Method for regulating a short-term power increase of a steam tubine

A technology of steam turbine and power, which is applied in the steam generation method using heat carrier, steam engine device, steam superheating, etc., which can solve the problems of low degree of throttling and efficiency loss, and achieve the effect of strong regulator response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

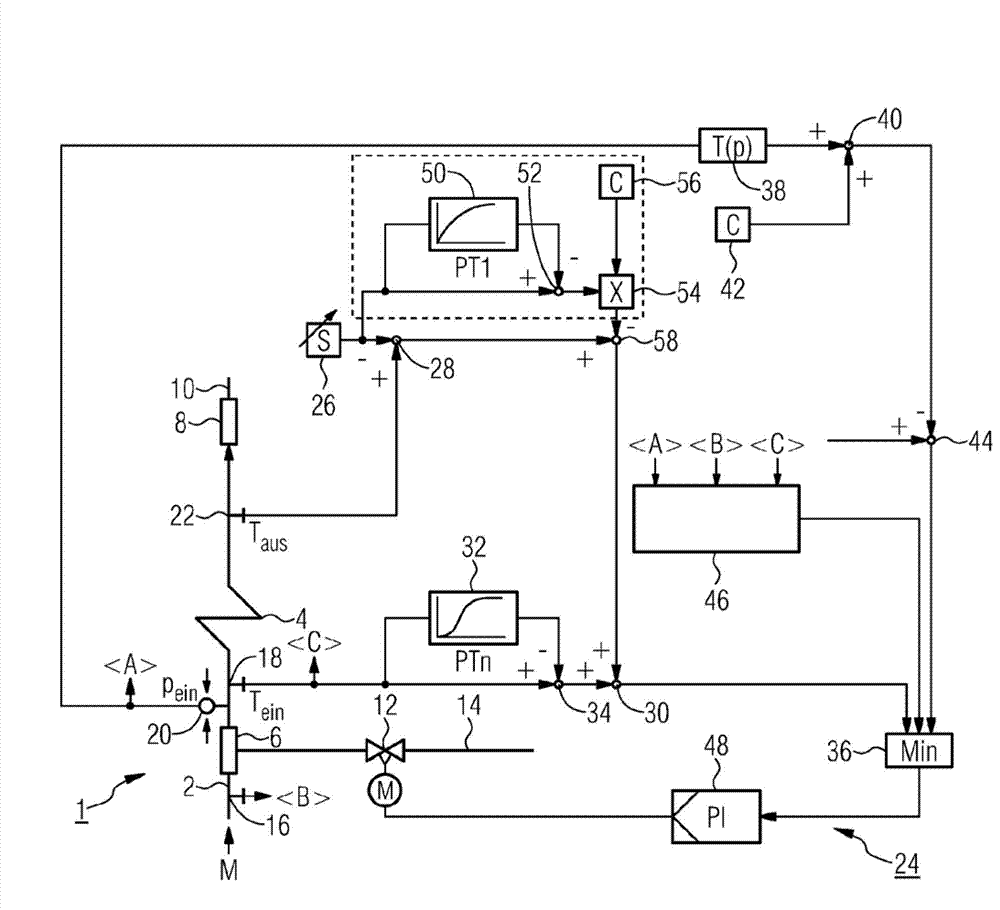

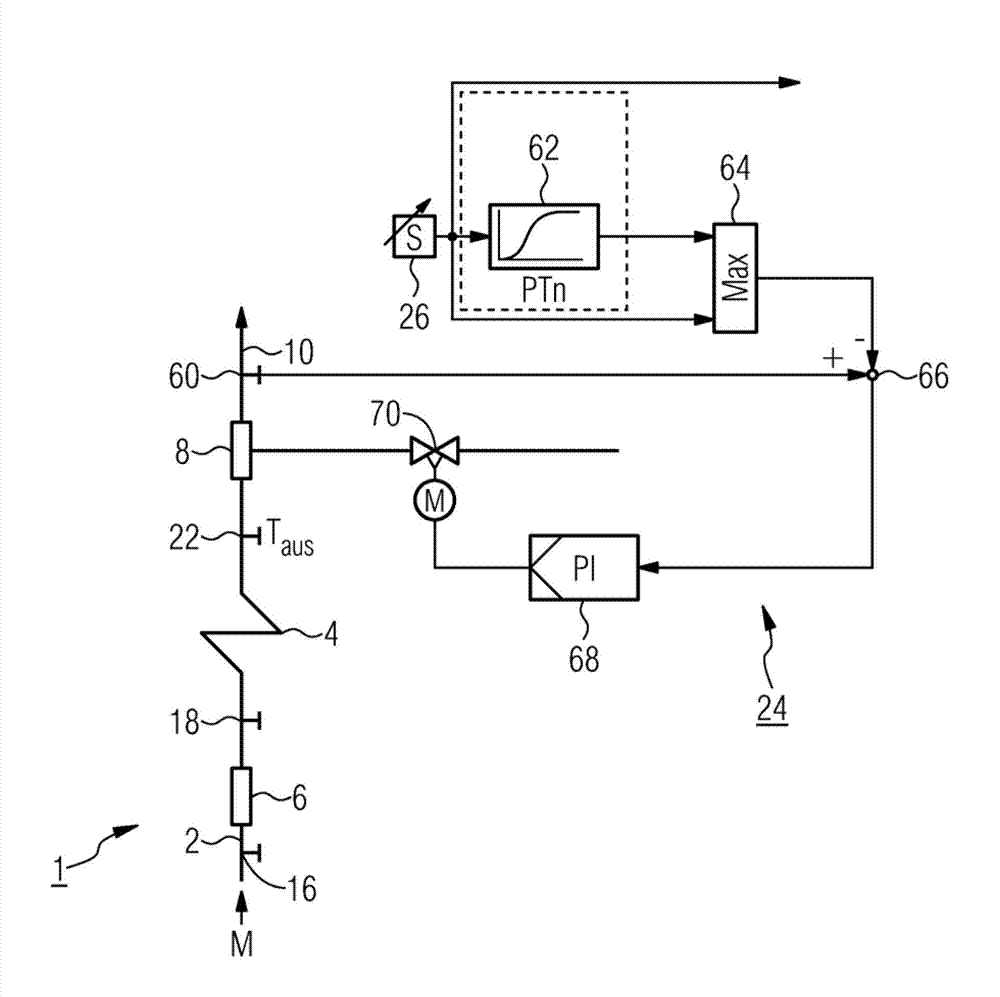

[0033] exist figure 1 The high-pressure part of the waste heat steam generator 1 is schematically illustrated in . Of course, the invention can also be used in other pressure stages for regulating intermediate superheating. figure 1 A part of the flow path 2 of the flow medium M is schematically illustrated. Of the heating surfaces of the economizer, evaporator and superheater which are usually arranged in the high-pressure part of the waste heat steam generator 1 , only the last superheater heating surface 4 is shown in the figure. The spatial arrangement of the individual superheater heating surfaces 4 in the hot gas channel is not shown and can vary. The illustrated superheater heating surfaces 4 may respectively represent a plurality of series-connected heating surfaces, but are not shown differently for the sake of clarity.

[0034] The flow medium M enters into figure 1 The part shown in is previously conveyed by the feed pump at a corresponding pressure into the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com