Continuous transformation large-transformation-range hydraulic transformer for high speed valve-controlled hydraulic cylinder

A technology of hydraulic transformers and high-speed valves, which is applied in the direction of fluid pressure converters, accumulator devices, fluid pressure actuators, etc., can solve problems such as large noise and vibration, application restrictions, and small pressure transformation range, and achieve unlimited Vibration and noise, easy control, less throttling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

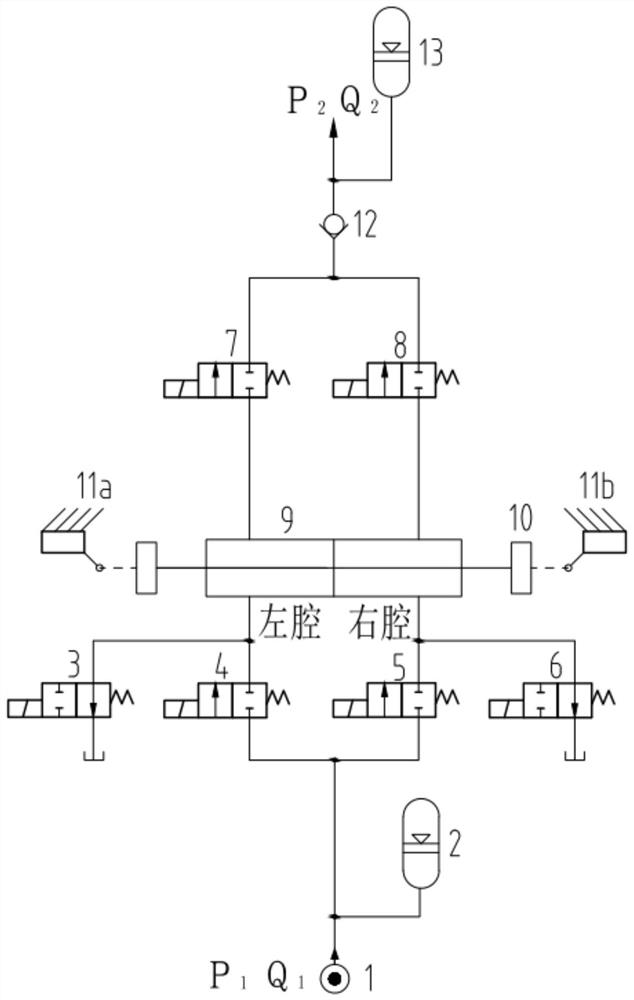

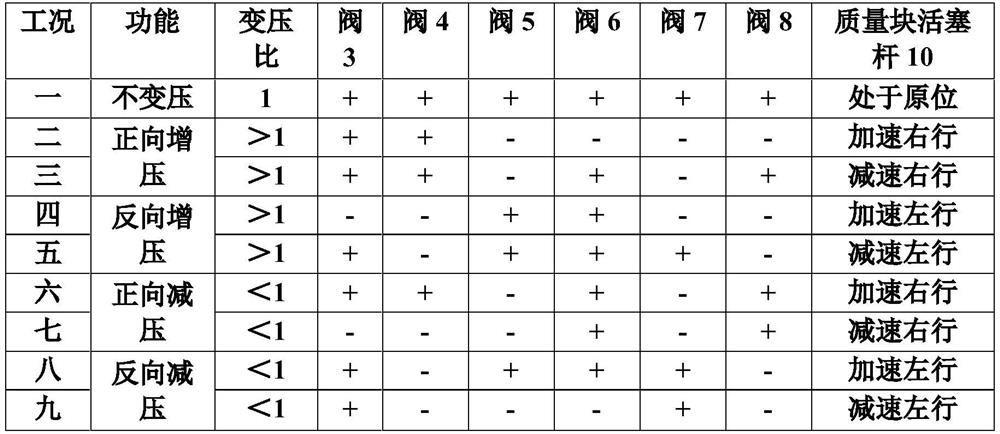

[0033] Such as figure 1 As shown in the figure, a high-speed switch valve-controlled hydraulic cylinder hydraulic transformer with large variable pressure range and continuous variable pressure includes a hydraulic cylinder 9, which is divided into a left cavity and a right cavity, and the two ends of the piston rod of the hydraulic cylinder 9 have mass blocks. The piston, the piston rod and the two mass blocks together form the mass block piston rod 10, and travel switches (11a, 11b) are respectively arranged at the end of strokes on the left and right sides of the mass block piston rod 10, when the mass block piston rod 10 reaches the left or right Trigger the limit switch at the end of the stroke.

[0034] The oil outlet of the high-speed on-off valve 4 is connected to the left chamber, the oil outlet of the high-speed on-off valve 5 is connected to the right chamber, and the oil inlet of the high-speed on-off valve 4 and the high-speed on-off valve 5 are connected to each ...

Embodiment 2

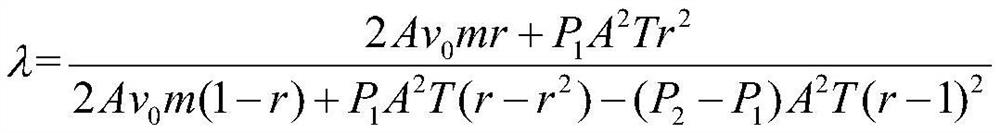

[0057] Suppose hydraulic source 1 provides pressure P 1 and flow Q 1 , the pressure supplied to the load is P 2 , the flow rate is Q 2 , the cross-sectional area of the piston rod 10 of the mass block is A, one period of the PWM control signal is T, the mass of the piston rod 10 of the mass block is m, the length of the hydraulic cylinder 9 is L, and the initial velocity of the piston rod 10 of the mass block is v 0 . Wherein, if the mass m of the mass block piston rod 10 is large, its velocity will be very small in the working condition where the hydraulic energy is converted into kinetic energy, and the displacement will be small in the same period, resulting in the flow rate Q 2 is very small; if the mass m of the mass block piston rod 10 is very large, its speed will be very high, and in the same period, the displacement will be very large, which will easily lead to the inability to complete a working condition within the length L of the hydraulic cylinder 9, so m Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com