Fluid-filled, frequency-dependent damper

A fluid-filled, damper technology, used in shock absorbers, shock absorbers, springs/shock absorbers, etc., to solve problems such as increased damping resistance and inability of dampers to achieve frequency-dependent characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

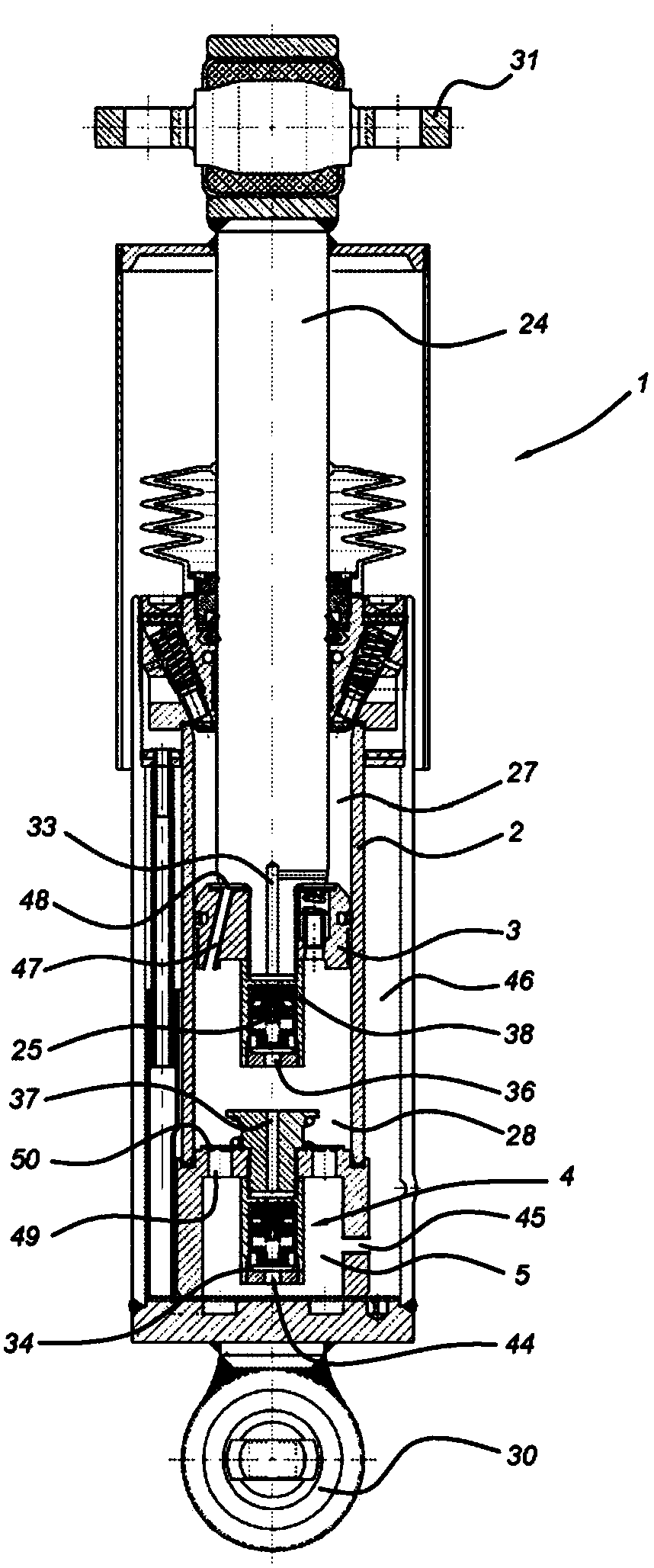

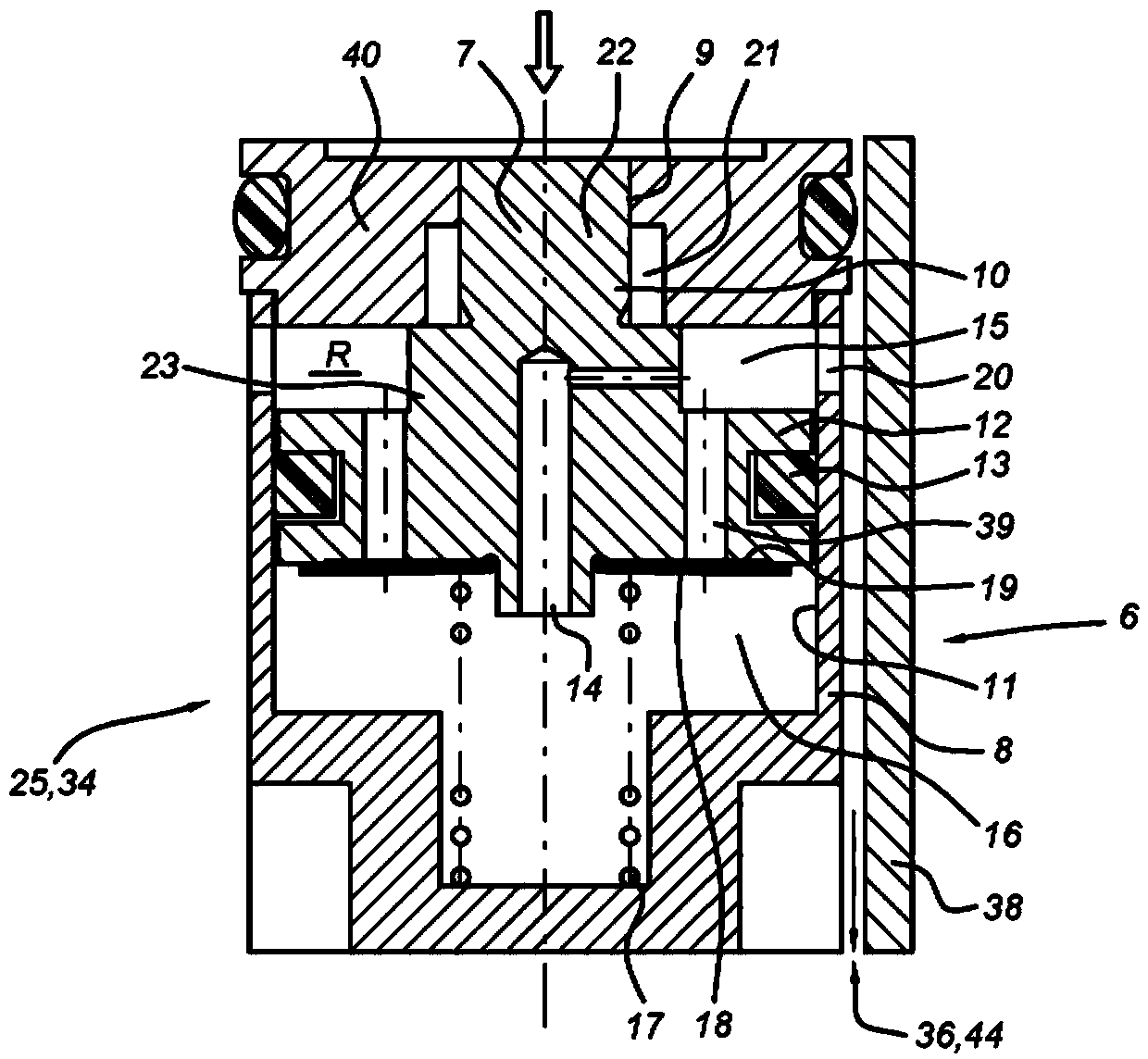

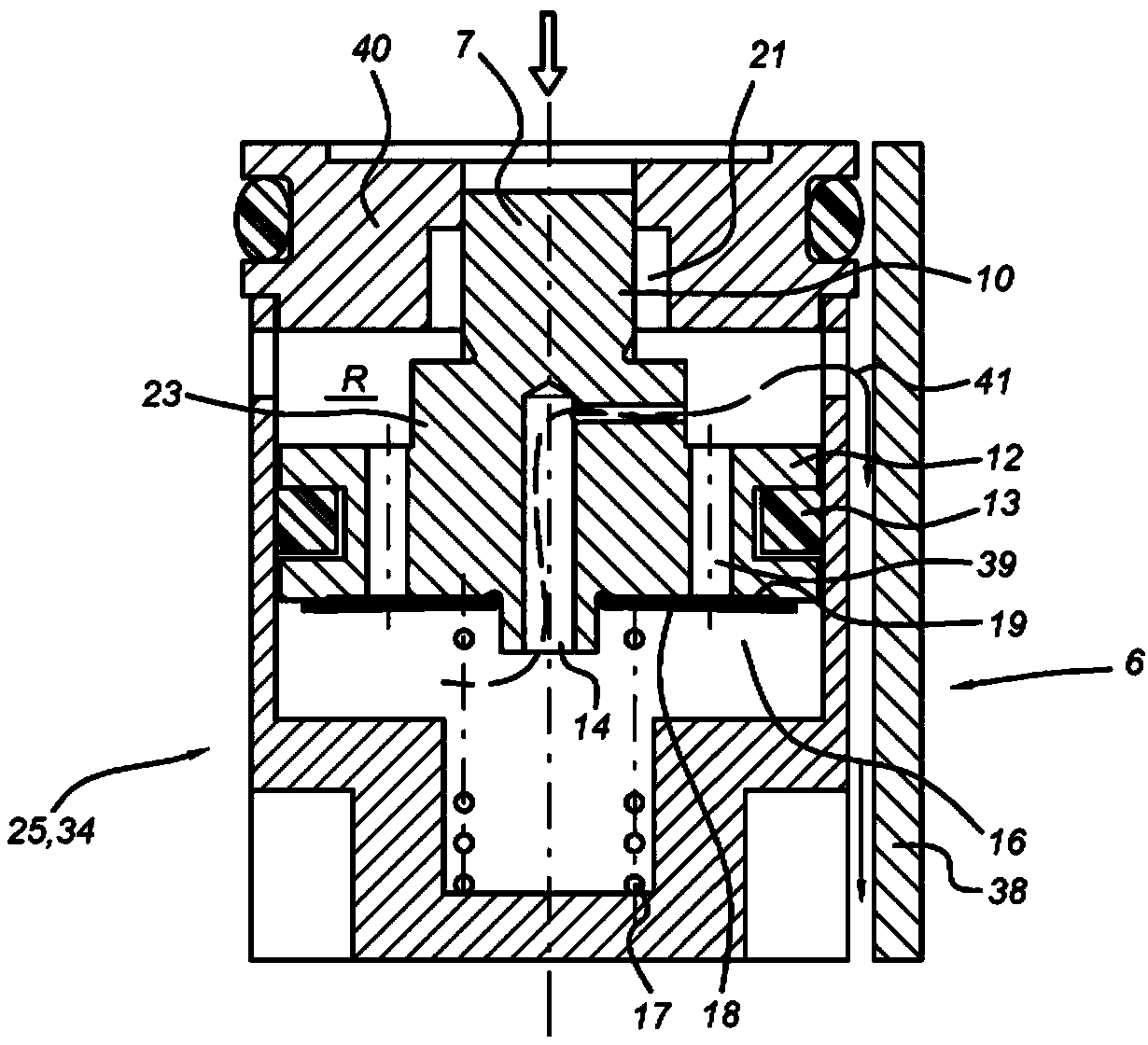

[0027] figure 1 A damper 1 is shown, in this example a train damper. The damper consists of a cylinder 2 provided with a cylinder attachment portion 30 and a piston 3 connected to an opposite piston attachment portion 31 by means of a piston rod 24 . The piston 3 divides the cylinder 2 into a first cylinder chamber 27 and a second cylinder chamber 28 . In the piston there are passages known per se in the prior art, such as a conduit 47 with a non-return valve 48, such that the piston can move relative to the cylinder. In addition, there is a throttle member 25 configured according to the invention in the piston. The throttling member is provided between a passage 33 leading to the first cylinder chamber 27 serving as the first main chamber with respect to the throttling member 25 and an opening 36 leading to the first main chamber serving as the throttling member 25 and an opening 36 leading to the The second cylinder chamber 28 of the second main chamber of the flow member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com