Pipe clamp of lost foam

A kind of lost foam and mouth pipe technology, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problem of large-diameter cast iron pipes with heavy weight, increasing the excavation area of pipe joints, and inability to solve pipe joints. There are problems such as buttresses, so as to reduce construction time, improve compactness, reduce construction excavation area and cushion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

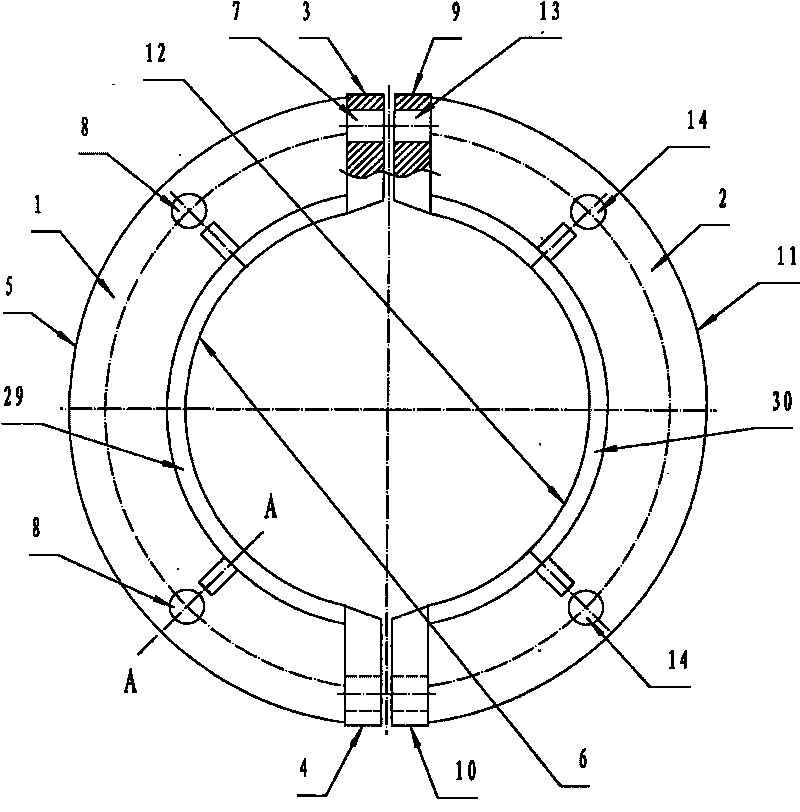

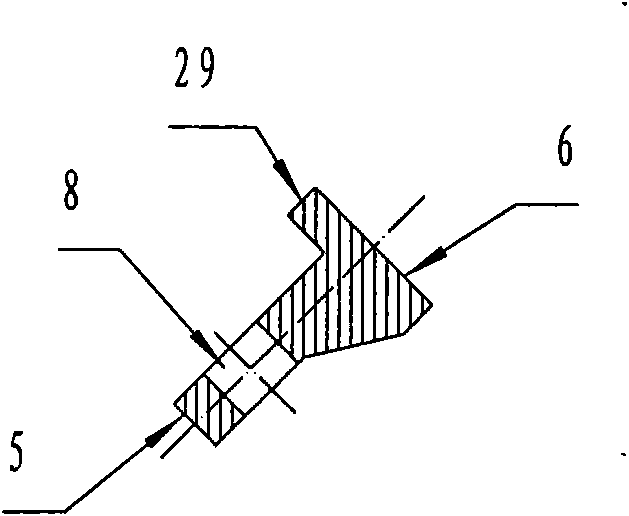

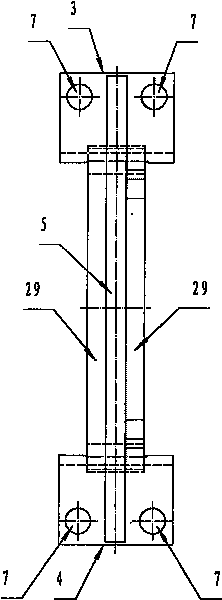

[0033] Such as Figure 1 to Figure 8 As shown, the lost foam pipe ferrule in this embodiment has a pipe ferrule base, which is characterized in that the pipe ferrule base is composed of a socket ferrule and a socket ferrule, and the socket ferrule has a first semicircular socket ferrule unit 1 and the second semicircular socket pipe clamp unit 2, the first semicircular socket pipe clamp unit 1 has one end 3 of the first semicircular socket pipe clamp unit, the other end 4 of the first semicircular socket pipe clamp unit, and the first semicircular socket pipe clamp unit The outer surface 5 and the inner surface 6 of the first semicircular socket clamp unit, one end 3 of the first semicircular socket clamp unit and the other end 4 of the first semicircular socket clamp unit both have a first socket bolt connection hole 7, and the first The side wall of the semicircular socket pipe clamp unit 1 has a through first fixing bolt connection hole 8, and the second semicircular socket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com