Preparation method of glycyrrhiza sweetening and moistening essence for mouth stick

A technology of licorice and mouth sticks, which is applied in the fields of essential oils/spices, tobacco, applications, etc., can solve the problems of cigarette tip spices, filter sticks polluting the environment, and cigarette aroma loss, etc., and achieve good development and application prospects. Avoid loss and pyrolysis, increase the effect of sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

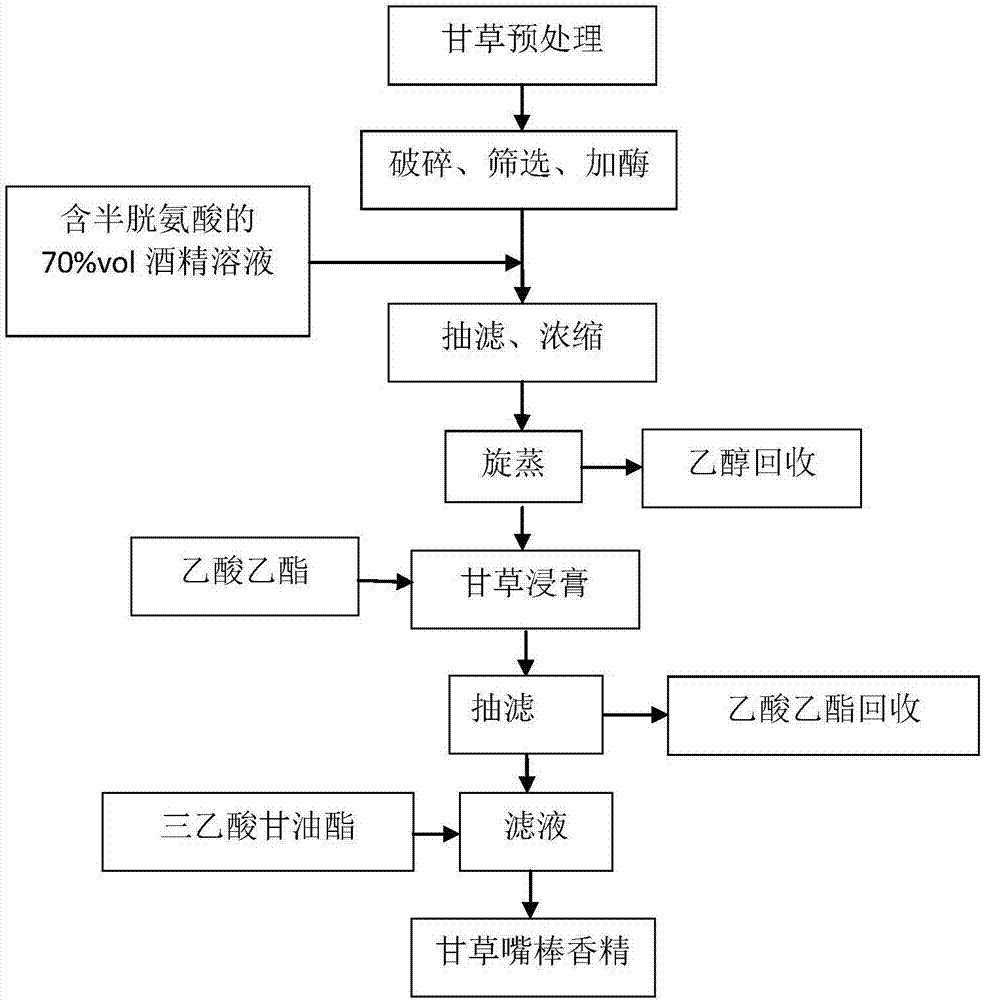

[0032] The raw materials of licorice are graded according to the year water content and other indicators, and the licorice of the appropriate grade is selected, crushed to the size of rice grains, and screened and filtered with a 5-mesh sieve. After filtering, configure the licorice mixture according to the mass ratio of licorice: cellulase: polyphenol oxidase: peroxidase = 14:1:1:1. Take 1kg of licorice mixture, add 3Kg of cysteine in 70% ethanol solution, wherein the mass fraction of cysteine is 10%, stir evenly, and control the central temperature to 55°C for warm soaking for 4h. After the solution was filtered with suction, the filtrate was collected and concentrated. The filtrate was divided into 4 parts, and the ethanol was spin-dried at 60°C by a rotary evaporator to obtain an extract, and the ethanol was recovered for reuse. Add 350 mL of ethyl acetate to the extracted extract after spin-dried ethanol, and ultrasonically extract for 10 min. The extract was filter...

Embodiment 2

[0034] Glycyrrhizae raw material is pulverized and sieved in the manner of Example 1. After filtering, configure the licorice mixture according to the mass ratio of licorice: cellulase: polyphenol oxidase: peroxidase = 18:1:1:1. Take 1kg of licorice mixture, add 4Kg of cysteine in 70% ethanol solution, wherein the mass fraction of cysteine is 10%, stir evenly, and control the central temperature to 55°C for warm soaking for 4h. After the solution was filtered with suction, the filtrate was collected and concentrated. The filtrate was divided into 4 parts, and the ethanol was spin-dried at 60°C by a rotary evaporator to obtain an extract, and the ethanol was recovered for reuse. Add 350 mL of ethyl acetate to the extracted extract after spin-dried ethanol, and ultrasonically extract for 10 min. The extract was filtered with suction and the ethyl acetate contained therein was spin-dried until no liquid remained. Ethyl acetate was collected for reuse. Sweep the extract th...

Embodiment 3

[0036] Glycyrrhizae raw material is pulverized and filtered according to the manner of Example 1. After filtering, configure the licorice mixture according to the mass ratio of licorice: cellulase: polyphenol oxidase: peroxidase = 20:1:1:1. Take 1kg of licorice mixture, add 5Kg of cysteine in 70% ethanol solution, wherein the mass fraction of cysteine is 10%, stir evenly, and control the central temperature at 55°C for warm soaking for 4h. After the solution was filtered with suction, the filtrate was collected and concentrated. The filtrate was divided into 4 parts, and the ethanol was spin-dried at 60°C by a rotary evaporator to obtain an extract, and the ethanol was recovered for reuse. Add 350 mL of ethyl acetate to the extract after spin-dried ethanol, and extract by ultrasonic for 15 min. The extract was filtered with suction and the ethyl acetate contained therein was spin-dried until no liquid remained. Ethyl acetate was collected for reuse. Sweep the extract t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com