Patents

Literature

48results about How to "Reduce throttling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

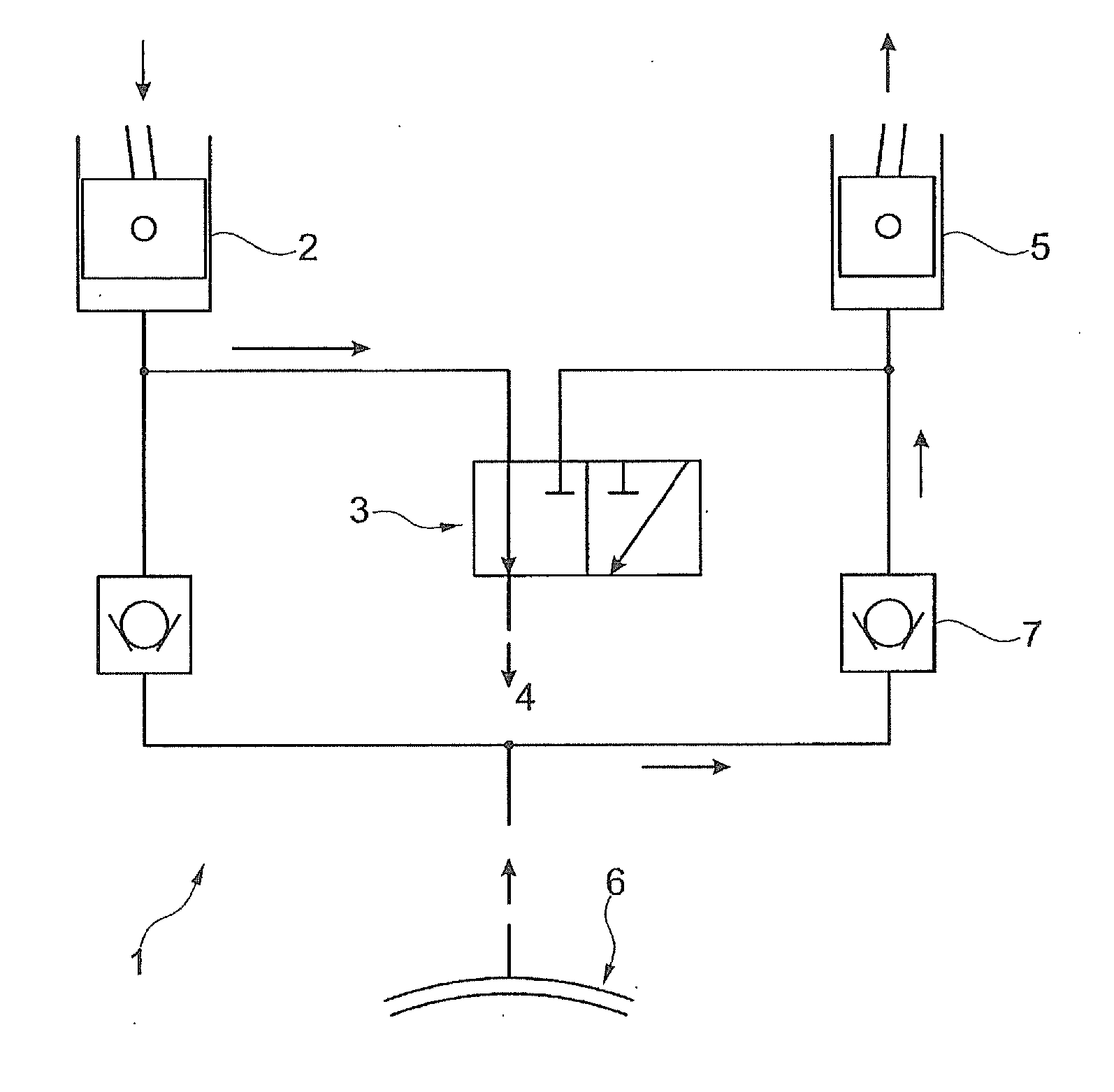

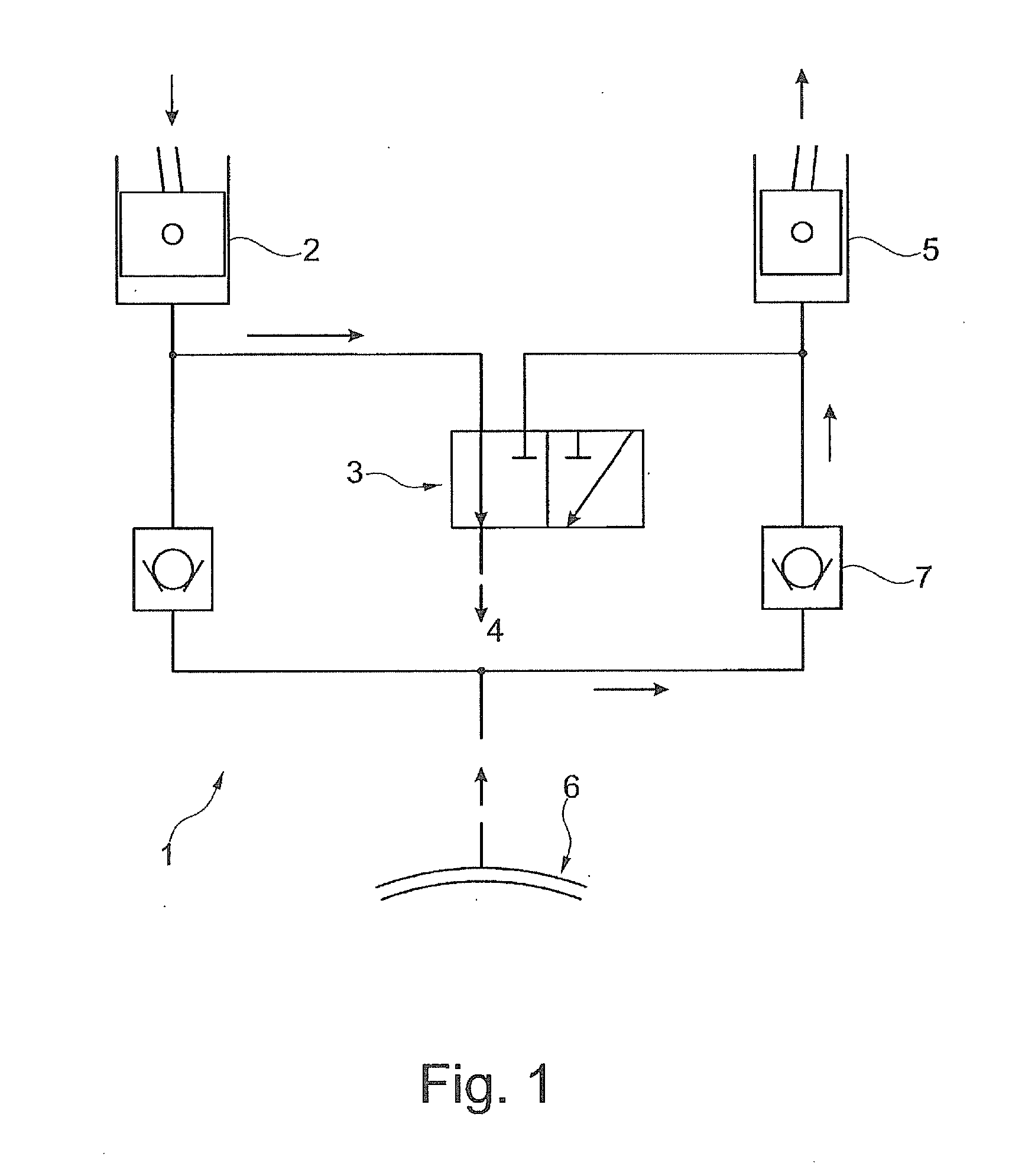

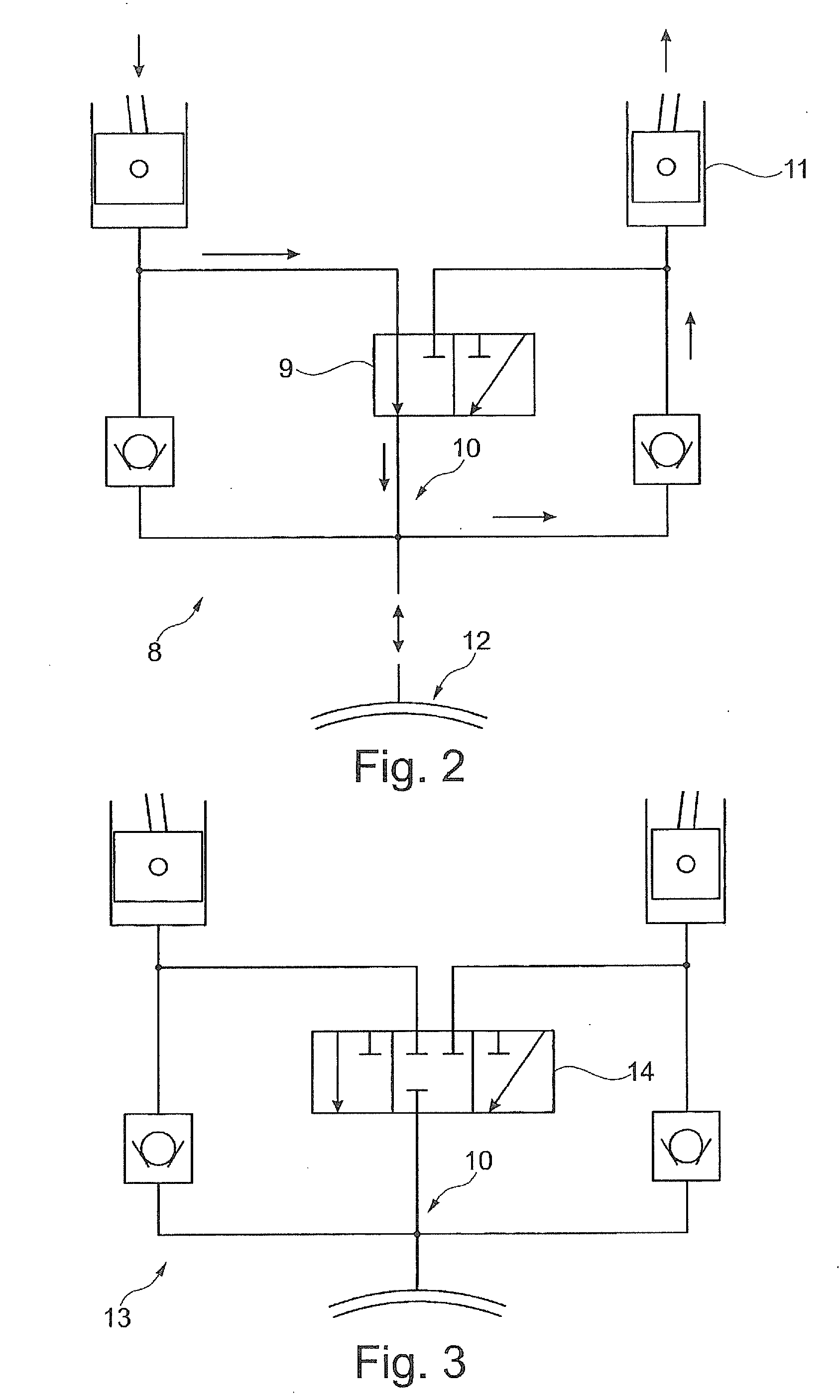

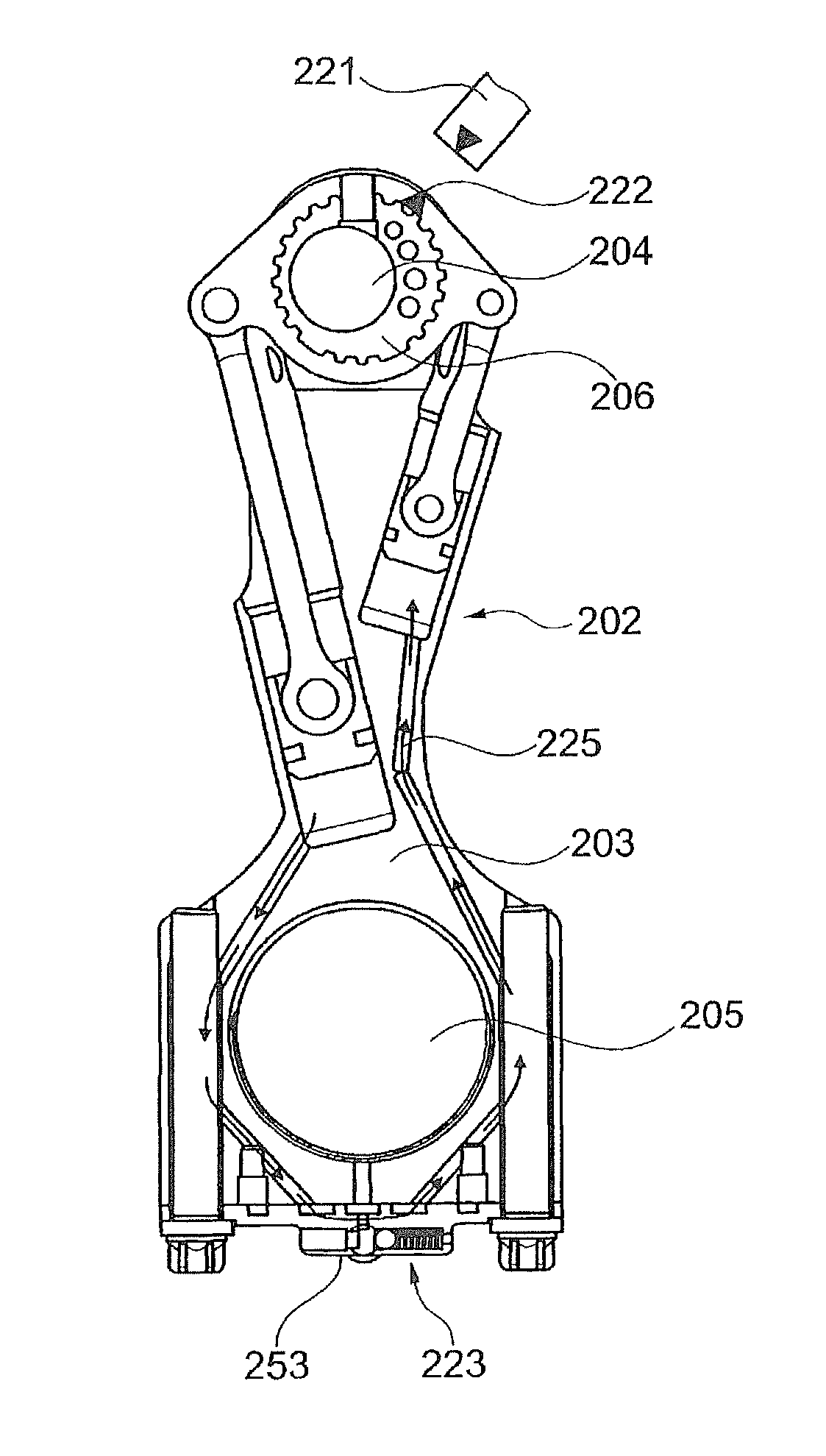

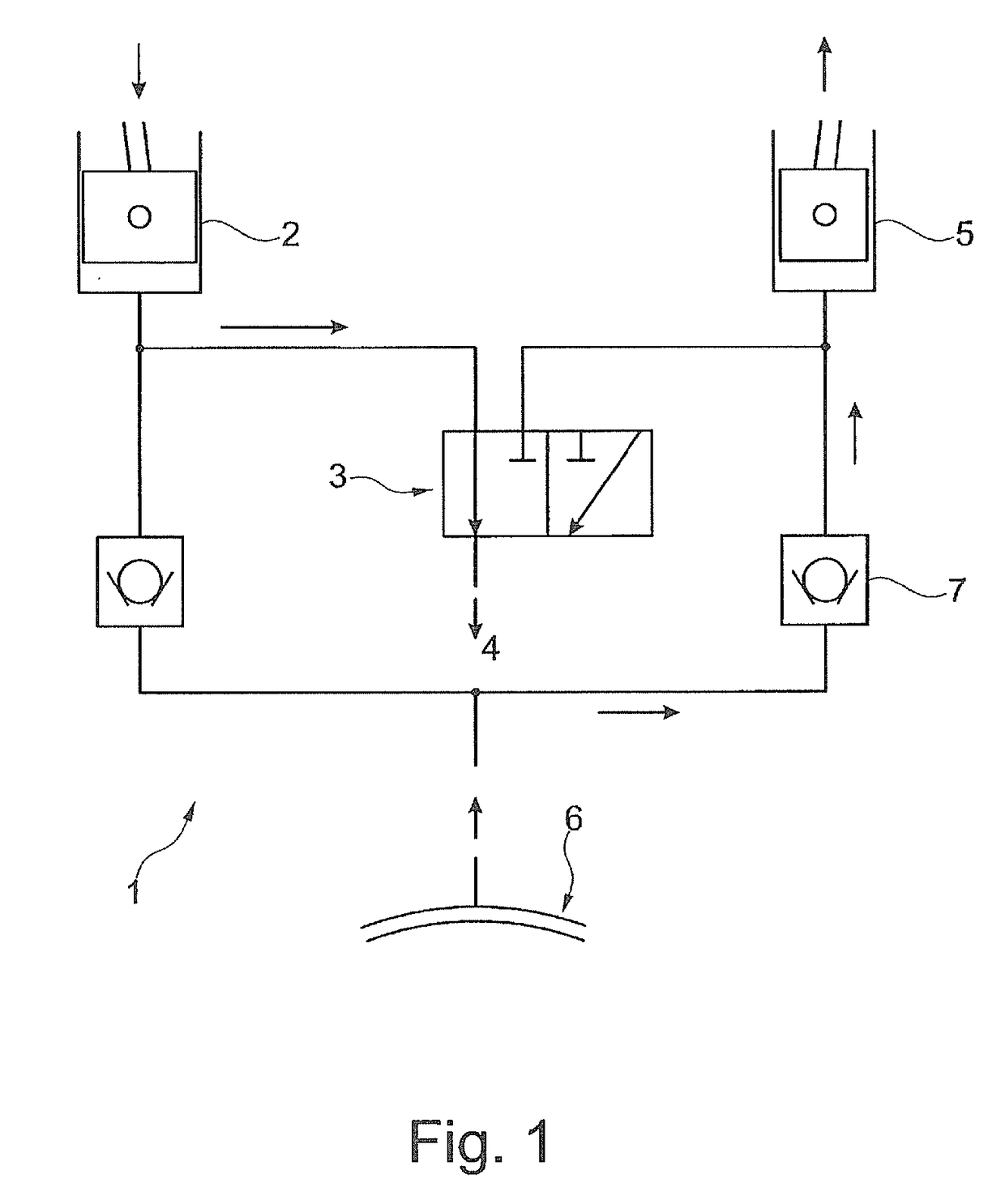

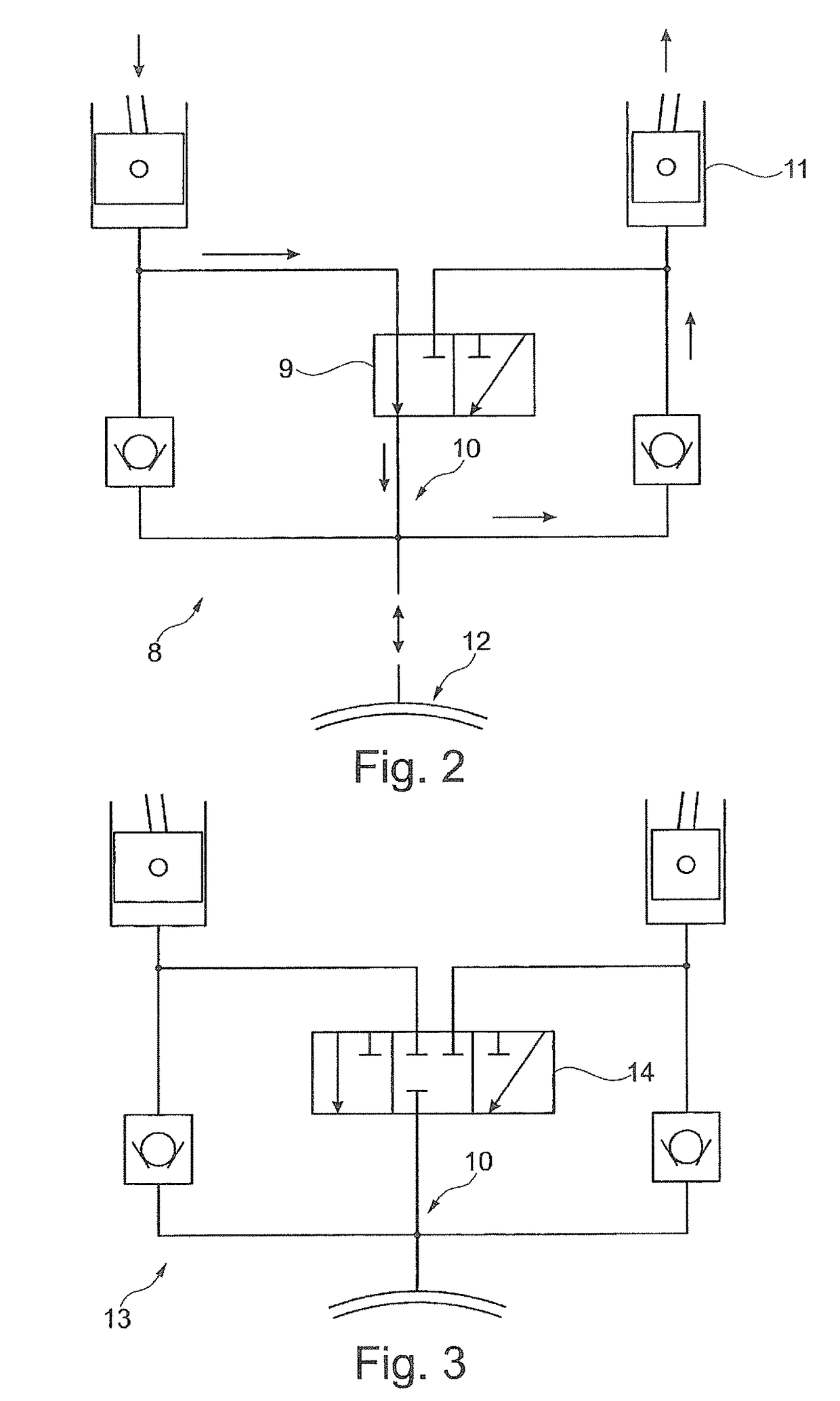

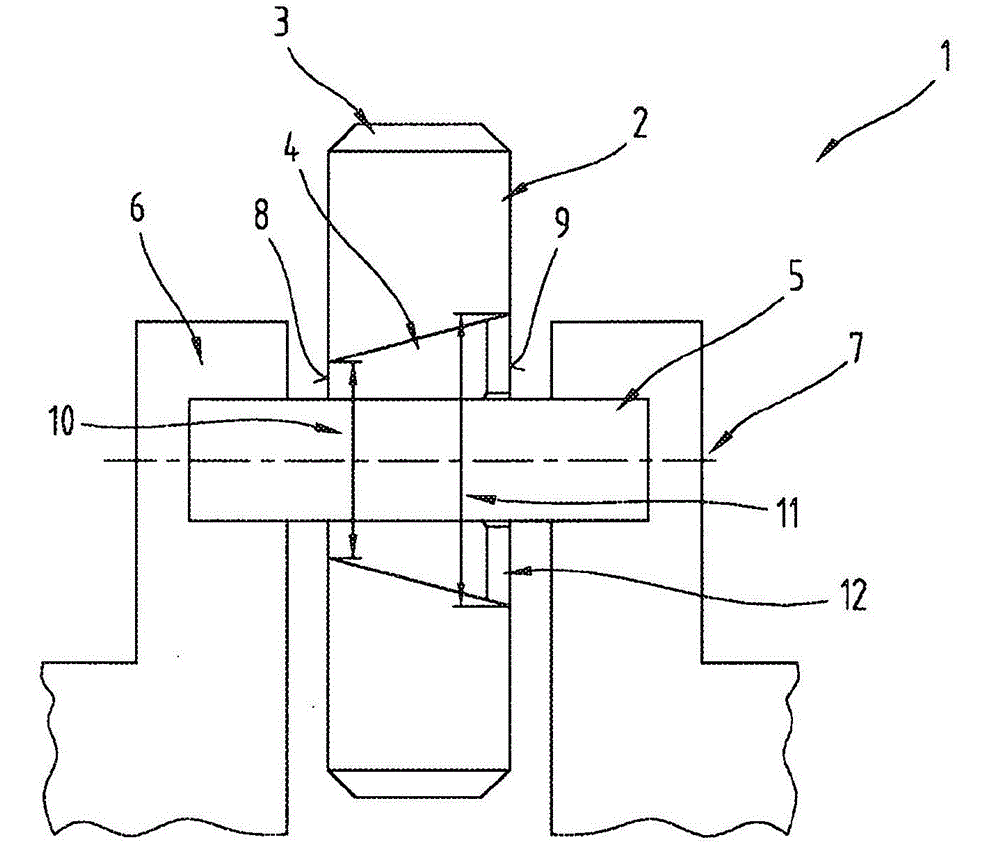

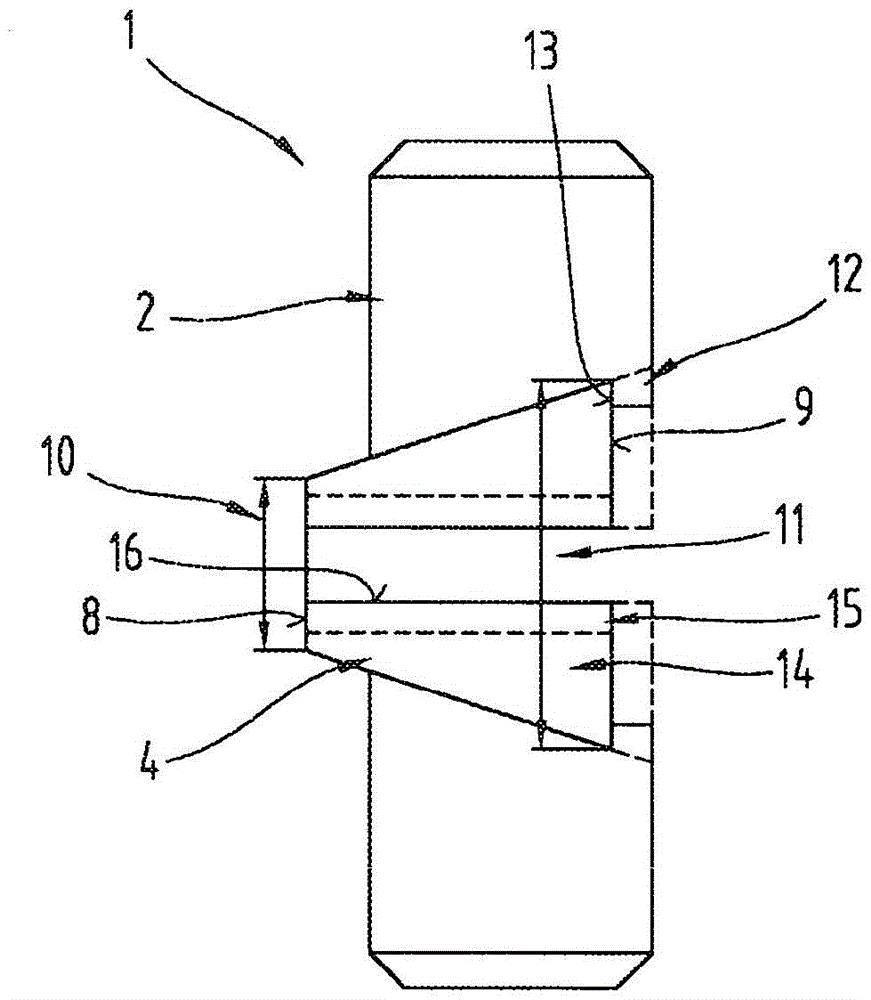

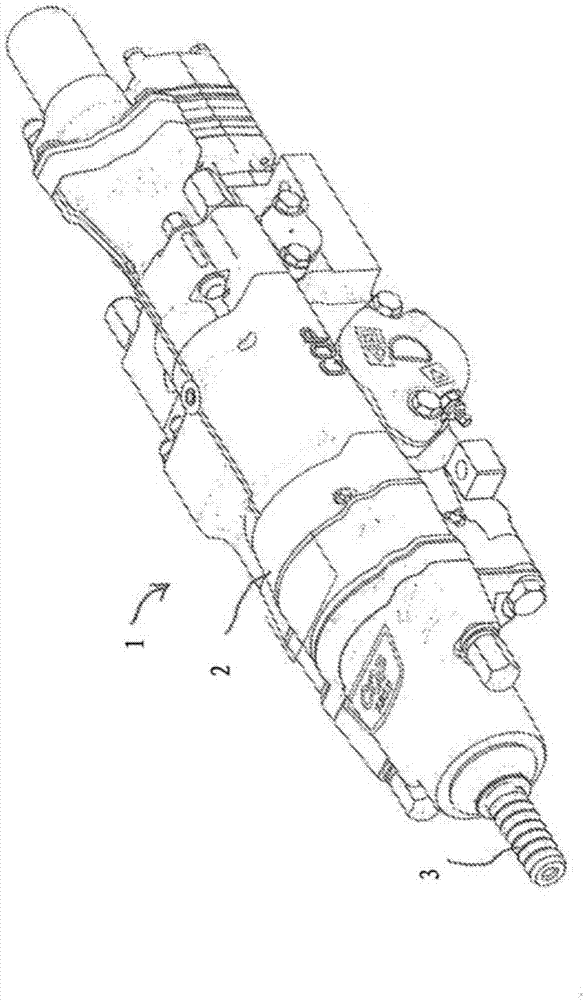

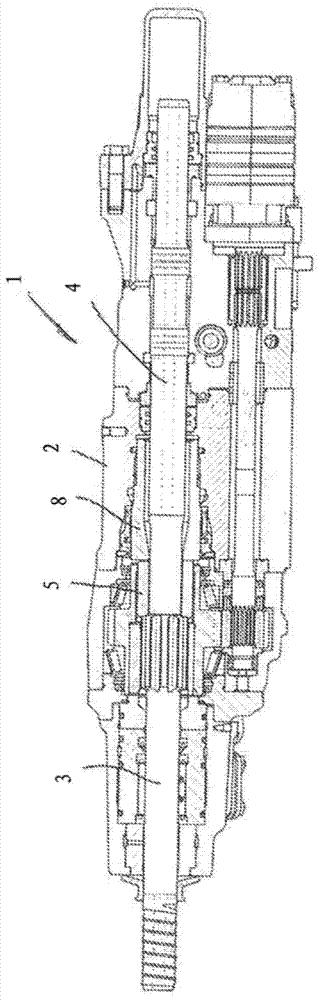

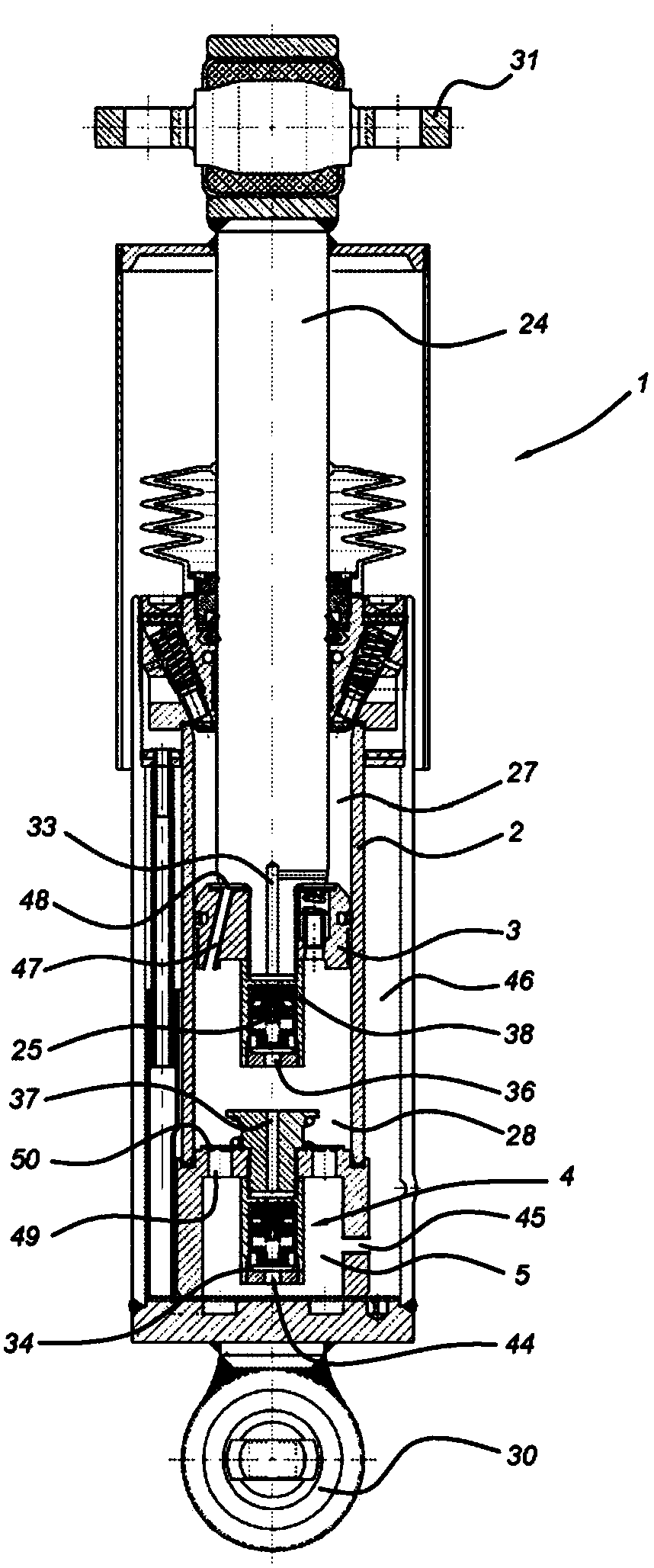

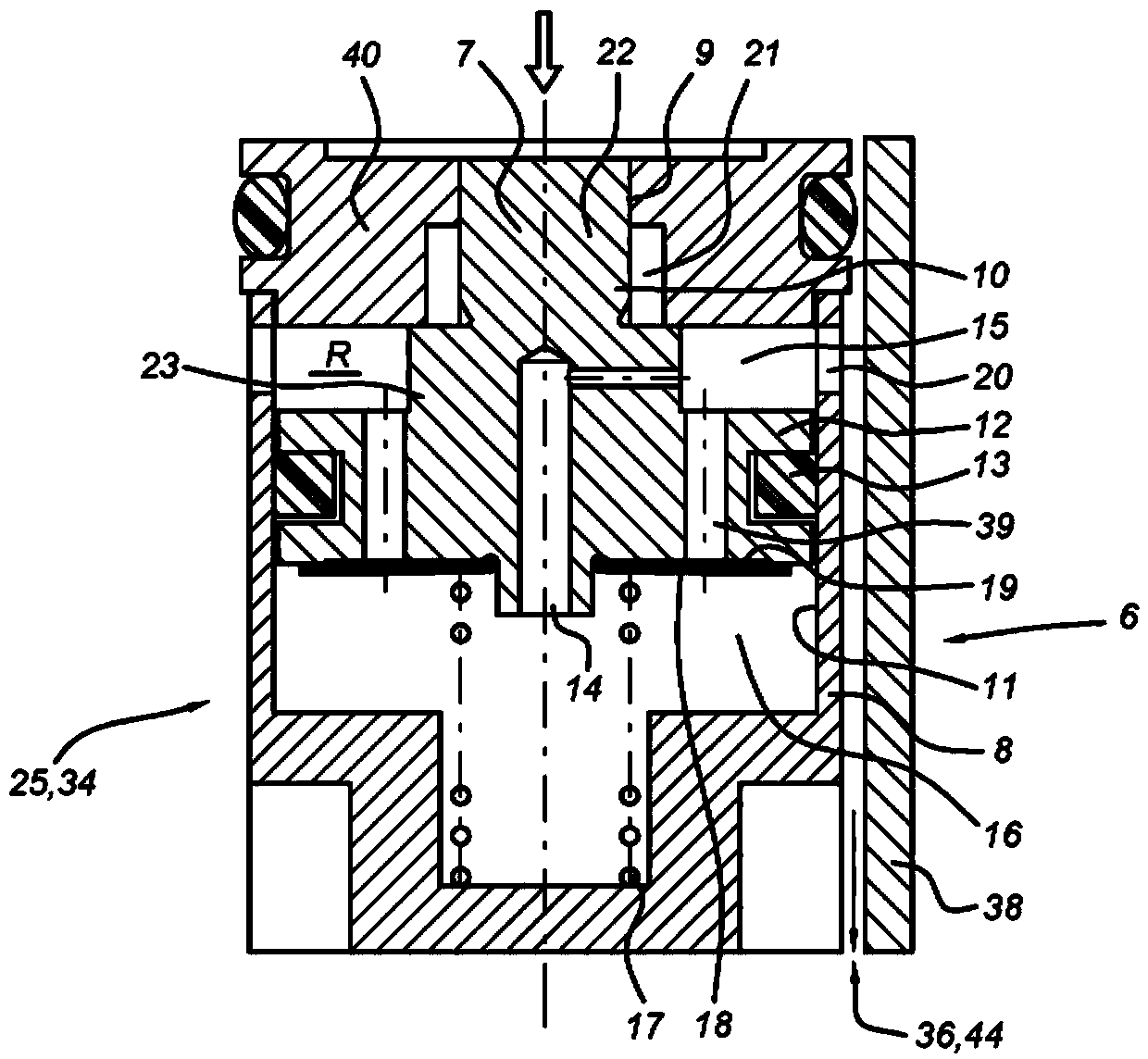

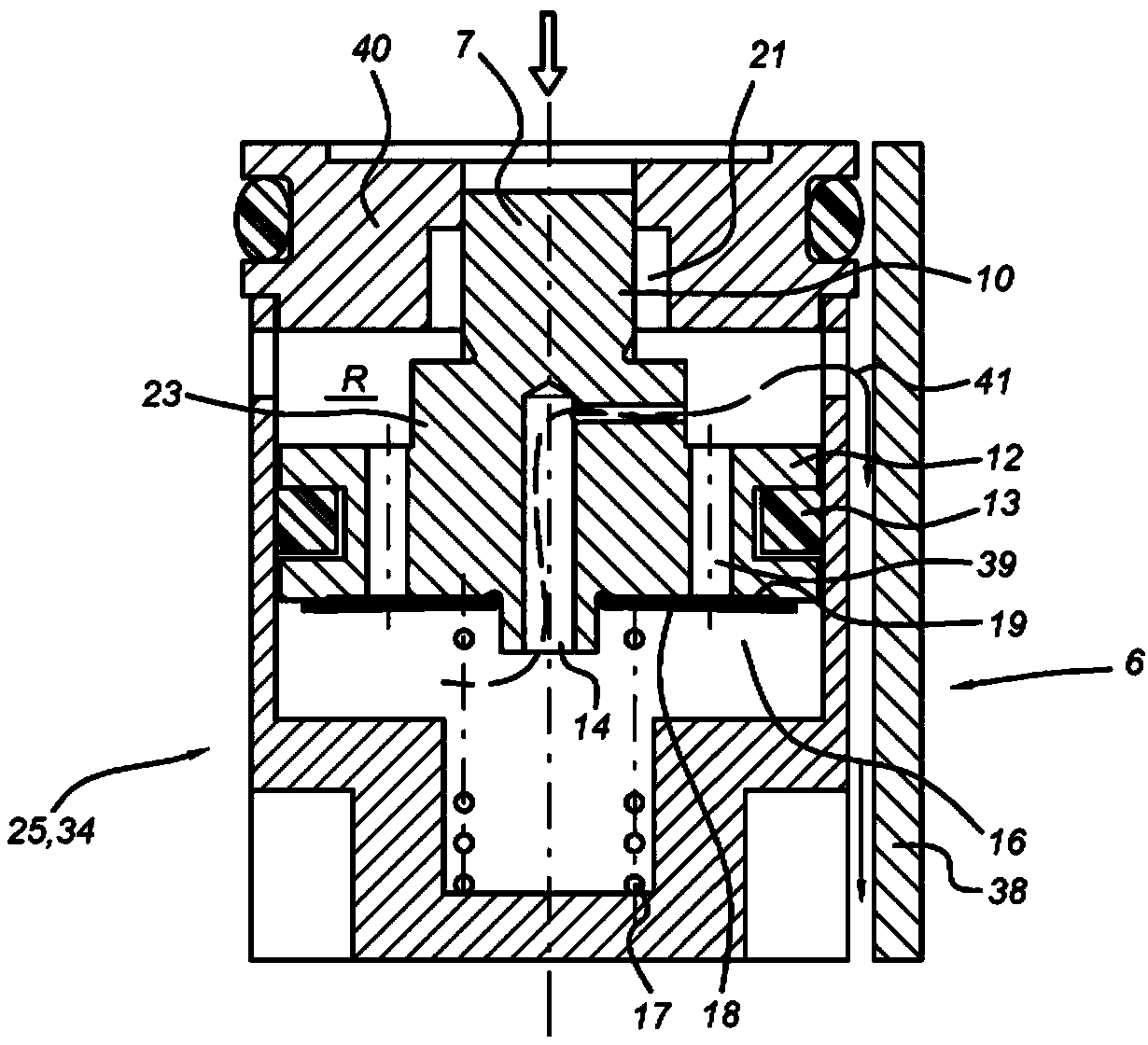

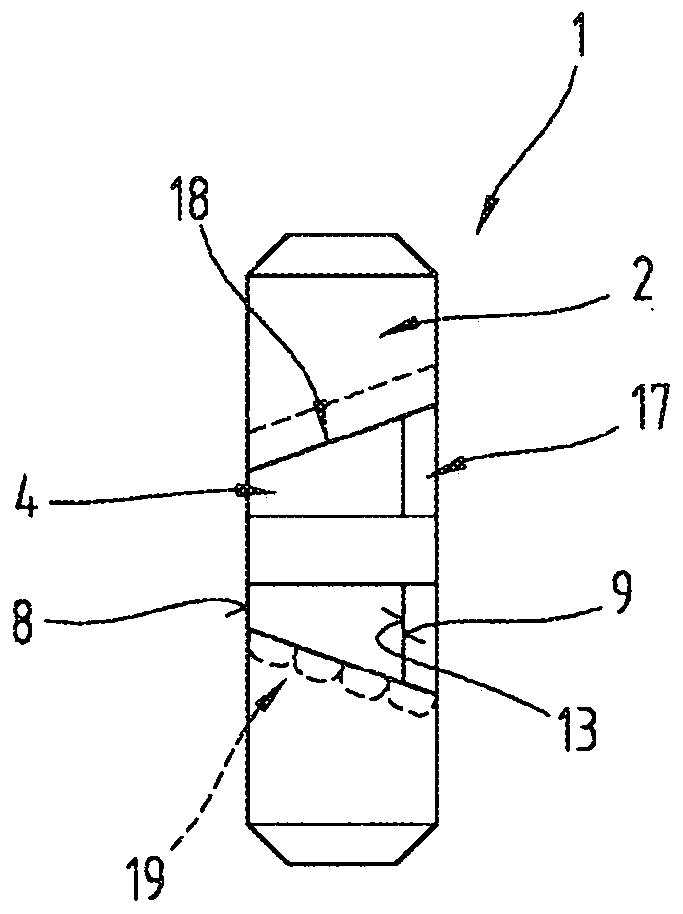

Hydraulic freewheel for an internal combustion engine with variable compression ratio

ActiveUS20150260094A1Little temperature dependenceReduce throttlingRotary bearingsConnecting rodsFlywheelEffective length

A reciprocating-piston internal combustion engine having a hydraulic adjustment mechanism which is assigned to a connecting rod and which comprises at least one eccentric, for adjusting at least one variable compression ratio in at least one cylinder of the reciprocating-piston internal combustion engine by means of a change in an effective length of a connecting rod. Also proposed is a method for changing the effective length of a connecting rod.

Owner:FEV

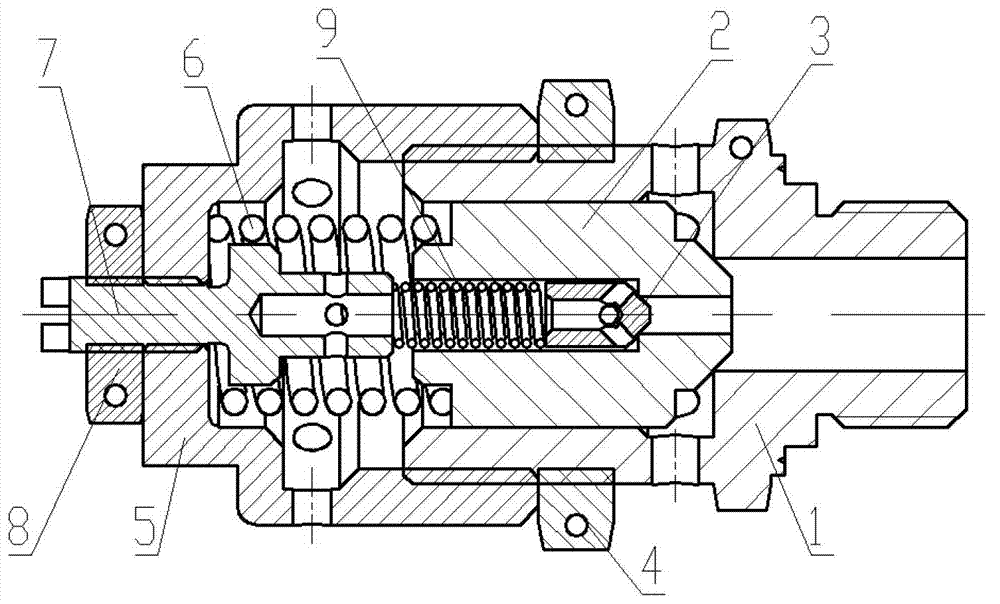

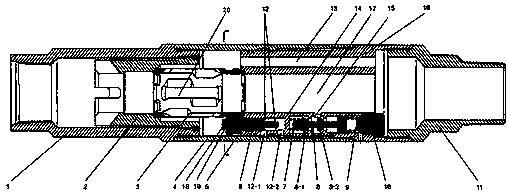

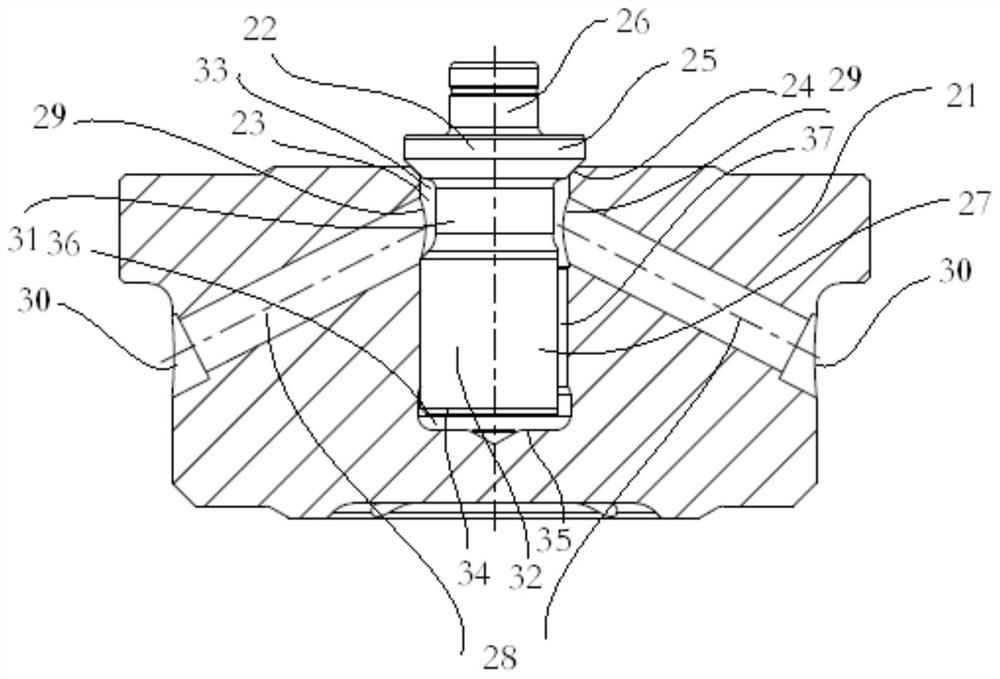

Dual-opening-pressure dual-displacement safety valve

ActiveCN103032612AReliable functionEasy to use and maintainEqualizing valvesSafety valvesPressure systemAtmospheric pressure

The invention discloses a structural design and a realization way of a dual-opening-pressure and dual-displacement safety valve. The safety valve is provided with two different pressure regulation mechanisms capable of providing opening pressures of two different types and corresponding displacements, wherein a primary pressure-displacement regulating mechanism is composed of a valve body, a valve core, a main spring, a spring sleeve and a locking nut and provides the primary opening pressure and displacement of the safety valve; and a secondary pressure-displacement is composed of a valve core, a built-in valve core, a secondary spring, a regulation rod, a spring sleeve and a regulating nut and is used for providing the secondary opening pressure and displacement of the safety valve. The dual-opening-pressure dual-displacement safety valve is applicable to various air pressure systems, is used for releasing gas with pressure higher than the safe pressure of the systems and maintaining the safe operation of the system, and is especially applicable to a condition that the gas supply of the system is limited; when the pressure of the system is slightly higher, small displacement is needed for performing slow pressure relief, so that the gas in the system is prevented from being rapidly lost and being supplied. The safety valve is of an all-metal structure and is also applicable to high temperature systems.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

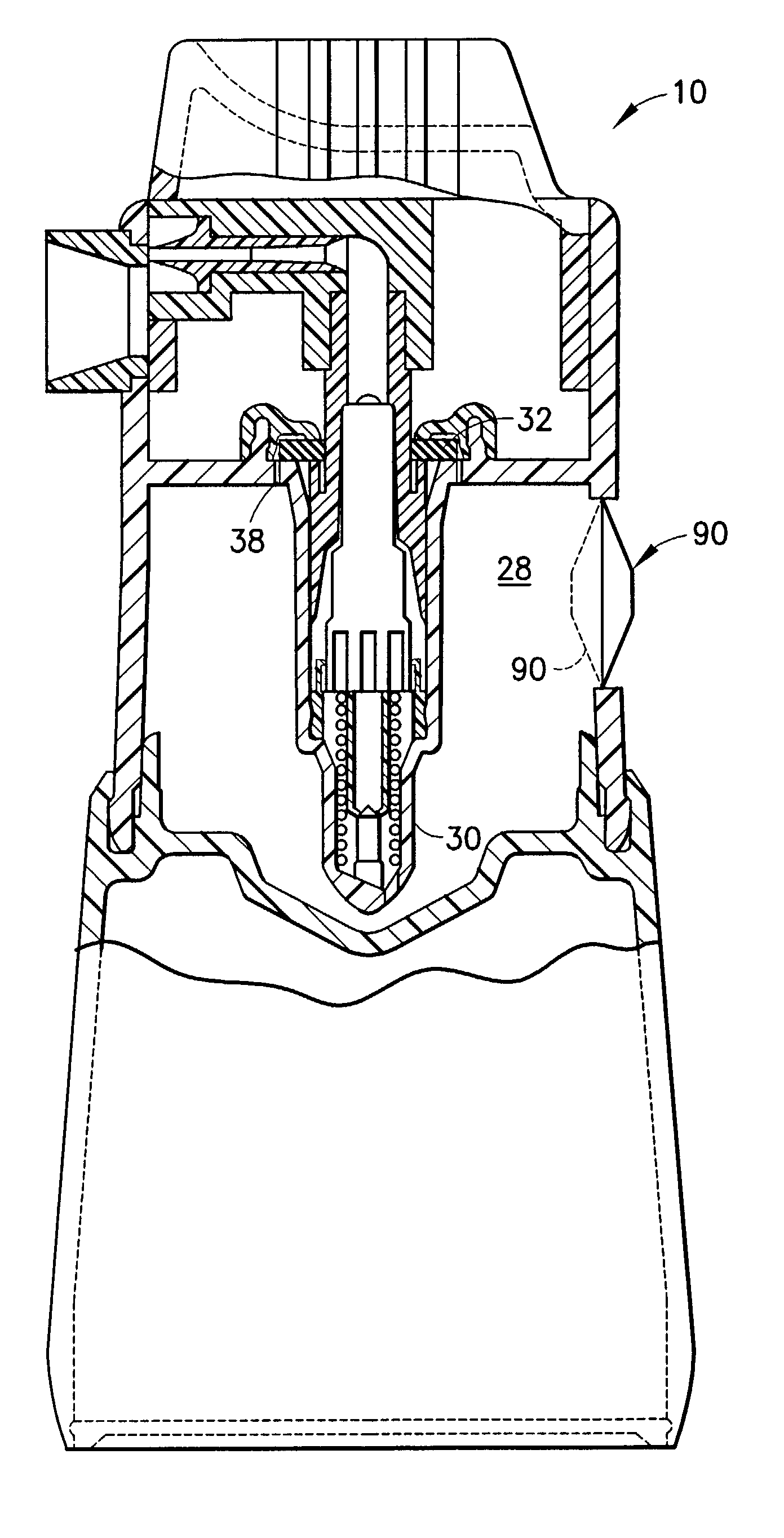

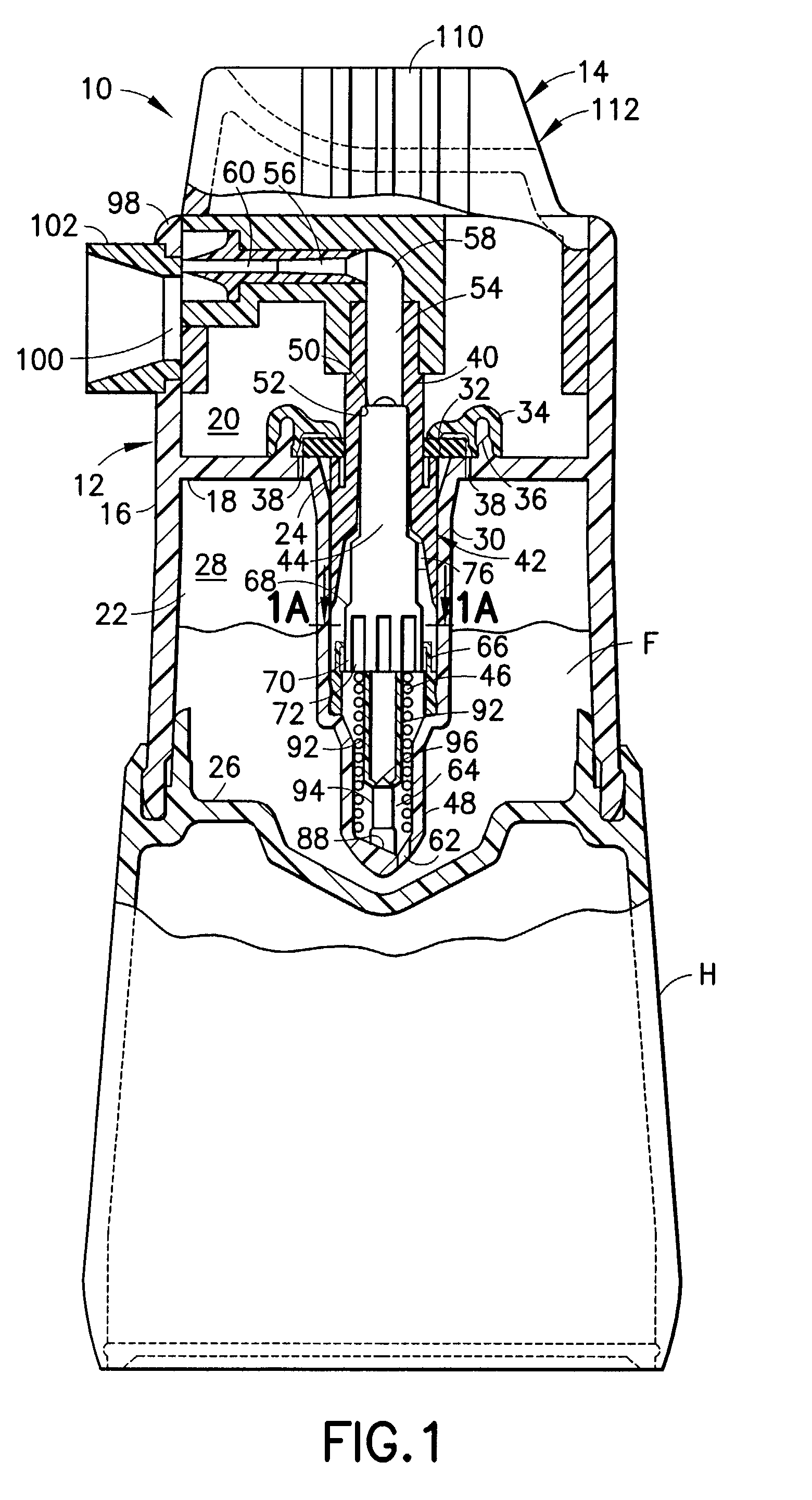

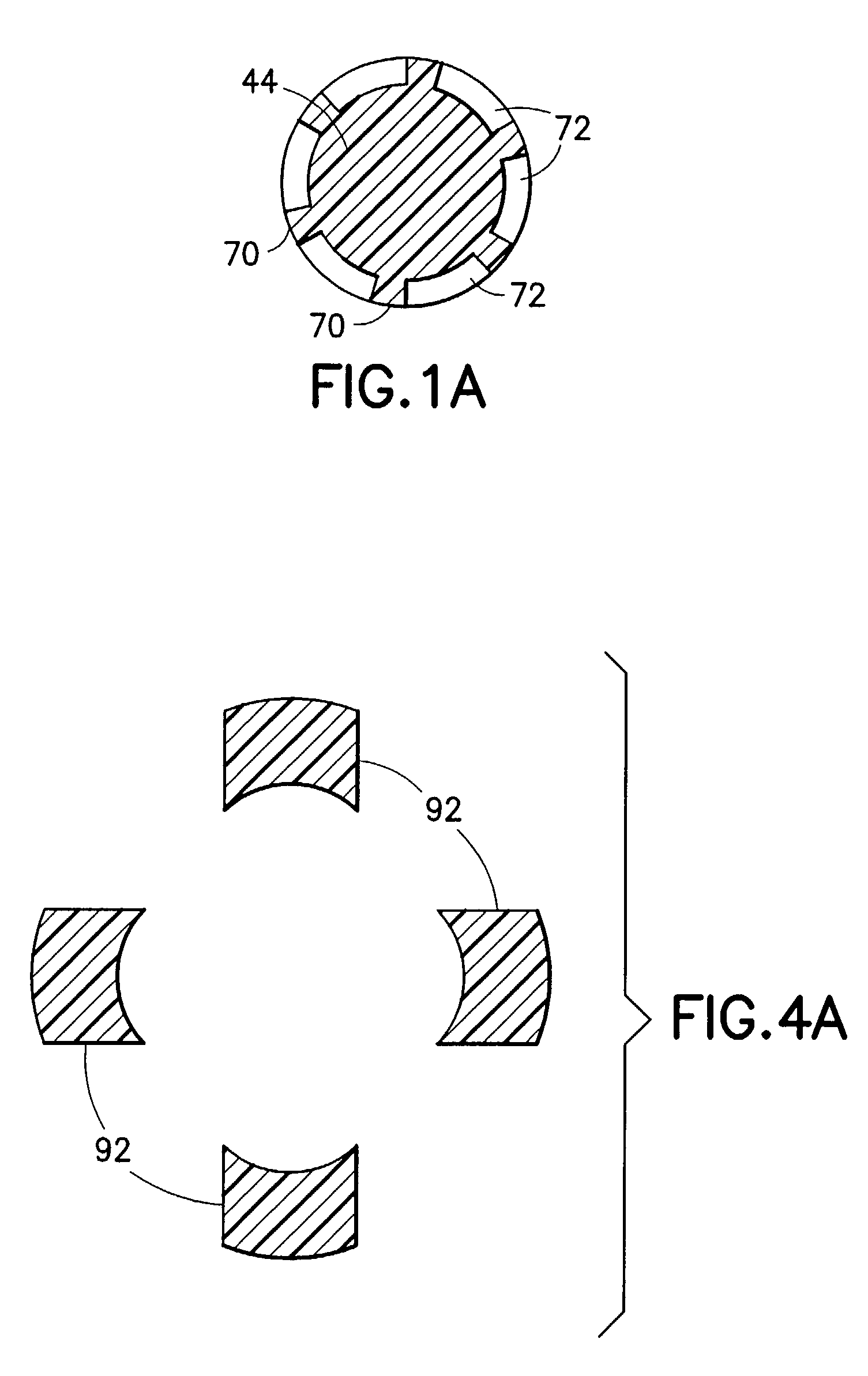

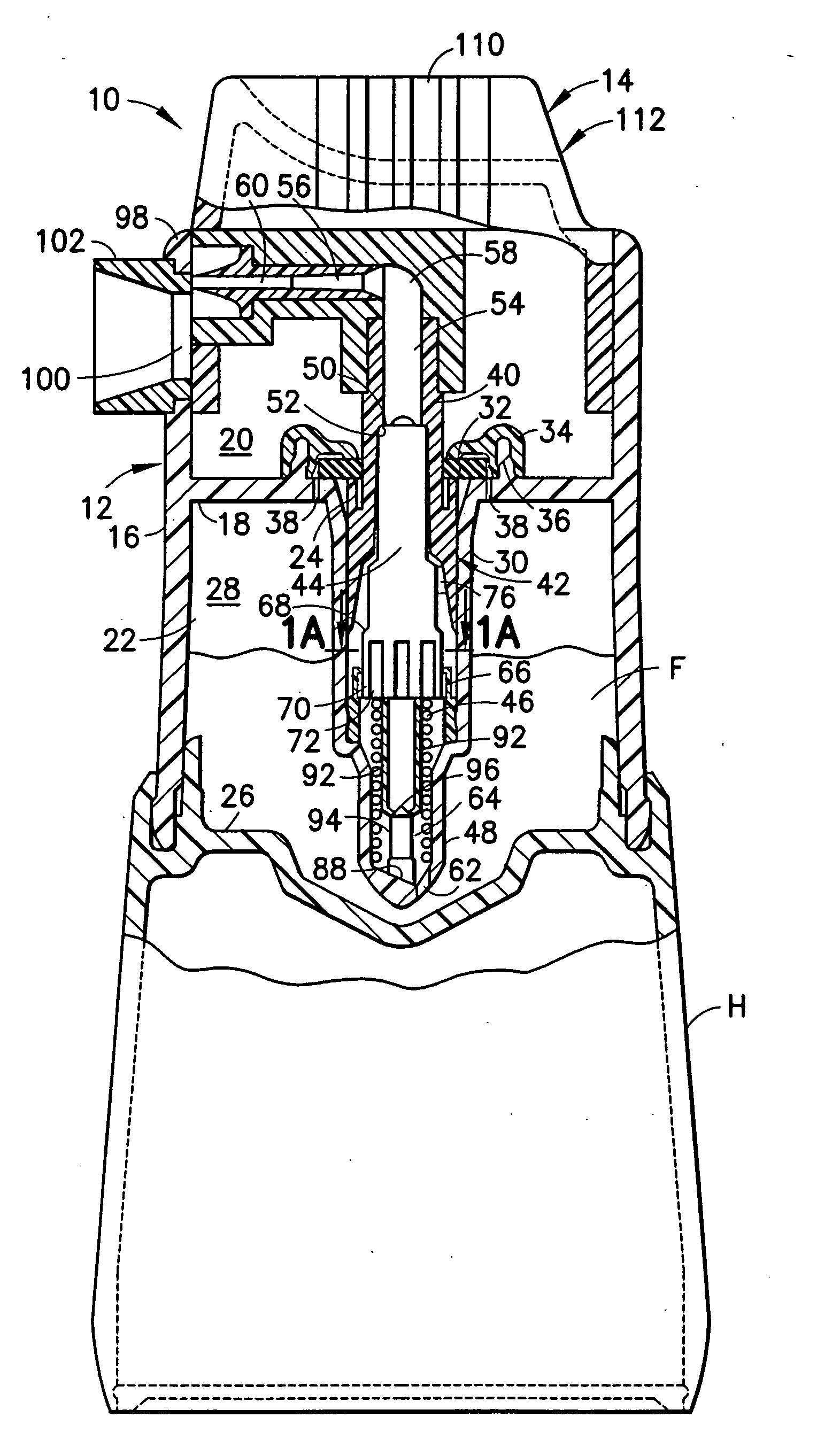

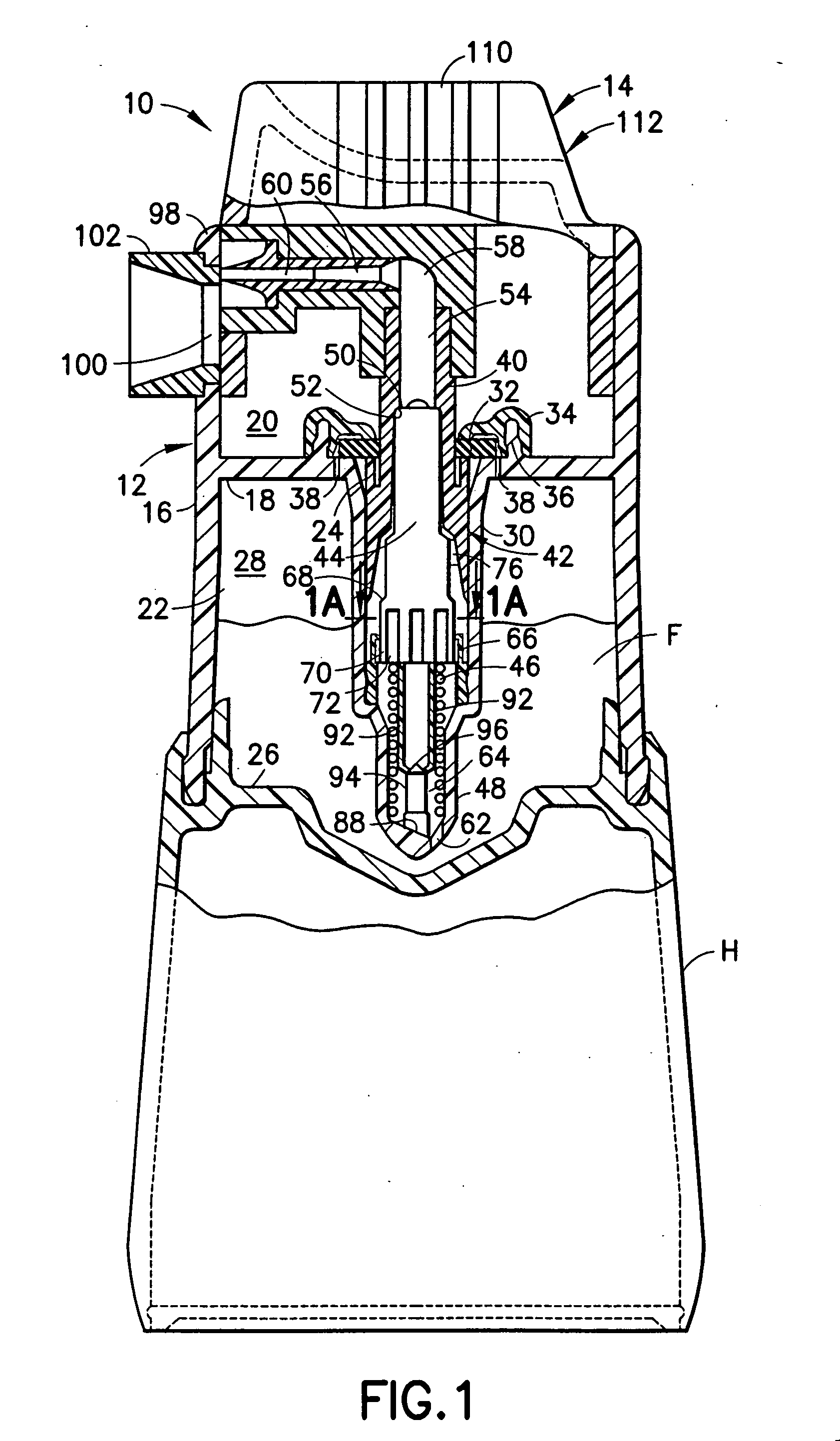

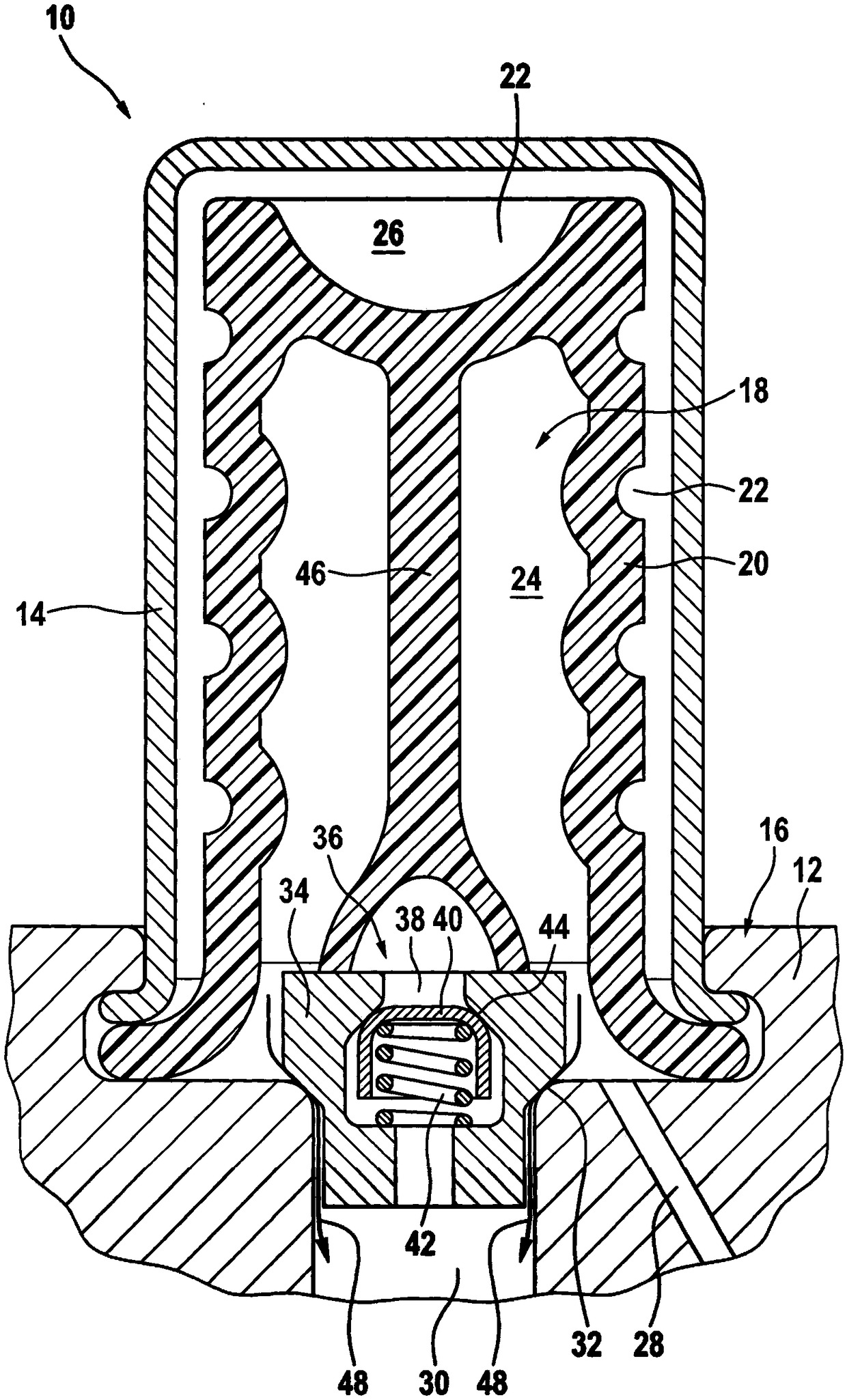

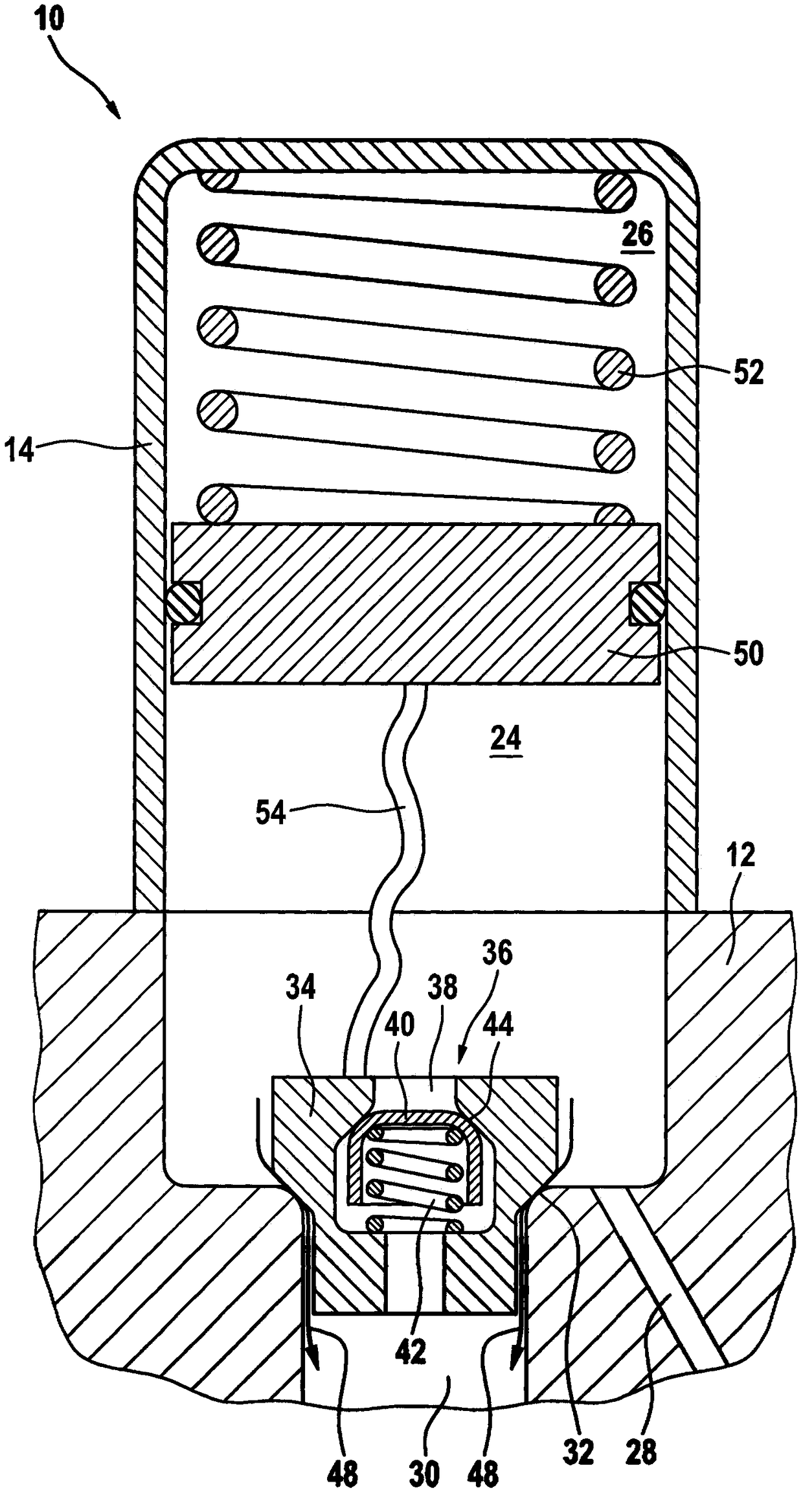

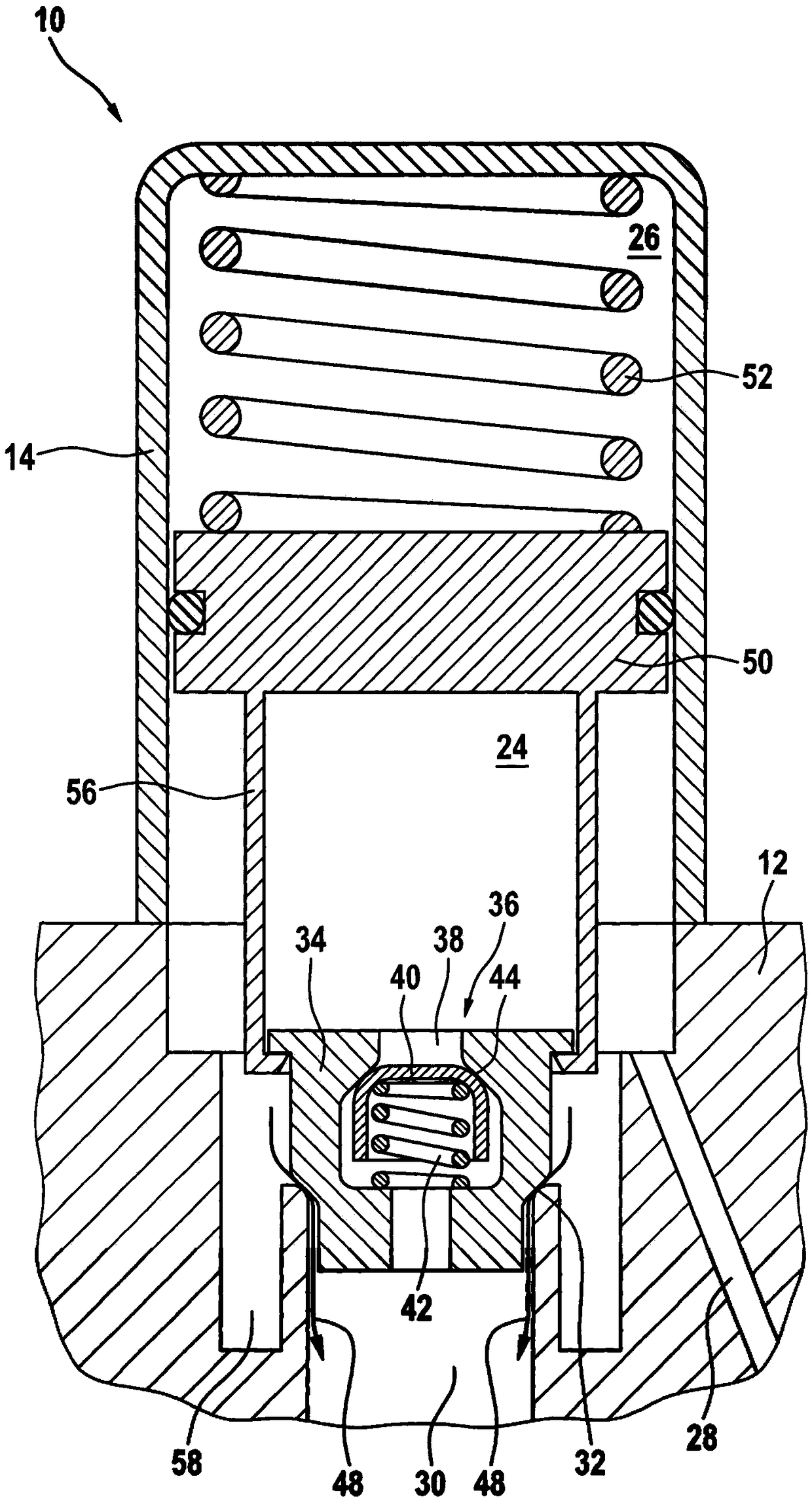

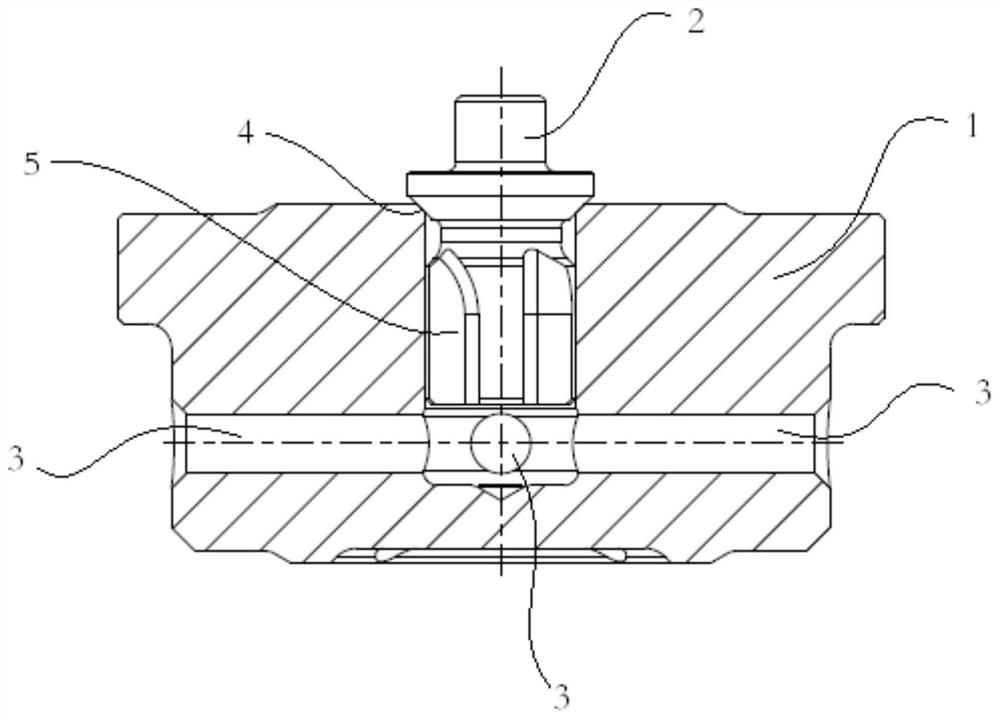

Microdispensing pump

InactiveUS7014068B1Inhibit atomizationMinimizing throttlingLarge containersSingle-unit apparatusMomentumPre compression

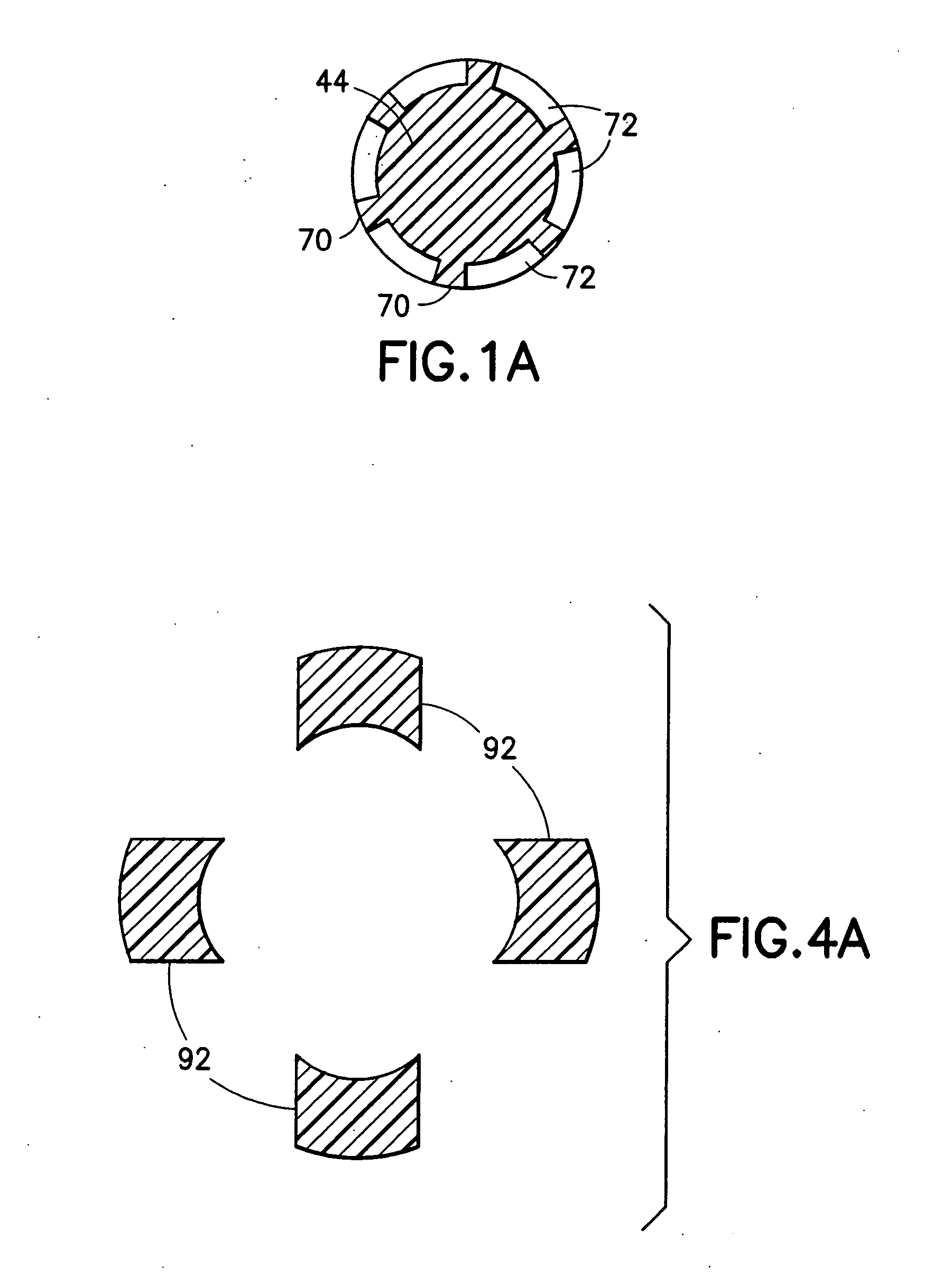

A pre-compression pump (10) dispenses microdoses of fluid (F). The pump minimizes pulsing due to pressure fluctuations. The pump is provided with the following to limit pulsing: a low force slow return velocity return spring (46); enlarged fluid passage (58); elastic bumper (74); and, a ratchet tooth (76) bearing against the stem (44). Further, a deflectable diaphragm (90), a splined (70) stem (44), no dip tube, and an off-center, gravitational low-point pump inlet (62) assist in priming the pump. The pump includes a stem (44) with delfectable fingers (92) to ensure sufficient momentum in pump operation. Detents (118) and grooves (120) selectively lock a nozzle cap (14) in an inoperative position. To ensure cleanliness, nozzle (60) cleaning is provided, wiping of the nozzle to remove meniscus (M) therefrom, cuts (104) formed in a shroud (98) assist in drawing excess fluid from the nozzle, and an empty volume (108) for collecting fluid run-off from the nozzle. A handle (H) is mounted to the pump providing a grip.

Owner:COHEN

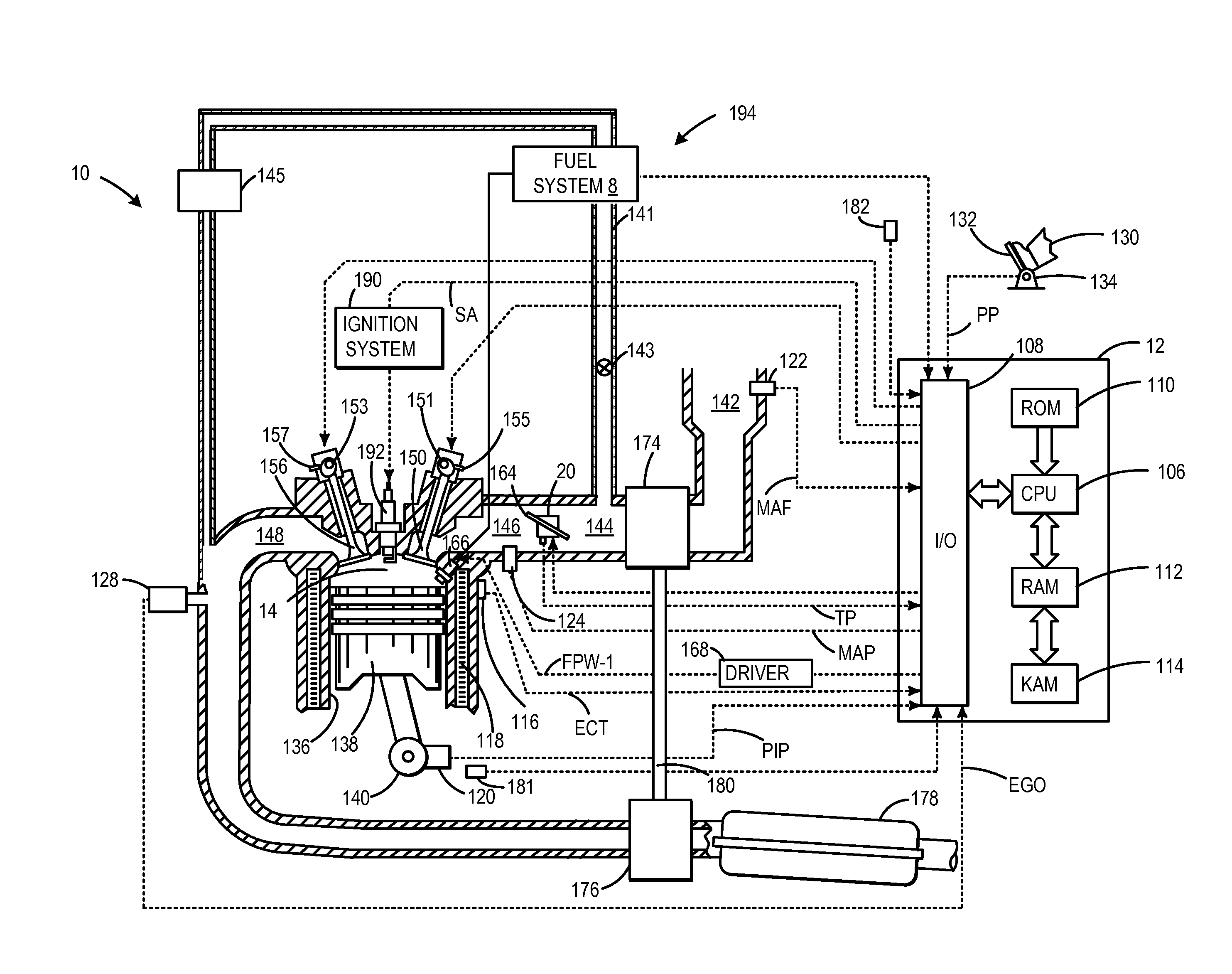

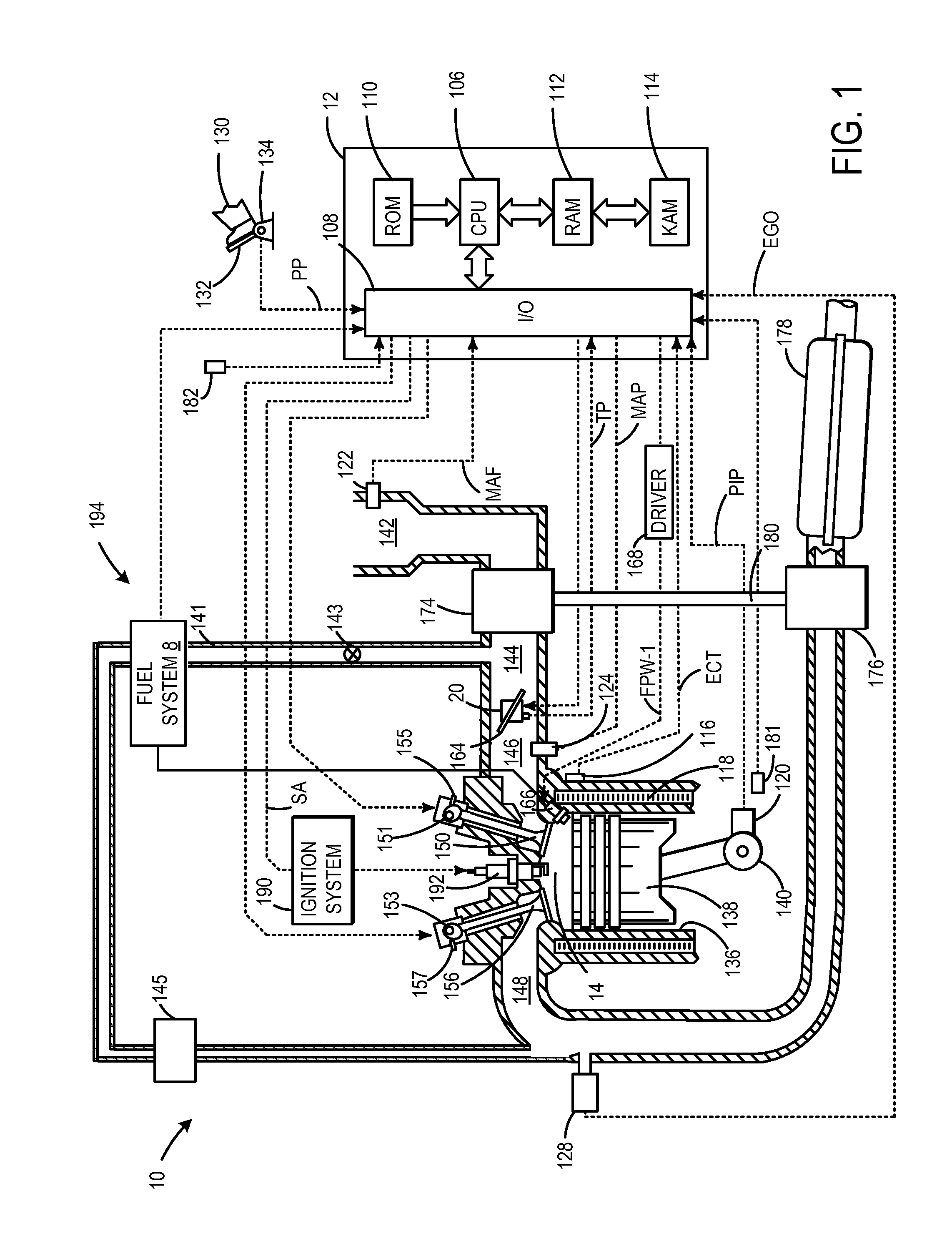

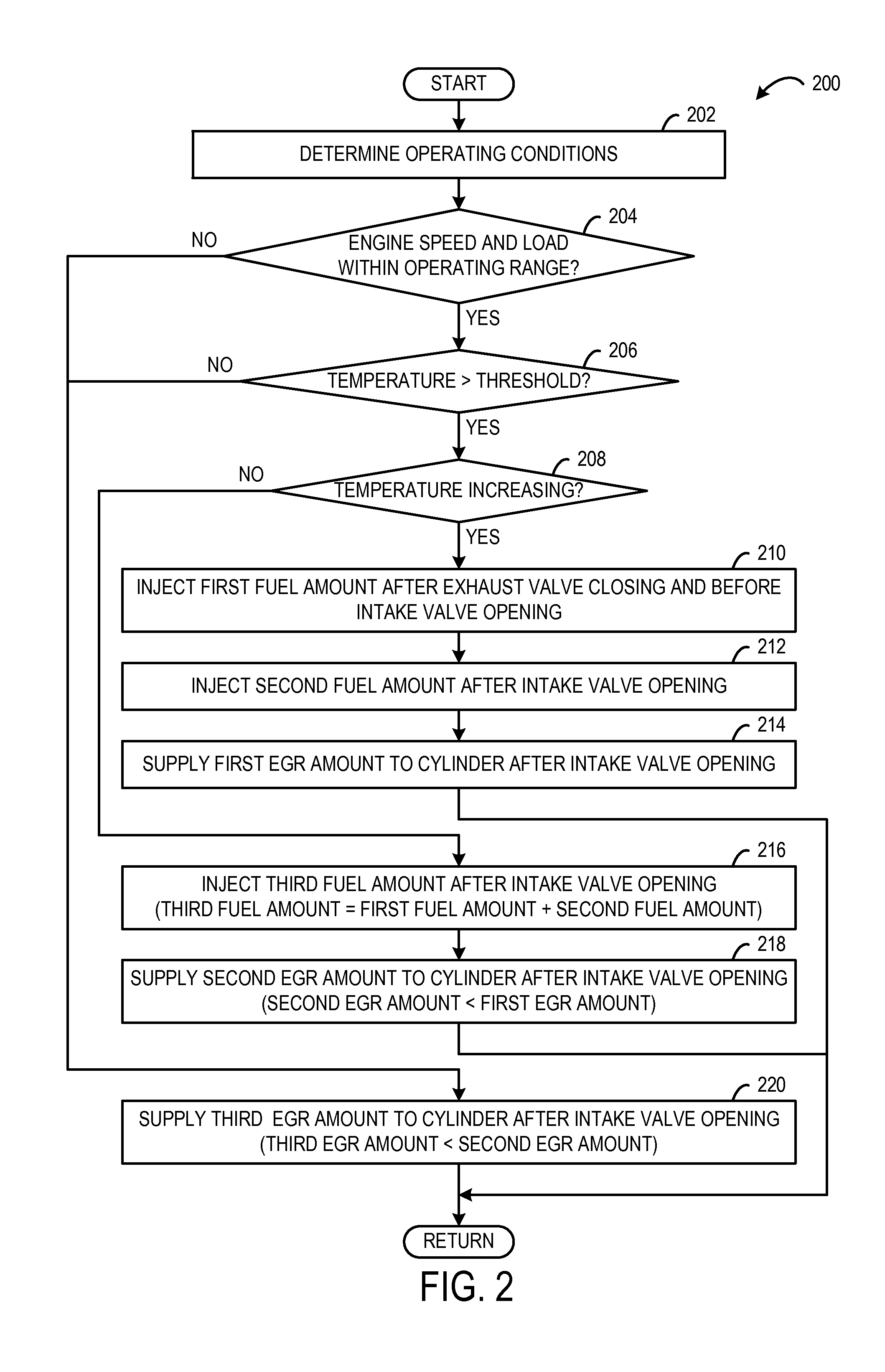

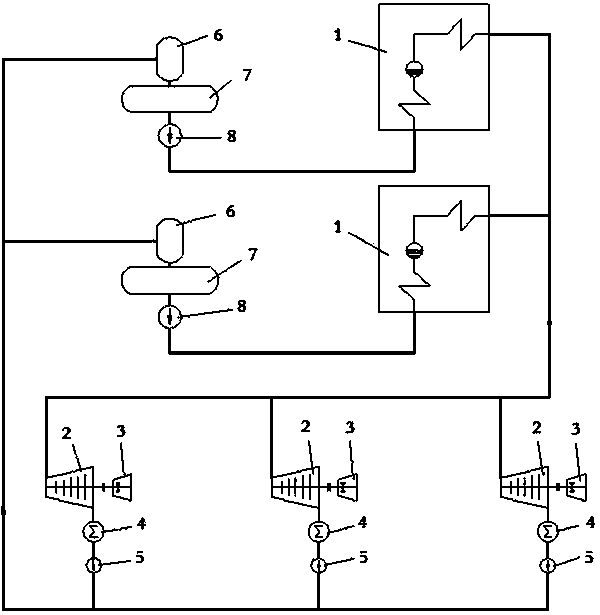

Approach for controlling exhaust gas recirculation

ActiveUS20140100760A1Reduce throttlingImprove fuel efficiencyElectrical controlInternal combustion piston enginesExhaust valveInlet valve

Various embodiments related to controlling EGR in an engine are disclosed. In one embodiment, a first EGR amount is supplied to a cylinder at a first temperature and a first engine speed and load. Further, at the first engine speed and load, as engine temperature increases from the first temperature to a second temperature, a first fuel amount is injected after exhaust valve closing and before intake valve opening while a second EGR amount is supplied to the cylinder that is greater than the first EGR amount.

Owner:FORD GLOBAL TECH LLC

Microdispensing pump

InactiveUS20060086760A1Inhibit atomizationMinimizing throttlingLarge containersSingle-unit apparatusMomentumPre compression

A pre-compression pump (10) dispenses microdoses of fluid (F). The pump minimizes pulsing due to pressure fluctuations. The pump is provided with the following to limit pulsing: a low force slow return velocity return spring (46); enlarged fluid passage (58); elastic bumper (74); and, a rachet tooth (76) bearing against the stem (44). Further, a deflectable diaphragm (90), a splined (70) stem (44), no dip tube, and an off-center, gravitational low-point pump inlet (62) assist in printing the pump. The pump includes a stem (44) with deflectable fingers (92) to ensure sufficient momentum in pump operation. Detents (118) and grooves (120) selectively lock a nozzle cap (14) in an inoperative position. To ensure cleanliness, nozzle (60) cleaning is provided, wiping of the nozzle to remove meniscus (M) therefrom, cuts (104) formed in a shroud (98) assist in drawing excess fluid from the nozzle, and an empty volume (108) for collecting fluid run-off from the nozzle. A handle (H) is mounted to the pump providing a grip.

Owner:COHEN

Inbound transition control for a tail-sitting vertical take off and landing aircraft

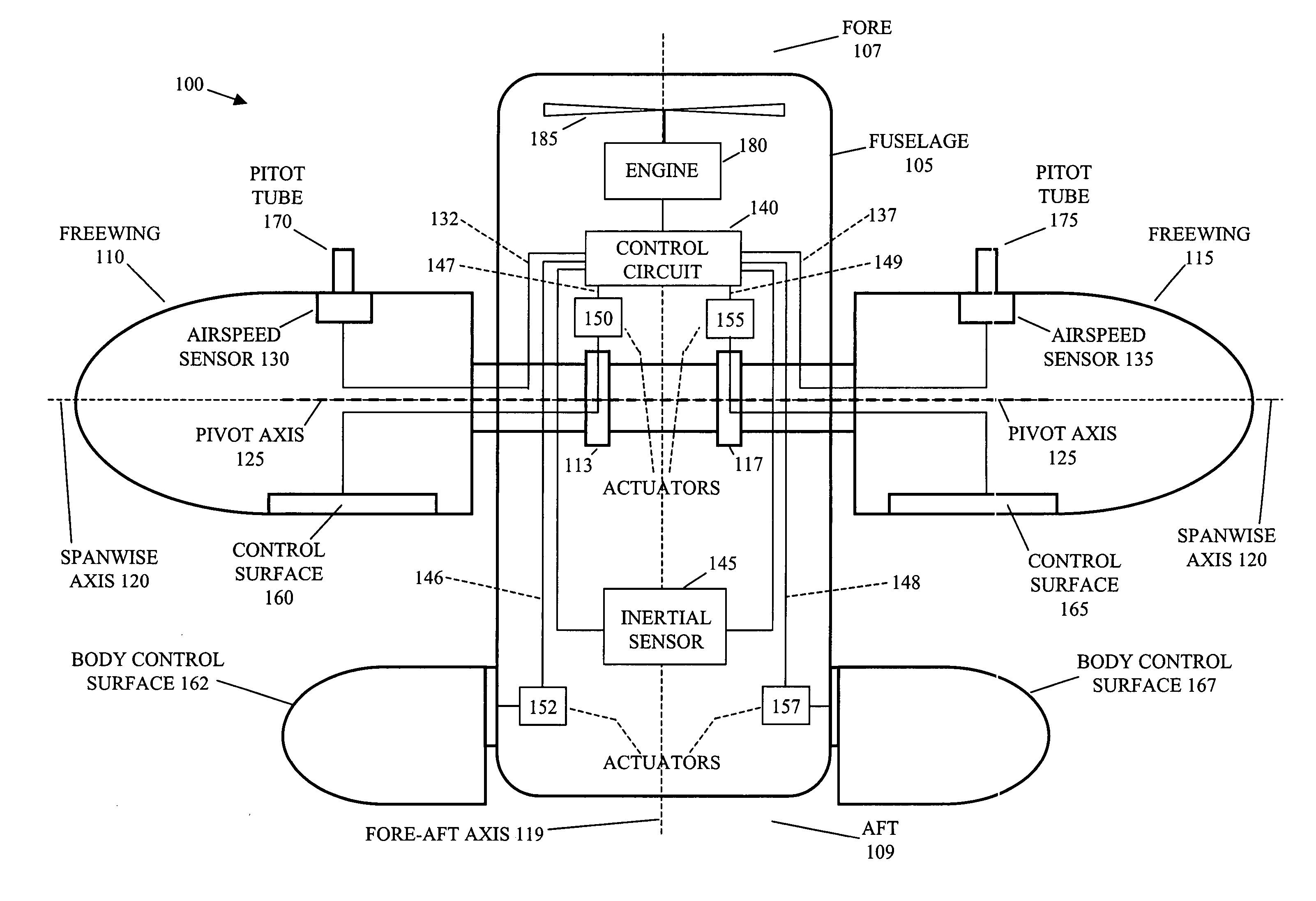

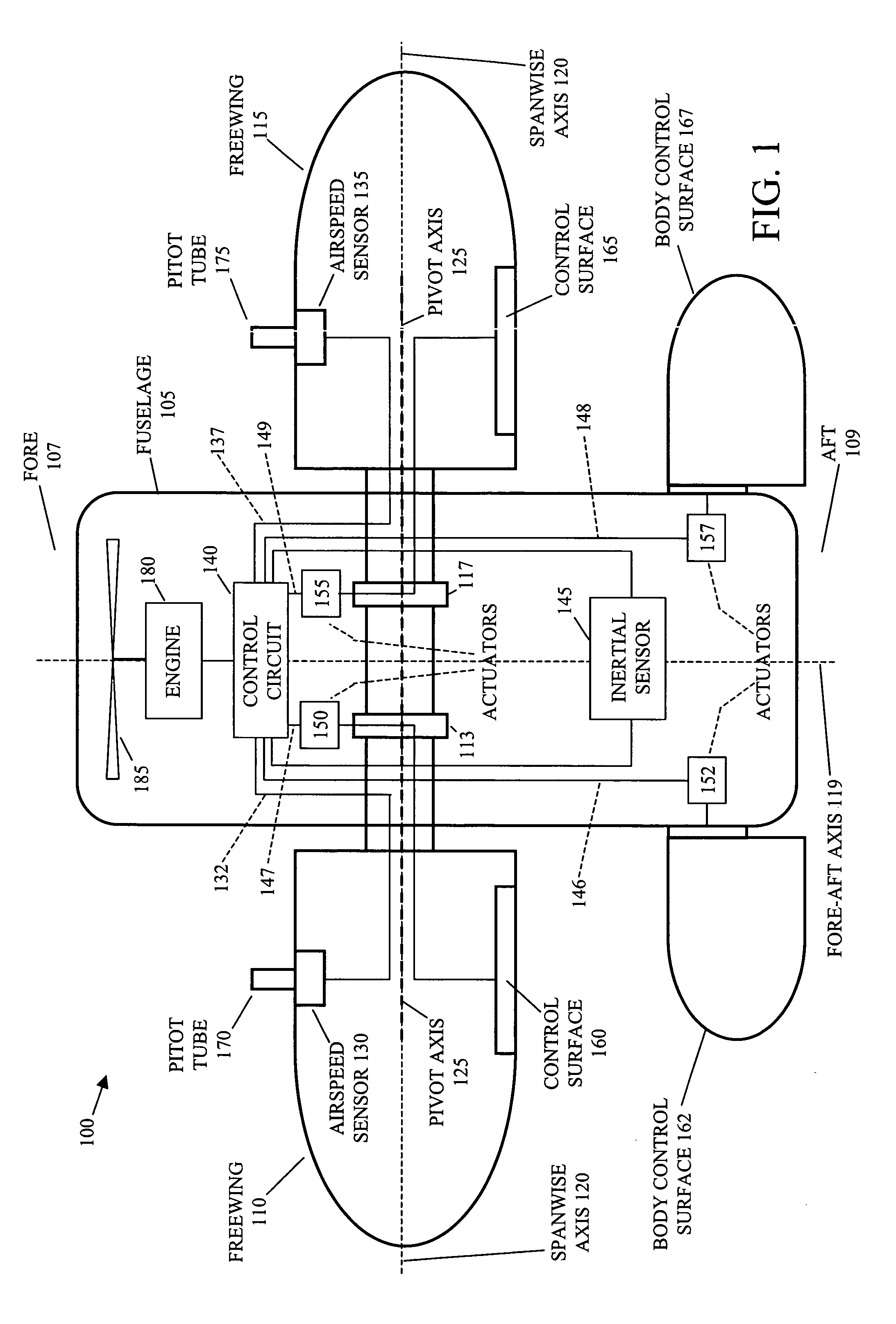

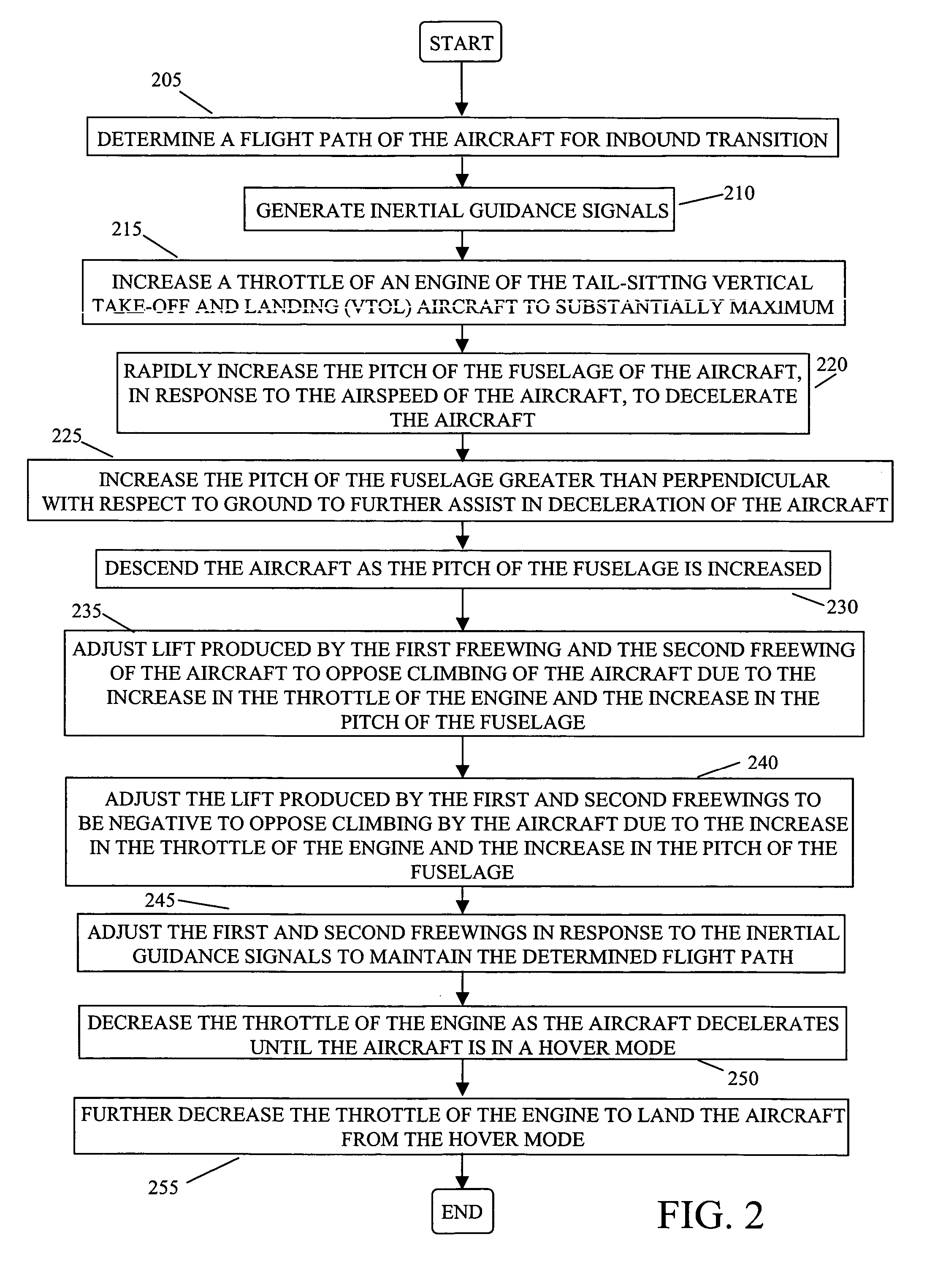

InactiveUS20070069065A1Reduce throttlingPositive liftEfficient propulsion technologiesWingsControl signalActuator

A system for controlling inbound transition of an aircraft includes a fuselage and first and second freewings pivotably mounted on opposing sides thereof. The system includes an airspeed sensor that outputs an airspeed indication signal. The system includes a controller for increasing aircraft engine thrust to substantially maximum for inbound transition, and for generating pitch and freewing control signals. The system includes actuators for actuating aircraft control surfaces in response to the pitch control signal to rapidly increase pitch of the fuselage to decelerate the aircraft, and for actuating freewing control surfaces in response to the freewing control signal to adjust lift produced by the freewings to oppose climbing of the aircraft due to the increase in engine thrust and the increase in the fuselage pitch. The controller is configured to decrease the engine thrust as the aircraft decelerates until the aircraft is in a hover mode.

Owner:AURORA FLIGHT SCI CORP

Hydraulic freewheel for an internal combustion engine with variable compression ratio

ActiveUS9677469B2Little temperature dependenceReduce throttlingRotary bearingsConnecting rodsExternal combustion engineEffective length

Owner:FEV

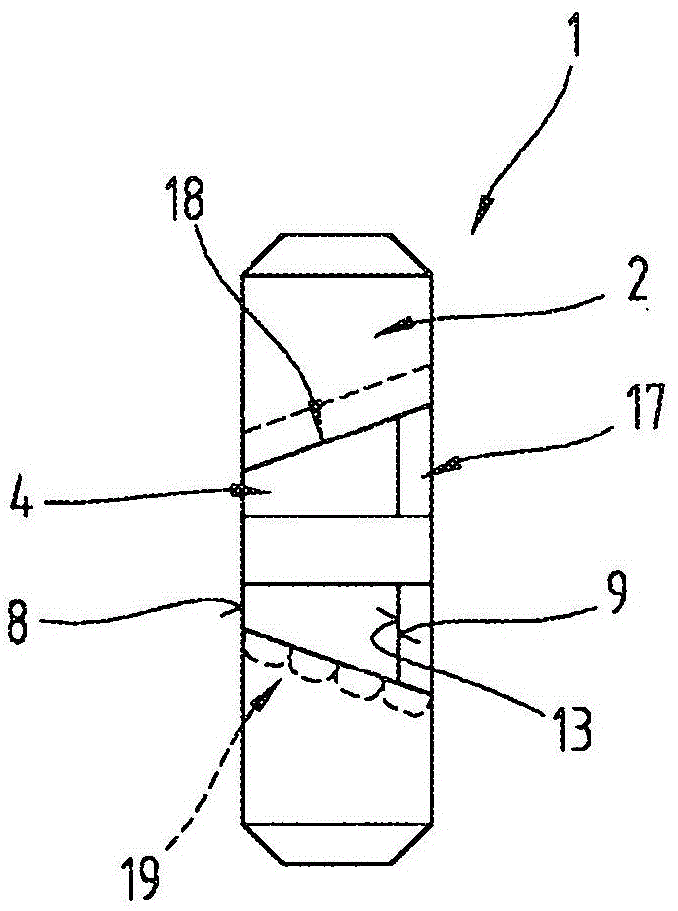

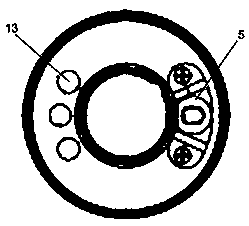

Wind power plant gear mechanism

The invention relates to a wind power plant gear mechanism (1) with an axle (5) and a gearwheel (2), wherein at least one sliding bearing bush (4, 20) is arranged between the axle (5) and the gearwheel (2), and wherein the at least one sliding bearing bush (4, 20) is connected to the gearwheel (2) via a conical press fit, wherein the at least one sliding bearing bush (4, 20) has a first end surface (8) and a second end surface (9) which lies opposite the former along a longitudinal centre axis (7) through the at least one sliding bearing bush (4, 20), and wherein the first end surface (8) has a diameter d (10) and the second end surface (9) has a diameter D (11), wherein the diameter D (11) is greater than the diameter d (10), and wherein a bearing surface (13) for the at least one sliding bearing bush (4, 20) is formed so as to adjoin the end surface (9) with the diameter D (11).

Owner:MIBA SINTER AUSTRIA

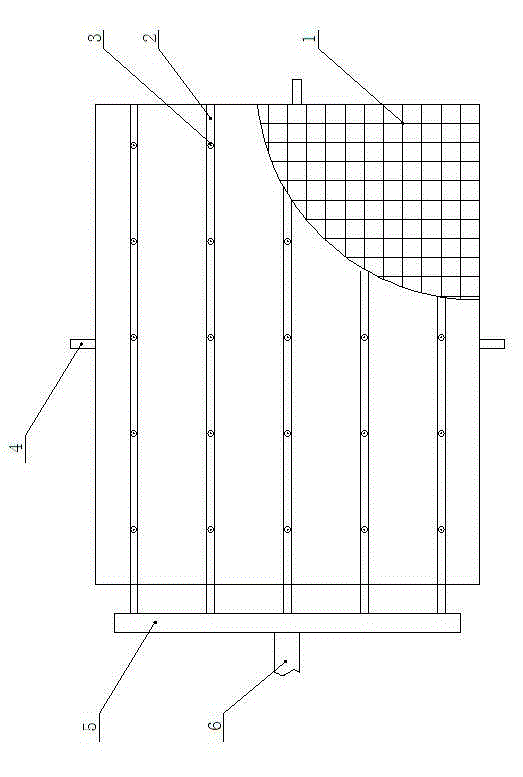

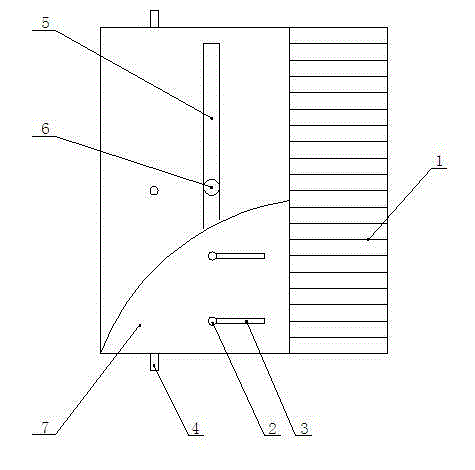

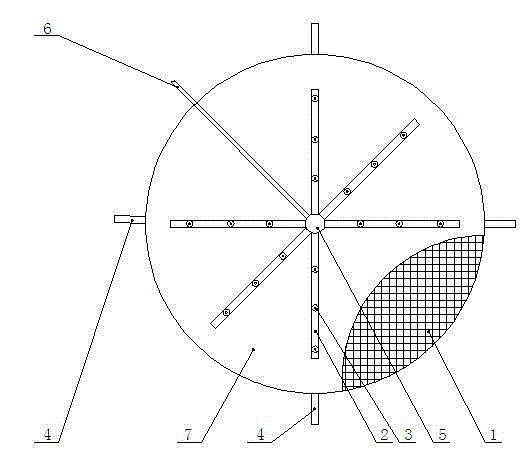

Wind speed and wind volume measuring device based on static pressure principle

InactiveCN103336141AReduce throttlingImprove test accuracyFluid speed measurement using pressure differenceVolume/mass flow by differential pressureGratingMeasurement device

The invention relates to a wind speed and wind volume measuring device based on the static pressure principle. The wind speed and wind volume measuring device comprises a box body with two openings at two ends; one opening is an air inlet, and the other opening is an air outlet; a rectification grating is arranged and mounted in the air inlet; the inner box body behind the rectification grating serves as an air flow channel; pitot tubes are uniformly laid in the air flow channel; each pitot tube is only provided with an air inlet and a full-pressure port; the full-pressure port of each pitot tube is communicated with a pitot tube full-pressure gathering tube; the pitot tube full-pressure gathering tube is communicated with a full-pressure gathering tube; a full-pressure conveying tube is arranged and mounted on the full-pressure gathering tube; a static pressure testing tube is laid in the air flow channel. The wind speed and wind volume measuring device combines two testing methods, namely an air channel surface test and a pitot tube static pressure testing hole test, utilizes testing air channel static pressure on the air channel surface to replace the pitot tube static pressure, and reduces route I pitot tube static pressure testing pipeline, so as to reduce air channel throttling; the box body is used to replace part of existing air channel, thereby solving the deficiency of lack of straight tube for wind speed measuring device in a large wind box structure.

Owner:STATE GRID CORP OF CHINA +2

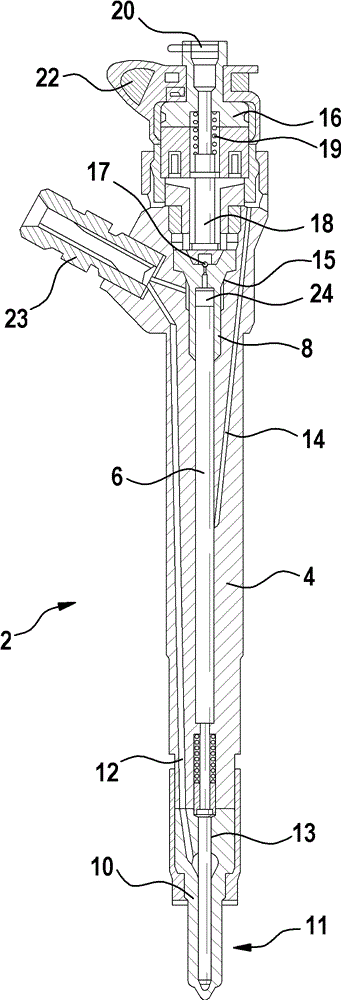

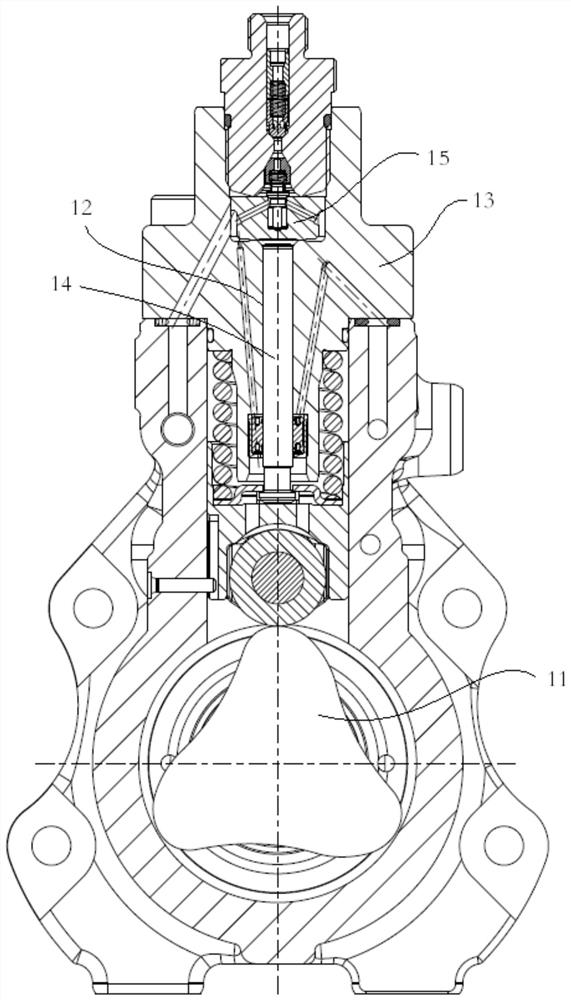

Injector control valve of electric control internal combustion engine

ActiveCN104265530AImprove wear resistanceImprove reliabilityFuel injection apparatusMachines/enginesSteel ballEngineering

The invention relates to an injector control valve of an electric control internal combustion engine. The injector control valve comprises a gag bit, a control valve base, an injector basal body, a gag bit rod, a steel ball, a control panel, a control piston, an electromagnetic driver and a gag bit return spring. The injector control valve is characterized in that the support sealing surface at the upper end of the control panel is a conical concave curved surface; the conical concave curved surface consists of a large-angle conical surface, a circular arc transitional section and a small-angle conical surface in sequence from periphery to center; the angle of the large-angle conical surface is 130-150 degrees; and the angle of the small-angle conical surface is 90-125 degrees. The control valve can precisely and stably control the change of pressure in a pressure control room, so that the injection quantity of an injector is stable and controllable; and the control valve can effectively rotate the steel ball, so that the service life of the control valve is prolonged.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

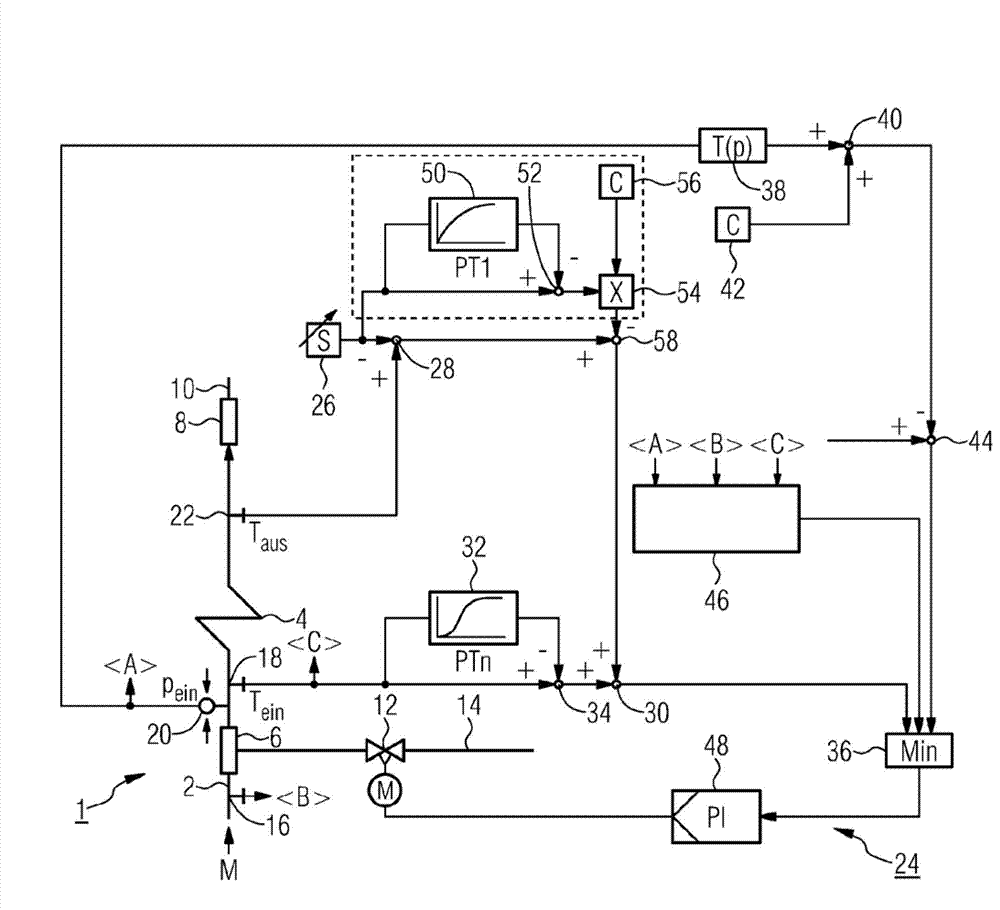

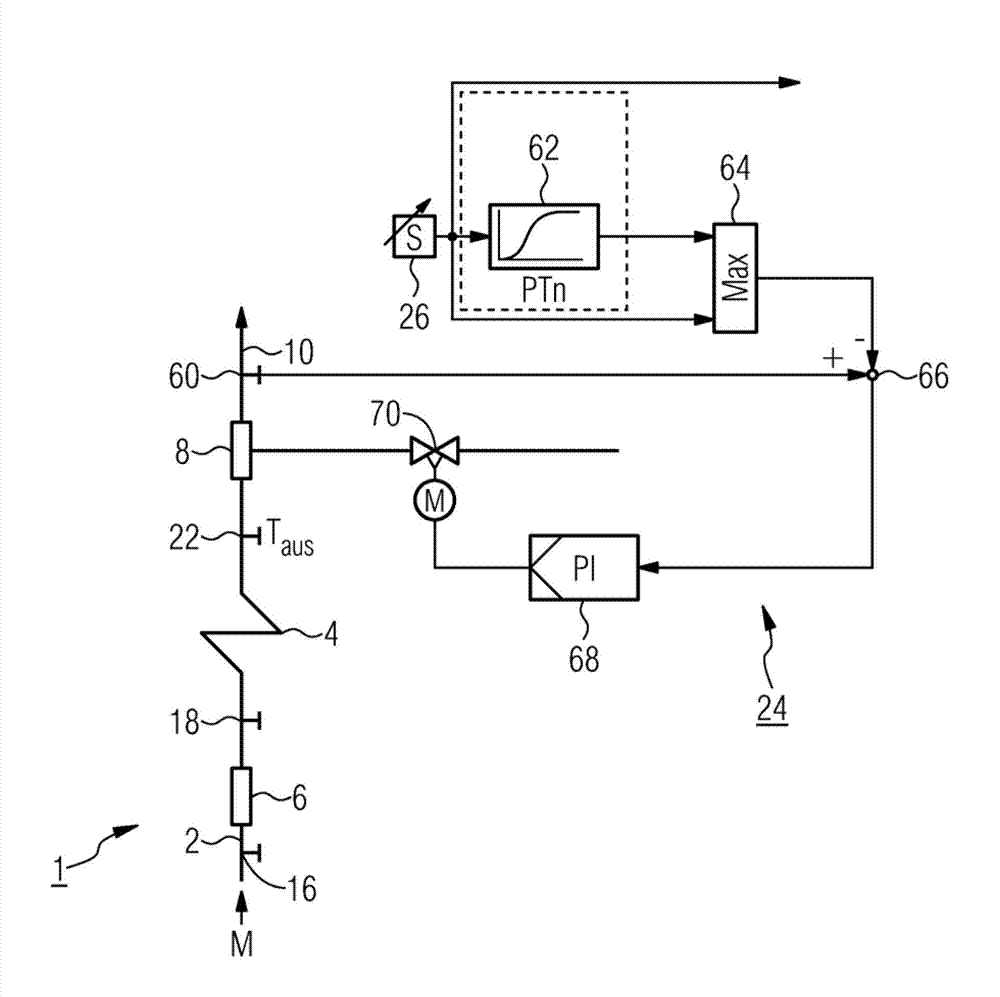

Method for regulating a short-term power increase of a steam tubine

ActiveCN103097671AStrong responseIncrease jet mass flowSuperheating controlEnergy industryEngineeringSuperheater

A method for regulating a short-term power increase of a steam turbine with an upstream waste-heat steam generator is provided. The steam turbine has a number of economizer, evaporator and super heater heating surfaces forming a flow path for a flow medium. The flow medium is tapped off from the flow path in a pressure stage and is injected into the flow path on the flow-medium side between two super heater heating surfaces of the respective pressure stage. Amount of flow medium injected is regulated with a characteristic value which is a discrepancy between the outlet temperature of the final super heater heating surface and a predetermined temperature nominal value. The temperature nominal value is reduced and the characteristic value is temporarily increased more than in proportion to the discrepancy for a time period of the reduction for achieving a short-term power increase of the steam turbine.

Owner:SIEMENS ENERGY GLOBAL GMBH CO & KG

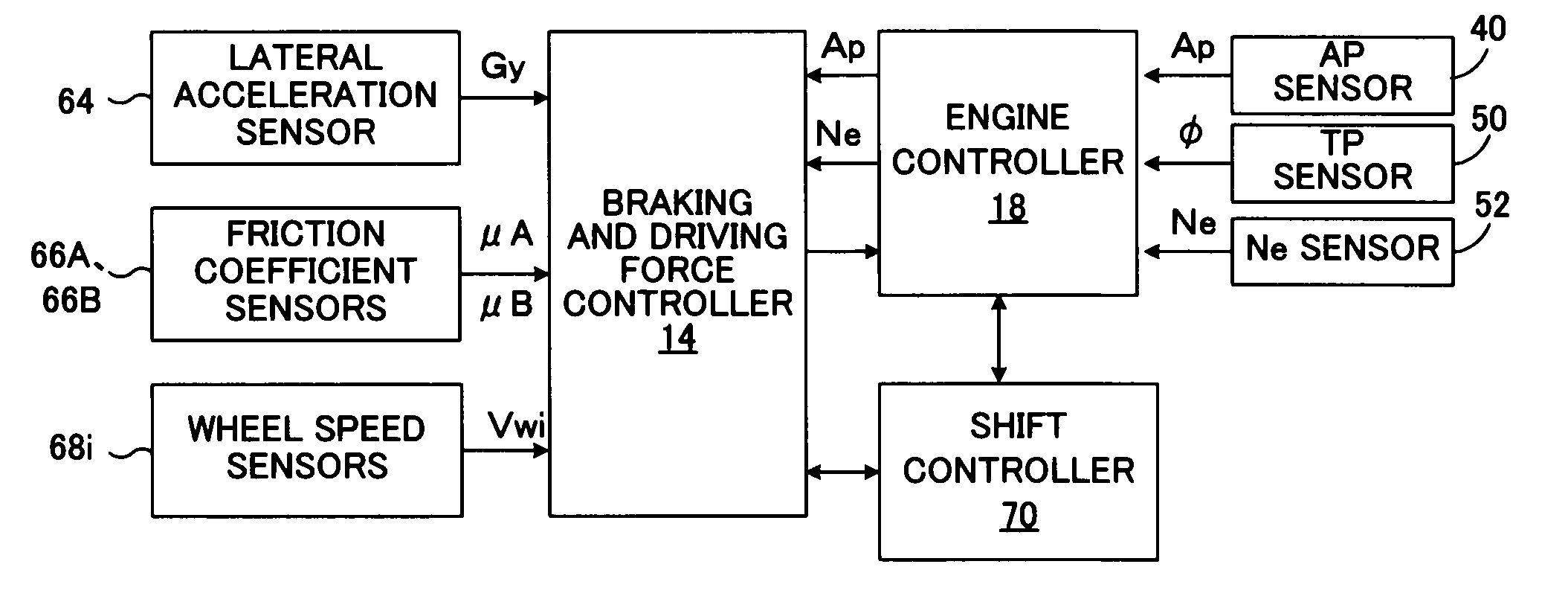

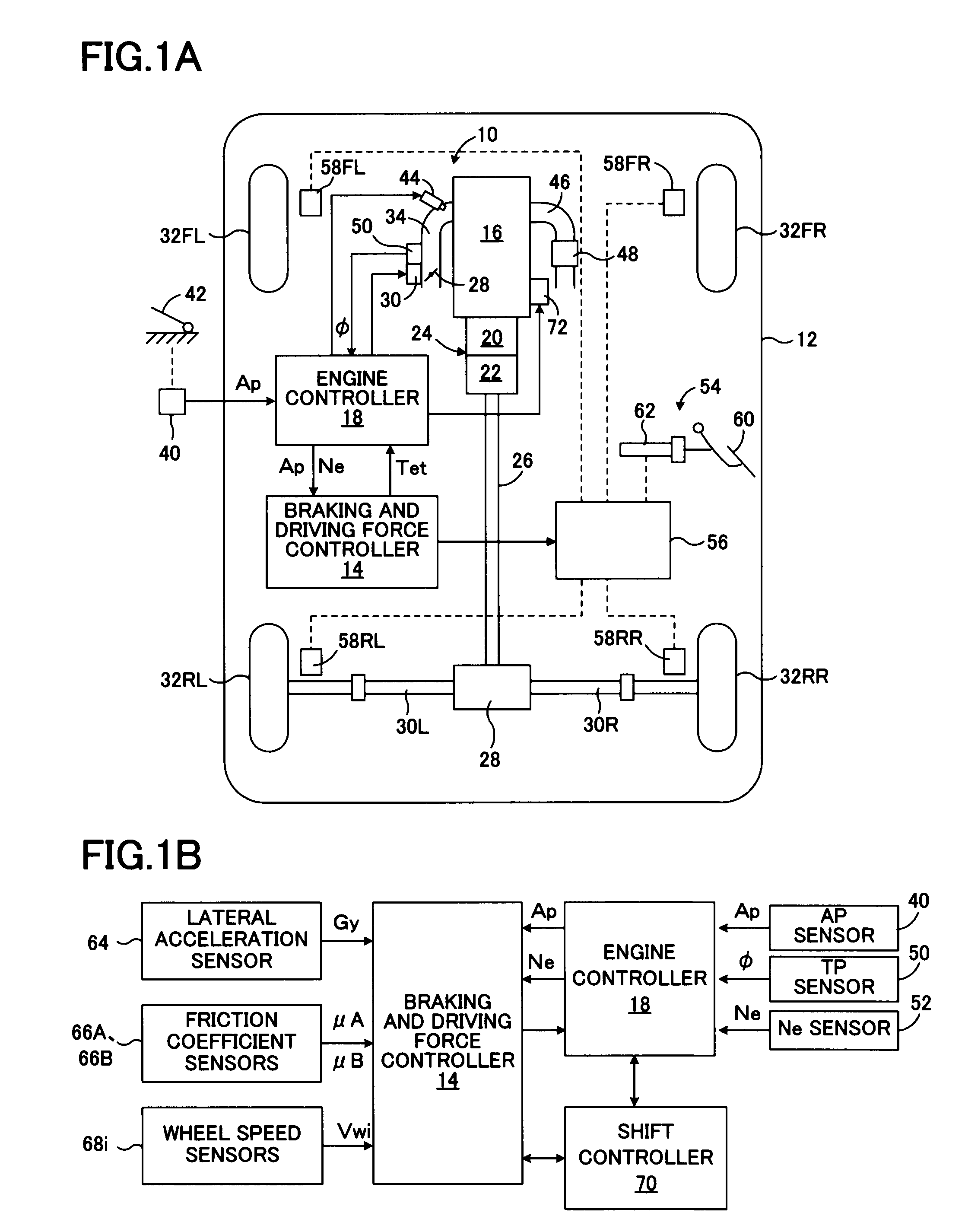

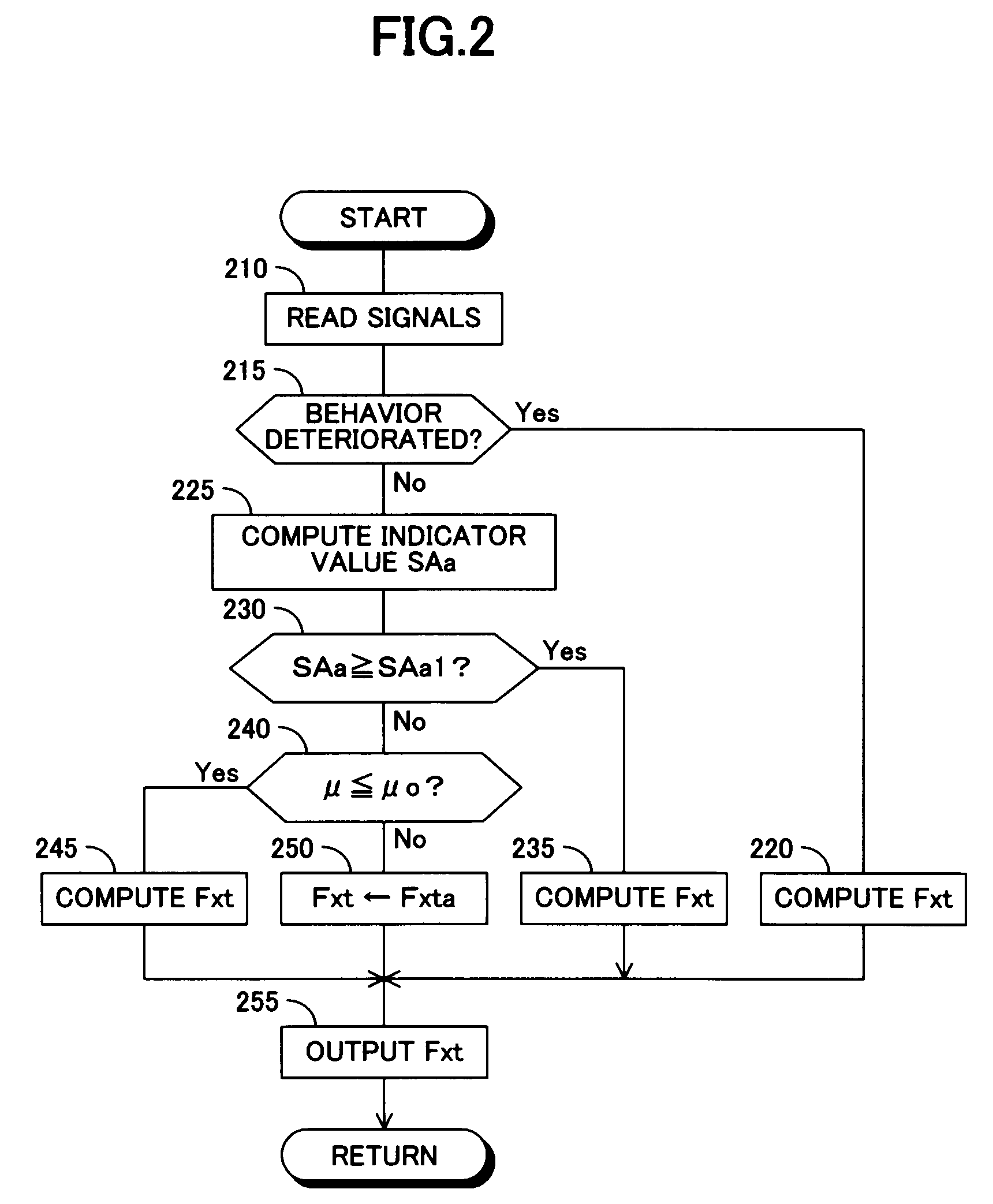

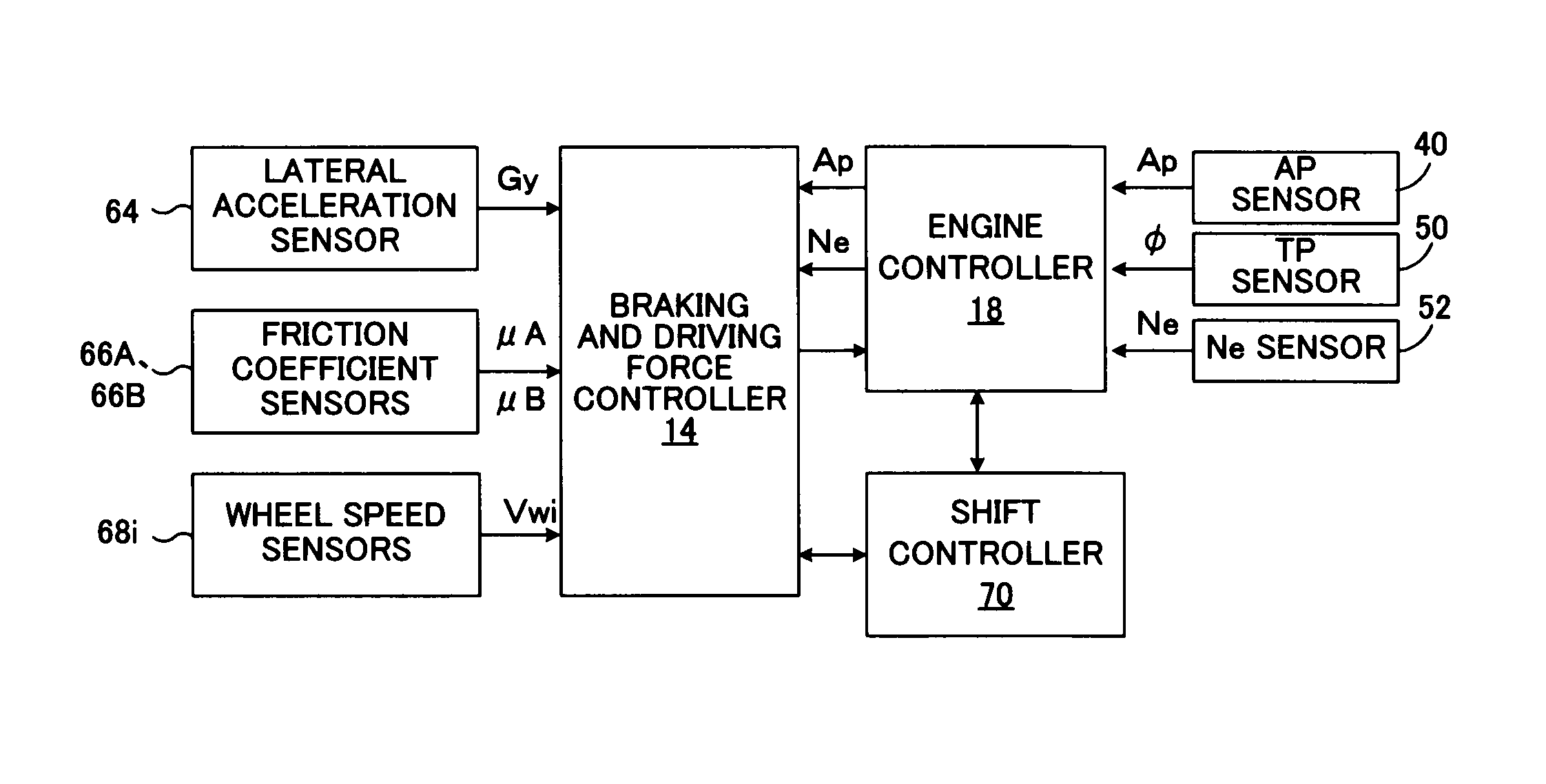

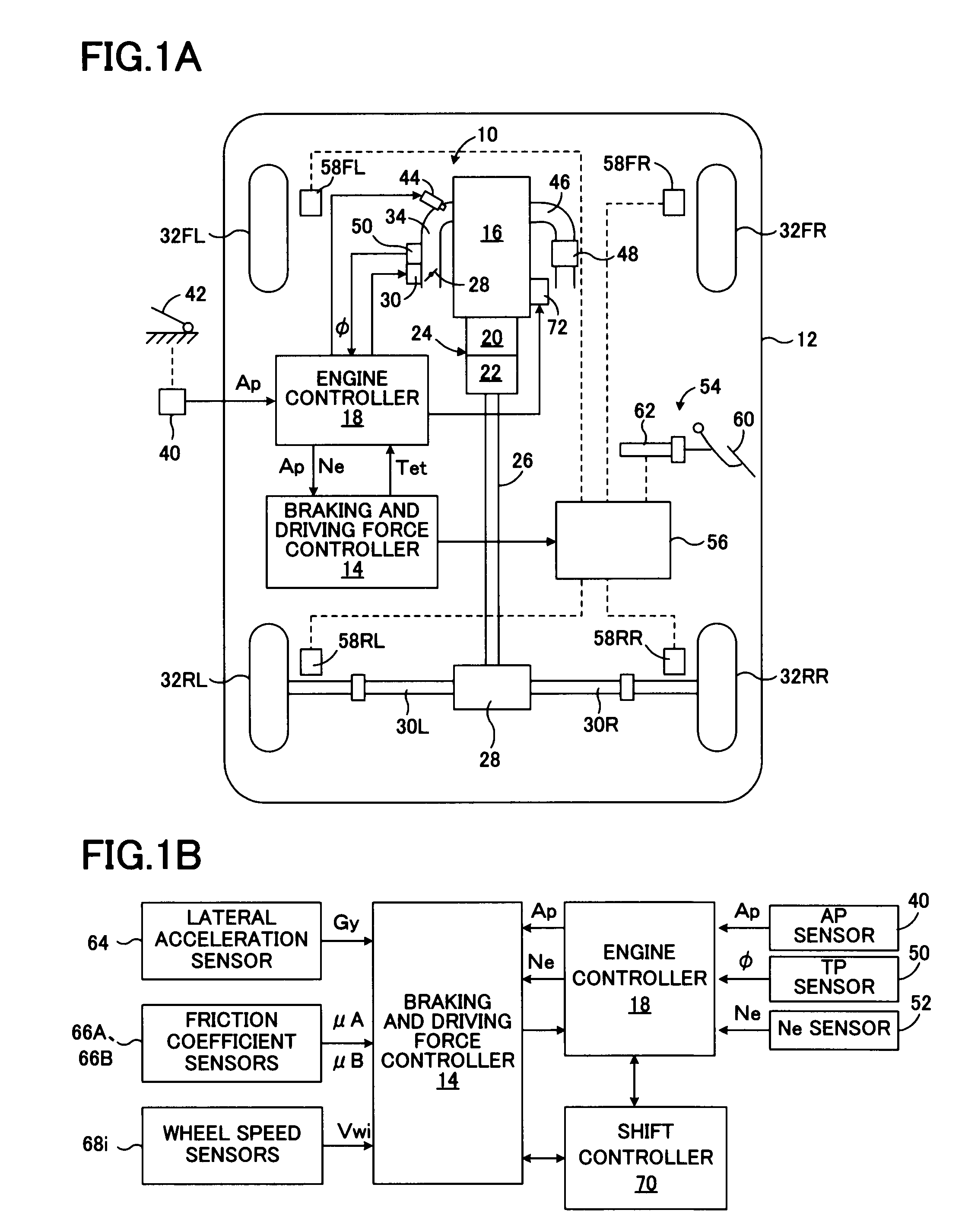

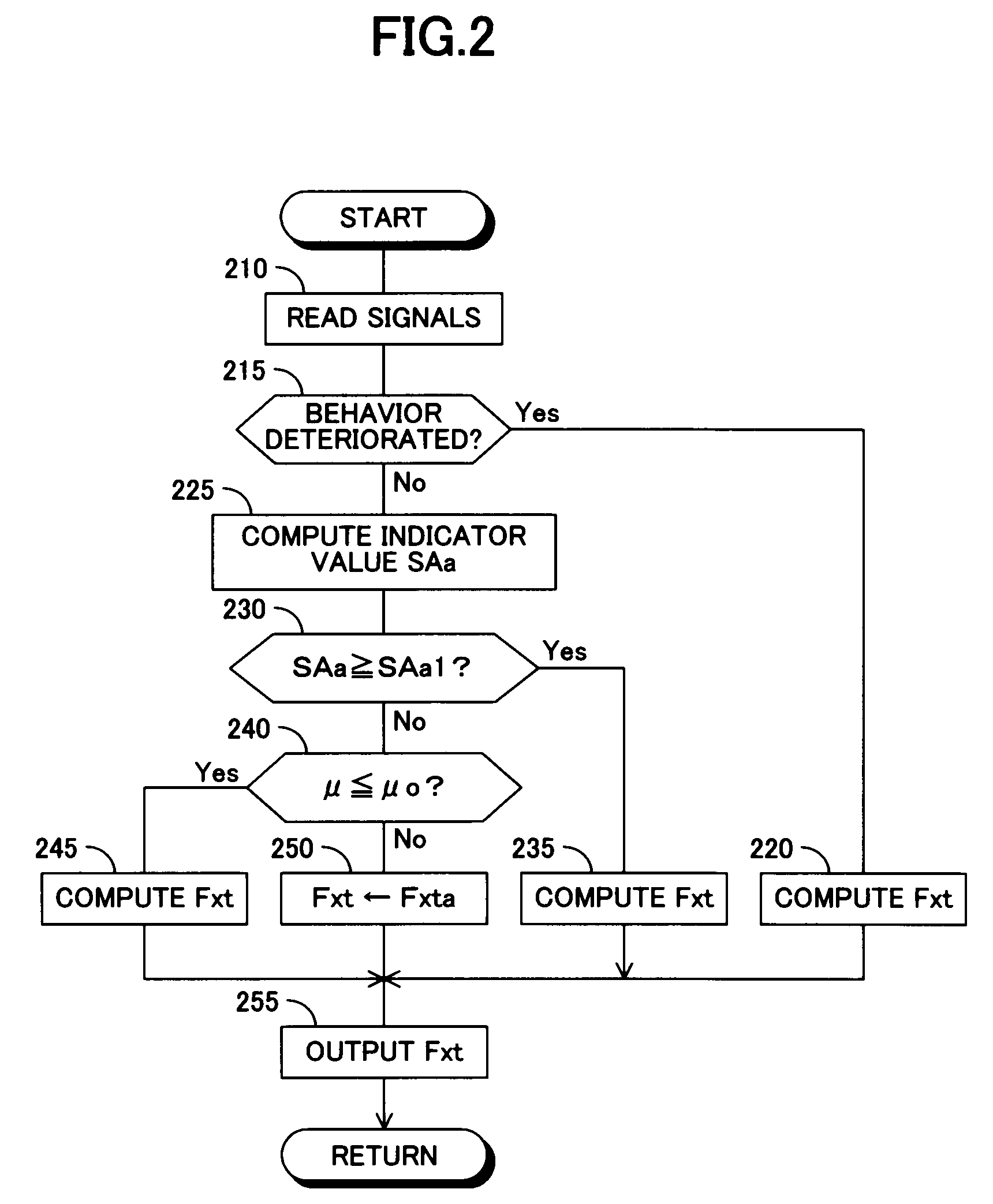

Driving force controller for vehicle

ActiveUS20100004832A1Reduce the driving forceReduce supplyElectrical controlDigital data processing detailsIgnition timingThrottle opening

An object of the present invention is to effectively reduce driving force of a vehicle, when the driving force of the vehicle must be reduced, while avoiding an increase in the temperature of exhaust gas and resultant deterioration of an exhaust gas purification catalyst, the object being achieved by effectively utilizing delaying of the ignition timing or reduction of the fuel supply amount to a possible extent, while preventing elongation of the execution time of control of delaying the ignition timing or control of reducing the fuel supply amount. When the driving force of the vehicle is excessively large, a target driving force Fxt is computed. When an indicator value SAa indicating the degree of necessity of reducing the driving force is equal to or greater than a first reference value SAa1, the throttle opening is reduced so that the driving force of the vehicle decreases more slowly than the target driving force Fxt. When the indicator value SAa is equal to or greater than a second reference value SAa2 greater than the first reference value SAa1, in addition to the reduction of the throttle opening, the ignition timing is delayed so that the driving force of the vehicle decreases faster than does in the case where only the reduction of the throttle opening is performed.

Owner:TOYOTA JIDOSHA KK

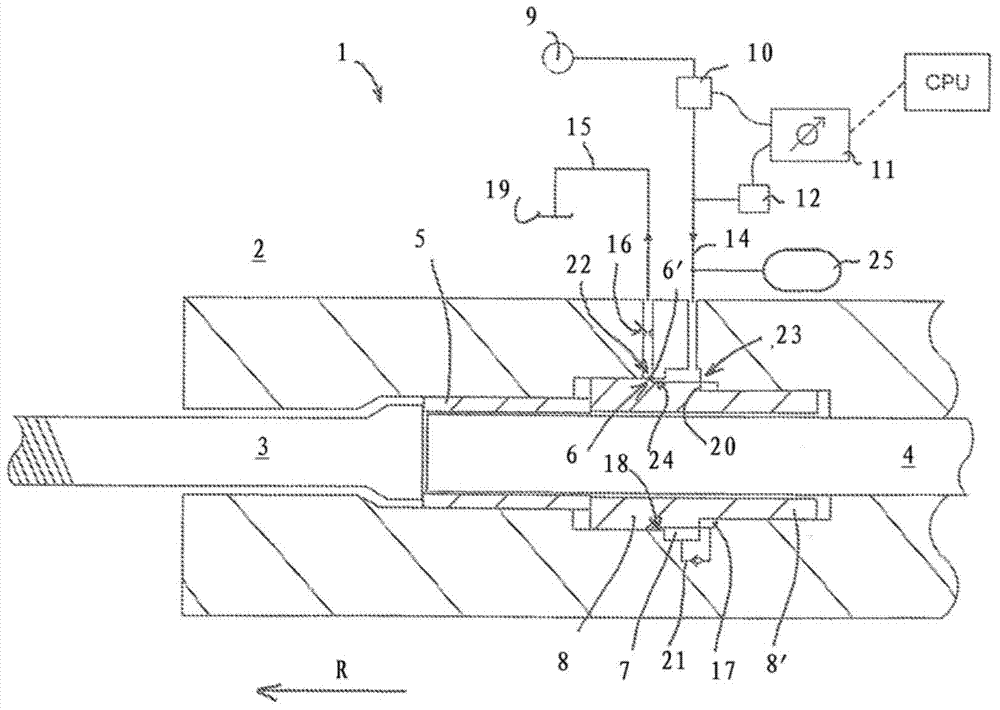

Damping device for percussion device, percussion device, rock drilling machine and method of damping in a rock drilling machine

ActiveCN104755230ASave energyReduce buffer flowReciprocating drilling machinesConstructionsControl signalEngineering

Damping device for a percussion device of a rock drilling machine (1) having a striking direction (R), including a damping piston (8) for action in an axial direction against a tool to be driven by the percussion device, wherein the damping piston (8) exhibits a piston portion (6), which is received in a damping chamber (7) whereto is connected a damping flow circuit including a supply conduit (14), and wherein an outlet conduit (15) is connected to the damping chamber. A damping flow regulator (10) being controllable in respect of damping flow in the damping flow circuit is arranged in said supply conduit (14), and a control means (11) is arranged to emit control signals to the damping flow regulator (10) for regulating said damping flow. The invention also concerns a percussion device, a rock drilling machine and a method.

Owner:EPIROC ROCK DRILLS AB

Bridge type concentric constant pressure water distributor

The invention discloses a bridge type concentric constant pressure water distributor. The bridge type concentric constant pressure water distributor comprises an upper joint, a positioning platform, aconcentric adjusting sleeve, an outer protective casing, an adjusting mechanism, a main structure and a lower joint. The outer protective casing is connected to one end of the upper joint, the main structure is connected to the other end of the outer protective casing, and the lower joint is connected to the other end of the main structure. One end of the positioning platform is installed insidethe upper joint in a sleeved mode, and the main structure is connected to the other end of the positioning platform. One end of the concentric adjusting sleeve is installed inside the positioning platform in a sleeved mode, and the main structure is connected to the other end of the concentric adjusting sleeve. The upper joint, the positioning platform, the concentric adjusting sleeve, the outer protective casing, the main structure and the lower joint are centrally penetrated and coaxially arranged, the adjusting mechanism is installed and pressed tightly between the main structure and the outer protective casing in a sleeved mode, and the concentric adjusting sleeve meshes with one end of the adjusting mechanism. The design combining electric direct adjustment of downhole flow and a constant pressure control technology is adopted in the bridge type concentric constant pressure water distributor, the flow control effect is improved, and the voltage stabilization and constant voltage control are realized.

Owner:PETROCHINA CO LTD

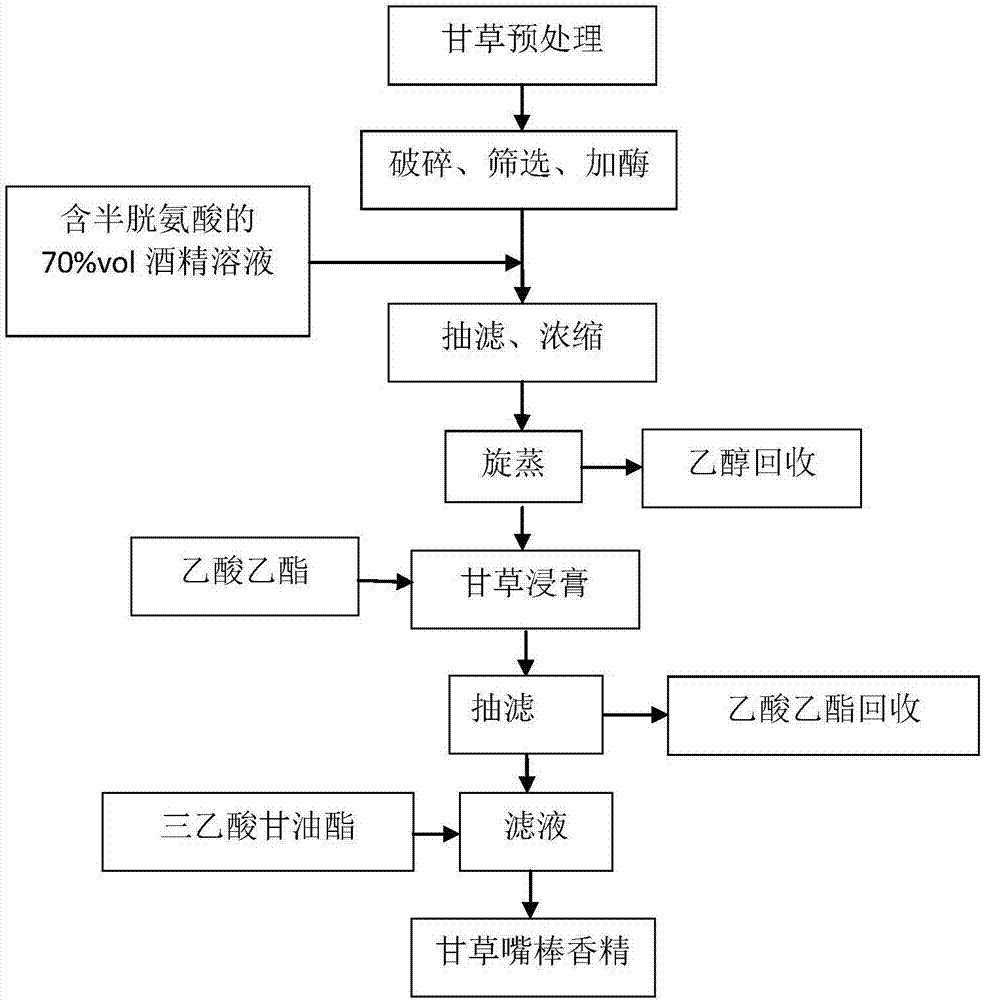

Preparation method of glycyrrhiza sweetening and moistening essence for mouth stick

ActiveCN107057856AAvoid lossAvoid pyrolysisTobacco smoke filtersEssential-oils/perfumesAlcoholIrritation

The invention belongs to the technical field of tobacco flavors and in particular relates to a method of preparing essence of a mouth stick for a cigarette by taking glycyrrhiza as extract. The essence is used for improving sucking sweet feel of tobacco and enhancing the sensing comfort, so that the sucking quality of tobacco is effectively enhanced. The preparation method of glycyrrhiza sweetening and moistening essence for the mouth stick comprises the following steps: enzymolysis, alcohol extraction, extraction and the like. The prepared essence is directly added in a mouth stick processing step, so that escape and pyrolysis of essence in the storage and ignition and suction processes of tobacco are avoided, the loss of flavors in static igniting period of the tobacco can be also avoided, throttling of cut tobacco and filter tip on the flavors can be reduced, and the transfer efficiency is increased. The glycyrrhiza sweetening and moistening essence for the mouth stick prepared by the invention can remarkably improve the quality of fragrance of the cigarette, reduce the irritation and improve the quality of the cigarette.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

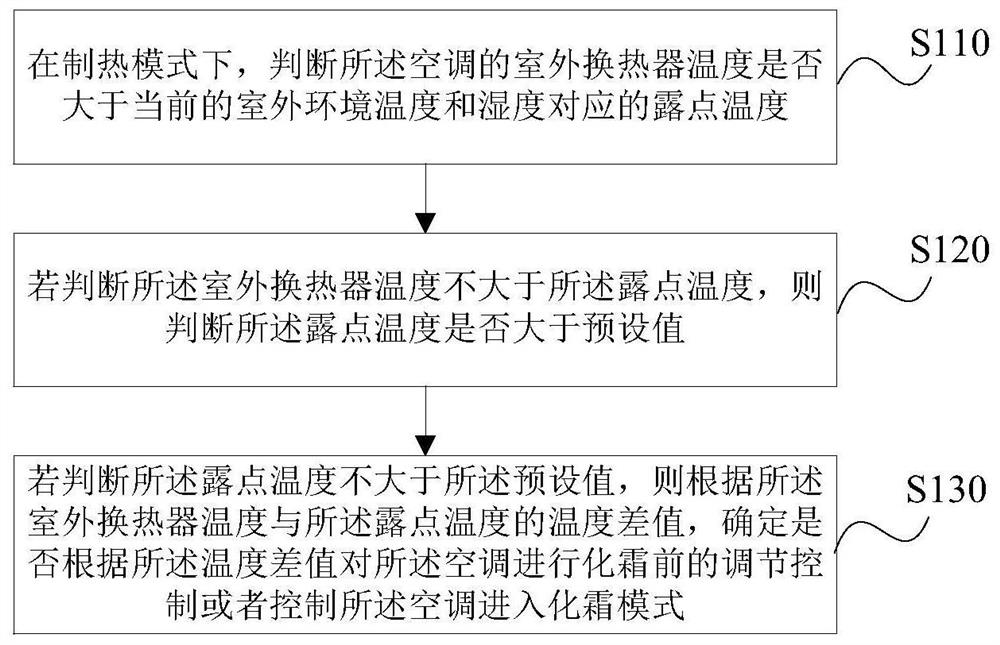

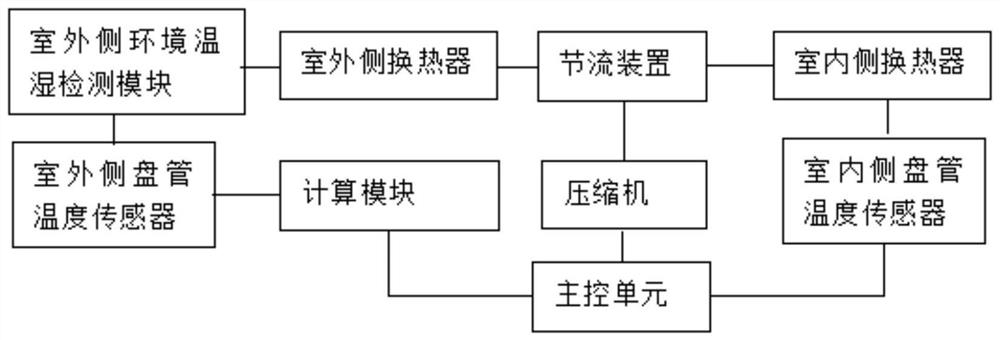

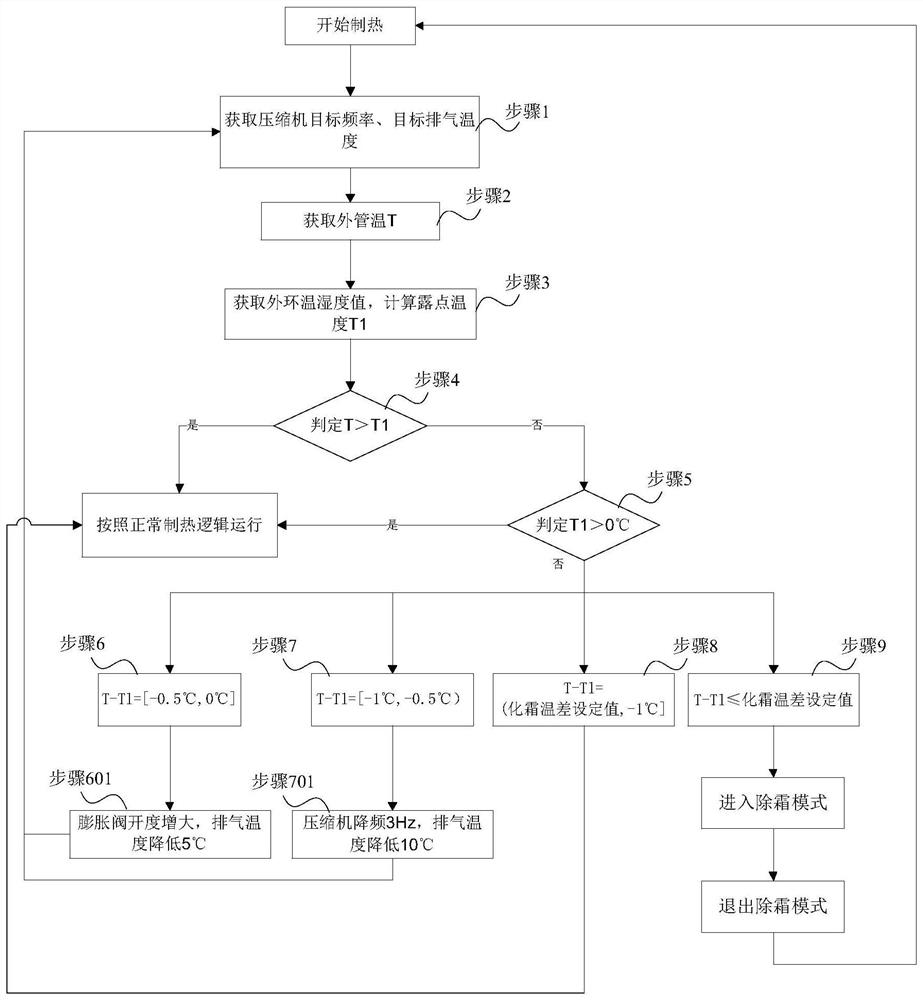

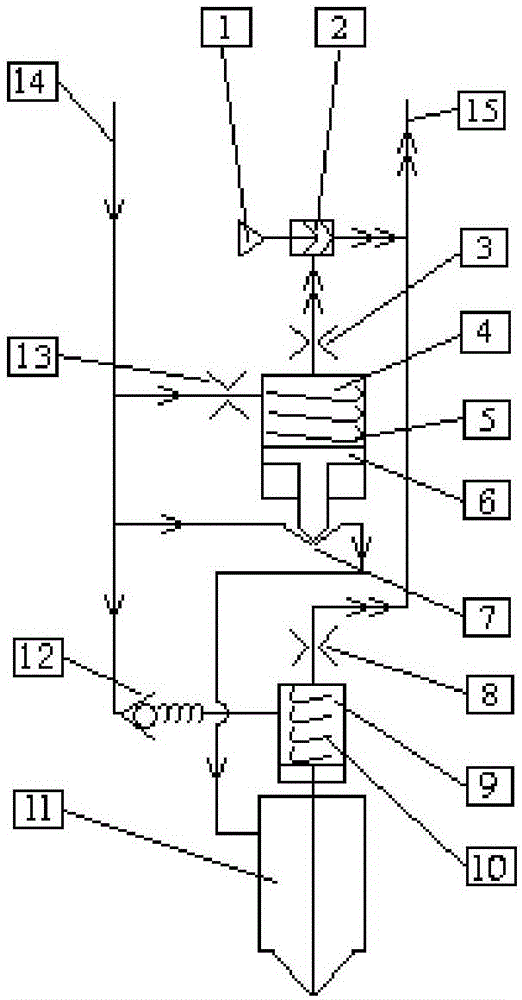

Air conditioner control method and device, storage medium and air conditioner

ActiveCN112283878AReduce energy lossImprove user experienceMechanical apparatusSpace heating and ventilation safety systemsProcess engineeringTemperature difference

The invention provides an air conditioner control method and device, a storage medium and an air conditioner. The method comprises the steps that under a heating mode, whether the temperature of an outdoor heat exchanger of the air conditioner is larger than the dew point temperature corresponding to the current outdoor environment temperature and humidity or not is judged; if it is judged that the temperature of the outdoor heat exchanger is not larger than the dew point temperature, whether the dew point temperature is larger than a preset value or not is judged; and if it is judged that thedew point temperature is not larger than the preset value, whether adjustment control before defrosting is conducted on the air conditioner or whether the air conditioner is controlled to enter a defrosting mode or not is determined according to the temperature difference value between the temperature of the outdoor heat exchanger and the dew point temperature. According to the scheme, the defrosting condition can be optimized and judged, useless energy consumption loss of the air conditioner is reduced, and the defrosting time is delayed.

Owner:GREE ELECTRIC APPLIANCES INC

Novel electrically-controlled oil injector

ActiveCN106089522AOpen resistance is smallOpen fastFuel injection apparatusMachines/enginesHigh pressureElectromagnetic valve

The present invention provides a novel electrically-controlled oil injector, comprising an electromagnetic valve, a control piston, a control cavity, a one-way valve, a needle valve cavity, an oil nozzle, a high-pressure oil line and a low-pressure oil line; the high-pressure oil line includes three branches, one branch leads to the control cavity through an oil inflow hole and then leads to the low-pressure oil line through an oil outflow hole, another branch leads to the oil nozzle through a lower end valve of the control piston, the remaining branch leads to the oil nozzle needle valve cavity through the one-way valve and then leads to the low-pressure oil line through a throttle hole, and the control piston is never rigidly connected with the oil nozzle. The novel electrically-controlled oil injector has the advantages that pressure of the oil nozzle needle valve cavity is turned into low pressure so that it is possible to reduce opening resistance for an oil nozzle needle valve; the control piston is used to actively control opening and closing of the high-pressure oil line leading to the oil nozzle so that it is possible to reduce closing resistance for the oil nozzle needle valve; the one-way valve is used to increase an oil line leading to the upper end control cavity of the oil nozzle so that it is possible to increase closing power for the oil nozzle needle valve. It is possible to greatly increase the opening and closing speed of the oil nozzle needle valve, thereby increasing oil injection.

Owner:CHINA NORTH ENGINE INST TIANJIN

Driving force controller for vehicle

ActiveUS8515632B2Reduce the driving forceIncrease temperatureElectrical controlDigital data processing detailsIgnition timingThrottle opening

An object of the present invention is to effectively reduce driving force of a vehicle, when the driving force of the vehicle must be reduced, while avoiding an increase in the temperature of exhaust gas and resultant deterioration of an exhaust gas purification catalyst, the object being achieved by effectively utilizing delaying of the ignition timing or reduction of the fuel supply amount to a possible extent, while preventing elongation of the execution time of control of delaying the ignition timing or control of reducing the fuel supply amount. When the driving force of the vehicle is excessively large, a target driving force Fxt is computed. When an indicator value SAa indicating the degree of necessity of reducing the driving force is equal to or greater than a first reference value SAa1, the throttle opening is reduced so that the driving force of the vehicle decreases more slowly than the target driving force Fxt. When the indicator value SAa is equal to or greater than a second reference value SAa2 greater than the first reference value SAa1, in addition to the reduction of the throttle opening, the ignition timing is delayed so that the driving force of the vehicle decreases faster than does in the case where only the reduction of the throttle opening is performed.

Owner:TOYOTA JIDOSHA KK

Fluid-filled, frequency-dependent damper

A fluid-filled, frequency-dependent damper comprises a cylinder connected to a cylinder attachment portion; a piston connected to a piston attachment portion, the piston being displaceable in the cylinder; a first main chamber; a second main chamber; and a throttling member for allowing and influencing a fluid flow between the first and second main chambers within the damper when the cylinder attachment portion and the piston attachment portion move away from and / or move towards each other. The throttling member comprising an auxiliary cylinder and an auxiliary piston provided in the auxiliary cylinder. The auxiliary piston divides the auxiliary cylinder in a first auxiliary chamber comprising a first opening providing a fluid connection of the first auxiliary chamber with one of the first and second main chambers, the first opening being closable by a first part of the auxiliary piston, and a second opening providing a fluid connection of the first auxiliary chamber with the other one of the first and second main chambers; and a second auxiliary chamber in fluid connection with the other one of the first and second main chambers via a throttling passage. The first opening is closed by the auxiliary piston in a rest position and is opened by movement of the auxiliary piston in the auxiliary cylinder.

Owner:KONI BV

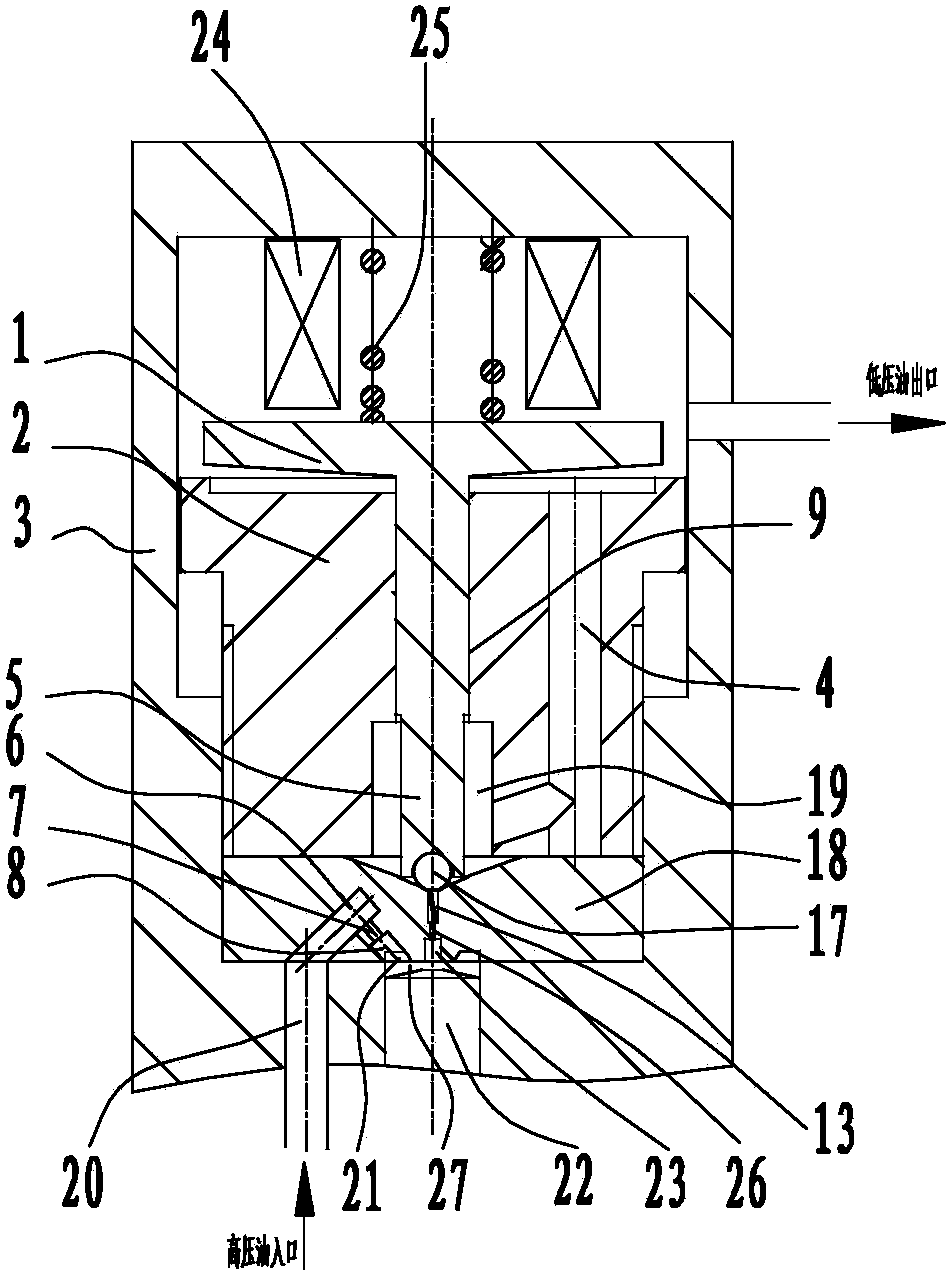

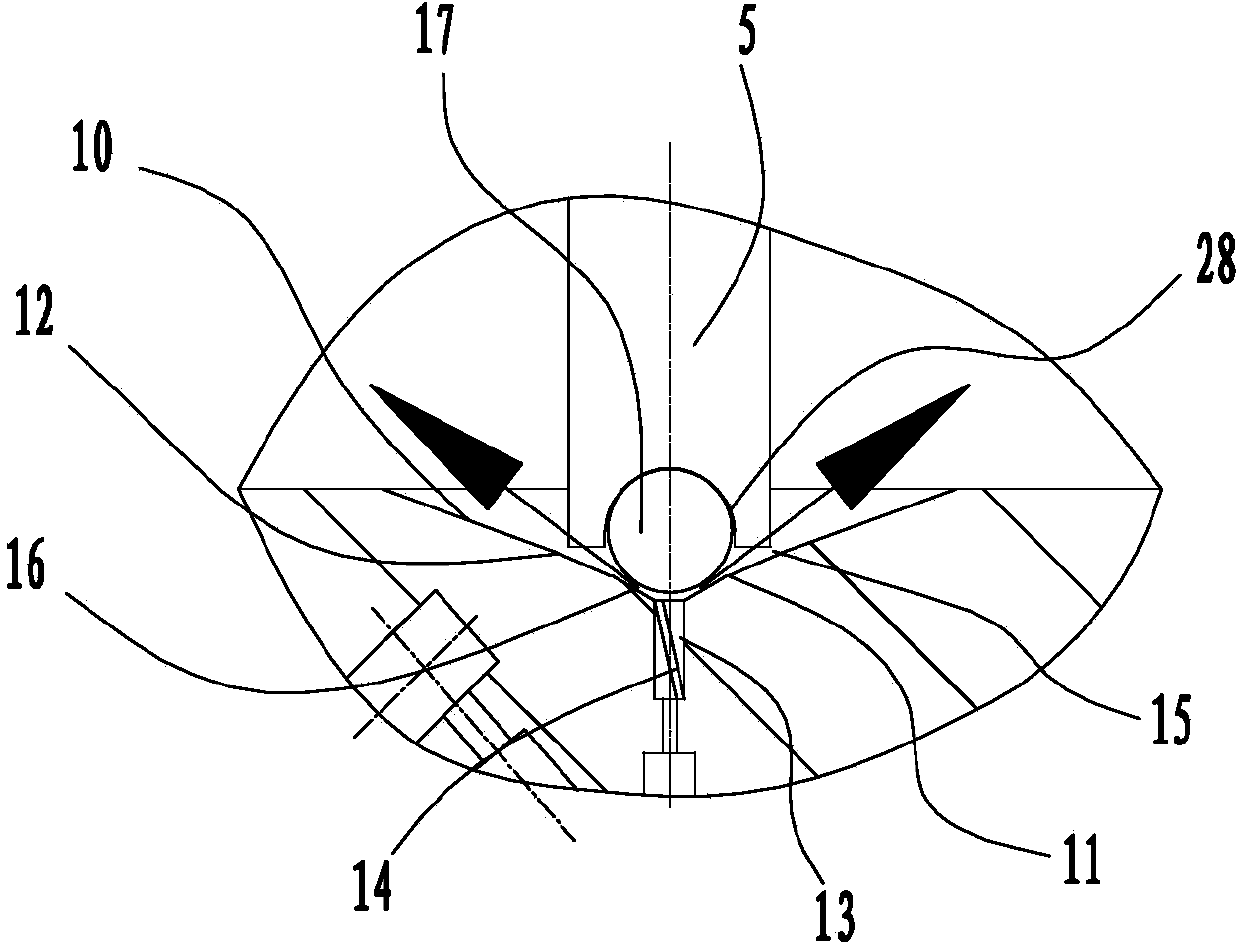

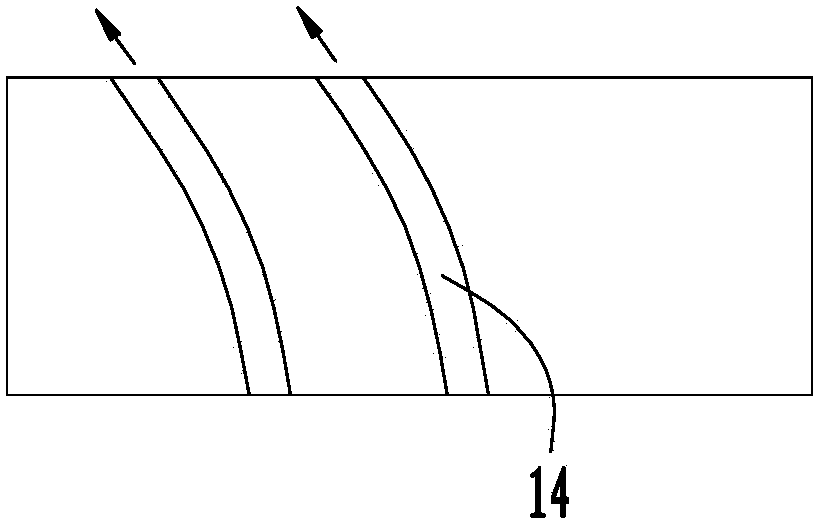

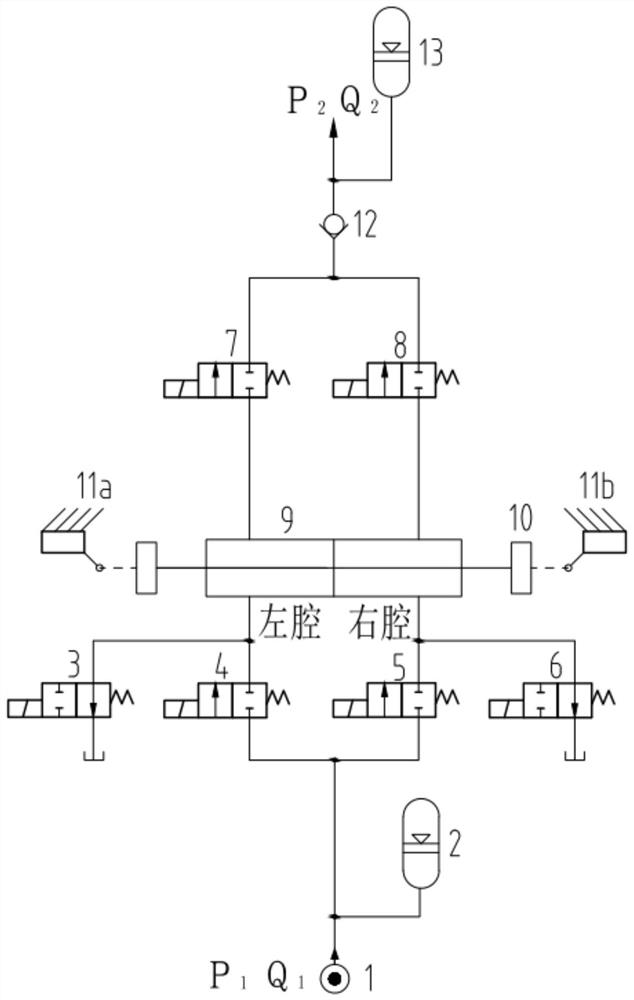

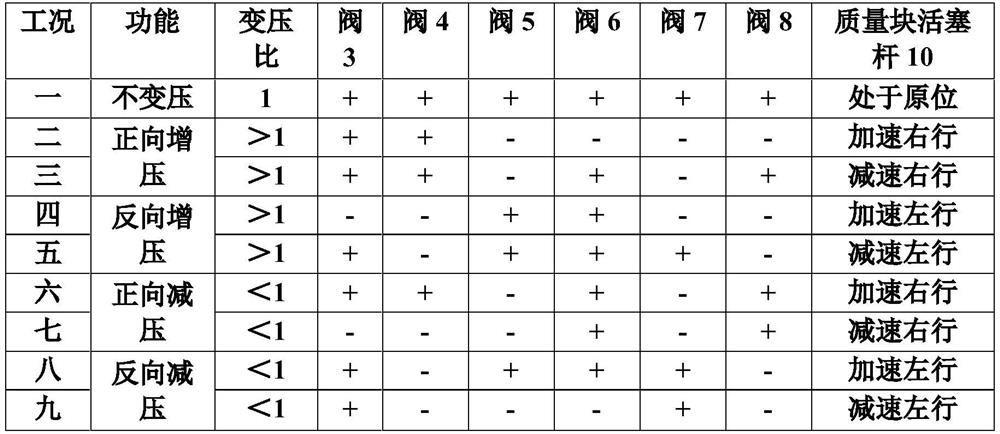

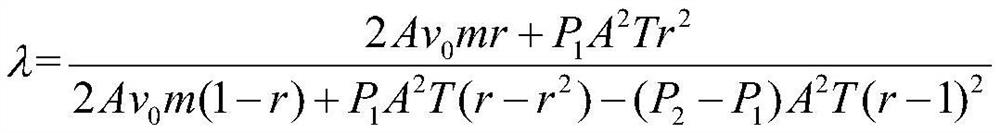

Continuous transformation large-transformation-range hydraulic transformer for high speed valve-controlled hydraulic cylinder

ActiveCN111706558AReduce throttlingEasy to controlAccumulator installationsFluid-pressure convertersHydraulic cylinderHydraulic ram

The invention provides a continuous transformation large-transformation-range hydraulic transformer for a high speed valve-controlled hydraulic cylinder. The transformer comprises a hydraulic oil cylinder; mass blocks are arranged at two ends of a piston rod of the hydraulic oil cylinder; the piston rod and the mass blocks constitute a mass block piston rod; and stroke switches are respectively arranged at stroke ends on the left and the right of the mass block piston rod. Through the combination of a one-way valve and a high-speed switch valve, flow direction of oil liquid is controlled, andwith the addition of an energy accumulator, continuous flow borne by flow direction of the one-way valve is realized. The integral structure is laterally symmetrical; the pressurization process and the depressurization process are functionally theoretically symmetrical; forward pressurization and reverse pressurization in the pressurization process are functionally theoretically symmetrical; and forward depressurization and reverse depressurization in the depressurization process are functionally theoretically symmetrical. Through the mutual conversion of hydraulic energy and kinetic energy ofthe mass block piston rod, continuous stepless transformation can be realized on the premise that the structure of a hydraulic cylinder is unchanged; a required hydraulic transformation ratio can beobtained through adjusting the duty ratio of a PWM signal; and the control is convenient, the structure is simple, and zero vibration or noise is realized.

Owner:XUZHOU NORMAL UNIVERSITY

Damper device of a hydraulic unit of a vehicle brake device with a damper chamber

A damper device (10) of a hydraulic unit of a vehicle brake device is designed with a damper chamber (26) whose chamber volume is variable, and a throttle (36) arranged downstream of the damper chamber (26). According to the invention, the throttle (36) has a variable throttling effect and this throttle effect is variable as a function of the chamber volume.

Owner:ROBERT BOSCH GMBH

Method for reducing maximal pressure of rail shared injector

InactiveCN104895690AReduce maximum pressureReduce manufacturing costElectrical controlFuel injection apparatusEngineeringOperation mode

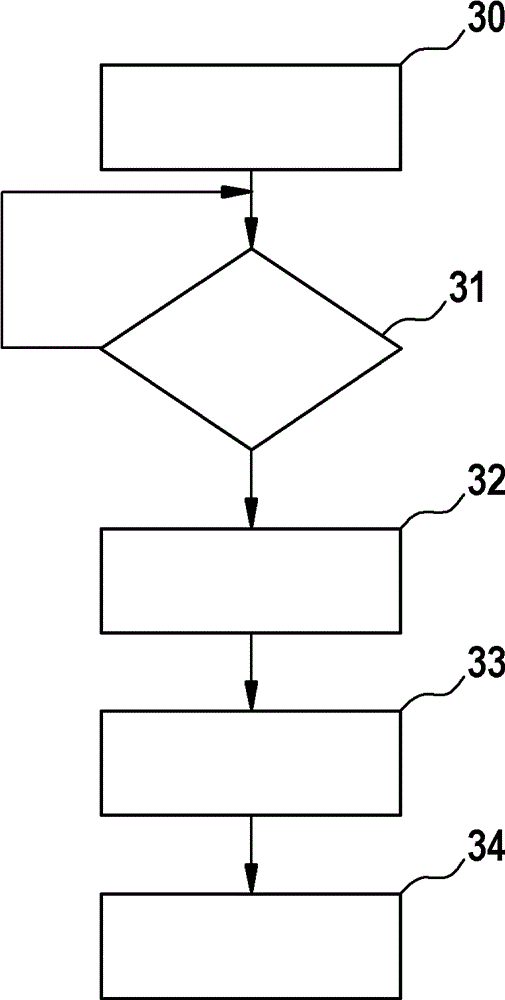

According to the embodiments of the invention, a method for reducing maximal pressure of rail shared injector in fault condition is provided. When a fault condition (31) is spotted, a special operation mode is initialized (32) for at least one rail shared injector (2). In this way, the maximal pressure in fault condition can be reduced without modifying other high voltage components or the design of rail shared injector. For these innovations, expensive manufacturing costs of injector (4), valve blocks (8) and injection nozzles (10) can be avoided.

Owner:ROBERT BOSCH GMBH

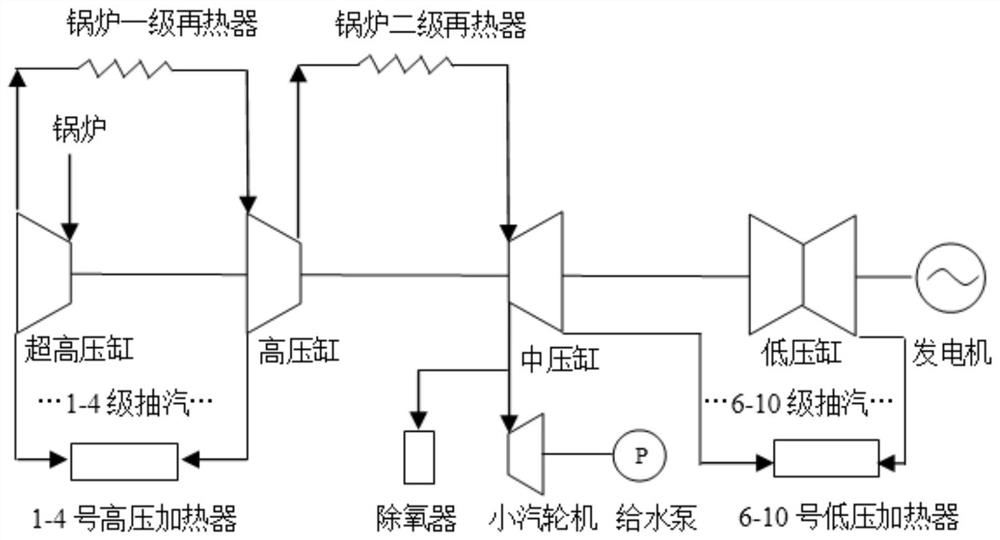

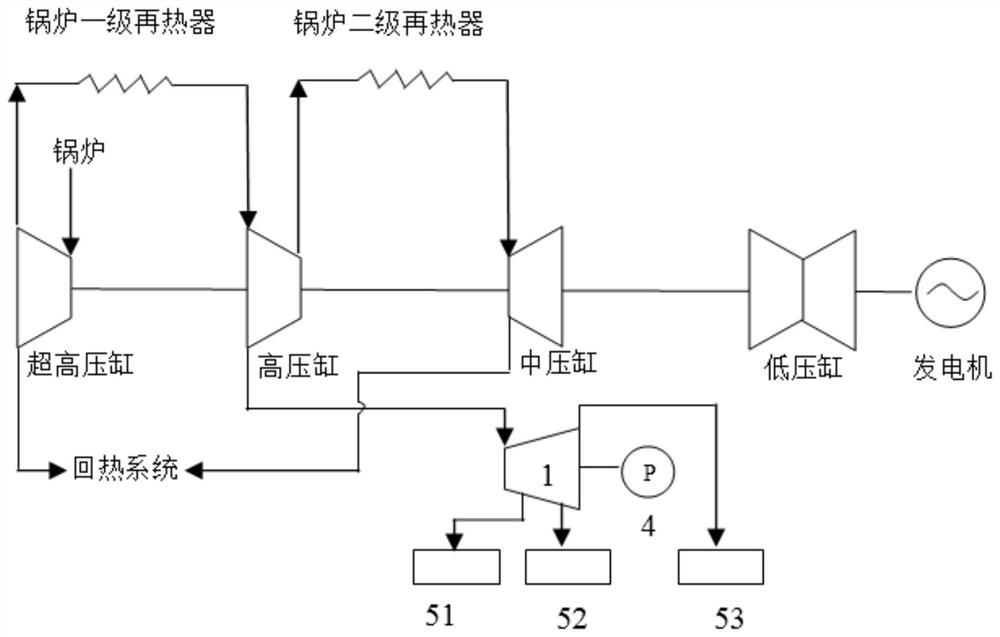

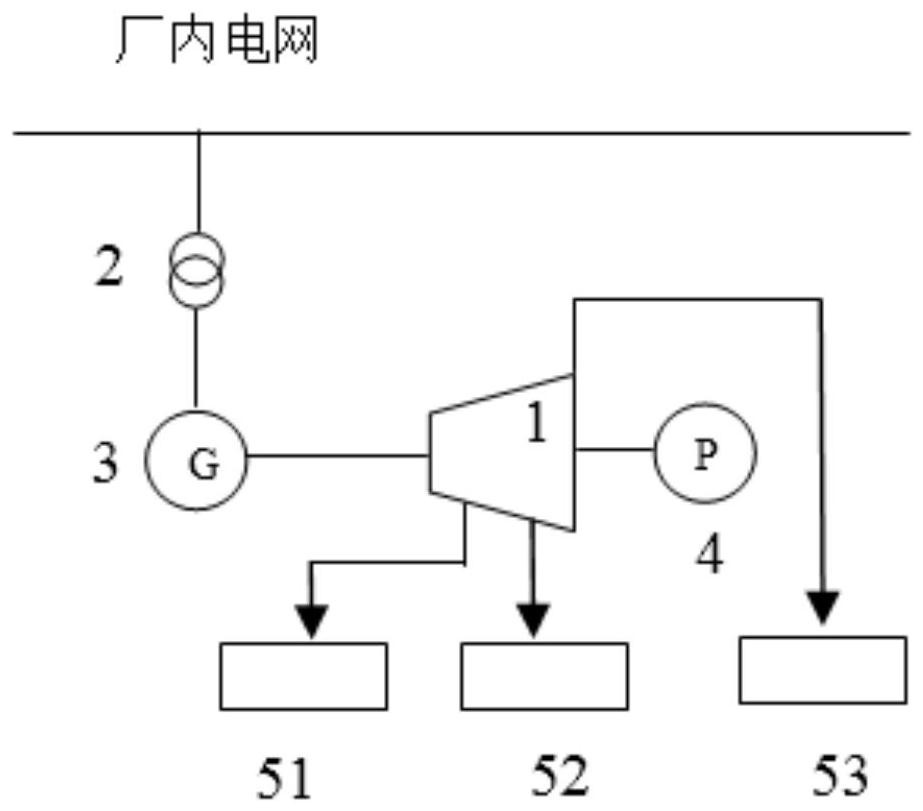

Thermodynamic system of extraction back pressure turbine and control method of thermodynamic system

ActiveCN113638776AImprove efficiencyImprove thermal economyLiquid degasificationEnergy industryUltra high pressureEngineering

The invention relates to a thermodynamic system of an extraction back pressure turbine and a control method of the thermodynamic system. According to the system, an ultrahigh pressure cylinder and an intermediate pressure cylinder are separately connected to a regenerative system; a high pressure cylinder is connected to a condensing turbine; and the turbine is connected to an auxiliary power grid through a generator motor and a converter. The control method comprises the steps that: a boiler is started, and the generator motor serves as a motor to drive the turbine and a feed pump shaft system to operate; after the turbine enters an impulse rotating mode, a turbine control valve is controlled to be enlarged, the turbine drags a feed pump to operate, and the generator motor operates as a generator; after the turbine rotates, the turbine and the feed pump enter a normal operation mode, the converter is adjusted to control and balance output of the turbine and the feed pump, and then the rotation speed of the feed pump is controlled; and when the converter and the motor generator break down, the turbine control valve is controlled to be turned down to prevent the turbine from overspeed. Compared with the prior art, the thermodynamic system has the advantages that the problem of a large heat transfer temperature difference can be solved, meanwhile, reliable operation of the system can be guaranteed, and the heat efficiency of the system is improved.

Owner:HUANENG POWER INT INC

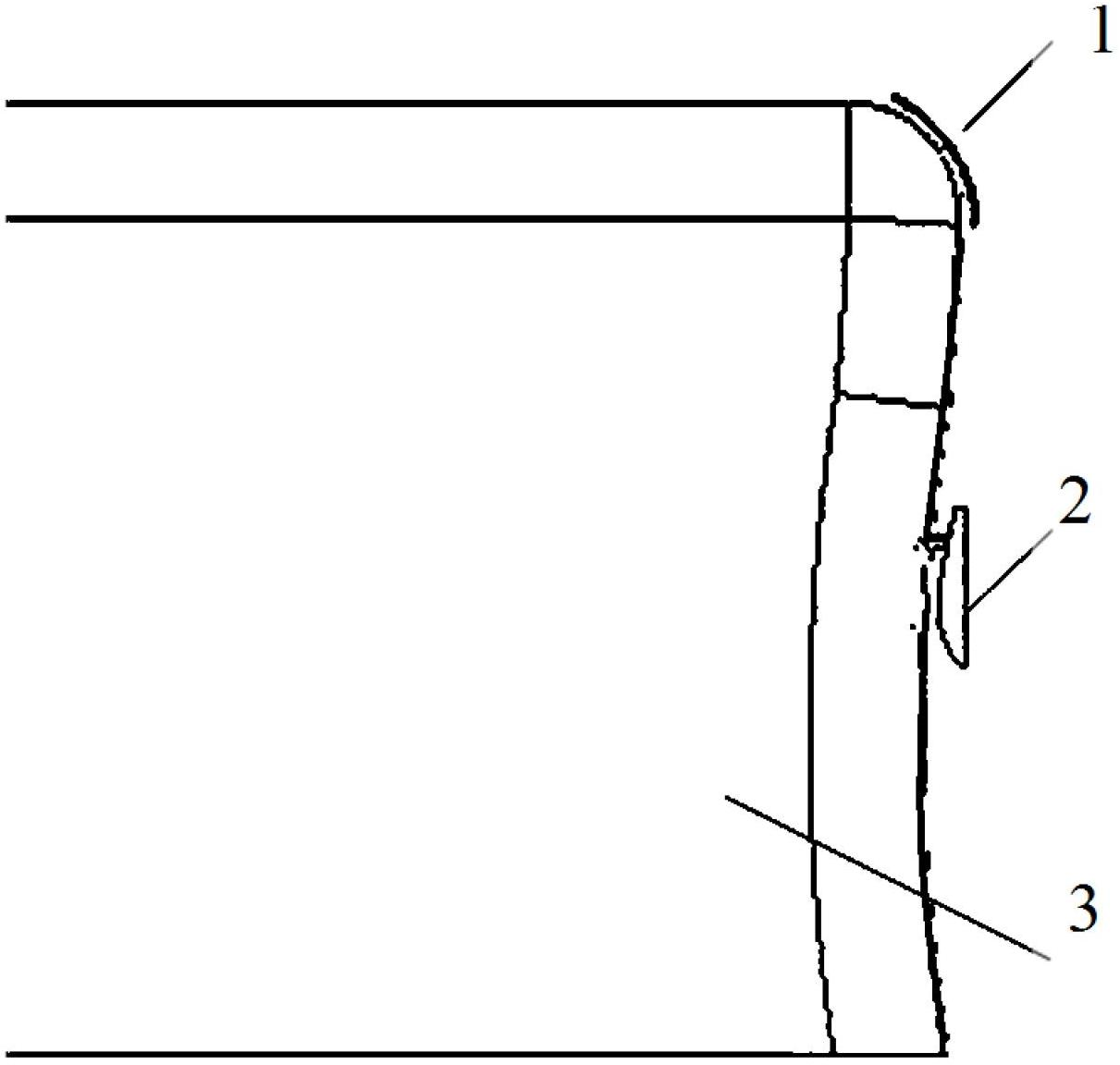

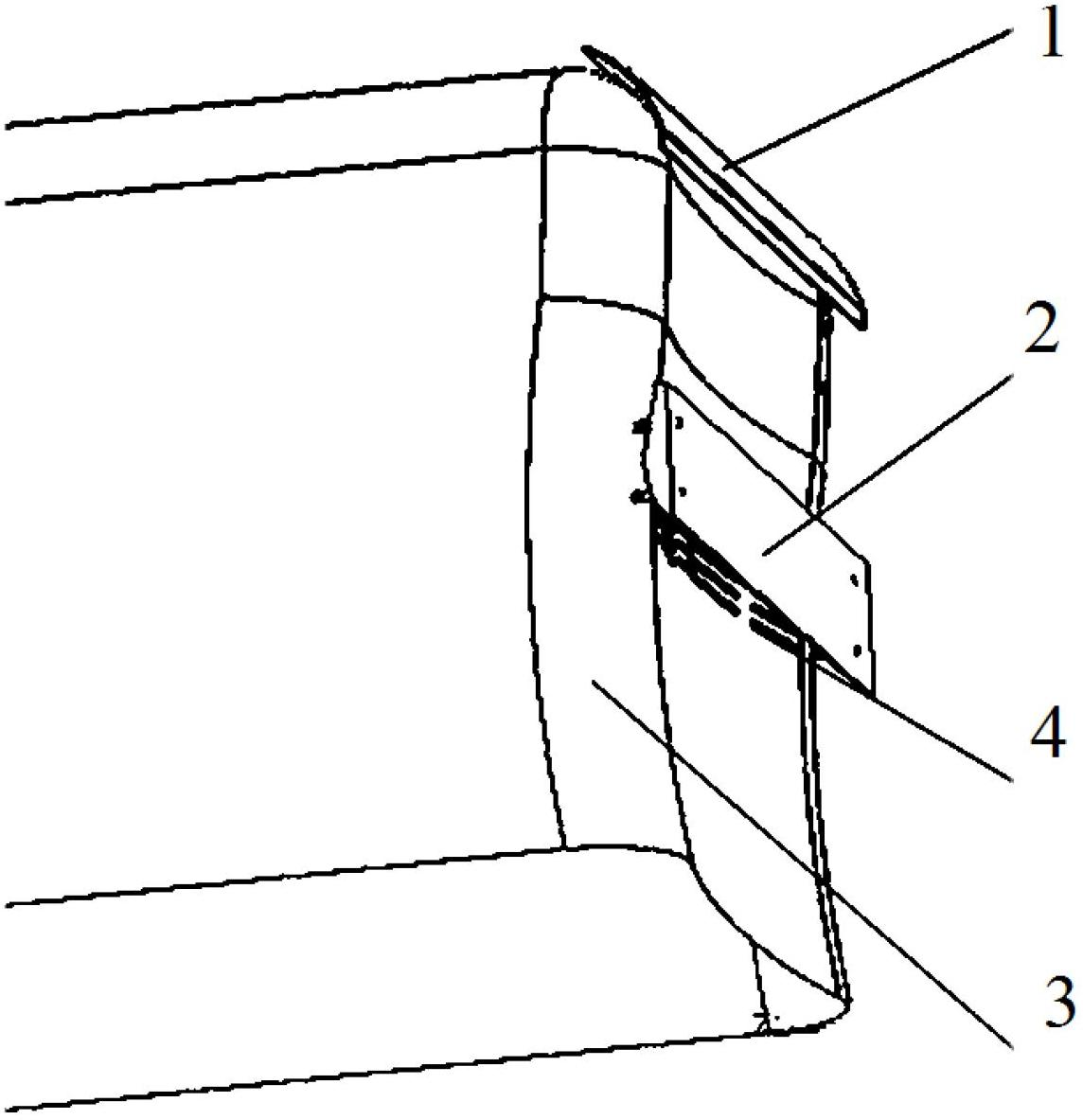

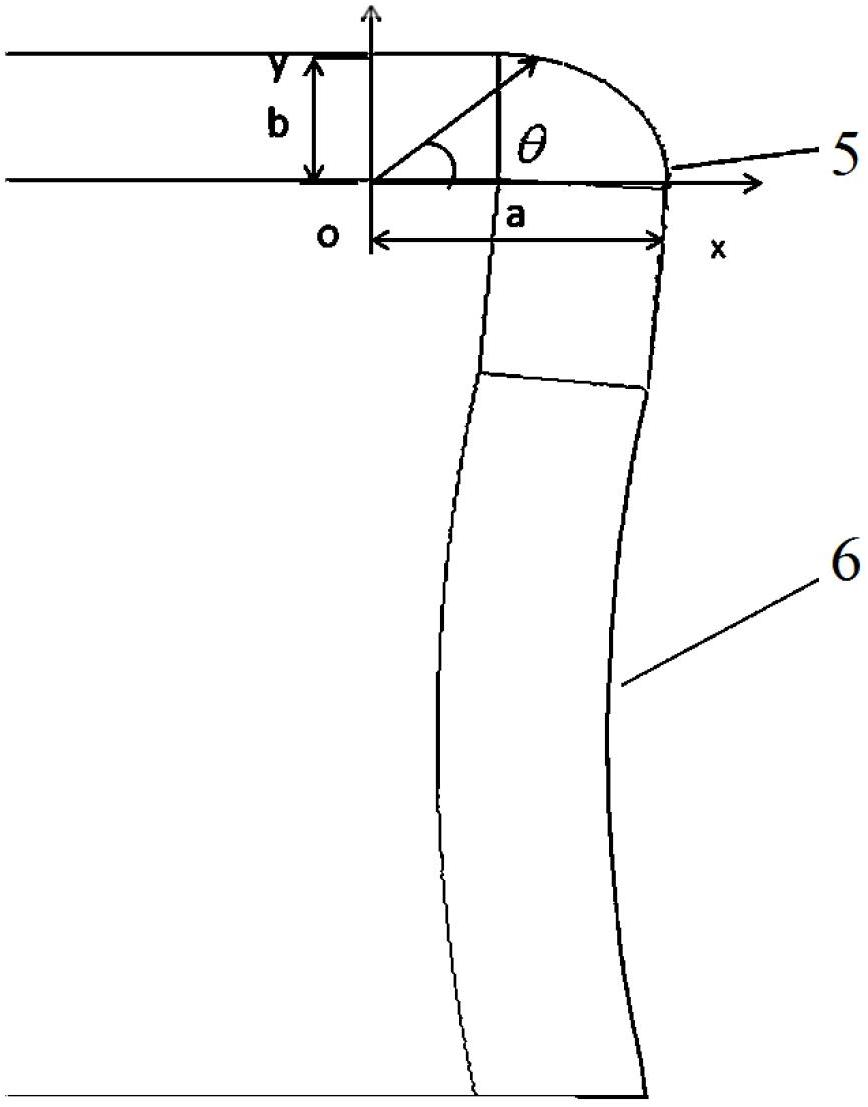

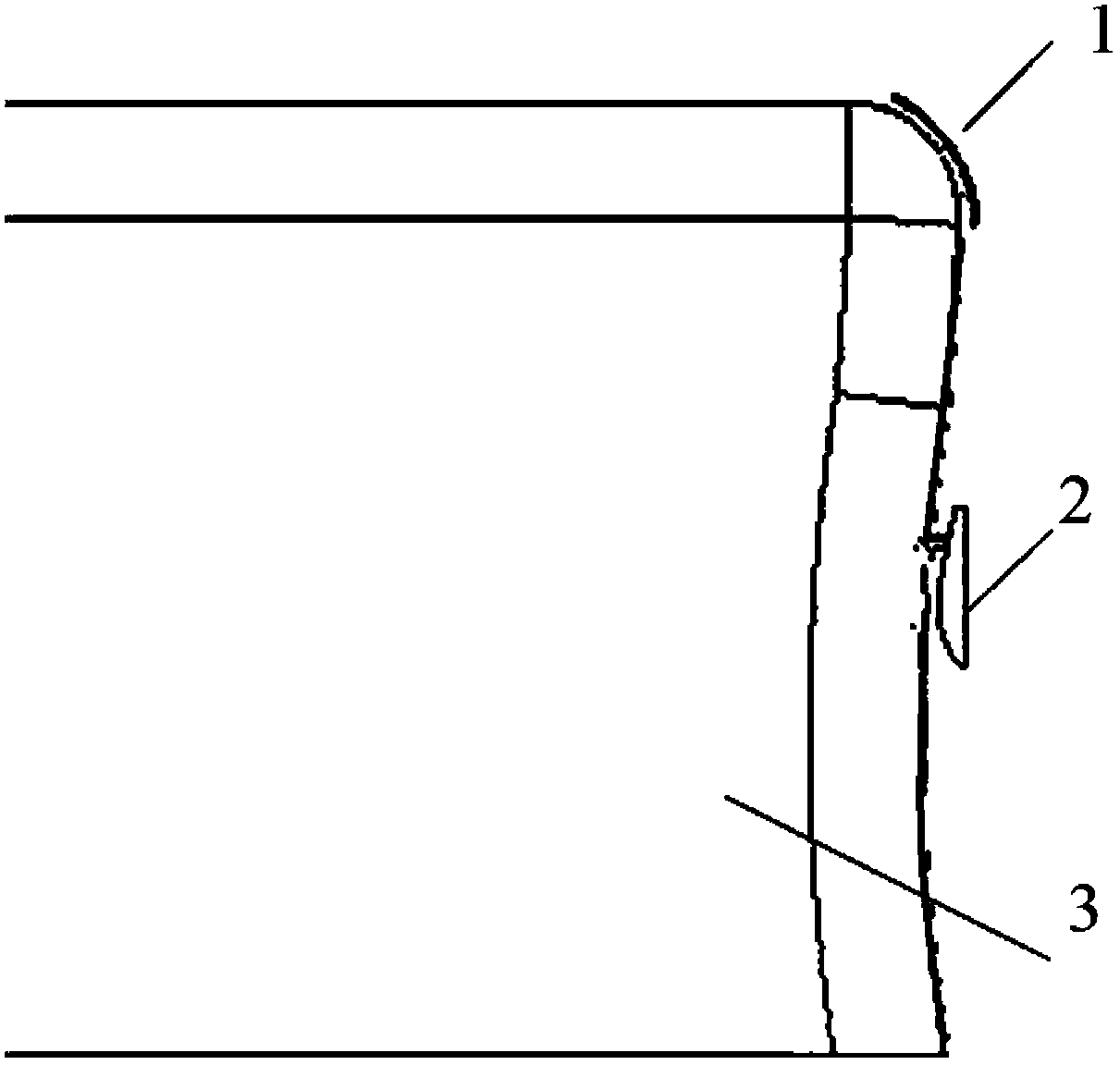

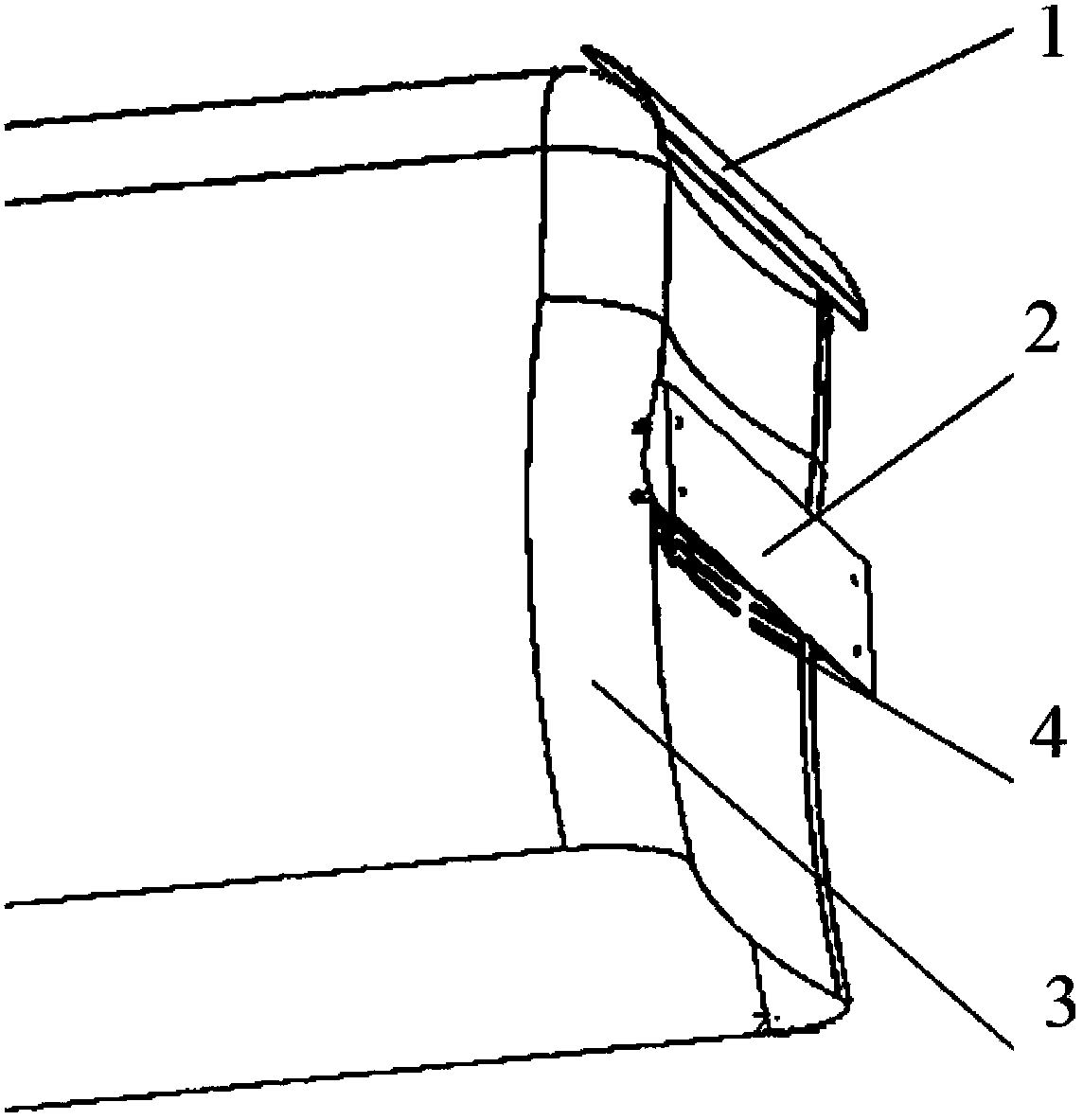

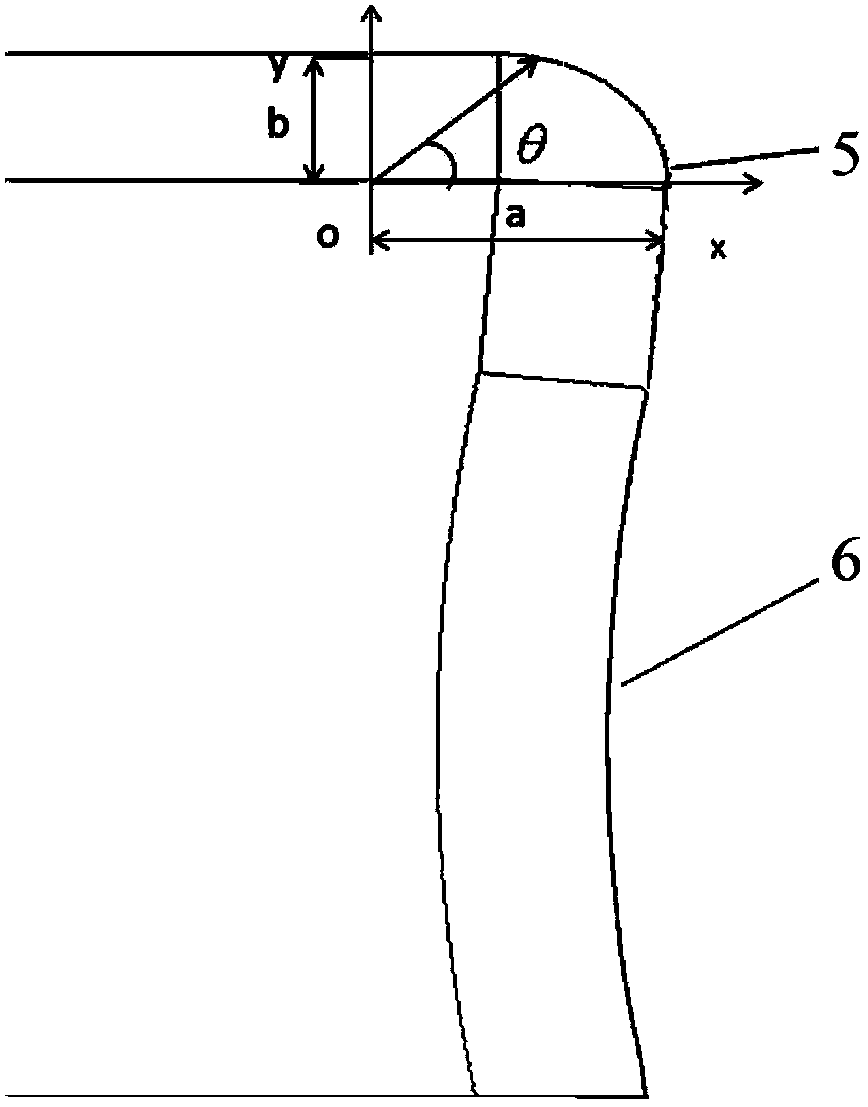

Passenger car rear body capable of effectively cooling engine cabin

InactiveCN102673656ASpeed up the flowImprove cooling effectSuperstructure subunitsVehicle body streamliningGratingHeat spreader

The invention discloses a passenger car rear body capable of effectively cooling an engine cabin. The passenger car rear body comprises the appearance shape of the rear body, an air-out grating and a convex streamline empennage. According to aerodynamic characteristics of a passenger car with a rear engine and a rear drive in running, a curve of a section of the engine cabin at the rear of the car is formed by combing a non-uniform rational B-spline with a lemniscate; and according to directions of airflow suction of a suction fan, the air-out grating is fan-shaped arc, a flow deflector is added at a transition position between the car roof and the car body, and the convex empennage is added behind the air-out grating. According to the passenger car rear body with the structure, throttling effect caused by air exhaust can be fully reduced, suction effect on air-out airflow can be realized, radiating performance of a radiator assembly of the car can be improved, airflow in the engine cabin can flow more smoothly, and possible overheating can be effectively lessened.

Owner:SHANDONG UNIV

Passenger car rear body capable of effectively cooling engine cabin

InactiveCN102673656BSpeed up the flowImprove cooling effectSuperstructure subunitsVehicle body streamliningGratingHeat spreader

The invention discloses a passenger car rear body capable of effectively cooling an engine cabin. The passenger car rear body comprises the appearance shape of the rear body, an air-out grating and a convex streamline empennage. According to aerodynamic characteristics of a passenger car with a rear engine and a rear drive in running, a curve of a section of the engine cabin at the rear of the car is formed by combing a non-uniform rational B-spline with a lemniscate; and according to directions of airflow suction of a suction fan, the air-out grating is fan-shaped arc, a flow deflector is added at a transition position between the car roof and the car body, and the convex empennage is added behind the air-out grating. According to the passenger car rear body with the structure, throttling effect caused by air exhaust can be fully reduced, suction effect on air-out airflow can be realized, radiating performance of a radiator assembly of the car can be improved, airflow in the engine cabin can flow more smoothly, and possible overheating can be effectively lessened.

Owner:SHANDONG UNIV

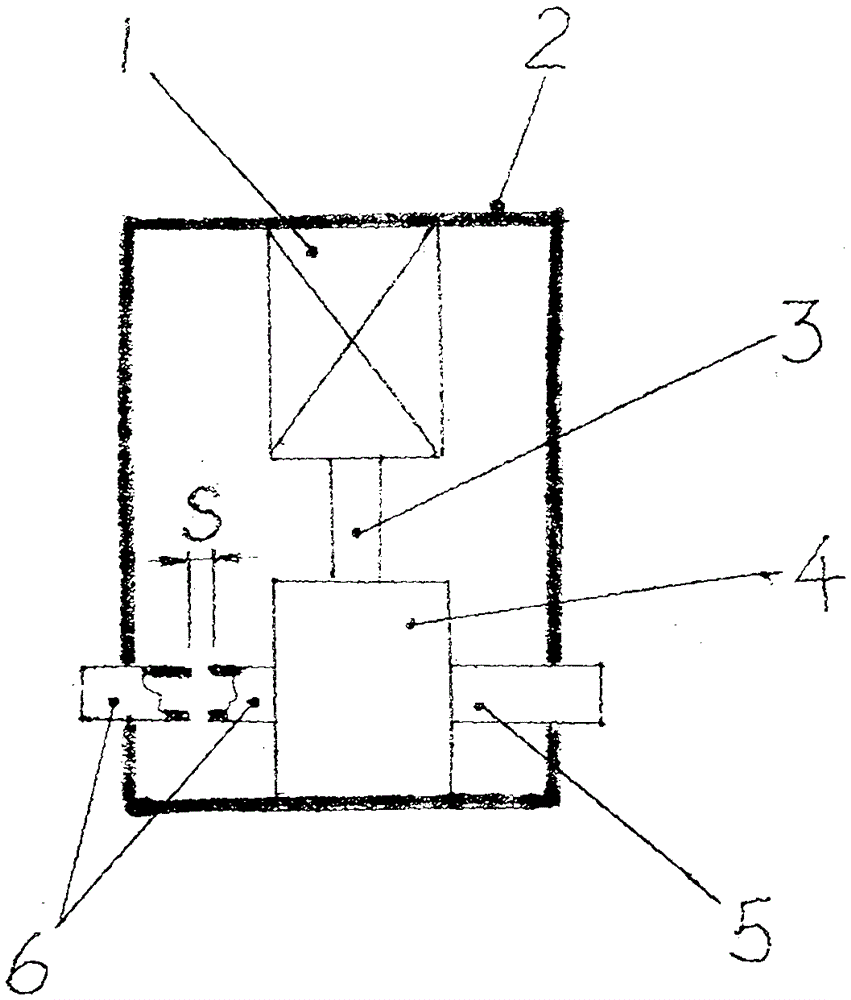

Air pump structure device that can reduce or eliminate air leakage during operation

InactiveCN102654122BNot easy to cause "throttling" lossThe degree of absolute containment of external leakagePositive displacement pump componentsPositive-displacement liquid enginesEngineeringAtmosphere

The invention provides an improved scheme of an air pump structure capable of reducing or avoiding air leakage in an operation process. The typical type is as follows: on the basis of the existing conventional and common air pump structure form, a metal shell (2) for implementing a three-dimensional surrounding property on an air pump (4) is additionally arranged; one part of an air inlet pipe (6), which is located in the middle of an inner cavity of the shell (2), is provided with a cut part with a seam width (S); or on the basis, a sealing structure treatment of seam splicing and pipe connection is solved through a welding process. The improved highest form is that the problem of stopping leakage is considered by completely avoiding the magnitude degree of gas molecules leaked by the structure. The key design idea is realized by that: the air pump (4) is allowed to inevitably leak gas from the inner part; however, the possibly-leaked gas is not structurally allowed to continually enter an atmosphere space. The 'cost performance' of the improved scheme is very high and the use scope is obvious.

Owner:CHINA JILIANG UNIV

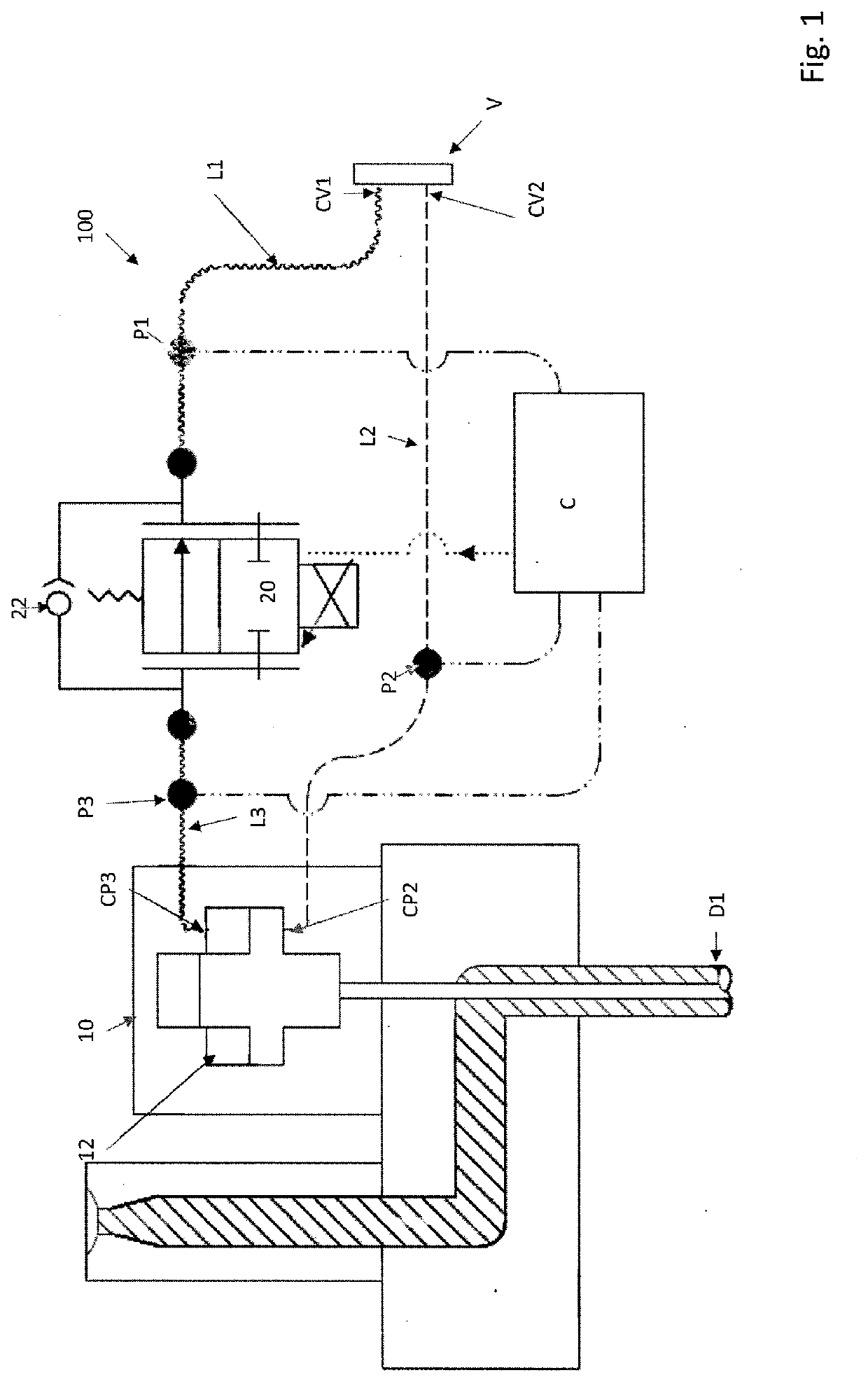

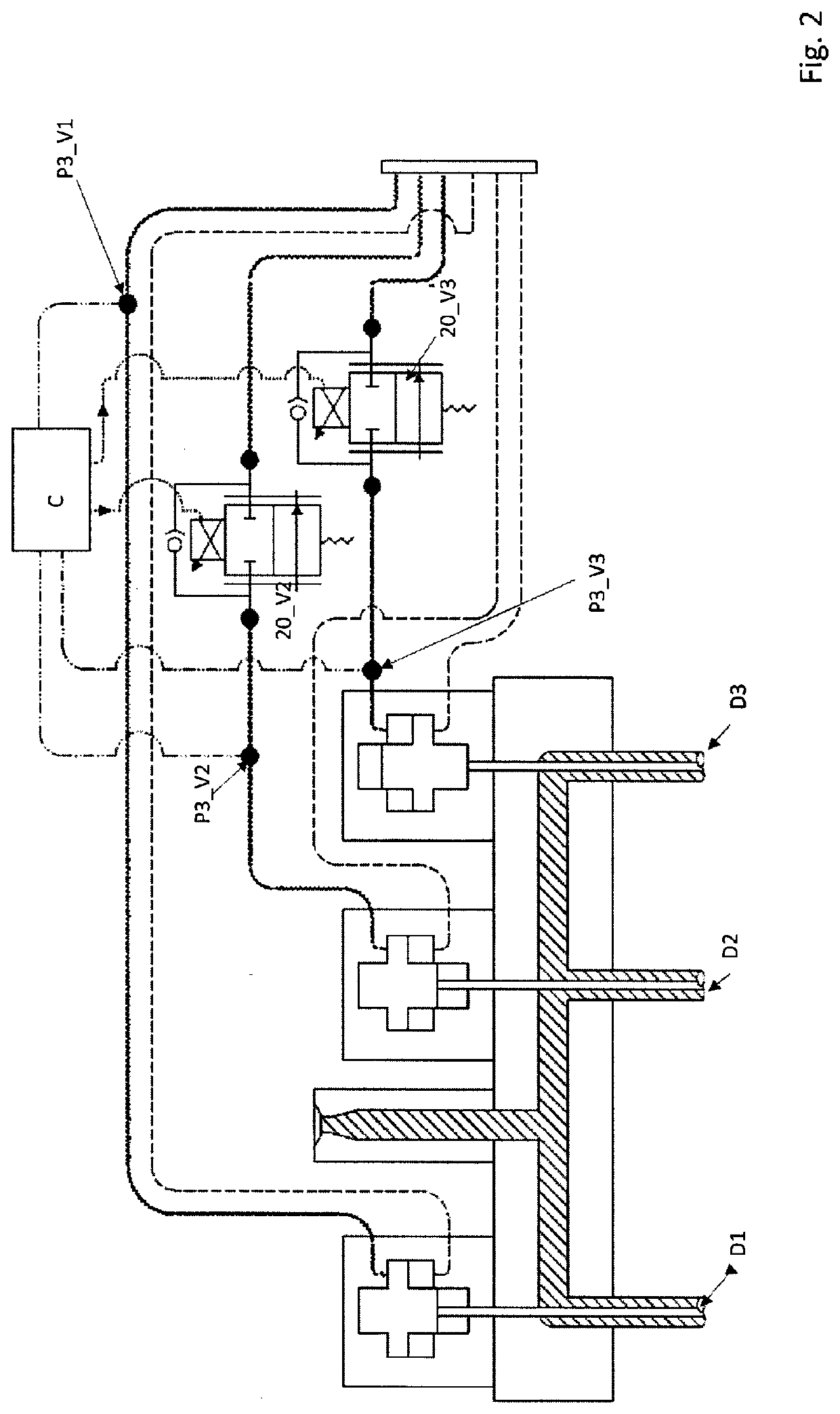

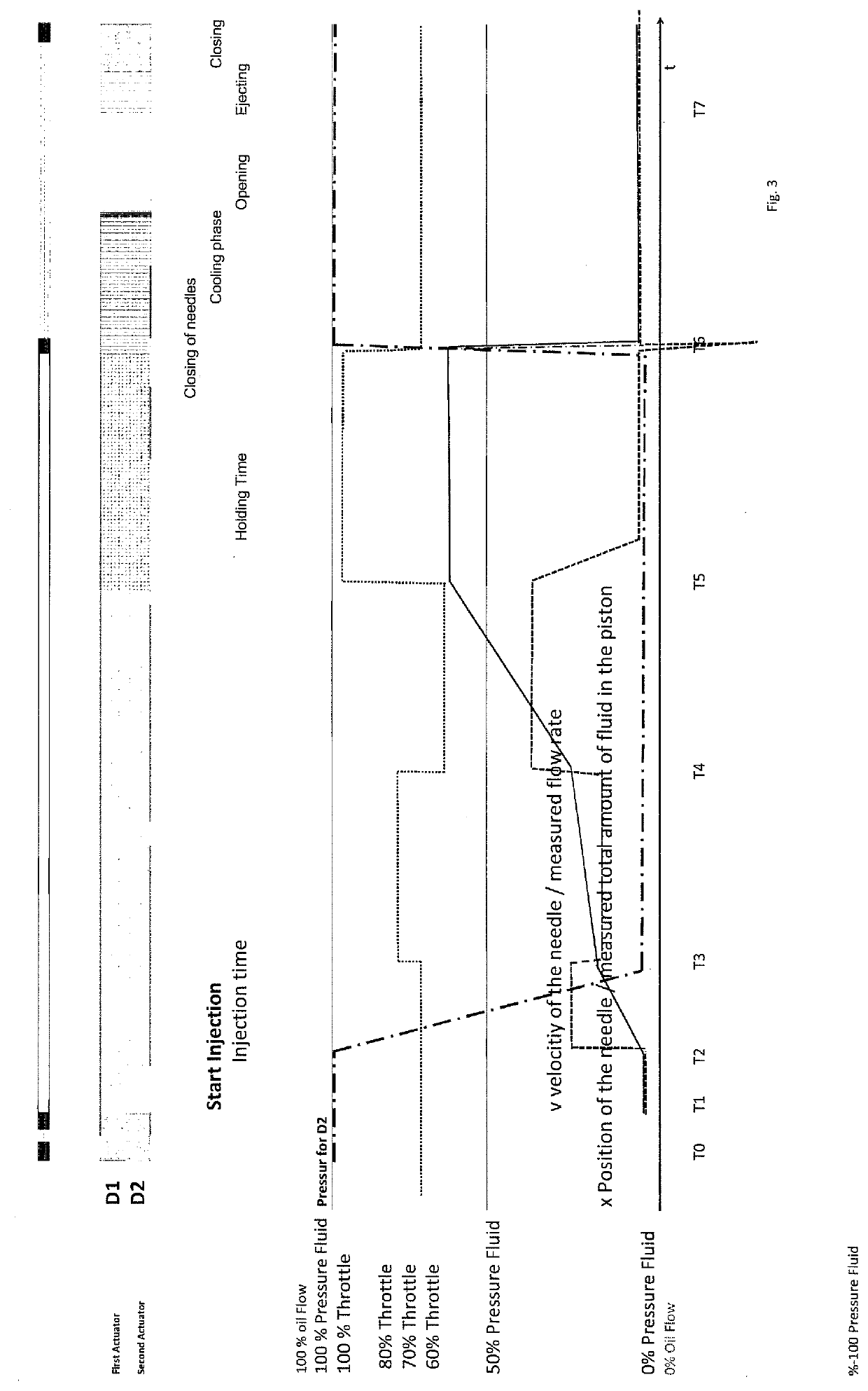

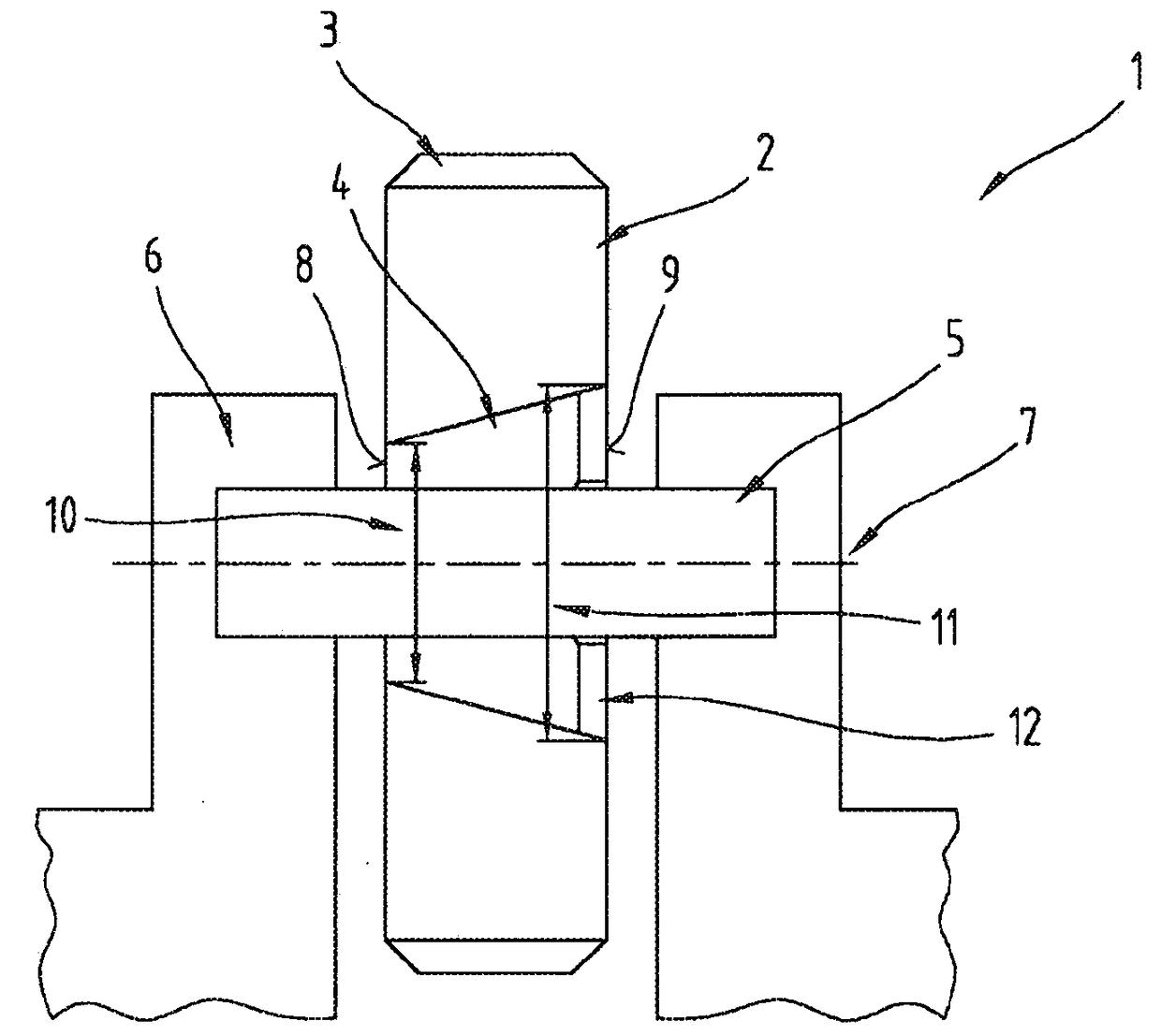

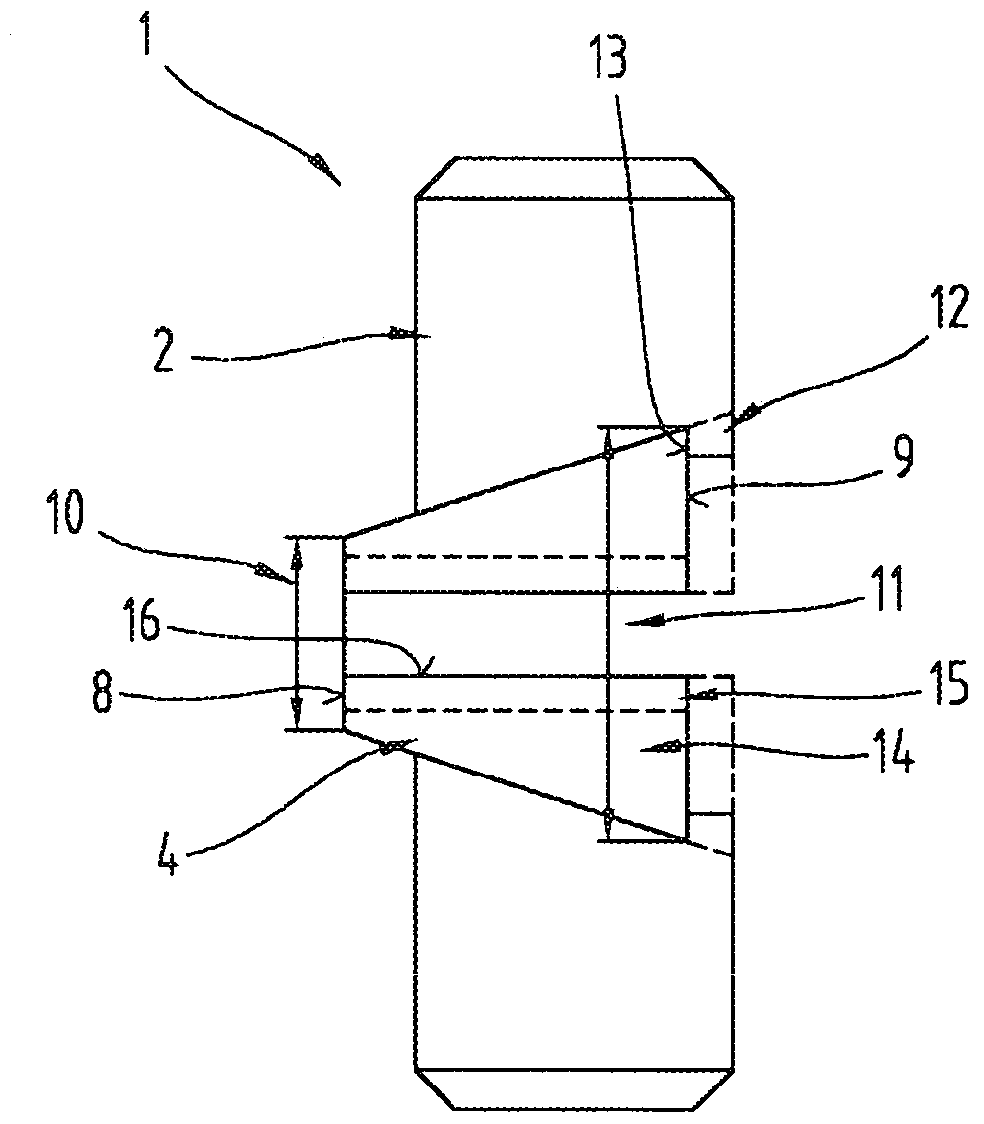

Flow control of an injection molding system

ActiveUS20200398468A1Easy to controlImprove accuracyFluid pressure controlFluid-delivery valvesLine tubingFuel tank

Injection molding system comprising at least one first actuator-system (D1, D2, D3), the first actuator system comprising: at least one piston drive having at least two pressure line connectors (CP2, CP3) to drive a piston to open or close a molding nozzle, pressure lines (L1, L2) connectable to a changeover valve (V) having a pressure line connector (P) and tank line connector (T) and at least two changeover pressure line connectors, wherein the first changeover valve pressure line connector (CV1) is connectable to a first pressure line (L1) and the second changeover valve pressure line connector (CV2) is connectable to a second pressure line (L2), wherein the second pressure line (L2) is connected to the second pressure line connector (CP2) of the piston drive, an electronically adjustable flow control valve having a first pressure line connector and a second pressure line connector, wherein the first pressure line connector of the adjustable flow control valve being connected to the first pressure line (L1) to allow a connection to the first pressure line connector (CV1) of the changeover valve (V), and the second pressure line connector is connected to a third pressure line (L3) which establishes a connection to the second pressure line connector (CP3) of the piston drive, at least one electronic flow sensor for (P1, P2, P3) sensing flow rate in the first, second and / or third pressure lines (L1, L2, L3), a controller connected to the adjustable flow control valve and to the at least one sensor, configured to electronically adjust the flow control valve, depending on information of the at least one sensor, controlling thereby the timing and the speed of the movement of the piston and the molding nozzle.

Owner:INCOE CORP

Wind power equipment drive mechanism

The invention relates to a wind power plant gear mechanism (1) with an axle (5) and a gearwheel (2), wherein at least one plain bearing bush (4, 20) is arranged between the axle (5) and the gearwheel (2), and wherein the at least one plain bearing bush (4, 20) is connected to the gearwheel (2) via a conical press fit, wherein the at least one plain bearing bush (4, 20) has a first end surface (8) and a second end surface (9) which lies opposite the former along a longitudinal center axis (7) through the at least one plain bearing bush (4, 20), and wherein the first end surface (8) has a diameter d (10) and the second end surface (9) has a diameter D (11), wherein the diameter D (11) is greater than the diameter d (10), and wherein a bearing surface (13) for the at least one plain bearing bush (4, 20) is formed so as to adjoin the end surface (9) with the diameter D (11).

Owner:MIBA SINTER AUSTRIA

Method for dragging cement production line rotating machine by adopting steam turbine

InactiveCN103742210AProcess does not affectReduce throttlingSteam generation plantsSteam engine plantsProcess engineeringDeaerator

The invention provides a method for dragging a cement production line rotating machine by adopting a steam turbine. The method comprises the steps: A, a driving part of the rotating machine adopts the steam turbine; B, a steam boiler produces steam and fees the steam into the steam turbine through a pipe; C, the steam turbine drives the rotating machine to rotate; D, dead steam produced by the steam turbine in working is discharged into a coagulator; E, water coagulated by the coagulator is fed into a deaerator; F, deoxidized water in the deaerator is fed into a deoxidizing water tank; G, water in the deoxidizing water tank is fed into the steam boiler; H water in the steam boiler is heated to form steam and the steam is fed into the steam turbine. A high-power high-voltage electric motor is replaced by the steam turbine, the output rotation speed and power of the steam turbine can be adjusted by adjusting the steam quantity of the boiler, the power requirement of the rotating machine is met, stepless speed regulation is achieved, energy consumption is reduced, and throttle and low-efficiency loss caused by process parameter adjustment in the cement production process are reduced.

Owner:陕西大唐新能电力设计股份有限公司

Oil inlet valve for high pressure oil pump and corresponding high pressure oil pump

ActiveCN109253005BShorten the lengthReduce throttlingMachines/enginesFuel injecting pumpsInlet valveOil pump

An oil inlet valve for high -pressure oil pump is disclosed, including: oil inlet valve core, which includes contacting the shoulder;At the edge of the oil inlet valve seat, the shoulder -to -shoulder can seal and contact or stay away from the oil inlet valve to achieve the closure or opening of the oil inlet valve. Among themThe fuel in the oil pores is connected to the oil inlet valve seat when the oil inlet valve is opened when the oil inlet valve is opened to the oil inlet valve seat;The hydraulic buffer structure of the off -time movement contains at least the dead area between the bottom of the oil inlet valve core and the bottom of the receiving cavity. There is a buffer fluid in the dead area.A high -pressure oil pump including this oil -in -in -law was also disclosed.According to the present invention, the length of the flowing path of the fuel in the oil inlet valve is reduced, and the closed speed of the oil -entering valve core through the hydraulic buffer structure can be reduced.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com