Method for reducing maximal pressure of rail shared injector

A technology of maximum pressure and injector, applied in the direction of fuel injection control, fuel injection device, machine/engine, etc., can solve problems such as affecting the function of the injector, and achieve the effect of timely identification and reduction of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

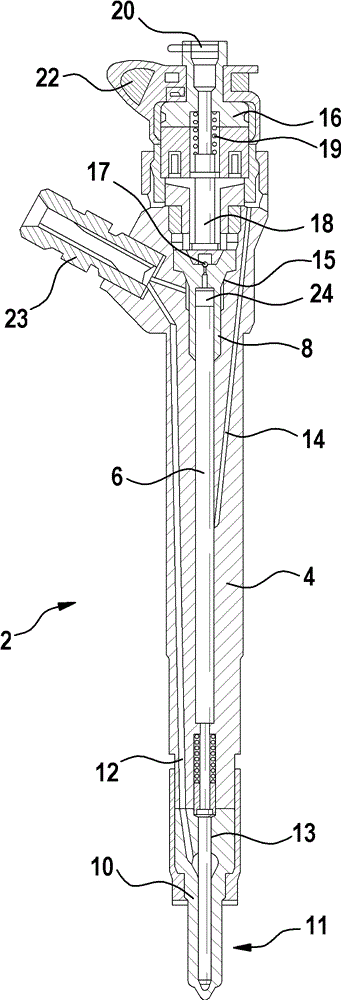

[0015] figure 1 An embodiment of a common rail injector 2 according to the prior art is shown. A schematic sectional view of a common rail injector 2 is shown. The common rail injector 2 comprises an injector body 4 , in which a valve piston 6 is arranged, which is guided at an upper end in a valve block 8 and whose lower end extends toward a nozzle 10 . The nozzle needle 11 is coupled to the valve piston 6 and is arranged inside the nozzle 10 . A magnetic head 16 , an armature assembly 18 and a return connection 20 are arranged at the upper end of the common rail injector 2 . Furthermore, the common rail injector 2 is connected to a power supply via an electrical connection 22 and to a fuel supply line via a high-pressure inlet 23 , which includes a dust filter.

[0016] The nozzle needle 11 is guided within the nozzle 10 in a nozzle needle guide 13 . The nozzle needle guide 13 essentially consists of a precisely drilled hole in the nozzle 10 , in which the nozzle needle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com