A helium leak detection method for stainless steel cladding of pools in the control area of nuclear power units

A nuclear power unit, stainless steel technology, applied in the testing of machine/structural components, testing of fluid tightness, and detecting the appearance of fluid at the leakage point, etc., can solve the problem that the stainless steel cladding cannot bear reverse pressure, the stainless steel cladding and the concrete base The pool space cannot be evacuated, etc., to eliminate hidden dangers of leakage and prevent radioactive leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

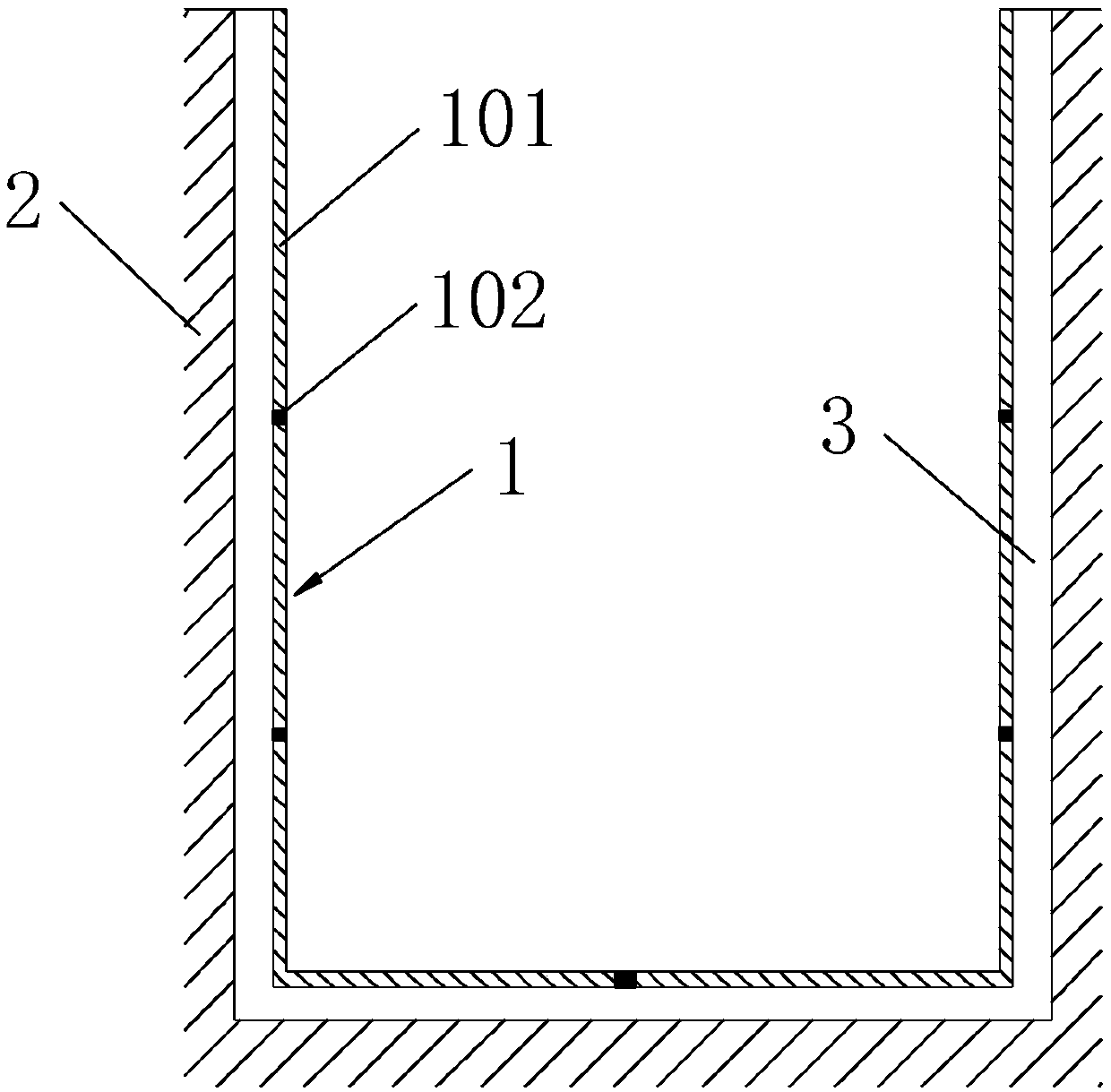

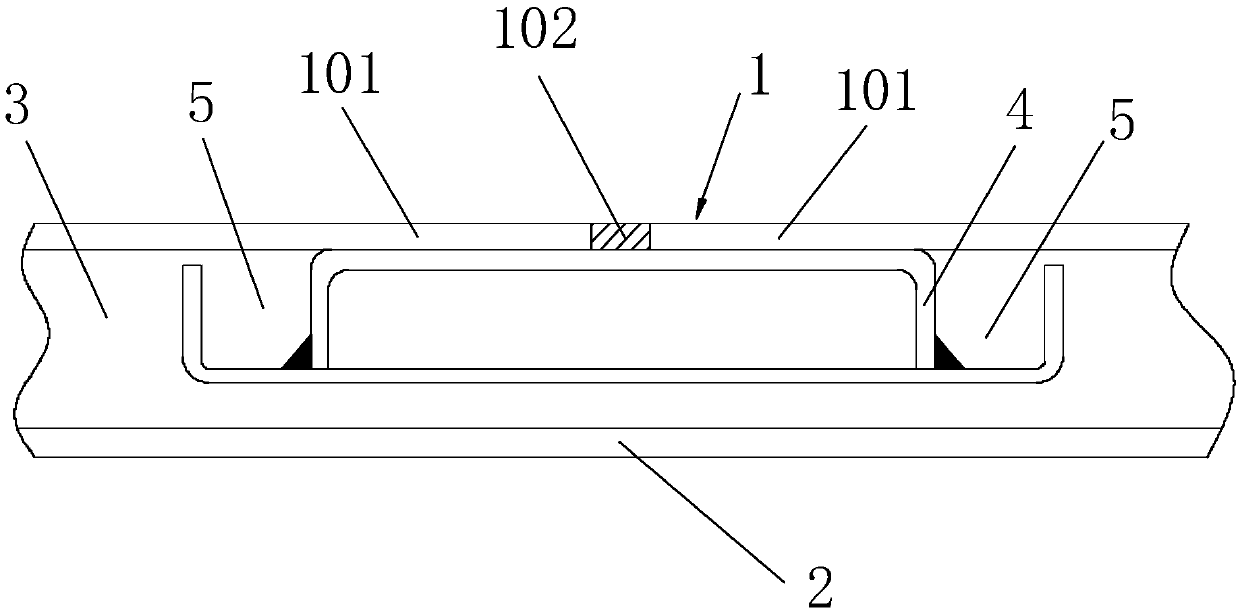

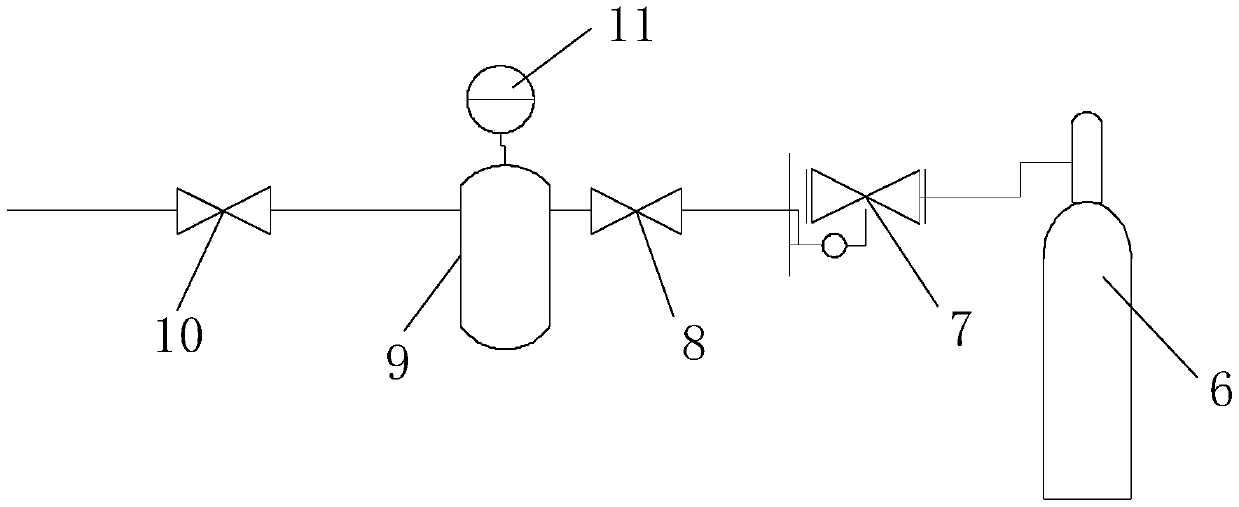

[0030] like figure 1 and figure 2As shown, a pool used in the control area of nuclear power units, the pool includes a concrete base pool 2 and a stainless steel plate group laid on the inner surface of the concrete base pool 2, the stainless steel plate set includes a plurality of stainless steel plates 101, each Adjacent stainless steel plates 101 are connected by welding, and the stainless steel plates 101 and the weld zone 102 together form the stainless steel cladding 1 located on the inner surface of the concrete base pool 2, and an approximately airtight accommodation space is formed between the stainless steel cladding 1 and the concrete base pool 2 3. The bottom of the concrete base pool 2 is provided with an outlet connected to the accommodation space 3, a channel steel 4 for supporting and fixing is provided under the weld area 102, and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com