Direct inserting self-sealing type plastic downspout

A technology of pipe fittings and plastics, which is applied in the field of in-line self-sealing plastic downspout fittings, which can solve problems such as troublesome connections, environmental protection, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

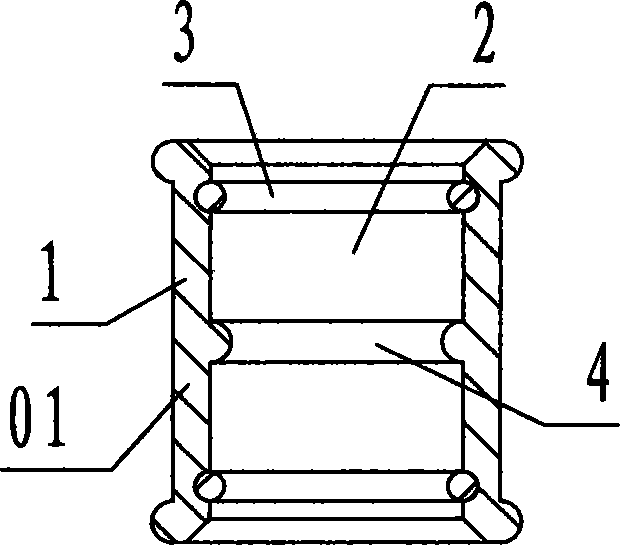

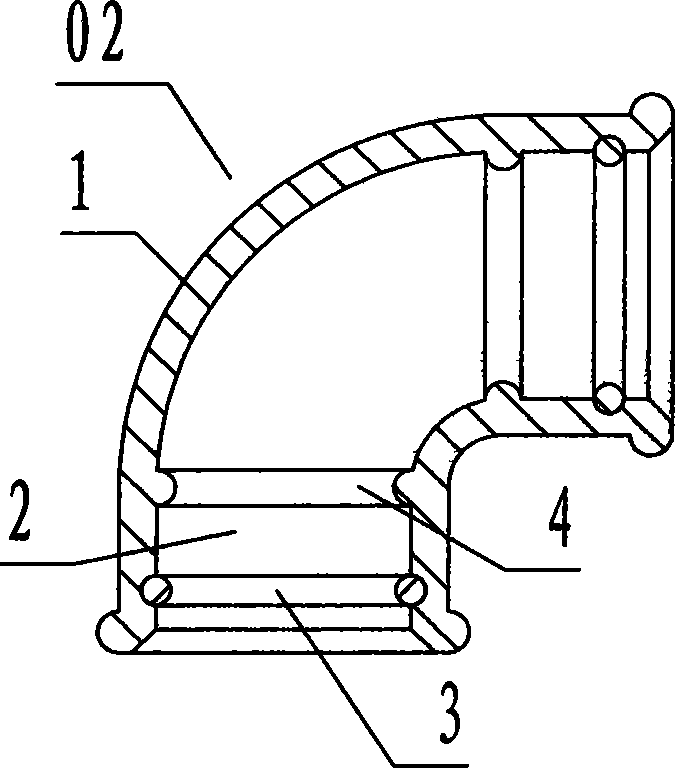

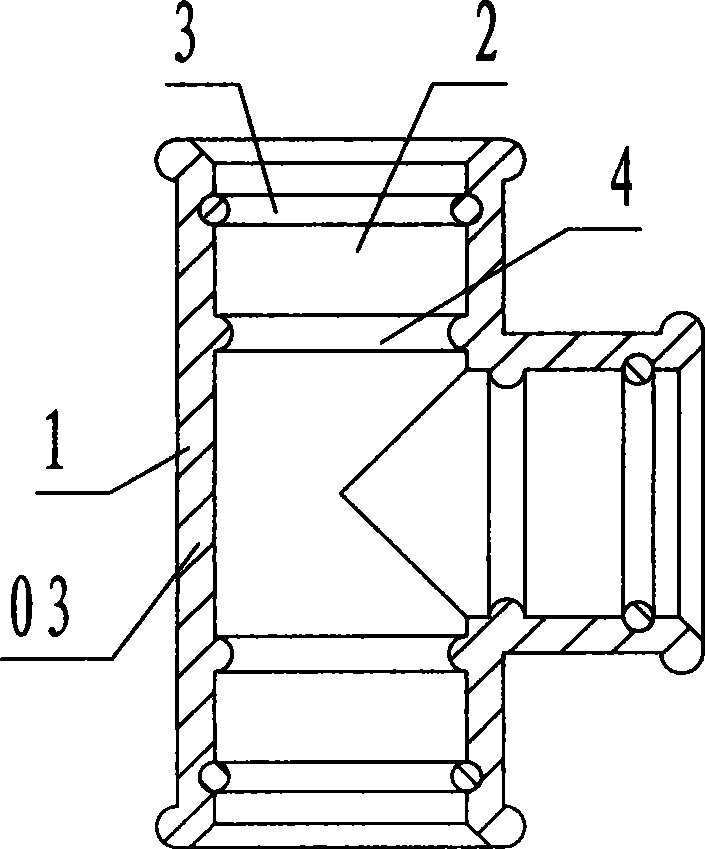

[0021] refer to Figure 1 to Figure 8 , an in-line self-sealing plastic downspout fitting of the present invention, comprising a pipe fitting body 1, an interface 2, an O-ring 3, and a ring retainer 4, wherein: the pipe fitting body 1 is a hollow thin-walled pipe-shaped plastic member; the pipe fitting The channel connecting the inner cavity of the body 1 with the outside world is called the interface 2; the interface 2 is in the shape of a cylindrical tube, and the interface 2 is respectively provided with an O-ring 3 and a ring stopper 4 from the outside to the inside; wherein, the O-ring 3 is a circular silicone rubber member with a circular cross section. The O-ring 3 is used as an insert. When the pipe body 1 is injection molded, it is compositely fixed and embedded in the inner wall of the interface 2 along the circumference of the interface 2. At the inner wall, the diameter of the inner ring of the O-ring 3 is smaller than the diameter of the inner wall of the interfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com