Injector control valve of electric control internal combustion engine

A technology of injectors and internal combustion engines, applied in fuel injection devices, machines/engines, mechanical equipment, etc., can solve problems such as difficulty in ensuring consistency and wear of line contact parts, achieve reasonable structural design, improve wear resistance, and pressure evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific drawings and embodiments.

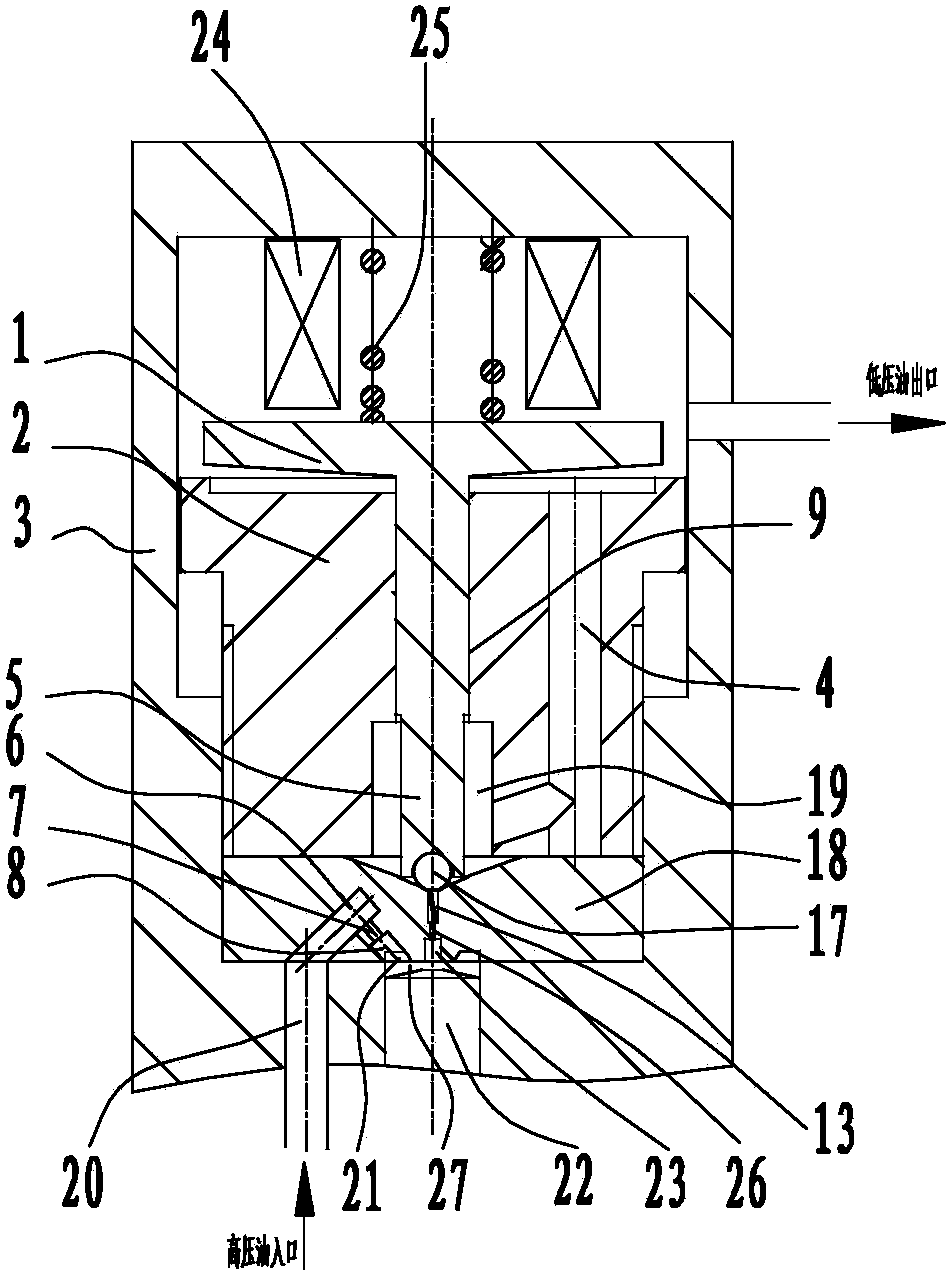

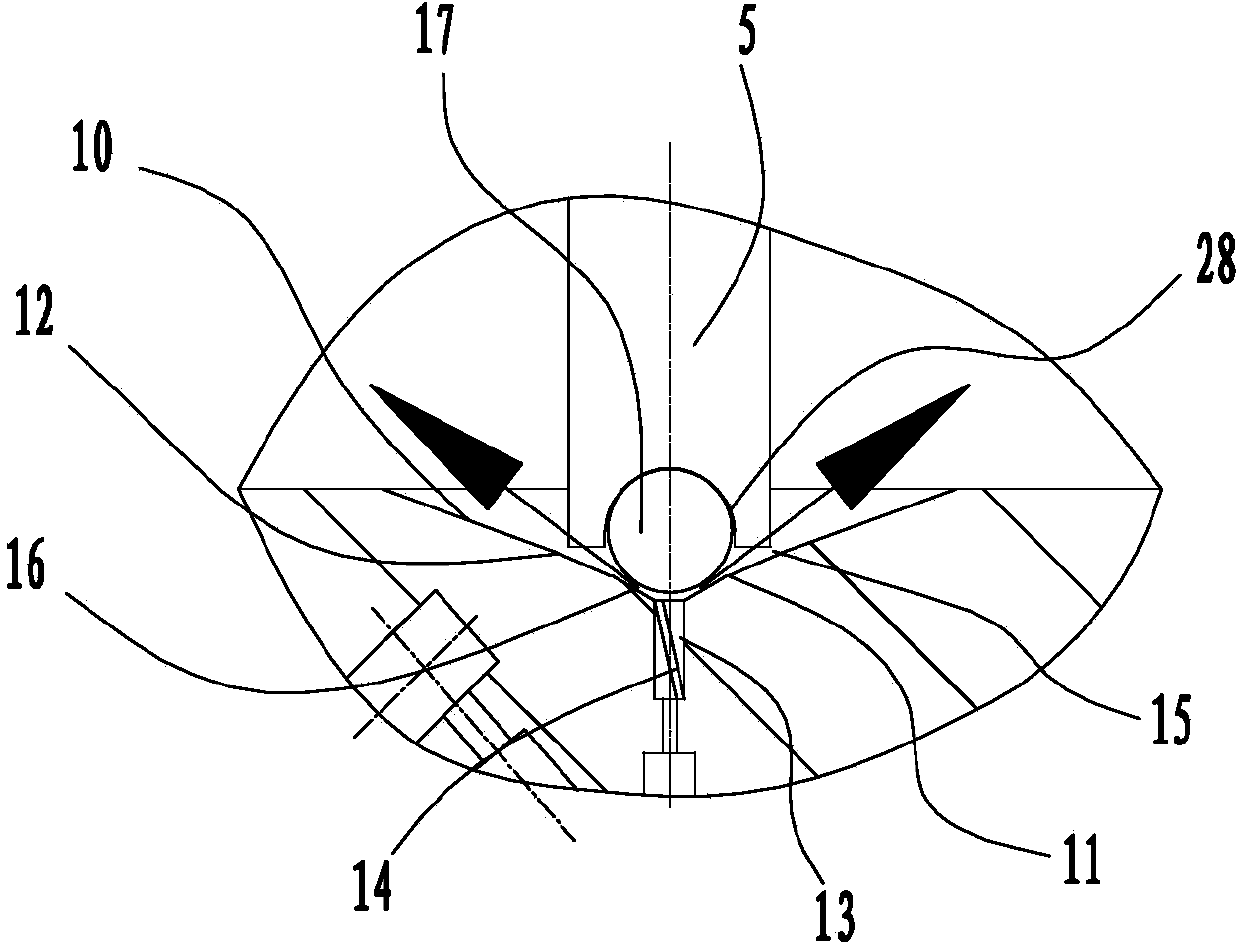

[0025] Such as figure 1 As shown: the electronically controlled internal combustion engine injector control valve in the embodiment is mainly composed of an armature 1, a control valve seat 2, an injector substrate 3, an armature rod 5, a steel ball 17, a control plate 18, a control piston 22, an electromagnetic driver 24 and an armature return spring 25, the control valve seat 2 is installed in the injector base 3, the center of the control valve seat 2 is provided with a control valve middle hole 9, the lower part of the armature 1 is provided with an armature rod 5, and the armature rod 5 is placed in the control In the hole 9 of the valve and can move axially, the armature rod 5 is matched with the hole 9 of the control valve, and the armature rod 5 is oriented by the hole 9 of the control valve; the electromagnetic driver 24 is arranged above the armature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com