocol proxy server leads the client side and the sever side to be connected directly.

Owner:FORTINET

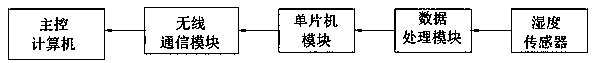

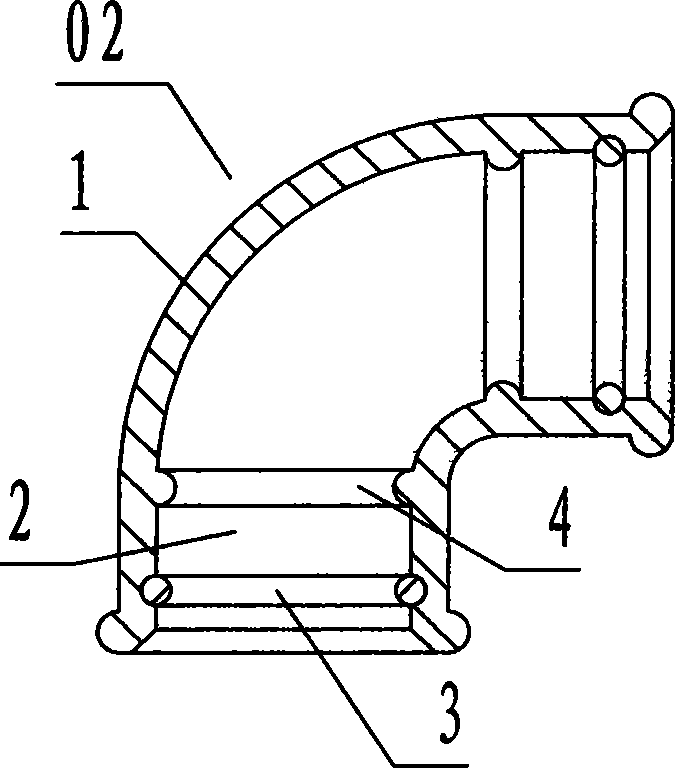

Double-sealing filling sleeve compensator

InactiveCN109668001AImprove sealingEliminate the risk of leaksPipeline expansion-compensationHigh concentrationEngineering

The invention discloses a double-sealing filling sleeve compensator, and relates to the field of compensators. Not less than three filling nozzles are annularly distributed in the outer walls of a lower barrel body and an upper barrel body separately; sealing fillers are filled at the inner sides of the lower barrel body and the upper barrel body, and between a guide bearing bush and a gland ringseparately; and a humidity sensor is arranged at one side close to a water drainage port, of the inner wall of the upper barrel body. According to the double-sealing filling sleeve compensator, a double-layer sealing structure is adopted, so that the sealing effect of the product in a working process is greatly improved; the humidity sensor is arranged between the two layers of sealing, whether aleakage phenomenon of equipment occurs or not can be directly viewed, and once the leakage phenomenon is found, a sealing agent can be injected into the filling nozzles in time by virtue of a high-pressure agent injection gun, so that the hidden danger of leakage is eliminated in time, high safety is achieved, and meanwhile, the loss brought by the stop maintenance of the equipment is effectivelyavoided; and high-concentration flexible graphite packing and flexible graphite powder are adopted as a sealing material, and the sealing agent is expanded at a high temperature, so that the sealing effect is greatly improved.

Owner:吴俊霖

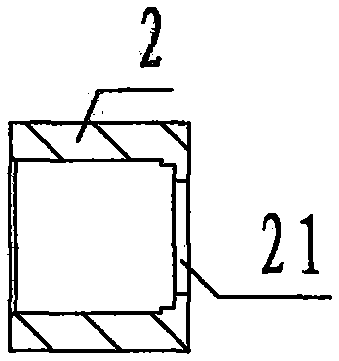

Press fitting stuck-type bottle cap, preparation method thereof and containing comprising press fitting stuck-type bottle cap

The invention discloses a press fitting stuck-type bottle cap, which comprises an outer sleeve, a seal closure and an inner sleeve; the outer sleeve consists of an upper sleeve and a lower sleeve; as a seal closure stop block for preventing the axial movement of the seal closure is arranged in the outer sleeve, when the bottle cap is opened and when the upper sleeve and the lower sleeve are separated, the seal closure is separated from a bottle mouth along with the upper sleeve, and the step that the seal closure is taken down from the bottle moth is omitted; the opening of the bottle cap is more convenient; moreover, as the seal closure is arranged in the outer sleeve, the seal closure is prevented from being polluted when not in use; when the bottle mouth is resealed, only the sleeves need to be screwed to the bottle mouth; the step that the bottle mouth is sealed by the seal closure is omitted; resealing of a bottle body is more convenient; meanwhile, an inner sleeve wraps the glass bottle mouth, so that the secondary appearance of a wine bottle is attractive and looks high in grade; the bottle cap is sealed by the seal closure, so that the seal effect is good, and the leakage hidden danger of a regular twist-off cap is eliminated.

Owner:HICAP CLOSURES CO LTD

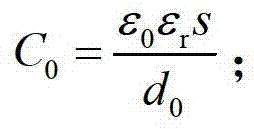

Fluid pressure measurement sensor based on high polymer thin film

InactiveCN103091030ASimple structureReduce volumeFluid pressure measurement using capacitance variationCapacitanceMetal electrodes

The invention discloses a fluid pressure measurement sensor based on a high polymer thin film and a measuring method thereof. The sensor comprises two metal electrode thin sheets, and one high polymer thin film is clamped between the two metal electrode thin sheets to form a capacitor. The high polymer thin film can feel pressure imposed by fluid and change thickness, the gap between the two metal electrode thin sheets is changed due to the thickness change, and thus the capacitance between the two metal electrode thin sheets is changed, and the pressure of the fluid can be calculated through detecting the variable quantity of the capacitance. The fluid pressure measurement sensor based on high polymer thin film is small in size, simple in structure, and low in cost, and supplies an effective way to solve the problem of fluid pressure measurement.

Owner:ZHEJIANG UNIV

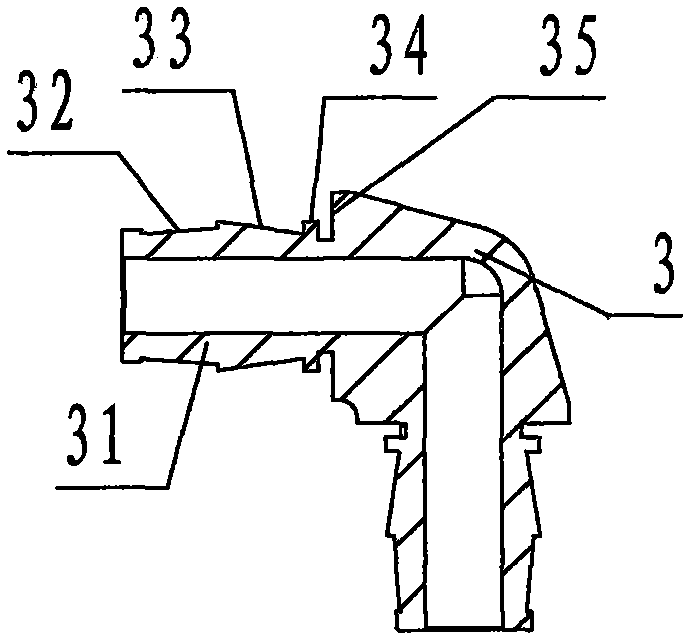

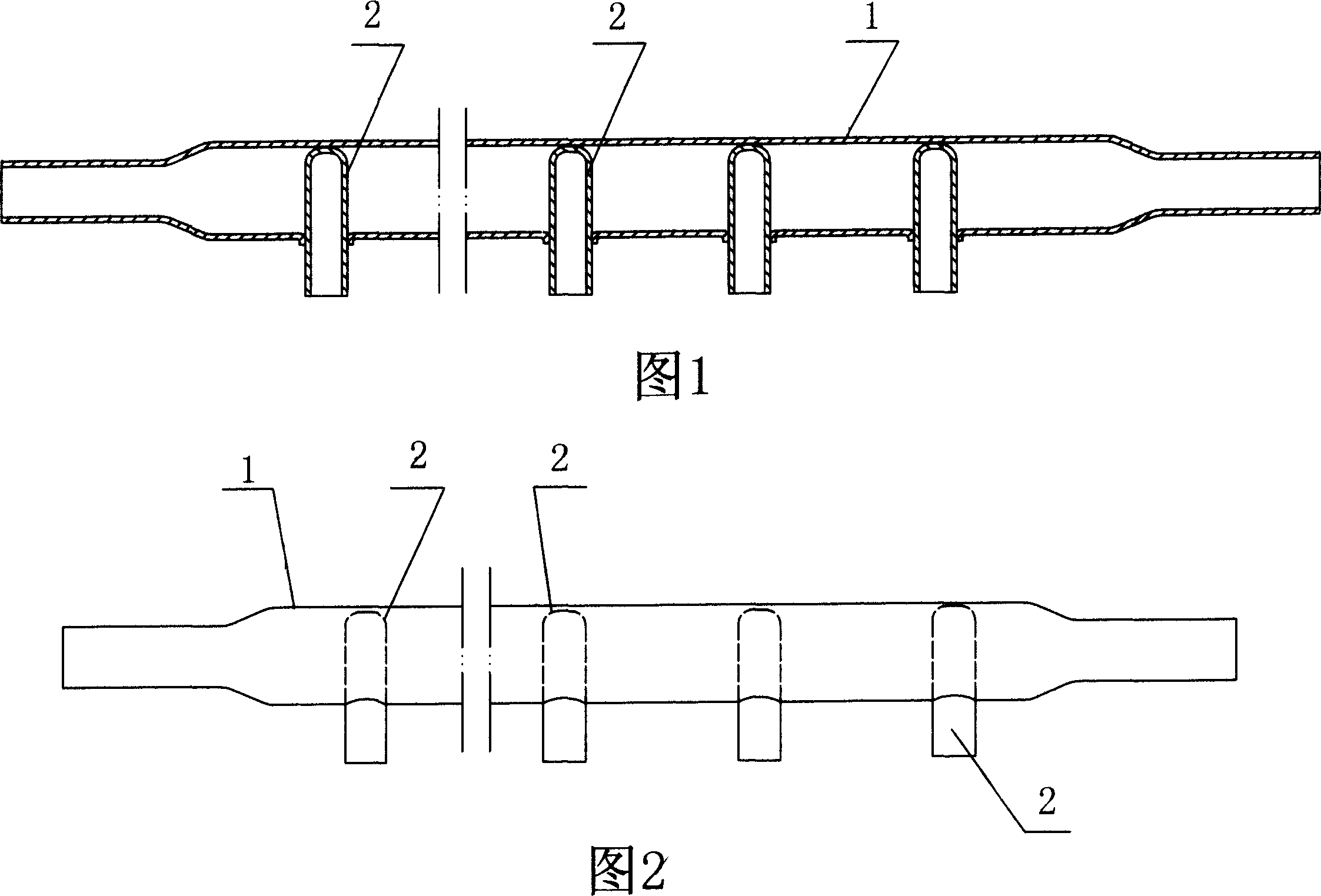

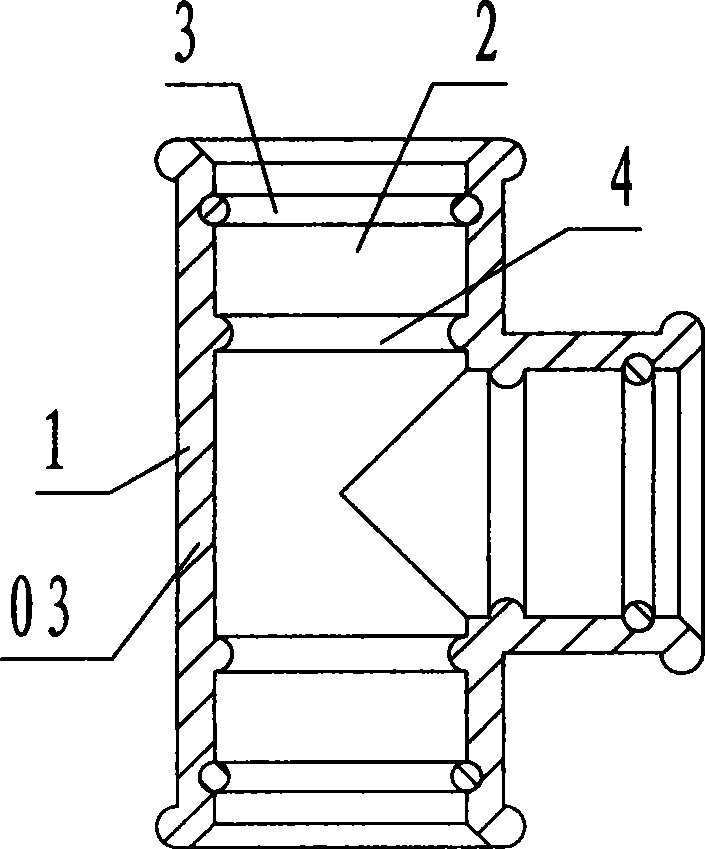

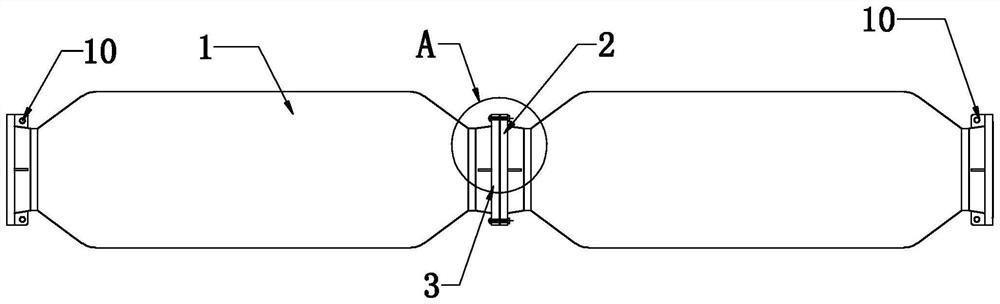

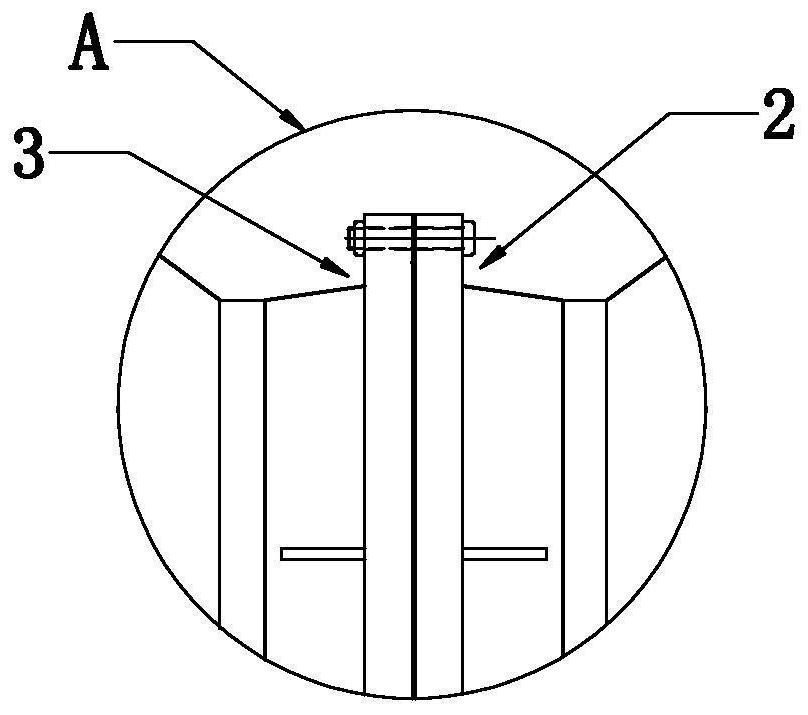

Cold-expanding, cold-hooping and self-sealing connecting type plastic floor heating pipe fitting

InactiveCN105333262AEnsure strength and sealEliminate leak hazardsPipe connection arrangementsThin walledRetaining ring

The invention discloses a cold-expanding, cold-hooping and self-sealing connecting type plastic floor heating pipe fitting. The cold-expanding, cold-hooping and self-sealing connecting type plastic floor heating pipe fitting comprises a pipe (1), a pipe hoop (2) and a pipe fitting body (3), wherein the pipe is a cylindrical tubular plastic component; the pipe hoop is a cylindrical tubular plastic component provided with a clamping ring; the pipe fitting body is a hollow and thin-wall type pipeline-shaped plastic component; a part in which an inner chamber of the pipe fitting body is connected with the outside is called a joint; an embedding groove, a tapered platform, a retaining ring and a retaining rib are arranged in the outer wall of the joint from left to right. When the pipe fitting is in application, the pipe hoop sleeves one end of the pipe; an external expander is inserted into the inner chamber of the pipe at the end; the pipe and the pipe hoop are synchronously expanded and swelled so as to obtain an expanding end port; then the expander is drawn out; the joint of the pipe fitting body is inserted into the expanding end port; after the expanding end port is contracted, the pipe can be hooped and self-sealed so as to be fixedly connected with the pipe fitting body; an indoor hot water floor heating pipeline can reach the purposes of ensuring the connection sealing performance and the connecting strength as well as removing the potential risk of leaking through the cold-expanding and cold-hooping connection.

Owner:华英伦科技(宁波)有限公司

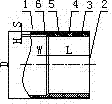

Composite type plastic pipe with wound netting wire and strengthened bell mouth and manufacturing process thereof

ActiveCN101788085AImprove performanceSave pipe wall materialsRigid pipesTubular articlesAdditive ingredientEngineering

The invention relates to a composite type plastic pipe with wound netting wires and strengthened bell mouths, and a manufacturing process thereof. The invention adopts the following technical scheme: the tube ball with a distance of the inner diameter length L to the end part of the bell mouth is a reinforced and thickened wall; the tube wall with a distance of the outer diameter length M to the end part of the bell mouth is a netting wire reinforced wall; and a viscose glue layer, a mark and a protection layer, the wall thickness S, diameter phi and outer diameter D are set according to corresponding ratios; plastic resin mulling-ingredient is utilized as the raw material; and simultaneously, products are manufactured under the synchronous control of a dryer, an extruder, a die head, a die, a vacuum box, a spraying box, a take-up winder, a high-frequency machine, a tractor, a cutter and the like. The technical scheme of the invention overcomes the defect that the axial rigidity of the existing pipe workpiece influences the axial flexibility, geology sinking resistance and tension resistance at the welding part of the bell mouth, as well as the defect that the non-roundness at the joint of the bell mouth leads the strength and rigidity at the cross section of the joint of the bell mouth of the pipe workpiece to be unable to load tubing pressure when the electrofusion pipe fittings are welded, and the like, thus being suitable for serving as connection pipe workpieces for various water delivery and gas transmission projects, and especially suitable for strengthening pipe walls and thickening the bell mouths of PE, PVC-U, PVC-M and the like.

Owner:HUNAN ZHENHUI PIPE IND

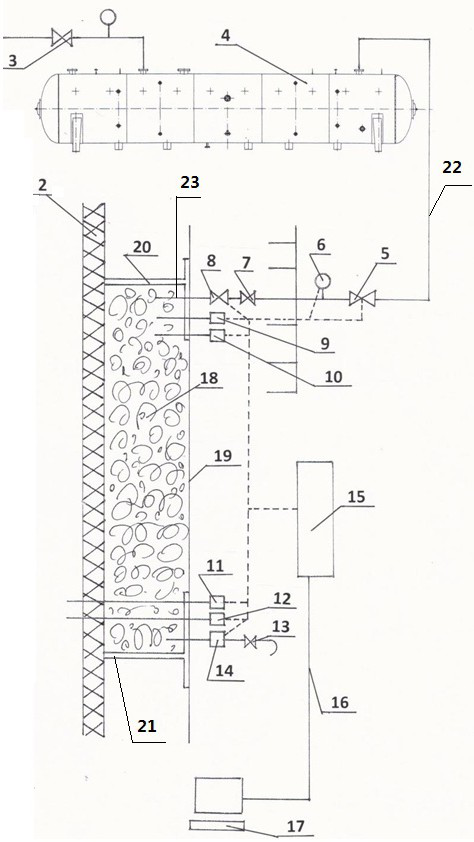

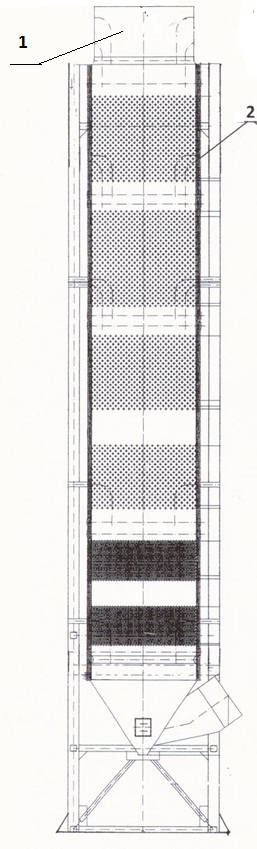

Nitrogen protection anti-explosion device and method of converter flue gas waste heat boiler

ActiveCN111854454AAvoid enteringPrevent oxidationIncreasing energy efficiencySteam boilersSteelmakingThermodynamics

The invention relates to a nitrogen protection anti-explosion device and method of a converter flue gas waste heat boiler, and belongs to the technical field of converter flue gas waste heat boilers.According to the technical scheme, one set of outer upper support (20) and outer lower support (21) are at least arranged on the circumference of the outer side of a waste heat boiler outer wall (2),a relatively closed space is formed between the waste heat boiler outer wall (2), an outer sealing layer (19), the outer upper support (20) and the outer lower support (21), and the space is filled with a protection layer insulation material (18); and nitrogen branch pipes (23) penetrate through the outer sealing layer (19) to enter protection layers. The device and method have the beneficial effects that air is prevented from entering the converter flue gas waste heat boiler, an alarm can be given in time for outer wall perforating of the converter flue gas waste heat boiler, the air leakingphenomenon of the converter flue gas waste heat boiler can be found in time, and the hidden danger of exploding and gas leaking can be eliminated. Severe influence is prevented from being generated onconverter steel making, and huge safety production accidents are eradicated.

Owner:江苏热盾节能环保科技有限公司

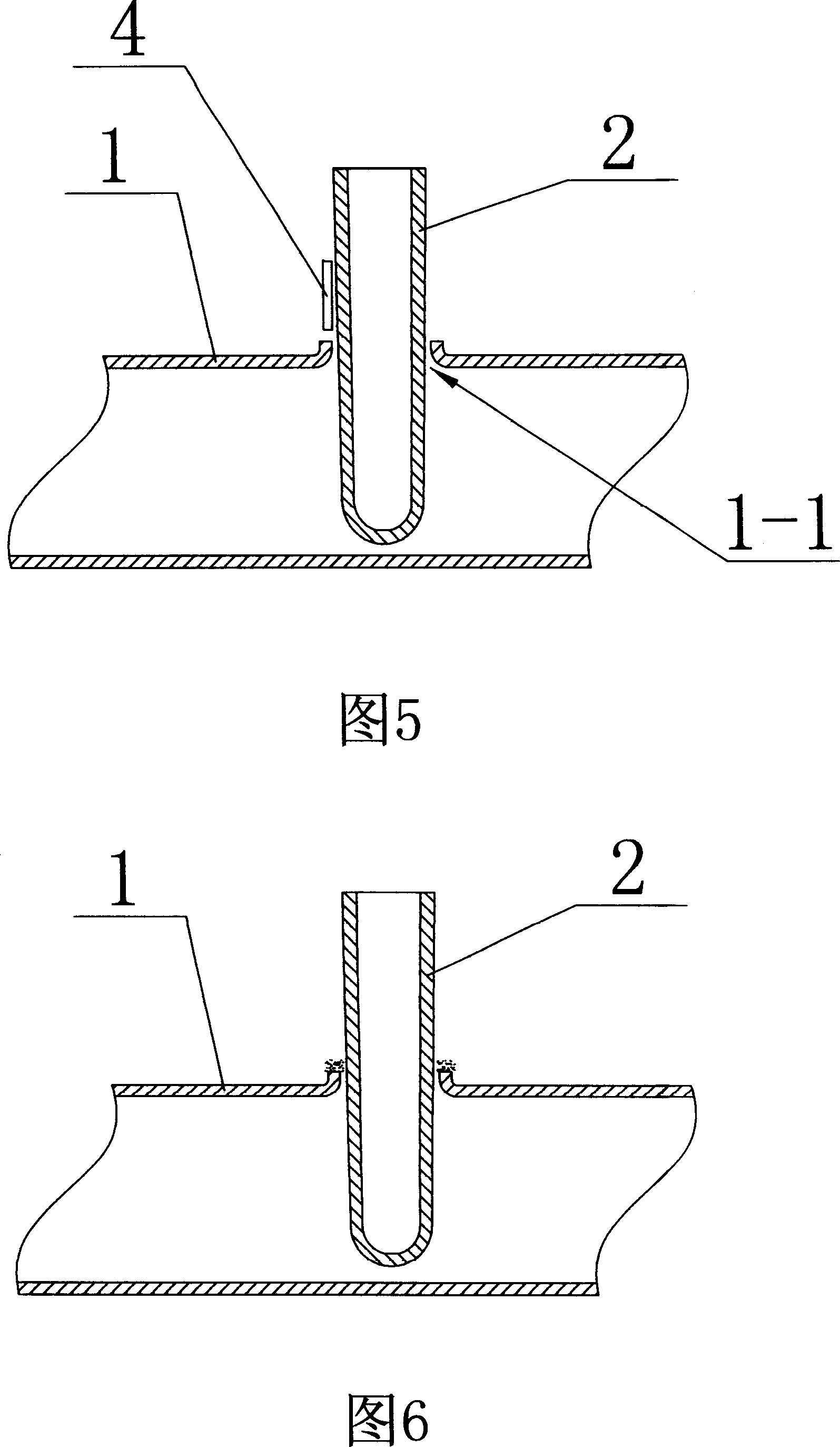

Water delivery tank and its welding method

InactiveCN101021366AEliminate gapsEliminate the risk of leaksSolar heat devicesSolar thermal energy generationWater channelEngineering

The invention discloses a water channel used for the solar energy collector and the sealing method. The water channel includes the main water pipe and bushing. The main pipe has many cross through holes which is fixed with the bushings. The two ends of the bushing are all out of the main water pipe. The method is: the bushing is inserted into the cross through hole and the two ends are all out of the hole, then are the below processes: the brazing silk ring is set in the joint between the main water pipe and the bushing which is sealed by the high frequency soldering machine, then the main water pipe and the bushing are all be turned over to make the other sealing joint up which is set on the brazing silk ring. The invention has the big heat exchanging area and high reliability, so the joint can not leak.

Owner:CONSOL CHANGZHOU ENERGY

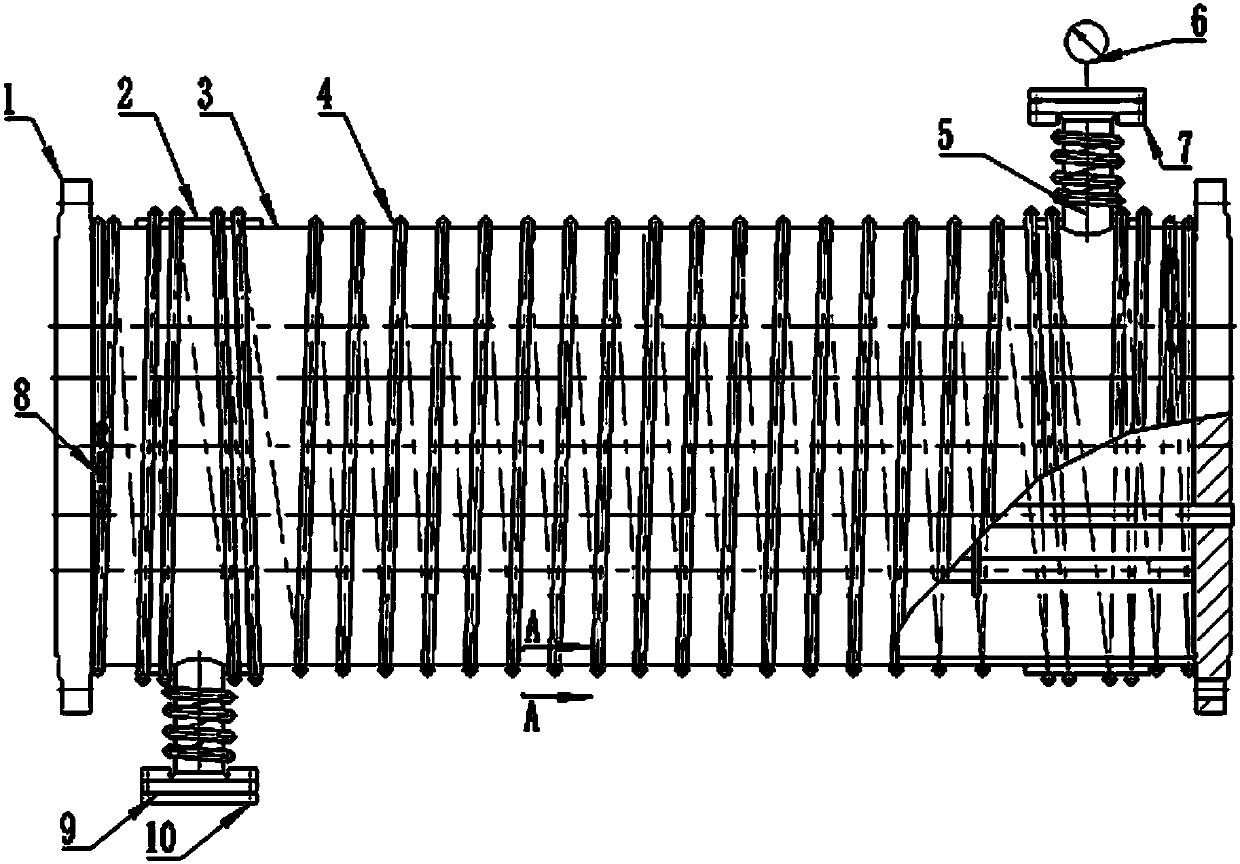

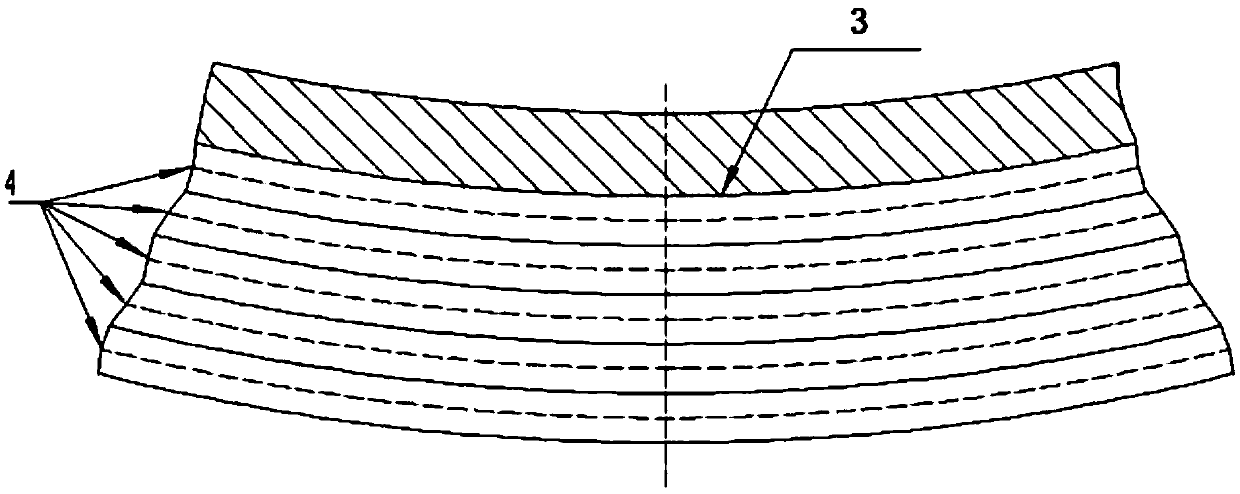

Device for enhancing shell strength during heat exchanger tube head pressure withstanding test and pressure testing method

PendingCN107782631ANo change in design thicknessHigh strengthMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesEngineeringTension stress

The invention belongs to the technical field of heat exchange devices in petrochemical engineering, and particularly relates to a device for enhancing shell strength during heat exchanger tube head pressure withstanding test and a pressure testing method. The device for enhancing shell strength during heat exchanger tube head pressure withstanding test is used for the pressure testing process of afixed tube sheet heat exchanger and is arranged on the shell of the heat exchanger, a plurality of flexible cables used for enhancing strength are wound on the shell of the heat exchanger, a dead zone reinforcing ring is arranged in the winding dead zone of a connecting part of the shell of the heat exchanger and a connecting pipe, and a pipe connecting flange component is arranged on a connecting pipe flange. According to the invention, the strength of the shell is effectively enhanced by utilizing the characteristics that the flexible cable is soft and liable to deform and capable of bearing tensile stress, and the device is low in cost, wide in application scope and strong in practicability.

Owner:PUYANG HAILIN SPECIAL EQUIP MFG PROTECTION

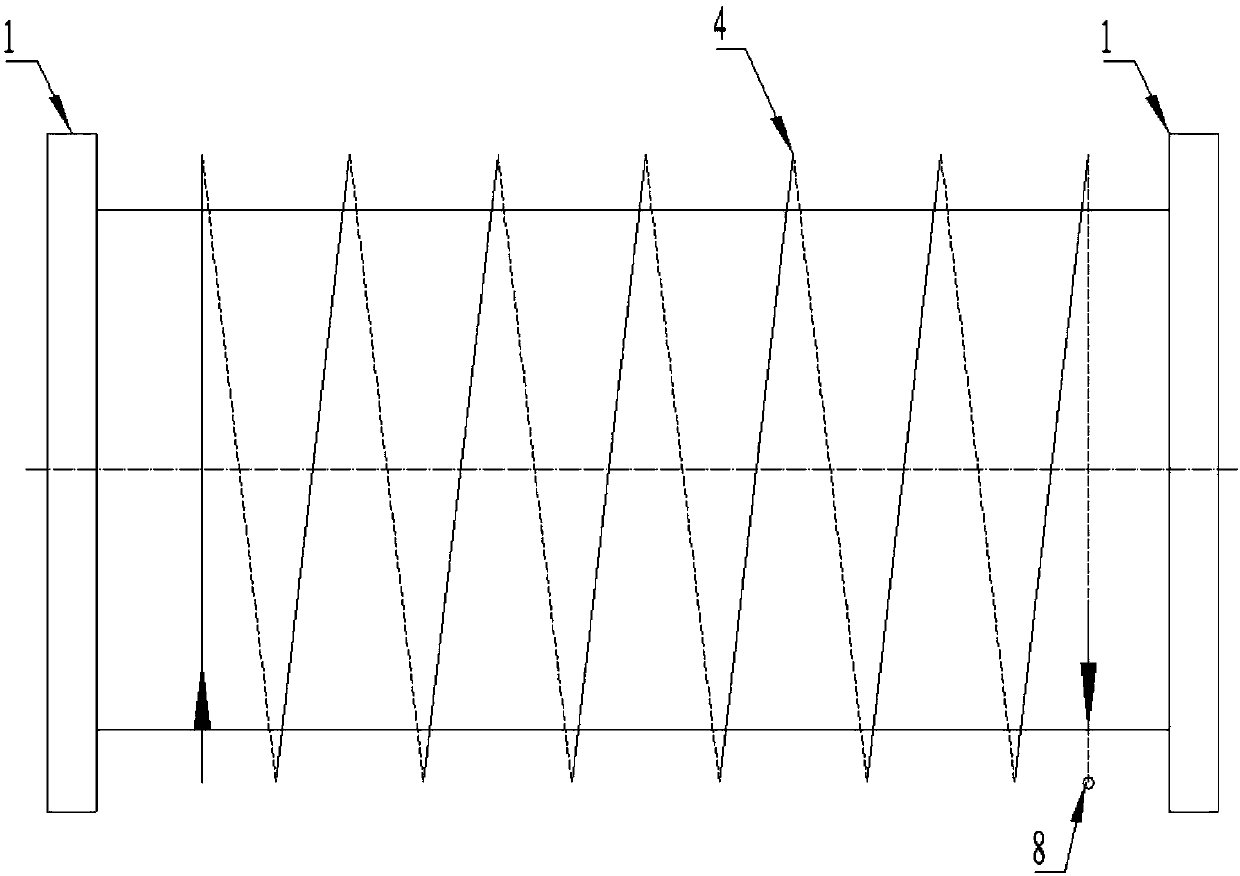

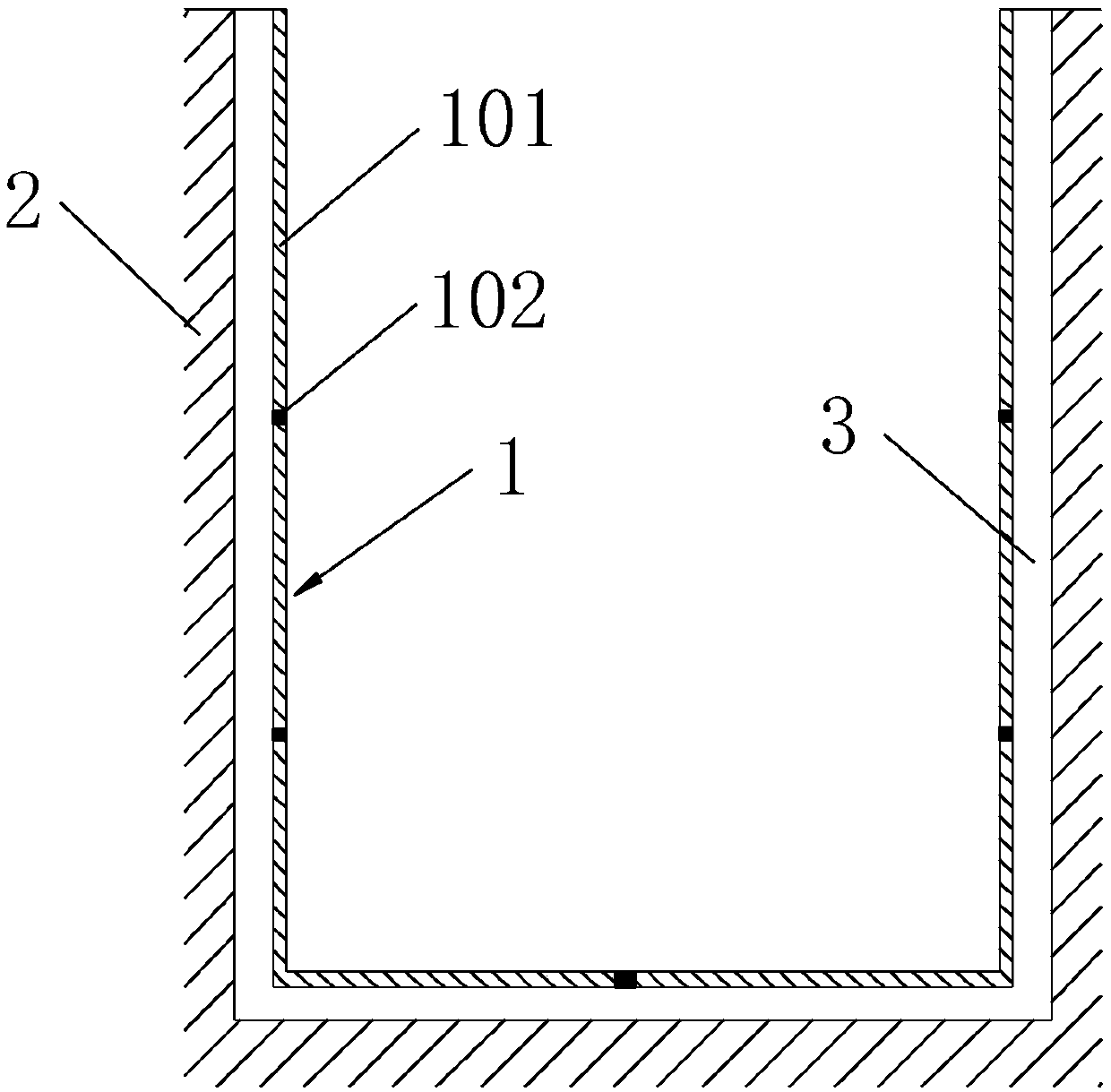

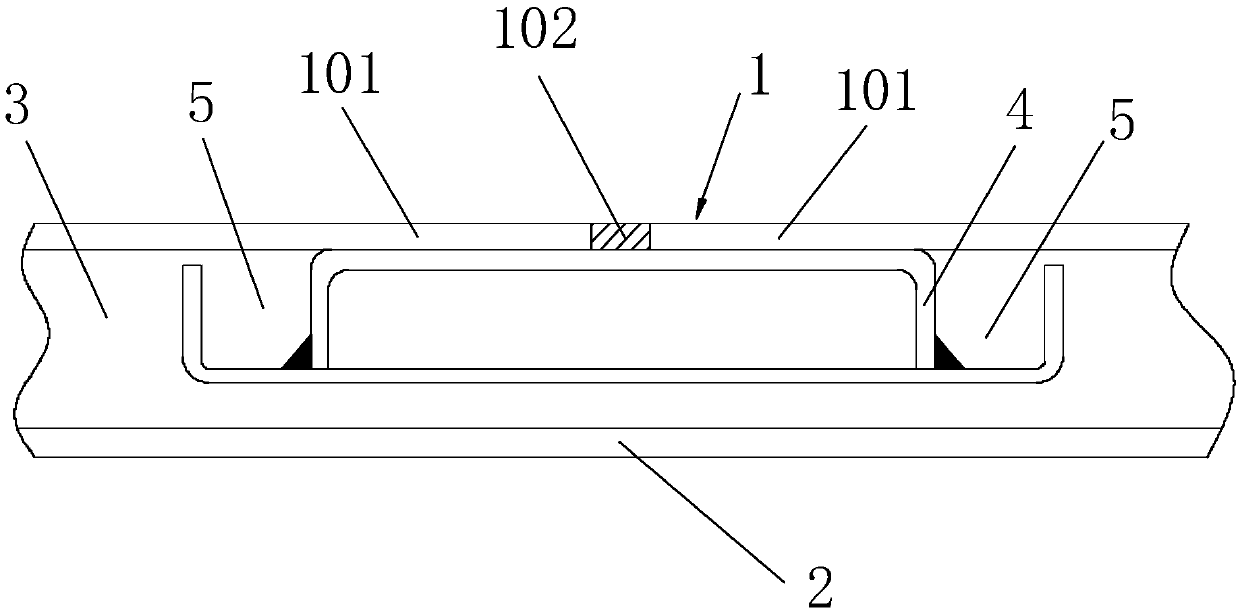

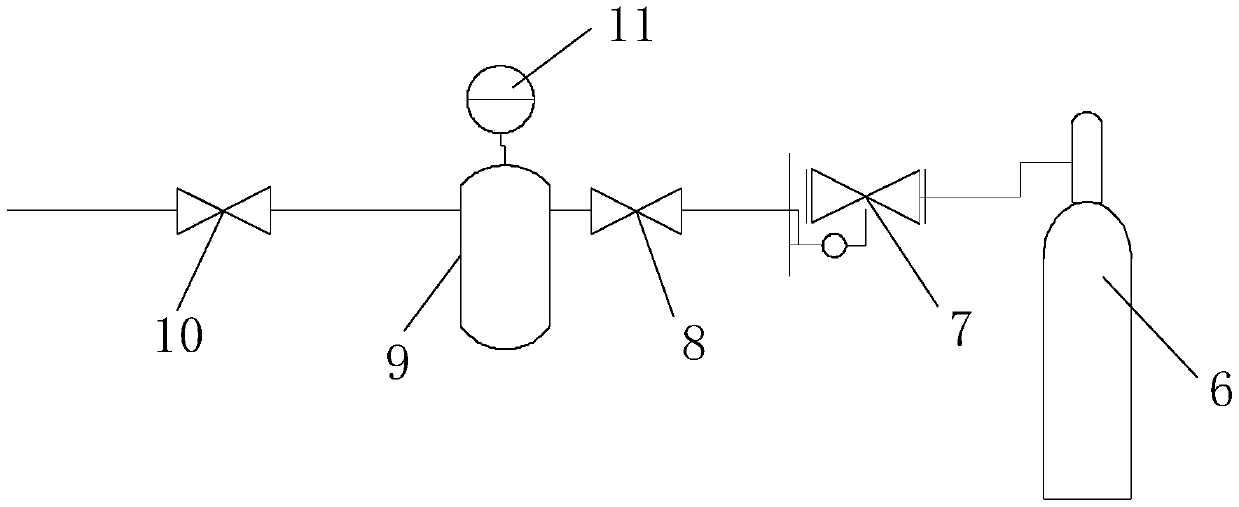

A helium leak detection method for stainless steel cladding of pools in the control area of nuclear power units

InactiveCN107449559BEliminate the risk of leaksPreventing Radiation LeakageDetection of fluid at leakage pointNuclear powerControl area

The invention relates to a helium leakage checking method used for a stainless steel cladding surface of a pool in a nuclear power unit control area. The pool includes a concrete base pool and a stainless steel plate group laid on the inner surface of the concrete base pool, the stainless steel plate group includes a plurality of stainless steel plates, each two adjacent stainless steel plates are connected by welding, the stainless steel plates and weld zones jointly form a stainless steel cladding surface on the inner surface of the concrete base pool, an approximately airtight accommodating space is formed between the stainless steel cladding surface and the concrete base pool, and the bottom of the concrete base pool is provided with a leading-out port connected to the accommodating space. The helium leakage checking method includes the steps of (1) using a helium filling device to be connected with the leading-out port to fill the accommodating space with helium; (2) verifying whether the accommodating space is filled with helium; and (3) performing helium leakage checking on the surfaces of the steel plates. After adoption of the abovementioned technical scheme, leak point checking can be conveniently performed on the stainless steel cladding surface of the pool before a nuclear power unit is on service.

Owner:SUZHOU NUCLEAR POWER RES INST +2

Gas-taking joint and online gas-taking method

InactiveCN104458345BNo leaksSafe dismantlingWithdrawing sample devicesEngineeringMechanical engineering

The invention relates to a gas taking connector and an online gas taking method. The gas taking connector comprises a fixed nut, a valve core with a gas taking ejector pin, a propelling part and a quick connector with an automatic sealing structure, wherein the gas taking ejector pin is fixed in the valve core, a through air duct is formed along the axial direction of the valve core, a pin head part stretches out of the front end of the valve core, and the front part and the rear part of the valve core are respectively provided with a baffle mechanism; the propelling part is arranged outside the valve core in a sleeving manner and snapped between the baffle mechanisms on the front part and the rear part of the valve core, the periphery of the propelling part is provided with outer threads which are matched with the inner threads of the fixed nut, and the propelling part is also provided with a propelling control part so as to drive the valve core to move in the fixed nut; one end of the quick connector can be connected with the tail end of the valve core in a sealing manner. By adopting the gas taking connector and the online gas taking method, the gas leakage in the gas taking process can be maximally eliminated, and the potential danger caused by the fault operation of people in the detection process can be prevented by virtue of the normalized operation method.

Owner:STATE GRID GANSU ELECTRIC POWER CORP +3

Steel wire enhanced bell and spigot composite plastic tube and fabrication process thereof

ActiveCN101881356BSimple structureSave raw materialsCorrosion preventionPipe protection against corrosion/incrustationConical tubeSystem maintenance

The invention relates to a steel wire enhanced bell and spigot composite plastic tube and a fabrication process thereof. The steel wire enhanced bell and spigot composite plastic tube is prepared by mainly enhancing an inner bell and spigot and an outer bell and spigot, reasonably configuring each corresponding ratio parameter and adopting the fabrication process. The steel wire enhanced bell andspigot composite plastic tube comprises the inner bell and spigot, a bush, the outer bell and spigot, a sealing ring adapted to the outer bell and spigot, a conical tube, a round tube A, an arc tube,a round tube B and a steel wire sleeve mainly covering the outer wall of the arc tube, wherein the inner bell and spigot and the bush are arranged at one end of the tube wall, the outer bell and spigot and the sealing ring are arranged at the other end of the tube wall, and the conical tube, the round tube A, the arc tube, the round tube B and the steel wire sleeve are sequentially connected to the tube wall. The invention overcomes the defects that in the traditional PE (Polyethylene) tube, a reticular enhancement mode and a bidirectional winding enhancement mode are adopted at the external of the tube wall to cause the axial rigidity of the tube to be too strong and enable the axial flexibility performance at the bell and spigot to be lowered, thereby influencing the geological subsidence resistance performance of a pipeline network system; the connecting part of the bell and spigots is easy to strain to break, thereby enabling maintenance of a water, gas and liquid supply system tobe difficult; fuel gas leaks to cause environmental pollution and the like. The invention is suitable for various water conveyance projects and connecting tubes of the water conveyance projects and is particularly suitable for enhancing bell and spigots of PE plastic tubes, PVC-U (Unplasticizied Polyvinyl Chloride) plastic tubes, PVC-M (High Impact Polyvinyl Chloride) plastic tubes and the like.

Owner:HUNAN ZHENHUI PIPE IND

A socket-reinforced composite plastic pipe and its manufacturing process

ActiveCN101788084BSimple structureSimple manufacturing processRigid pipesPipe waterSynchronous control

A socket-reinforced composite plastic pipe and its manufacturing process. It includes a pipe wall and a socket. A protruding ring is provided at the inner diameter of the L-length pipe wall at the end of the socket, and plastic resin mixed ingredients are used as raw materials. The technical scheme of making products under the synchronous control of drying machine, extruder, die head, mold, vacuum box, spray box, tractor, cutting machine and other equipment; it overcomes the existing polyethylene resin composite pipe-PE pipe, Because the cross-sectional strength and rigidity of the butt joint of the pipe socket cannot bear the pressure inside the pipe, the pipe wall will bulge, deform, and even crack, resulting in water leakage and air leakage in the pipe, resulting in difficulties in maintenance of water supply, gas supply, and liquid supply systems, serious loss of resources and gas consumption. Leakage causes defects such as environmental pollution; it is suitable for connecting pipes in various water transmission projects and gas transmission projects; it is especially suitable for thickening and strengthening sockets of plastic pipes such as PE, PVC-U, and PVC-M.

Owner:HUNAN ZHENHUI PIPE IND

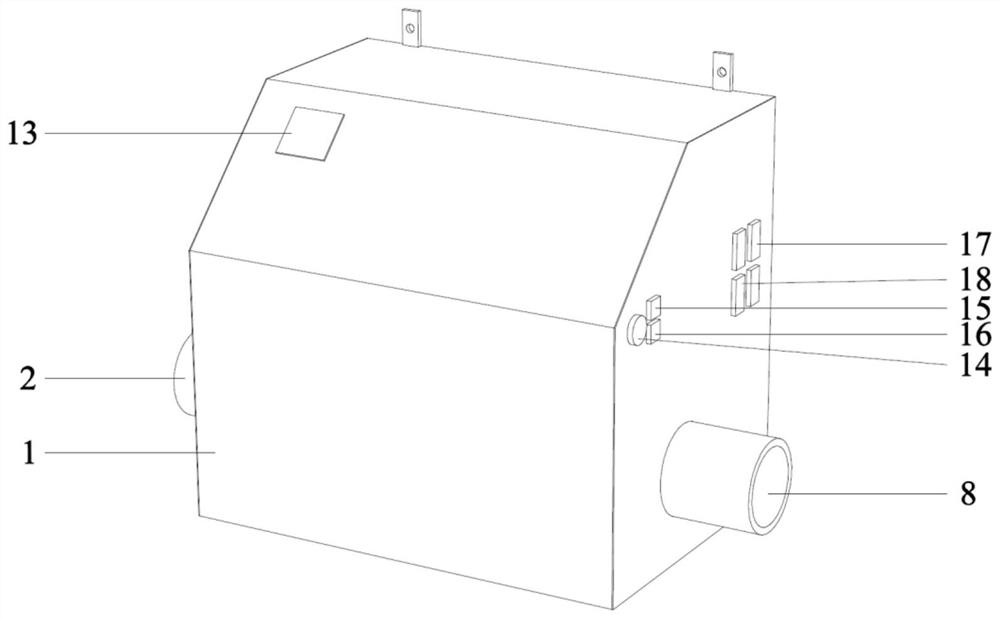

Gas heater

ActiveCN112555059AImprove overall conveying efficiencyEasy to disassembleInternal combustion piston enginesFuel supply apparatusGas heaterEngineering

The invention discloses a gas heater which comprises a gas inlet connector, a heat exchanger, an external water way connecting pipeline, a thermostat control valve, a gas outlet connector, a first gasinlet, a first gas outlet, a third gas inlet and a fourth gas outlet. A valve block is detachably mounted on the heat exchanger, and a mounting cavity is formed in the surface of the heat exchanger;and a connecting groove is formed in one side of the interior of the mounting cavity, a connecting plate is clamped in the connecting groove, a connecting ring is detachably mounted on the surface ofthe connecting plate, and a positioning hole is formed in the surface of the connecting ring. According to the scheme, the gas heater utilizes a hydraulic rod to drive a contraction ring to contract to fix gas inlet pipes of different types, so that it is ensured that the gas inlets are suitable for the gas inlet pipes of various types, and the problem that the gas inlets are fixed, the gas inletpipes are different in type, once the gas inlet pipes with the diameters smaller than the gas inlets are replaced to be used, pipe looseness is caused, and the gas conveying efficiency is reduced aresolved.

Owner:新乡市艾洁净化科技有限公司

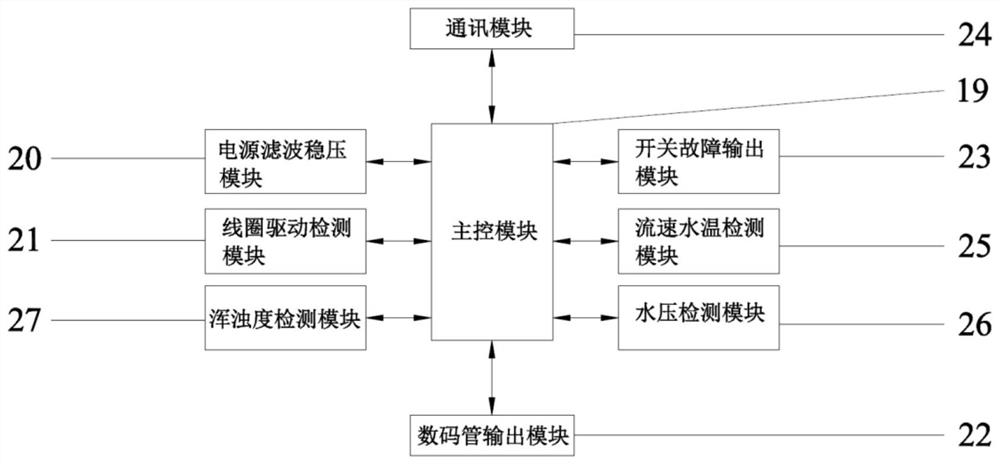

Industrial small scale inhibiting and removing device

PendingCN113277631AImprove cooling efficiencyIncrease profitWater treatment parameter controlScale removal and water softeningLine sensorProcess engineering

The invention discloses an industrial small scale inhibiting and removing device, belonging to the technical field of treatment of industrial circulating cooling water. The industrial small scale inhibiting and removing device comprises a machine case, wherein a water inlet pipe connector is arranged on the left side of the machine case; a flow velocity and water temperature detector is connected to the right side of the water inlet pipe connector; a transversely-arranged transparent pipe is connected to the right side of the flow velocity and water temperature detector; the outer side of the transparent pipe is sleeved with a coil; a water pressure sensor is installed at the bottom end of the transparent pipe; a stop water valve is installed on the right side of the transparent pipe; a water outlet pipe connector connected with the transparent pipe is arranged on the right side of the machine case; LED lamp beads are arranged in front of the right side of the transparent pipe; a light sensor is arranged behind the right side of the transparent pipe; and the machine case is provided with a control circuit board and a fault output relay. According to the invention, the phenomenon of scale deposition of the cooling equipment can be effectively reduced, the heat dissipation efficiency of the equipment is improved, and the device is simple in structure, low in production cost, low in operating environment requirement and suitable for wide industrial application.

Owner:江门市迎客松电气有限公司

Vacuumizing device for steam side of nuclear power station condenser

PendingCN113932626AImprove operational reliabilitySolve unreliable sealing andSteam/vapor condensersCondensed waterCorrosion

The invention belongs to the technical field of nuclear power station condensers, particularly relates to a vacuumizing device for the steam side of a nuclear power station condenser, and solves the welding problem of a vacuumizing pipeline and a titanium composite layer on the surface of a pipe plate by developing the vacuumizing pipeline of a stainless steel-titanium composite structure. The titanium composite layer is selected, the problem of corrosion of the vacuumizing pipeline in seawater is solved, the problem of corrosion of a welding seam between the vacuumizing pipeline and the titanium composite layer of the pipe plate is also solved, welding connection of the vacuumizing pipeline and the pipe plate is achieved, and the problem of sealing between the vacuumizing pipeline and the pipe plate is thoroughly solved. The hidden danger that seawater leaks to the condensed water side through a sealing structure between the vacuumizing pipeline and the pipe plate is eradicated, and the operation reliability of the condenser is improved.

Owner:JIANGSU NUCLEAR POWER CORP

Pipe clamp of lost foam

The invention relates to a pipe clamp of a lost foam. The pipe clamp is provided with a pipe clamp matrix which is constituted by a spigot pipe clamp and a socket pipe clamp, wherein the spigot pipe clamp is provided with a first and a second semicircle spigot pipe clamp units; one end and the other end of the first semicircle spigot pipe clamp unit are both provided with a first spigot bolt connecting hole; the side wall of the first semicircle spigot pipe clamp unit is provided with a first fixed bolt connecting hole; one end and the other end of the second semicircle spigot pipe clamp unit are both provided with a second spigot bolt connecting hole; and the side wall of the second semicircle spigot pipe clamp unit is provided with a second fixed bolt connecting hole. The socket pipe clamp is provided with a first and a second semicircle socket pipe clamp units; one end and the other end of the first semicircle socket pipe clamp unit are both provided with a first socket bolt connecting hole; the side wall of the first semicircle socket pipe clamp unit is provided with a third fixed bolt connecting hole; one end and the other end of the second semicircle socket pipe clamp unit are both provided with a second socket bolt connecting hole; and the side wall of the second semicircle socket pipe clamp unit is provided with a fourth fixed bolt connecting hole.

Owner:SICHUAN CHUANJIAN PIPES

Direct inserting self-sealing type plastic downspout

InactiveCN104712862AEliminate the risk of leaksSimple structureSleeve/socket jointsBranching pipesEngineeringSilicone rubber

The invention discloses a direct inserting self-sealing type plastic downspout. The direct inserting self-sealing type plastic downspout comprises a downspout body (1), a connecting port (2), an O-shaped ring (3) and a ring baffle (4), wherein the O-shaped ring and the ring baffle are sequentially arranged at the connecting port of the downspout body from outside to inside. When the direct inserting self-sealing type plastic downspout is applied, a pipe with an outward inclination angle at an end is directly inserted along the connecting port, the O-shaped ring made of silicone rubber is used for sealing between the downspout body and the pipe, the ring baffle is used for limiting the depth of the pipe inserted into the downspout body, pipe breakage and leakage caused by weathering or wall sedimentation are eliminated through the aging resistance of the O-shaped ring made of the silicone rubber and the free telescopic connecting relationship between the downspout body and the pipe, and the connection and use of the plastic downspout realize the purposes of convenient connection, high efficiency, environment protection, low cost and elimination of leakage risks.

Owner:胡昌永

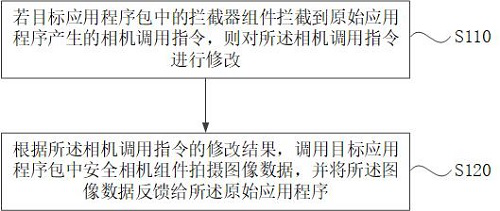

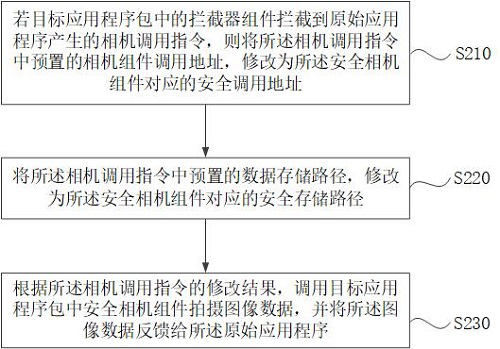

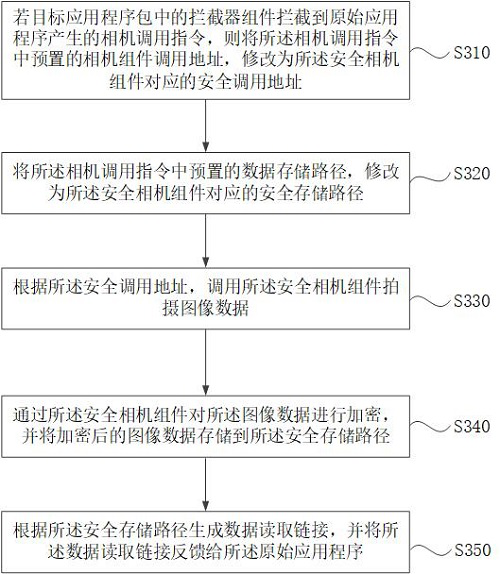

Data security protection method and device, medium and electronic equipment

InactiveCN113836567AImprove securityEliminate the risk of leaksTelevision system detailsDigital data protectionImaging dataReliability engineering

The embodiment of the invention discloses a data security protection method and device, a medium and electronic equipment. The method comprises the following steps: if an interceptor component in a target application program package intercepts a camera calling instruction generated by an original application program, modifying the camera calling instruction; wherein the original application program and the interceptor component are initialized through a guider component in a target application program package; and calling a security camera component in a target application package to shoot image data according to a modification result of the camera calling instruction, and feeding back the image data to the original application. By executing the technical scheme provided by the invention, the hidden danger of leakage of confidential information of an enterprise can be eliminated, the data security is improved, and meanwhile, the development cost is reduced.

Owner:北京指掌易科技有限公司

Conveying pipeline sealing structure

PendingCN113007477AAvoid wear problems caused by extrusion deformation and archingReduce contact surfaceEngine sealsHose connectionsButt jointSealant

The invention discloses a conveying pipeline sealing structure. The conveying pipeline sealing structure comprises a sealing flange and a butt joint flange which are arranged at the two ends of a pipe body, wherein the butt joint flange has a smooth outer side end face; an outer side end face of the sealing flange is provided with an annular sealing groove used for accommodating a linear sealing ring; the annular sealing groove is provided with a groove formed by the fact that the width size of an opening end is smaller than the width size of the inner bottom; a linear sealing ring is arranged in the annular sealing groove and can be limited in the annular sealing groove through the groove; and the sealing flanges and the butt joint flanges of the adjacent pipe bodies can be fixedly connected through fasteners after being in butt joint. The conveying pipeline sealing structure has the advantages that the sealing is easier and more durable under the same force, the collision is not easy to occur in the mounting process, the sealant is prevented from being damaged by collision, the hidden danger of leakage is eliminated, the problem of local wear is completely solved, the service life is prolonged, the problems of deformation generated in the use process and long-term extrusion and bonding of the flanges are also solved, the hidden danger of leakage is further eliminated, and the maintenance is convenient.

Owner:江苏西沙科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com