Static pressure gas labyrinth throttling control mechanism for dynamic and static pressure dry gas seal

A dry gas sealing, dynamic and static pressure technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of complex and changeable working conditions, and achieve the elimination of the increase of the seal end face clearance, the enhancement of the throttling effect, and the throttling. The effect of weakening the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

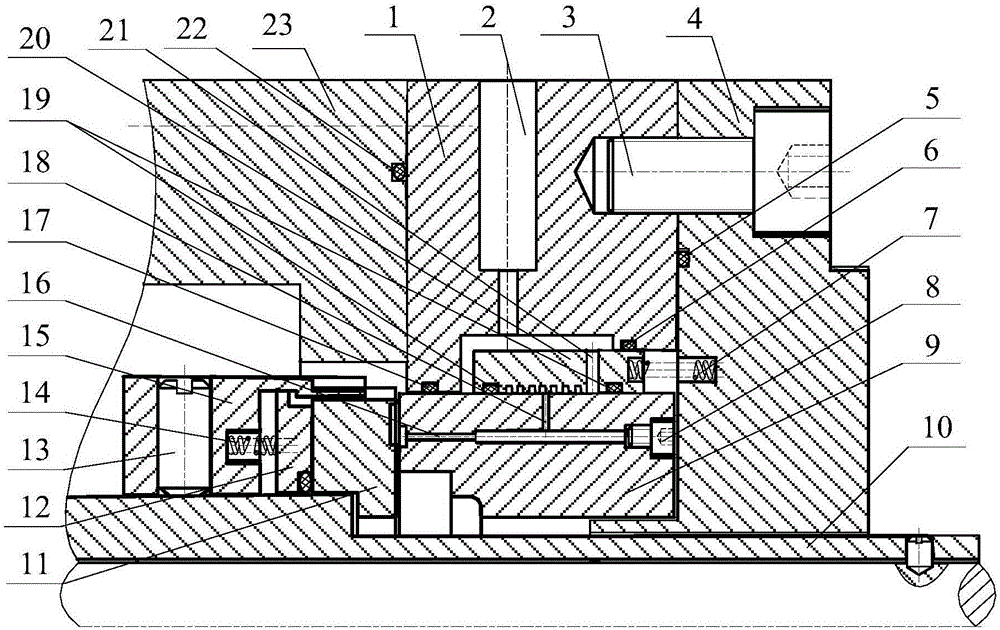

[0018] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

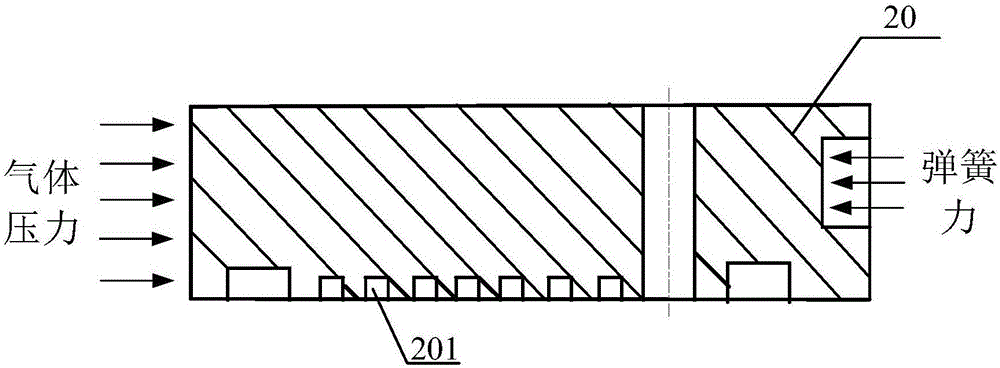

[0019] refer to figure 1 with figure 2 :

[0020] A static pressure gas labyrinth throttling control mechanism for dynamic and static pressure dry gas seals, the right side of the inner gland 1 is close to the outer gland 4, the left side of the inner gland 1 is close to the shell 23, and the moving ring 11 It is arranged between the housing 23 and the shaft sleeve 10, and the static ring 9 is arranged between the inner gland 1 and the outer gland 4, and its features are:

[0021] A push ring 12 and a dry gas seal thrust spring 14 are provided on the side of the moving ring 11 away from the sealing end face. The push ring 12 is set in the chute of the moving ring seat 15, and the moving ring seat 15 is installed on the shaft sleeve through the tightening screw 13. 10 on;

[0022] The outer peripheral surface of the static ring 9 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com