Press fitting stuck-type bottle cap, preparation method thereof and containing comprising press fitting stuck-type bottle cap

A technology of press-fitting card-type and bottle caps, which is applied in the field of liquor bottle caps, which can solve the problems of unsightly secondary appearance, hidden dangers of liquid leakage, sealing caps falling on the floor, etc., to achieve beautiful appearance and high-grade, and improve strength and stiffness, reducing the effect of torsional deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below with reference to accompanying drawing and embodiment:

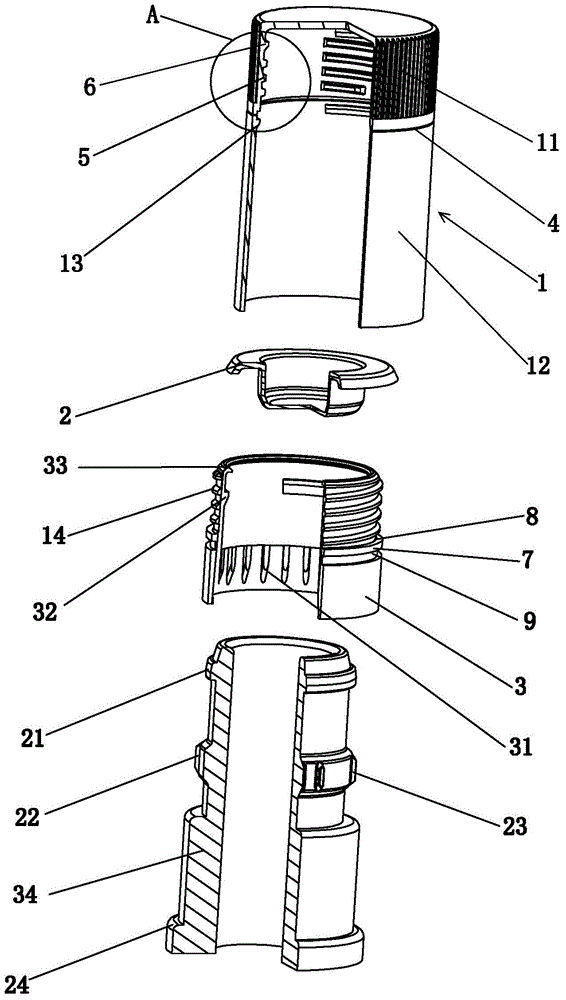

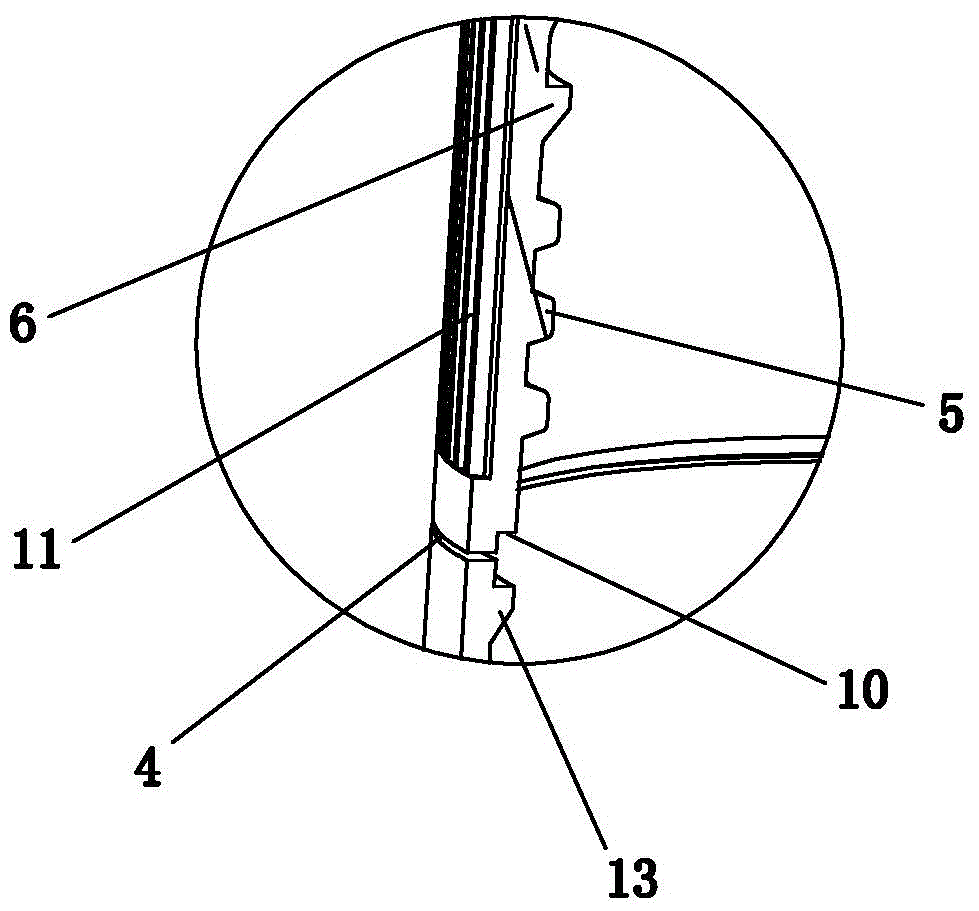

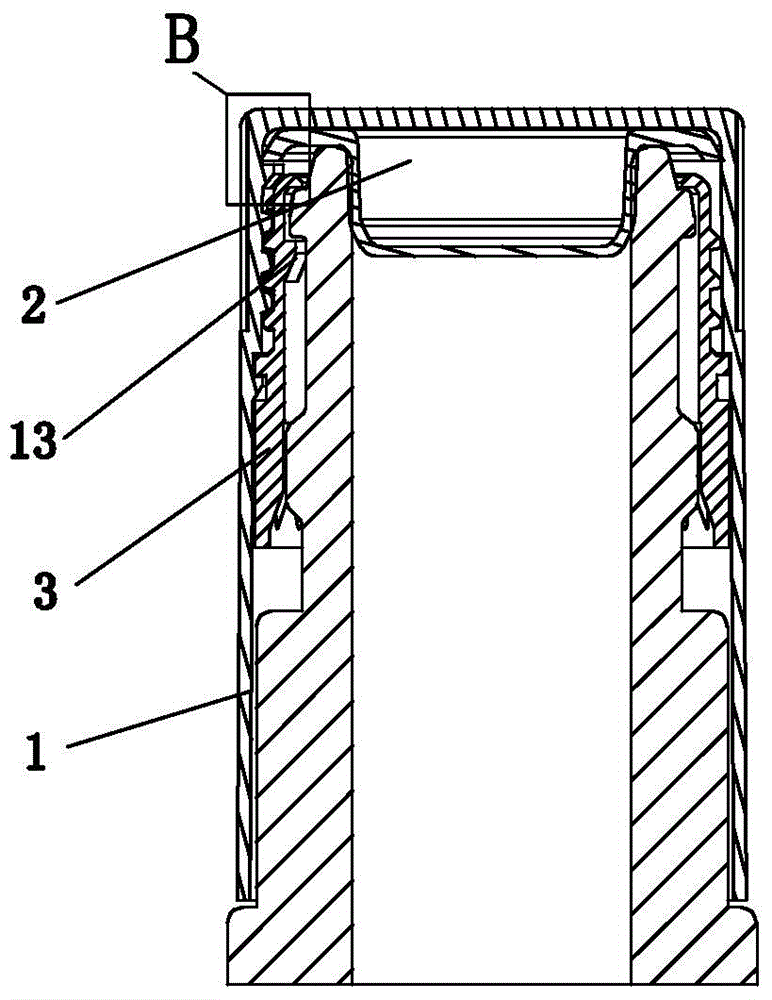

[0038] attached figure 1 - attached Figure 7 It can be seen that a press-fit card type bottle cap includes an outer sleeve 1, a sealing cap 2 and an inner sleeve 3, the outer sleeve 1 is composed of an upper sleeve 11 and a lower sleeve 12, and the upper sleeve 11 and the lower sleeve 12 are connected by the brittle part 4, the lower part of the inner peripheral surface of the inner sleeve 3 is provided with anti-rotation ribs 31, and the upper part of the anti-rotation ribs 31 is provided with inner sleeve limit protrusions 32;

[0039] The sealing cover 2 is arranged above the inside of the outer sleeve 1, and the inner peripheral surface of the outer sleeve 1 is provided with a sealing cover limit protrusion 6; between the sealing cover limit protrusion 6 and the brittle part 4, an inner thread 5 of the outer sleeve is arranged; The inner sleeve 3 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com