Method for dragging cement production line rotating machine by adopting steam turbine

A steam turbine and production line technology, applied in the direction of mechanical equipment, machine/engine, steam generation, etc., to achieve the effect of satisfying power, reducing throttling and low efficiency loss, and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

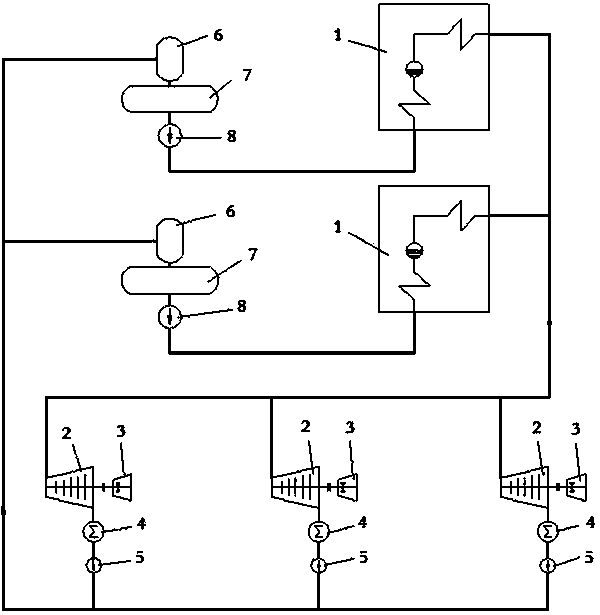

[0013] refer to figure 1 , the present invention provides a kind of method that the rotating machinery of cement production line adopts steam turbine to drive, comprises the following steps: step A: the driving part of rotating machinery 3 adopts steam turbine 2; Step B: steam boiler 1 produces steam and sends into steam turbine 2 through pipeline; Step C: the steam turbine 2 drives the rotating machine 3 to rotate; Step D: the exhaust steam after the steam turbine 2 works is discharged into the condenser 4; Step E: the water condensed by the condenser 4 is sent to the deaerator 6; Step F: the deaerator The water in 6 enters the deaeration water tank 7 after being deaerated; step G: the water in the deaeration water tank 7 enters the steam boiler 1;

[0014] Such as figure 1 As shown, the steam from the outlet of the steam boiler 1 is sent to each steam turbine 2 through the steam pipe network in the factory area, and the steam turbine 2 is driven to rotate. The steam turbine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com