Damping device for percussion device, percussion device, rock drilling machine and method of damping in a rock drilling machine

The technology of a buffer device and an impact device is applied to drilling equipment and methods, driving devices for combined rotary drilling, earthwork drilling and production, etc., to achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

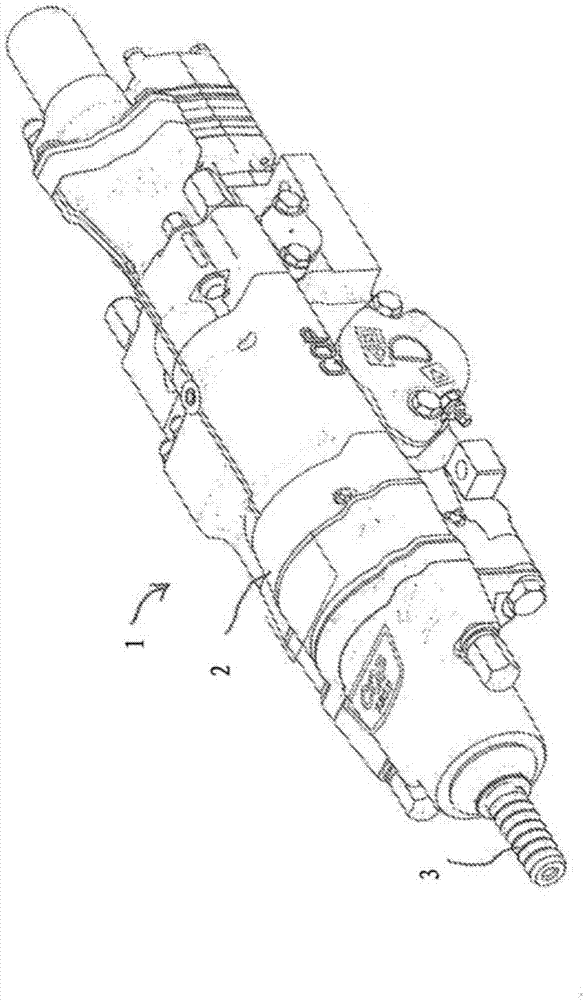

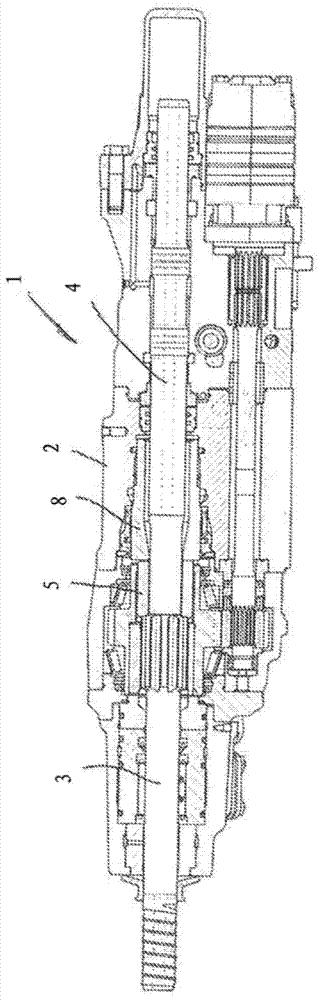

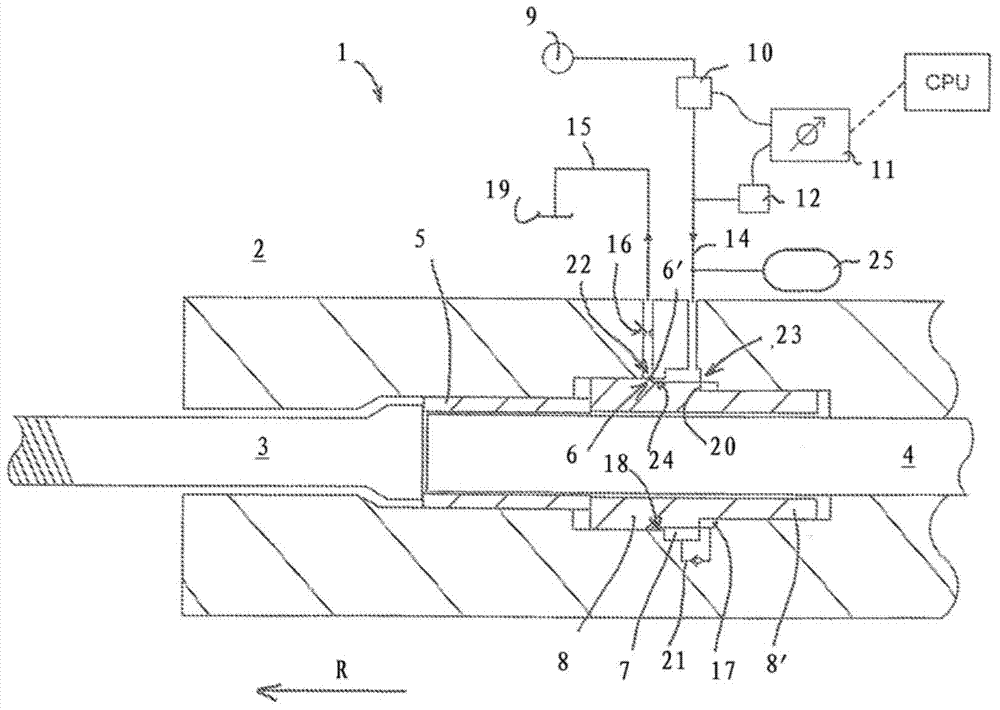

[0036] figure 1 and figure 2 A rock drilling machine 1 according to the invention is shown in perspective view and axial section, respectively, where 2 designates the housing of the rock drilling machine and 3 designates a shank adapter for connection to a drill steel to form a drill string.

[0037] Typically, the rock drill 1 is provided with a percussion piston 4 for intermittent beating action on the shank adapter 3 . Also applied against the shank adapter 3 is a drill sleeve 5 which is pressed in the striking direction in a manner known per se with the aid of a damping piston 8 . The purpose of the buffer is, for example, to receive and dampen reflected shock waves which occur during drilling. Due to the impact of the percussion piston, in certain operating situations, shock wave reflections tending to drive the shank adapter in a direction opposite to the direction of impact R, via the drill bushing Transfer to buffer piston.

[0038] Apart from the damping device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com