Conveying pipeline sealing structure

A technology of sealing structure and conveying pipeline, which is used in pipeline protection, engine sealing, pipeline damage/wear prevention, etc. Squeeze and bond flanges, prolong service life and prevent local wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

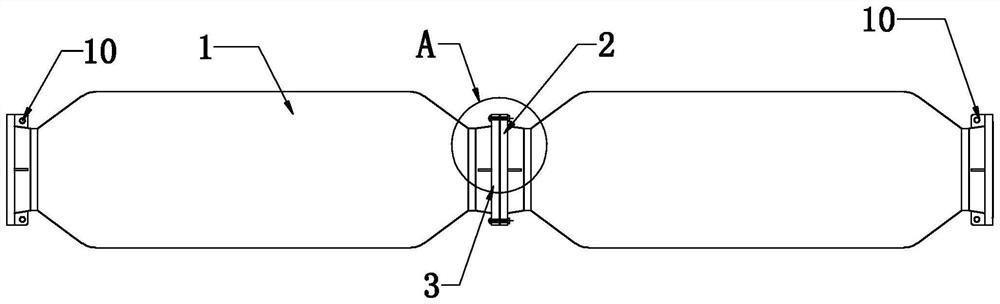

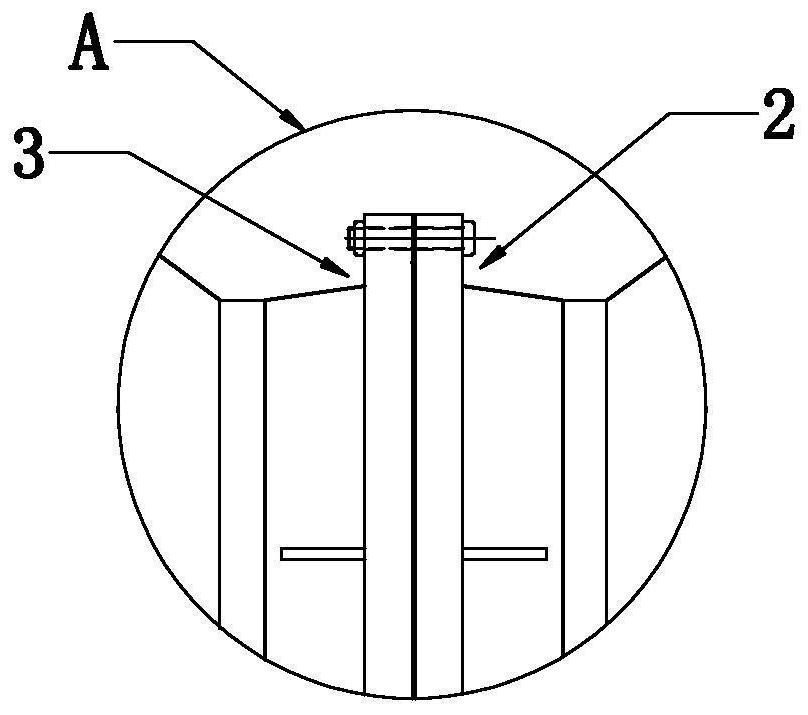

[0026] The conveying pipe sealing structure of the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

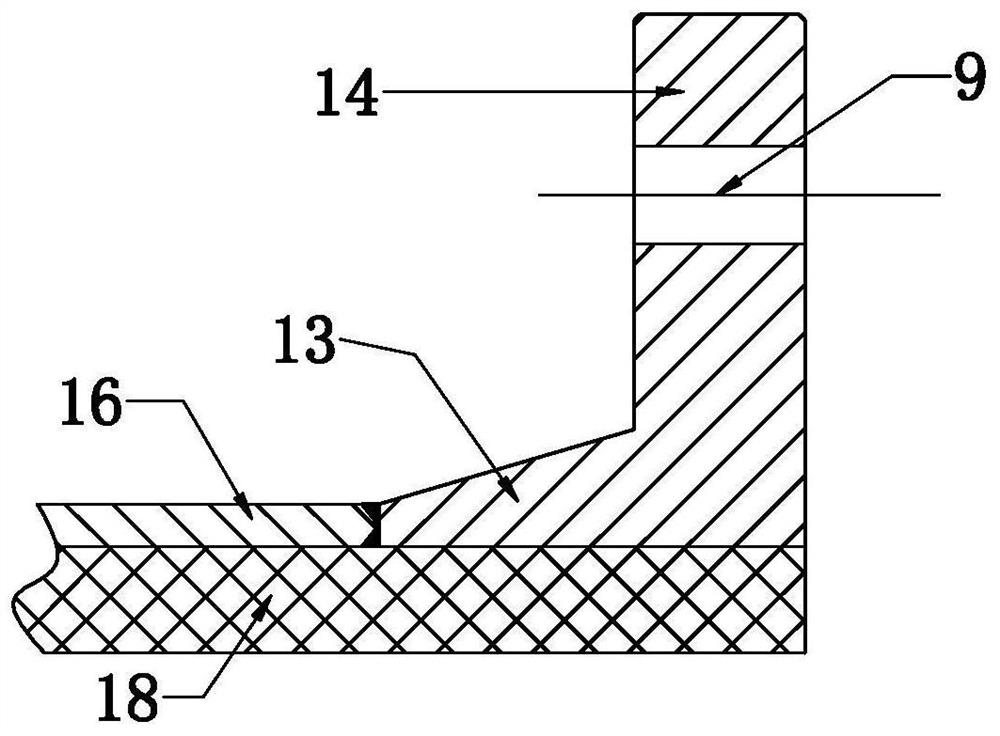

[0027] As shown, the delivery pipe sealing structure of the present invention is mainly used to self-floating tubes, of course, the products of other hoses, similar interfaces can be used to use this technical solution, which includes tubes 1. The sealing flange 2 and the docking flange 3 are provided on both ends, and the lifting tuning 10 is added to the sealing flange 2 and the docking flange 3 after the need for the self-floating tube, and the flange 3 has a smooth outer side. End face, of course, the outer end surface of the sealing flange 2 is also a smooth surface, and the flatness must be less than 2mm, the sealing flange 2 and the docking flange need to take a chamfer 1-1-2 to reduce sharpness, to avoid hidden dangers,

[0028] The outer end surface of the sealing flange 2 is opened with an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com