Patents

Literature

140results about How to "Good throttling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

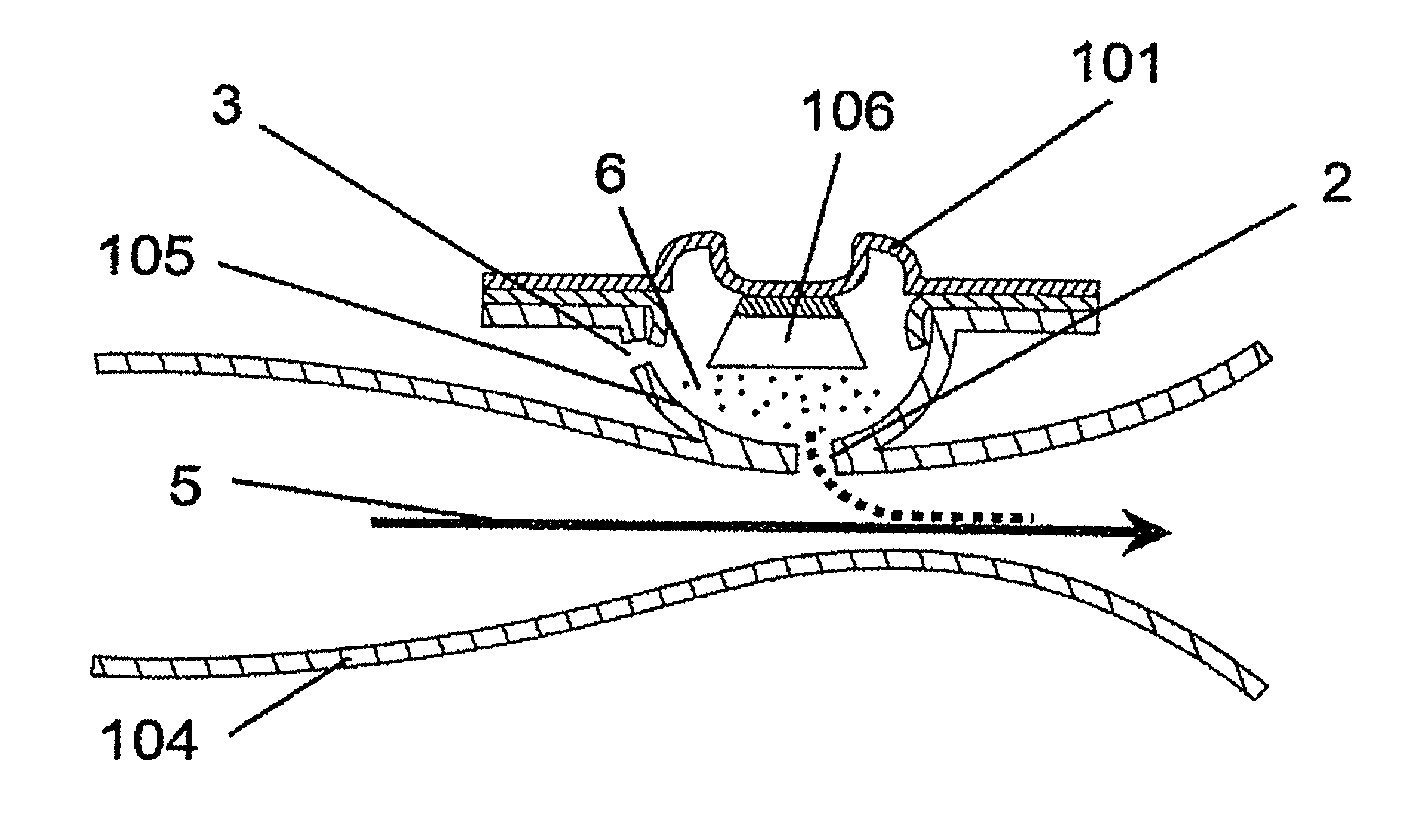

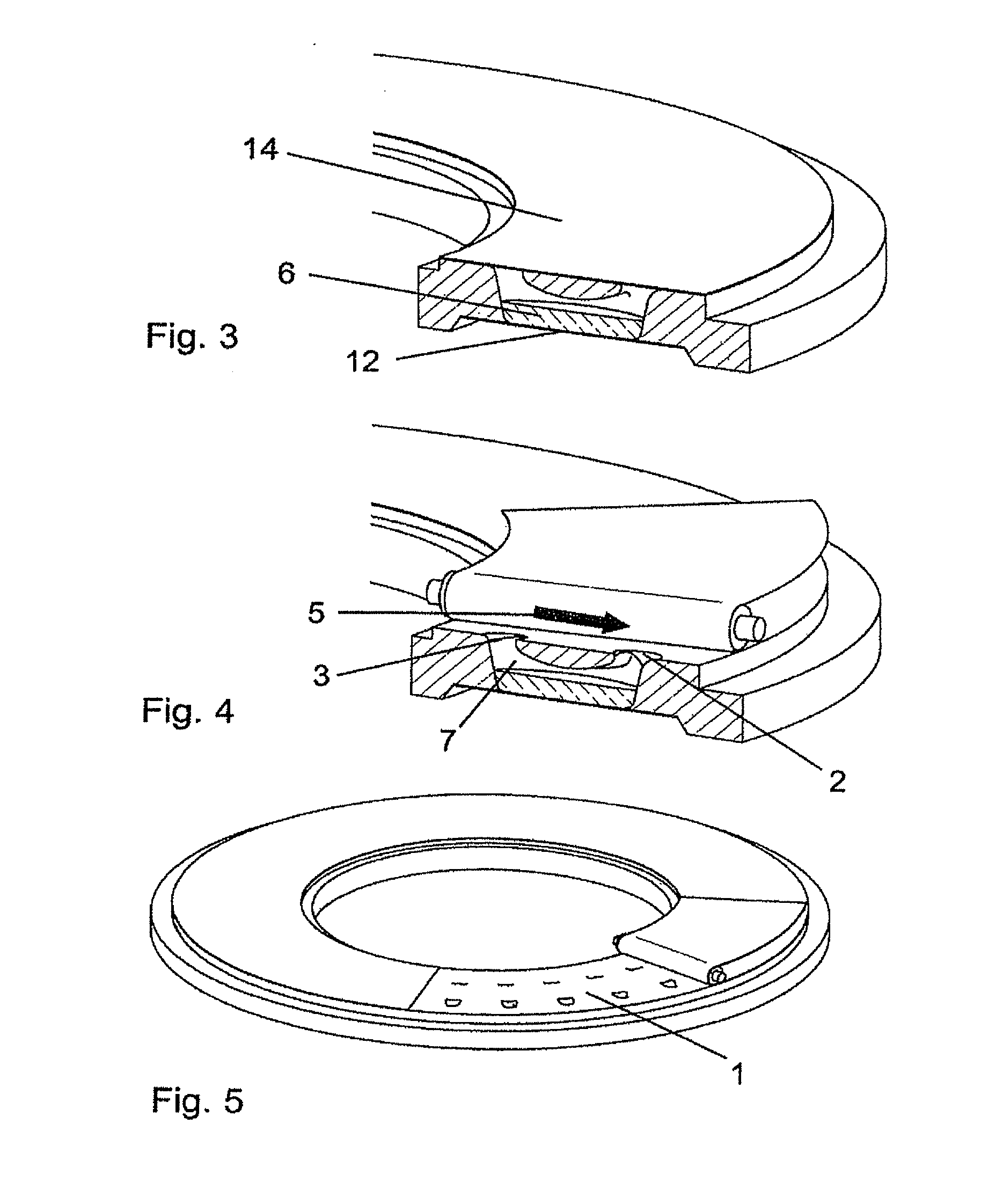

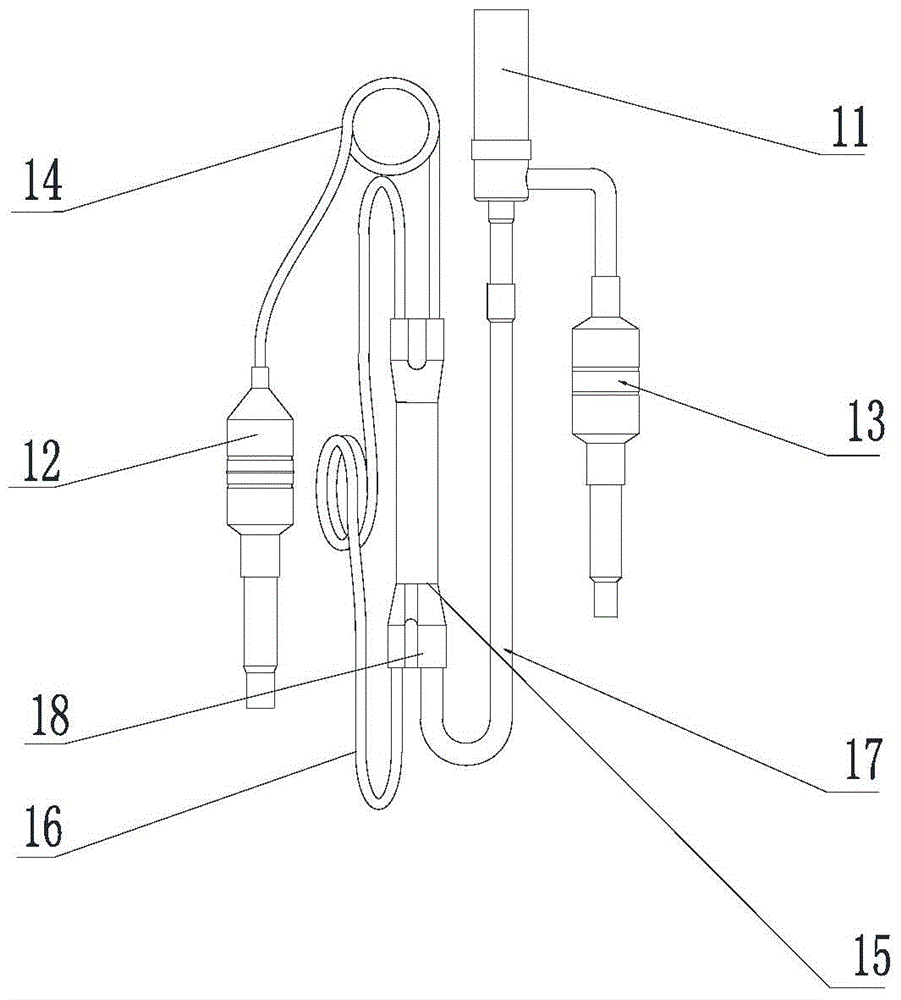

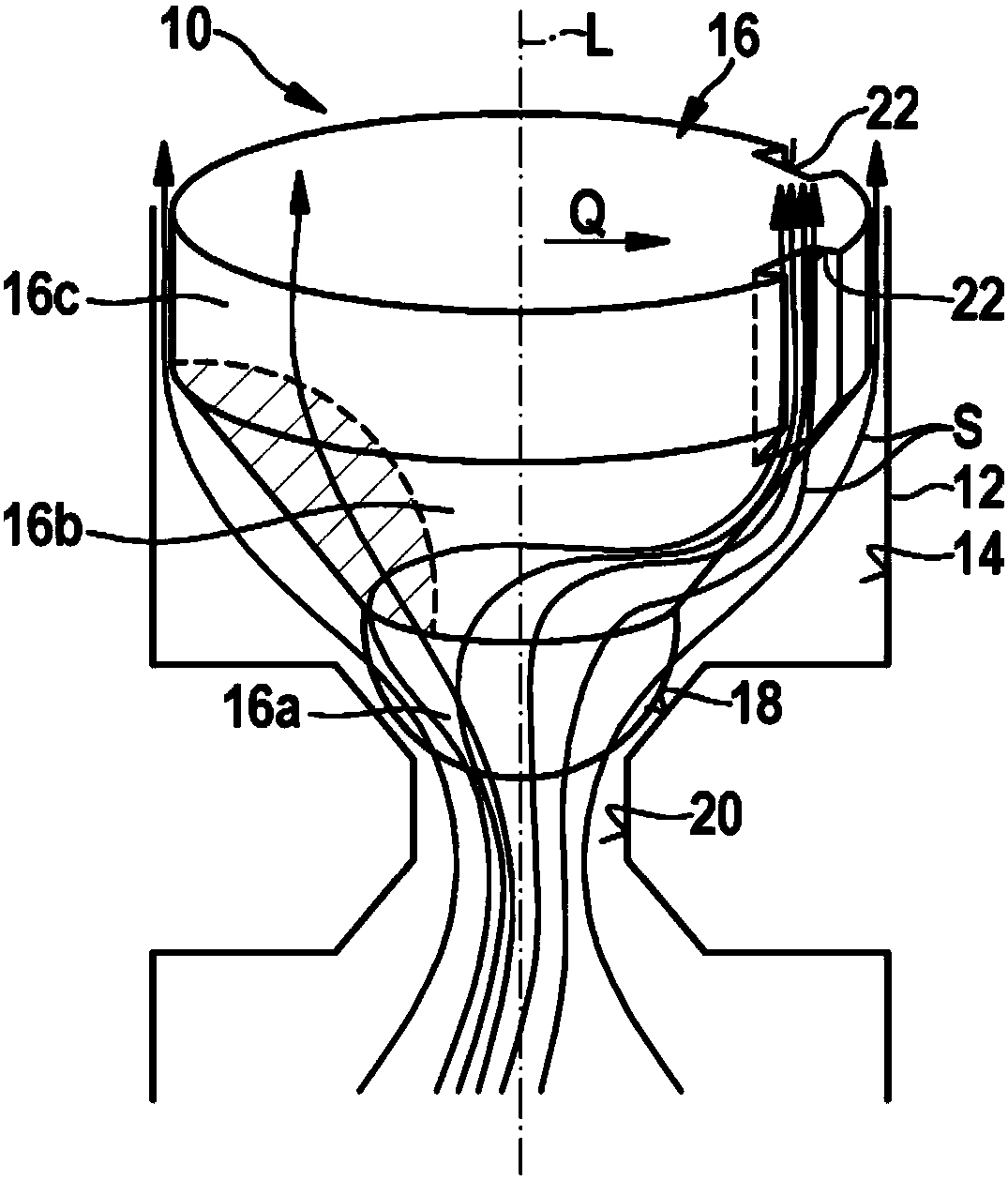

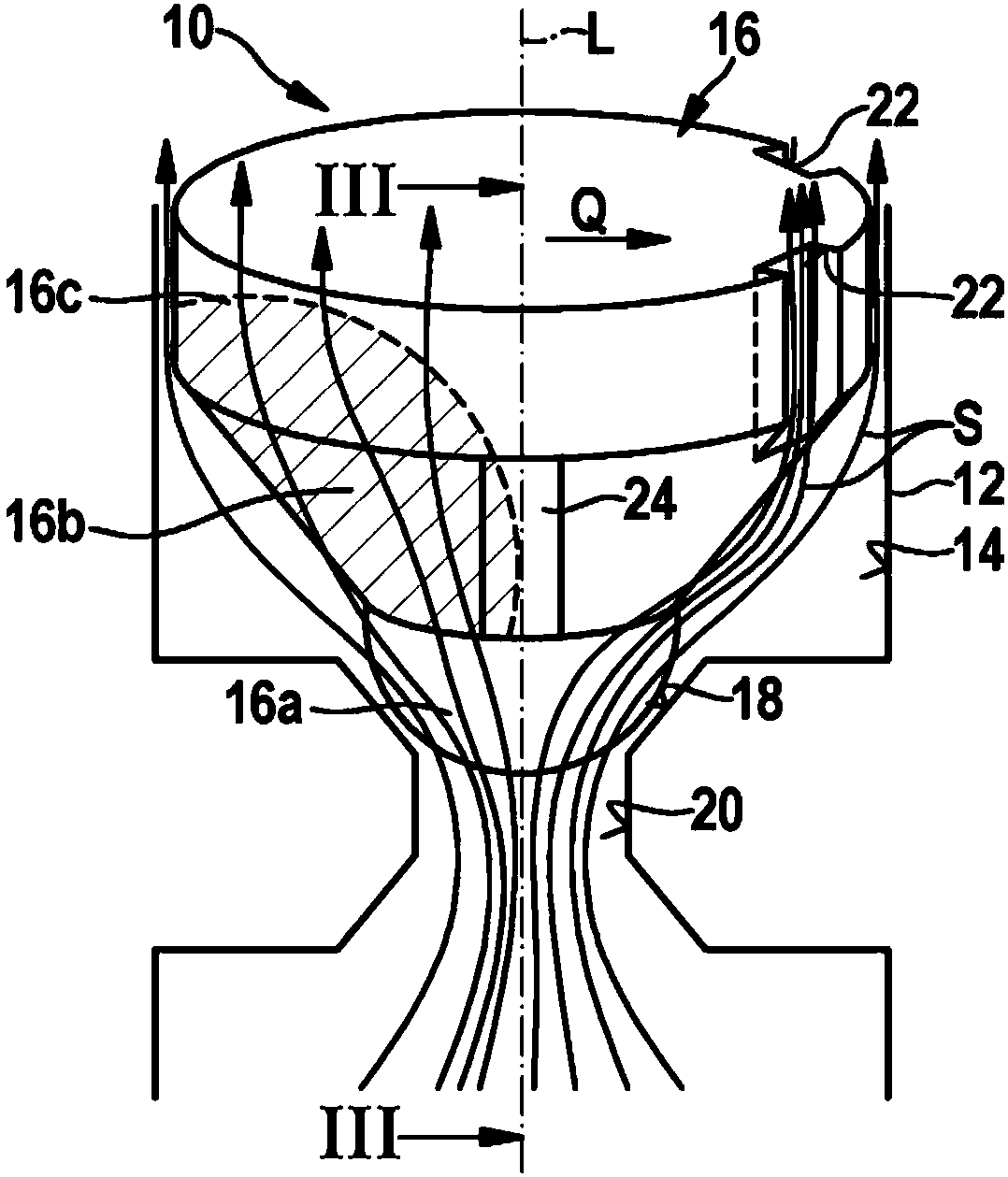

Medicament dispensing device, medicament magazine therefor and method of removing a medicament from a medicament chamber

ActiveUS20120247465A1Influence disaggregation and dispersion of medicamentGood throttling effectRespiratorsLiquid surface applicatorsDriving currentPharmacy medicine

A medicament dispensing device, a medicament magazine thereof, and a method of removing a medicament from the medicament magazine. The inhaler has a mouthpiece (9) and an air channel (4) connected thereto, as well as a medicament magazine with at least one medicament chamber containing a powdered medicament. A drive current is produced in the air channel, while a vacuum flow (5′) can be produced by the drive current and a constriction formed in the air channel. This narrowest part of the air channel that produces the vacuum flow is connected to a removal opening (2) which communicates with a control opening (3), in order to form an emptying current through the control opening via the removal opening. In a preferred embodiment the at least one medicament chamber including the control opening, the removal opening and a fill opening are housing in the one-piece medicament magazine.

Owner:BOEHRINGER INGELHEIM INT GMBH

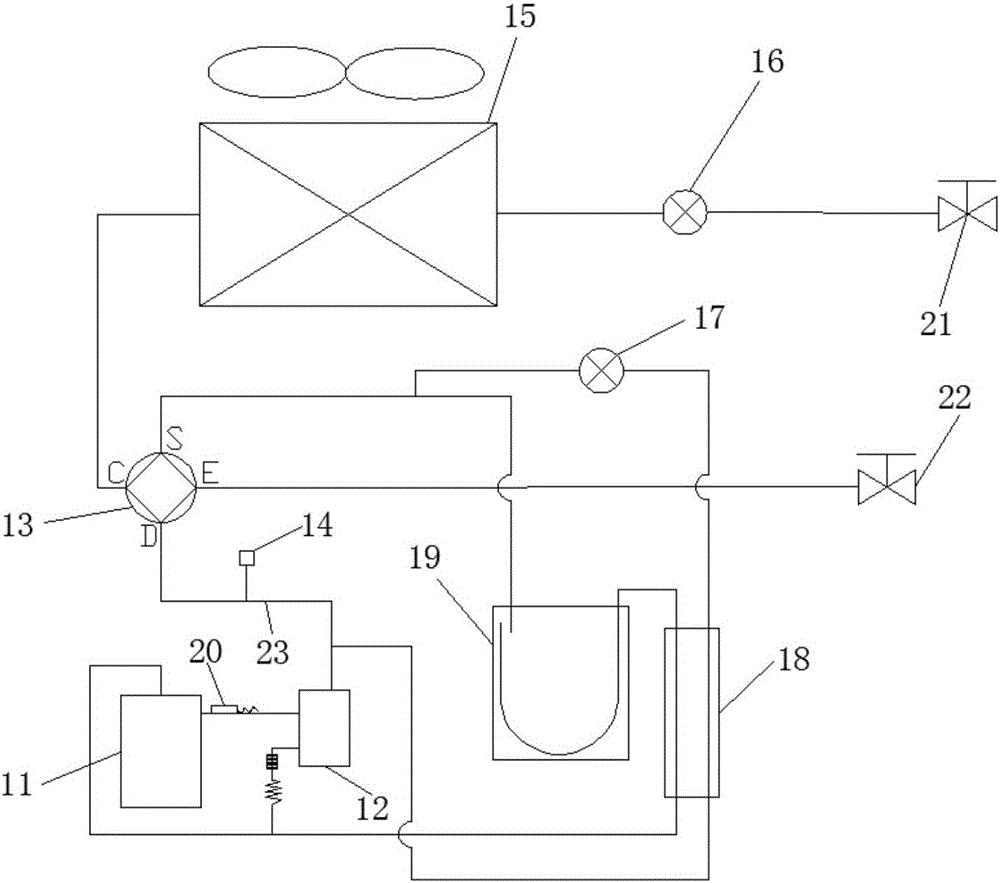

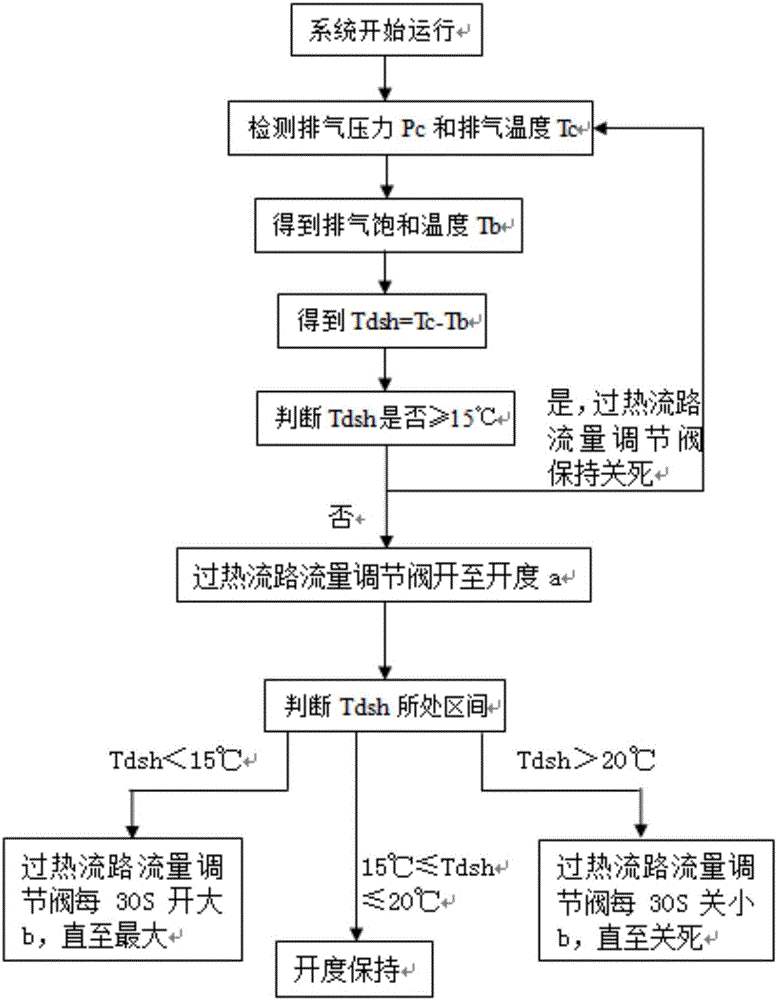

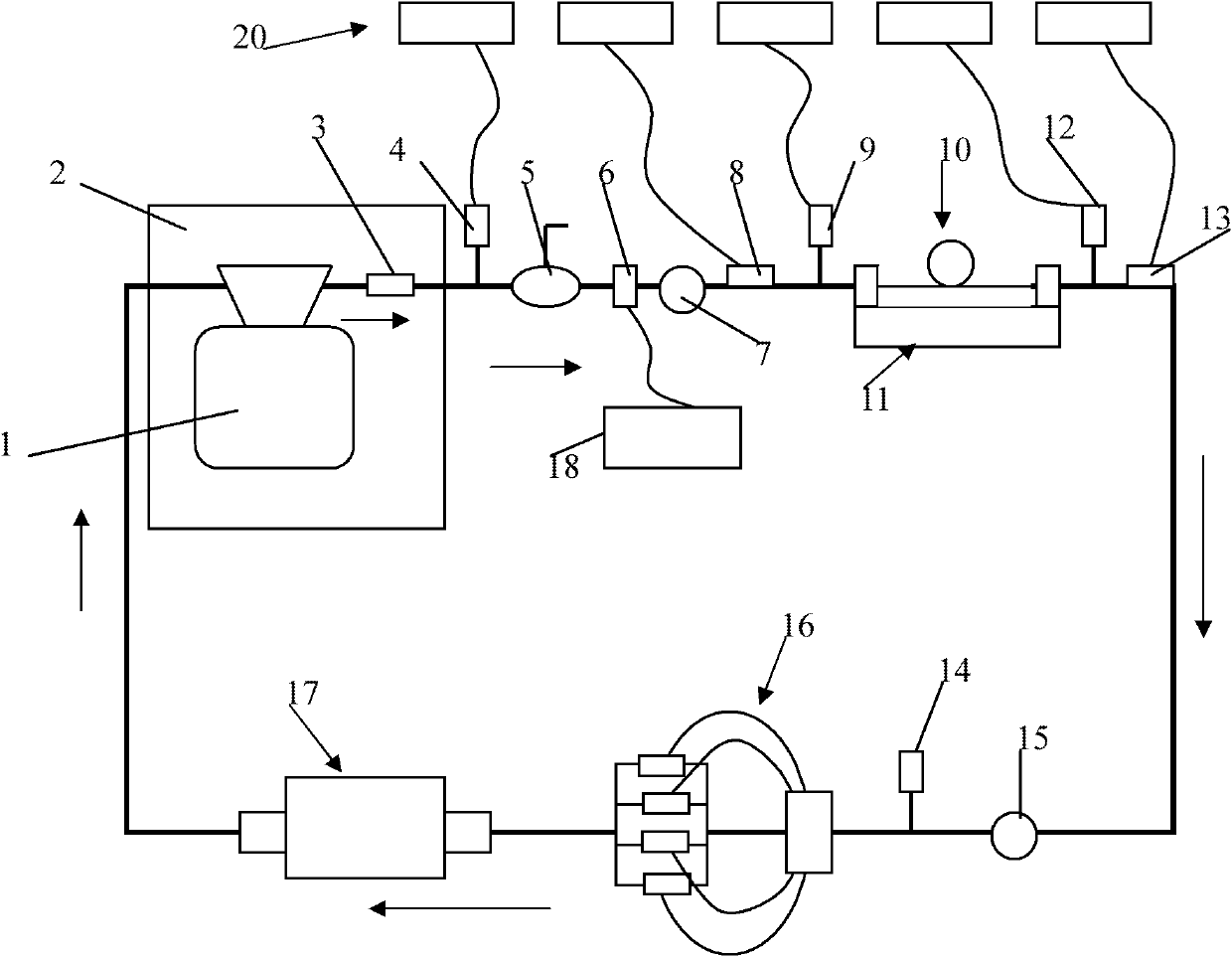

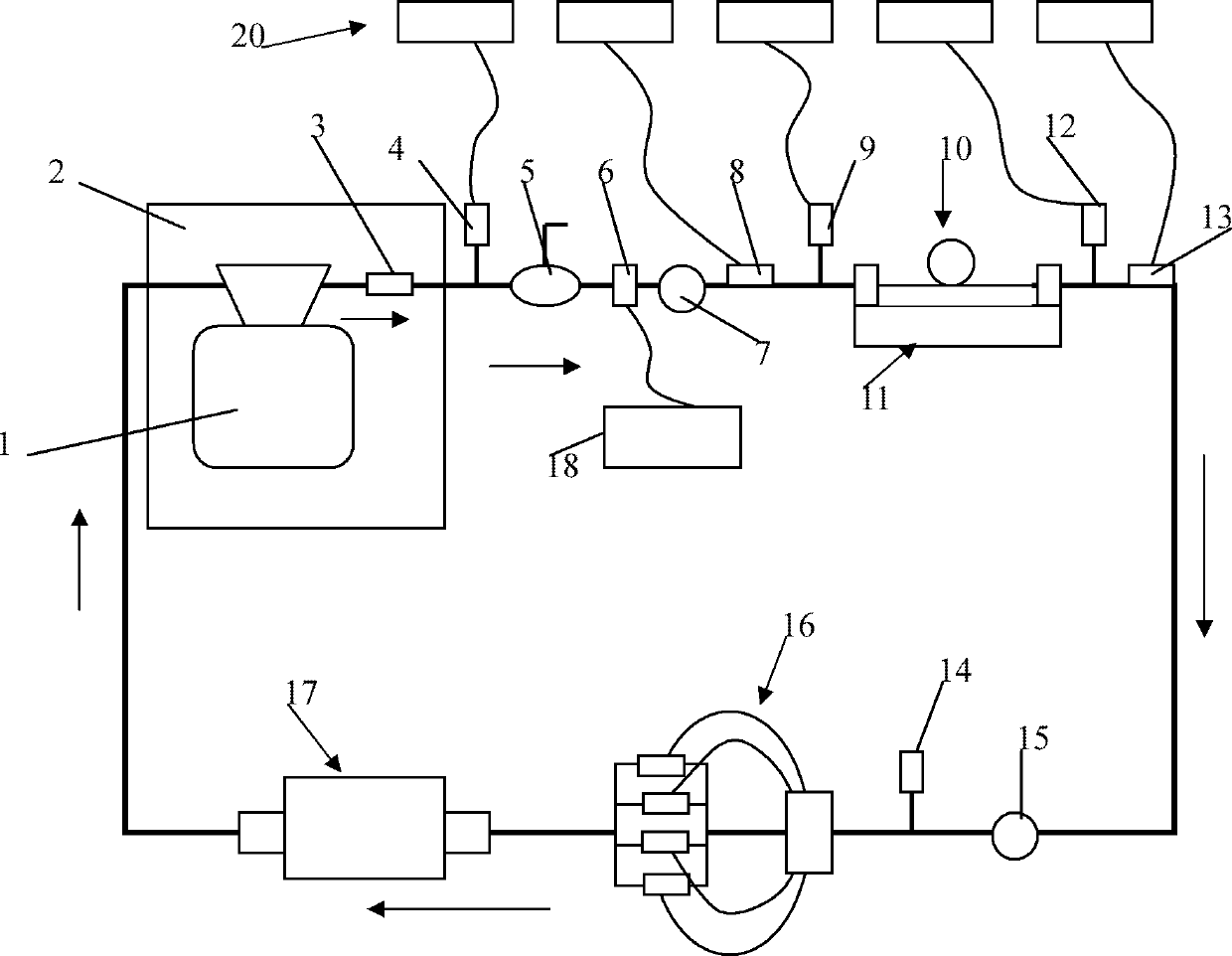

Device and method for improving running reliability of compressor

ActiveCN104964343AImprove operational reliabilityIncrease superheatMechanical apparatusSpace heating and ventilation safety systemsFour-way valveEngineering

The invention relates to the field of air conditioner control, in particular to a device and method for improving running reliability of a compressor. The device comprises a controller, the compressor, a four-way valve, an outdoor air cooling heat exchanger, a first outdoor unit stop valve, a second outdoor unit stop valve, a first heat exchanger and a detection device. The detection device acquires the discharge superheat degree; the controller adjusts the opening degree of a flow adjusting valve connected with the first heat exchanger according to the discharge superheat degree, and therefore the flow of gaseous refrigerant entering the first heat exchanger is controlled, the superheat degree of return air is improved, and the discharge superheat degree of the gaseous refrigerant discharged out of the compressor is made to meet requirements. According to the device and method, the liquid / gaseous refrigerant flowing to the compressor can be heated, and the discharge superheat degree of the gaseous refrigerant discharged out of the compressor is made to meet the requirements, so that the stable discharge superheat degree of an air conditioner can be kept at any environment temperature; therefore, the long-time running stability and reliability of the air conditioner are enhanced.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

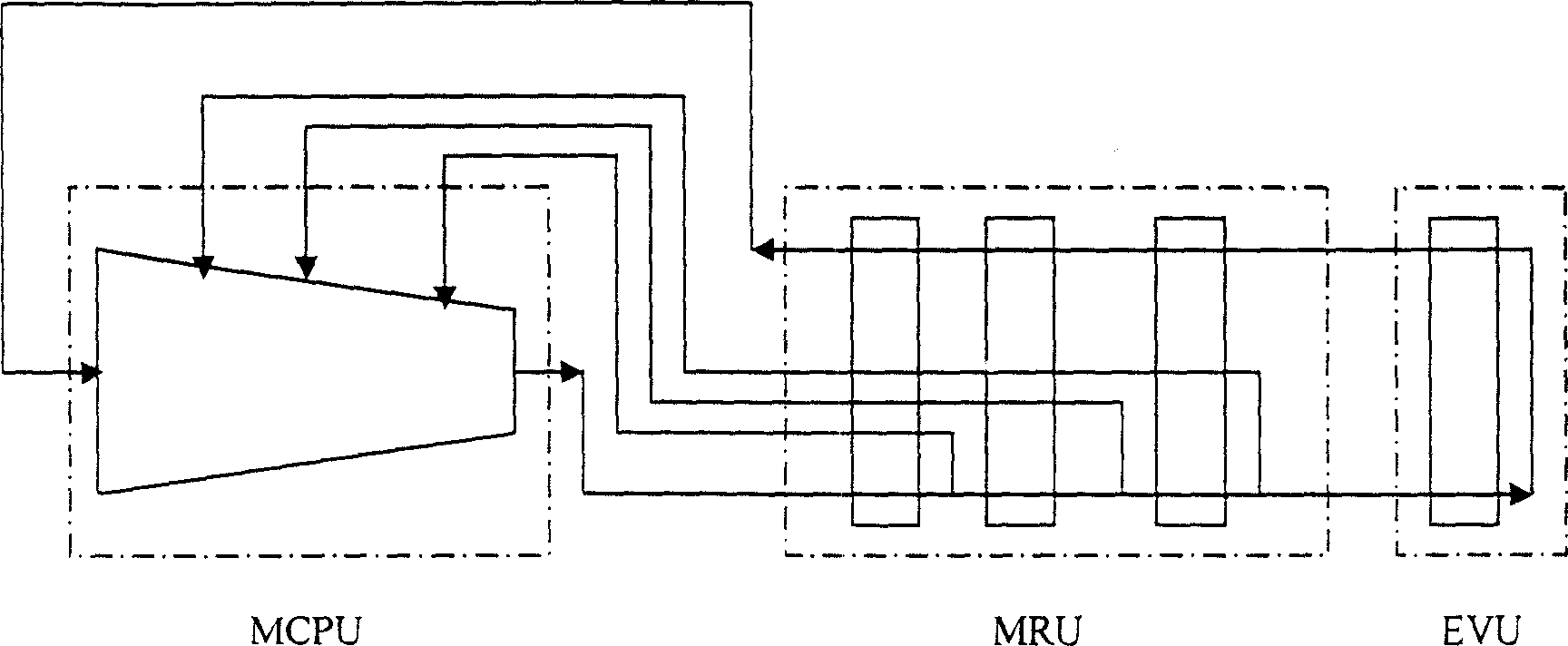

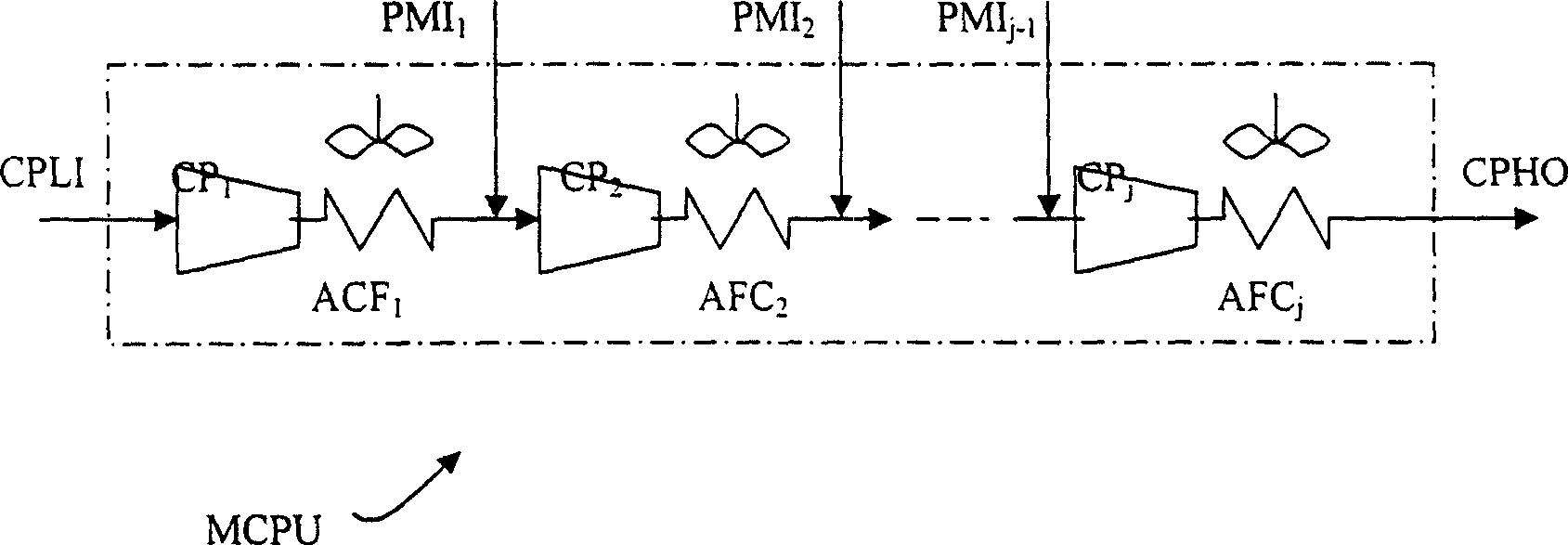

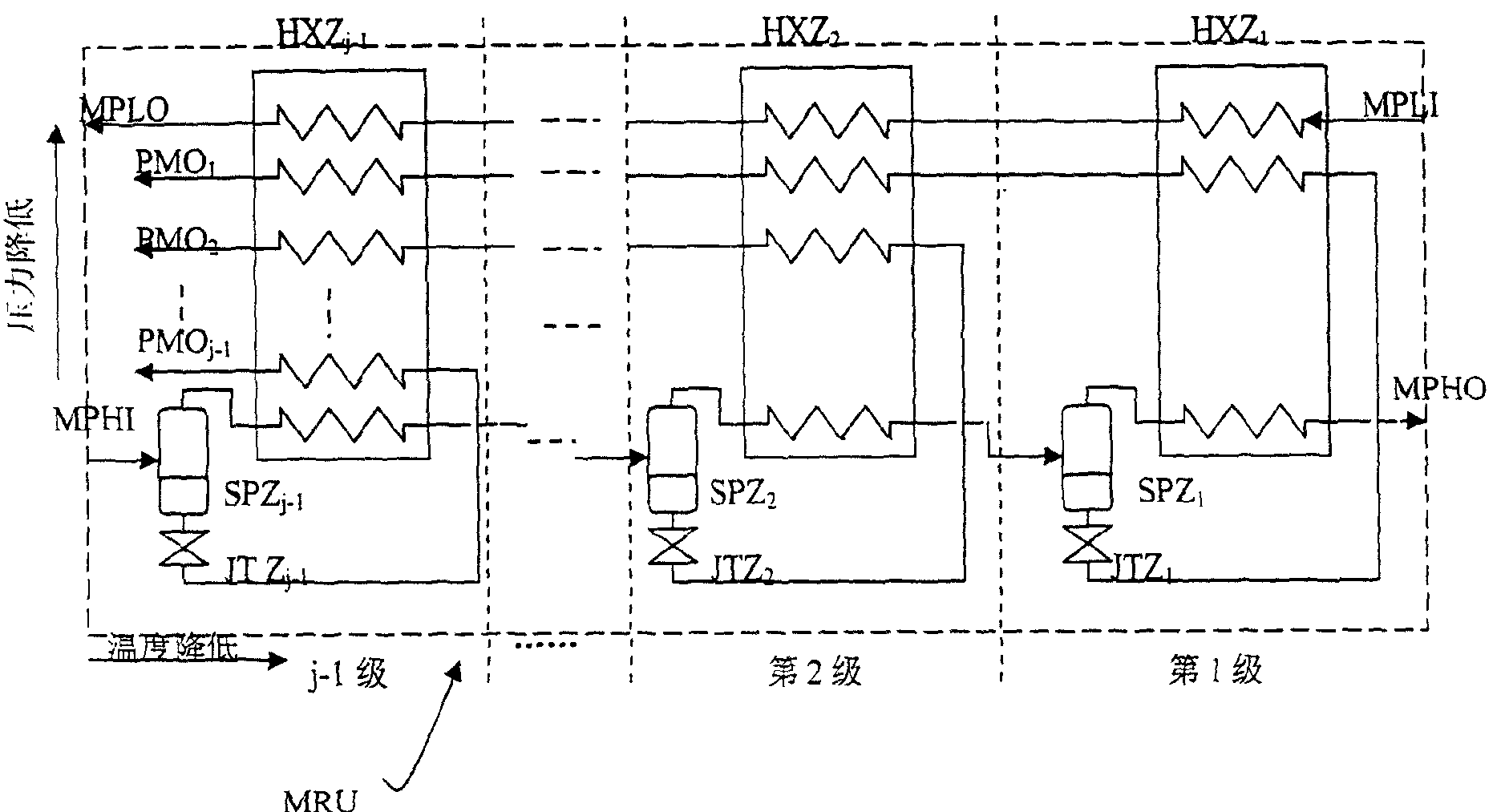

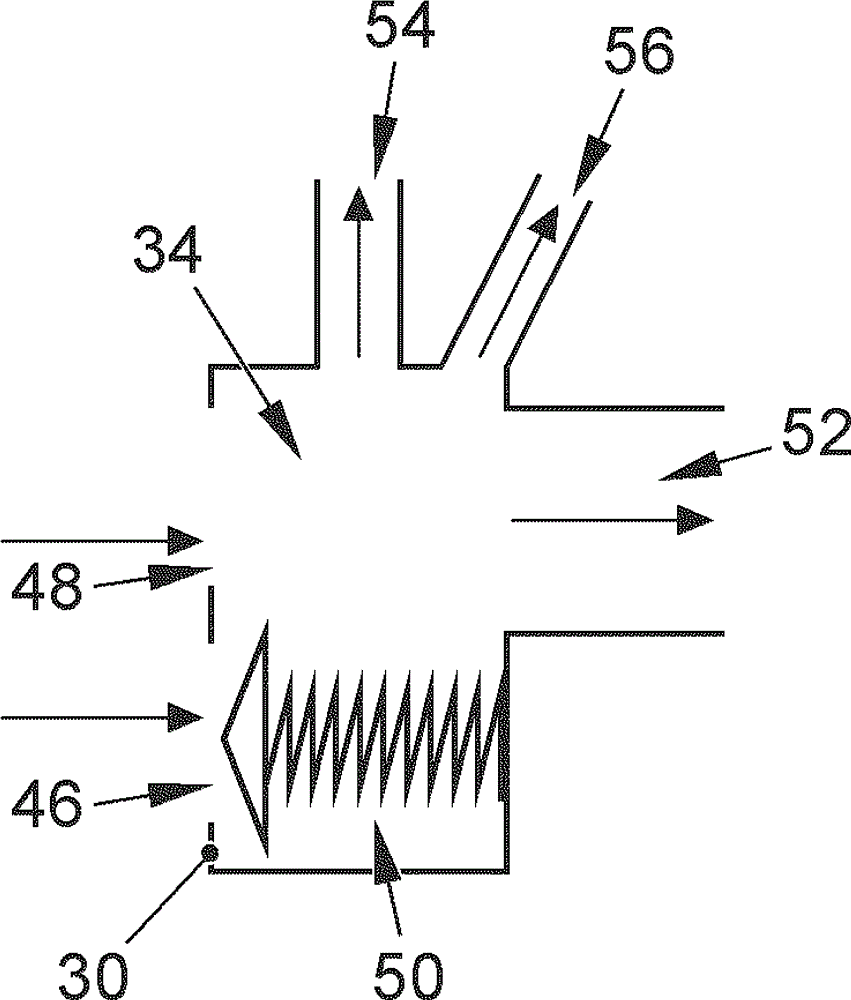

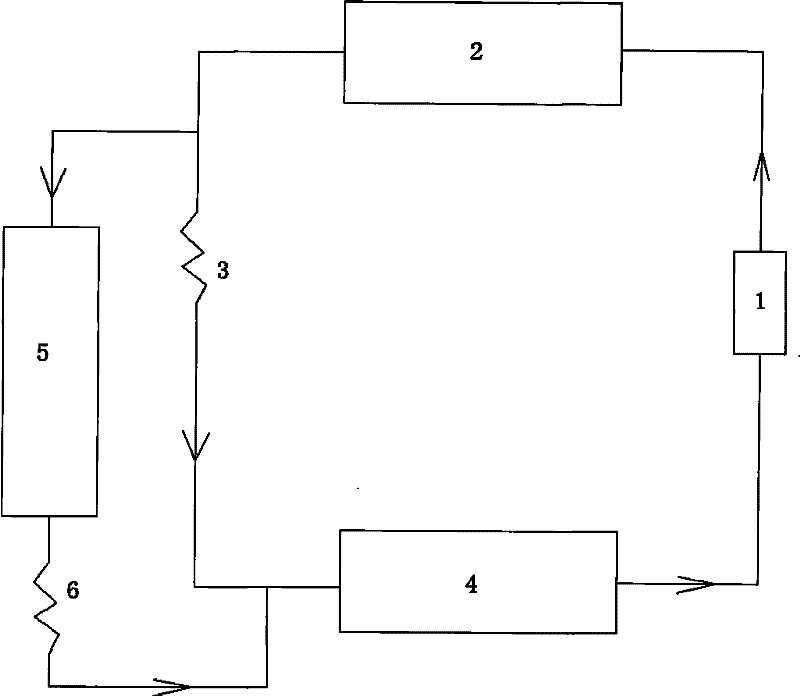

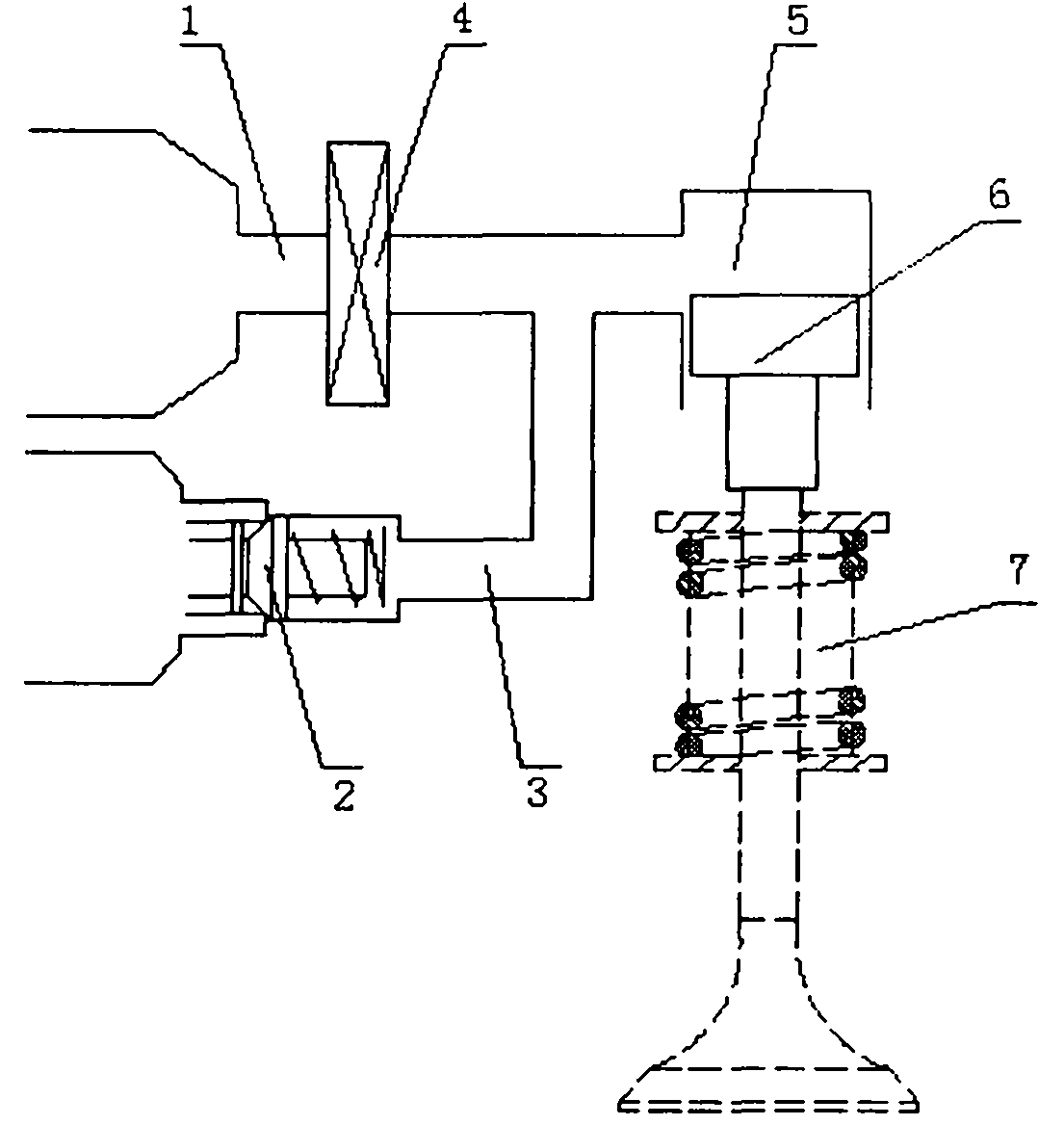

Multiple pressure grade mixed working medium cryogenic throttling refrigeration system

ActiveCN1683844AHigh thermal efficiencyGood throttling effectSolidificationLiquefactionProduct gasEngineering

The multiple pressure stage mixed work medium cryogenic throttling refrigeration system consists of several stages of compressor set unit MCPU, back heating pre-cooling unit MRU and evaporator unit EVU. The connection mode includes connecting the high pressure outlet of MCPU to the high pressure inlet of MRU, connecting the low pressure inlet of MCPU to the low pressure outlet one MRU, connecting the high pressure outlet operate MRU to the inlet of EVU, and connecting the outlet of EVU to the low pressure inlet of MRU. The present invention adopts high efficiency multiple-element mixed work medium. The refrigeration system has lowered irreversible loss of compression and back heating process thermodynamically, reduced loss in the practical flow and heat exchange process, and thus high thermodynamic efficiency, and is especially suitable for large and middle scale low temperature refrigerating and gas liquefying fields.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

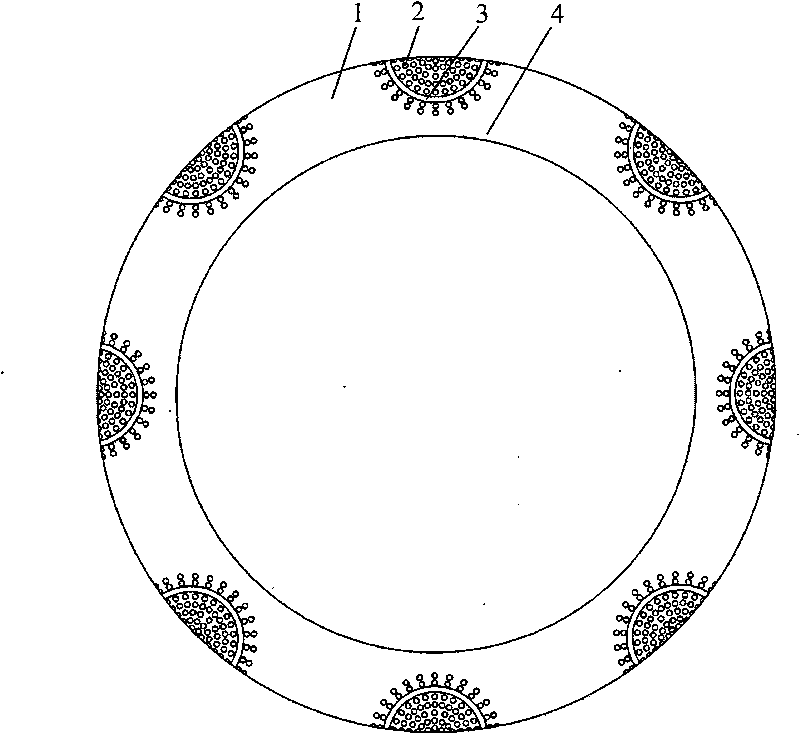

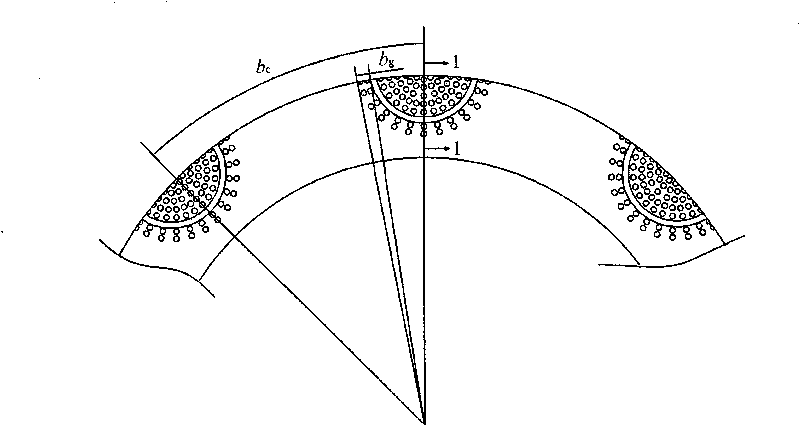

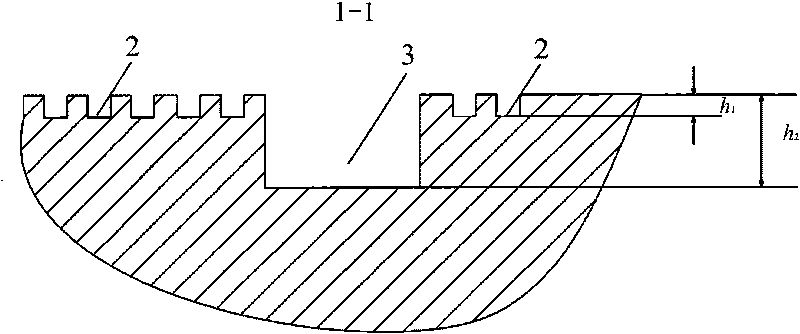

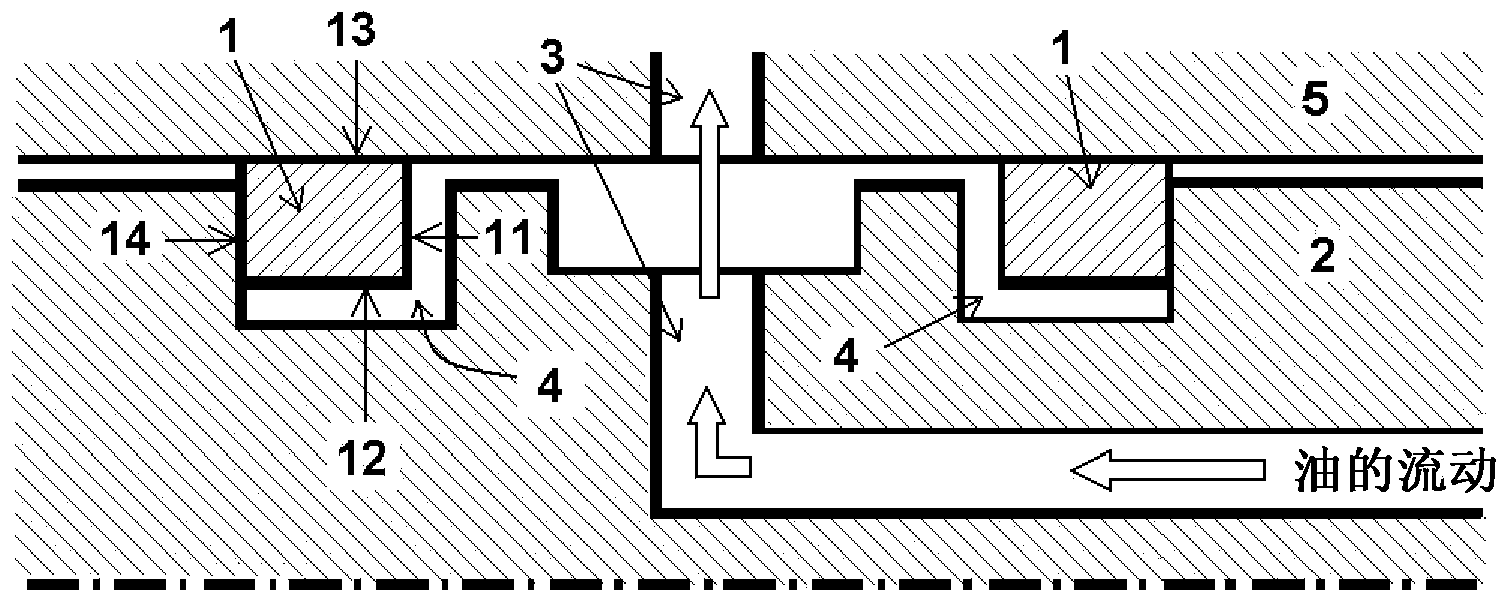

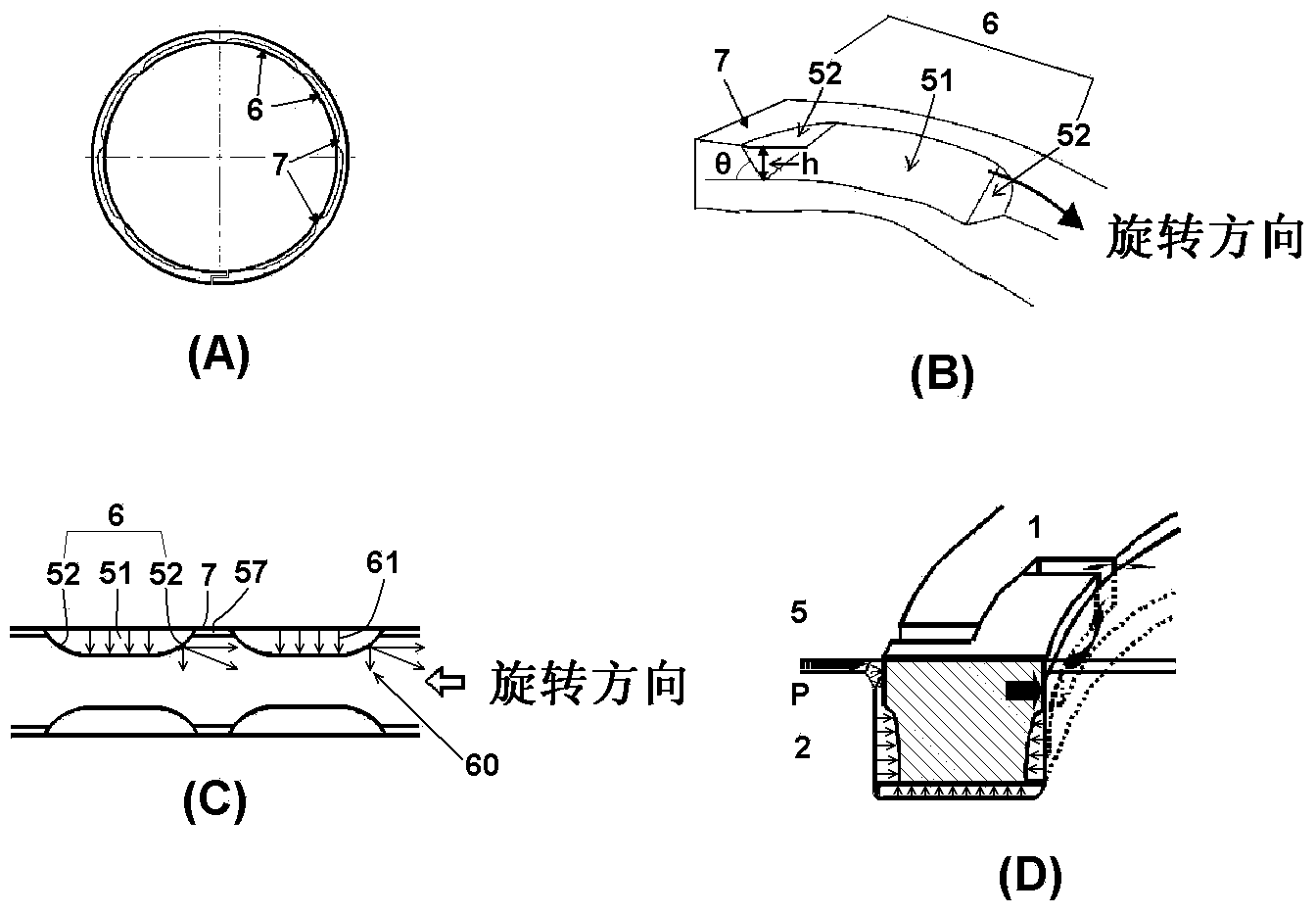

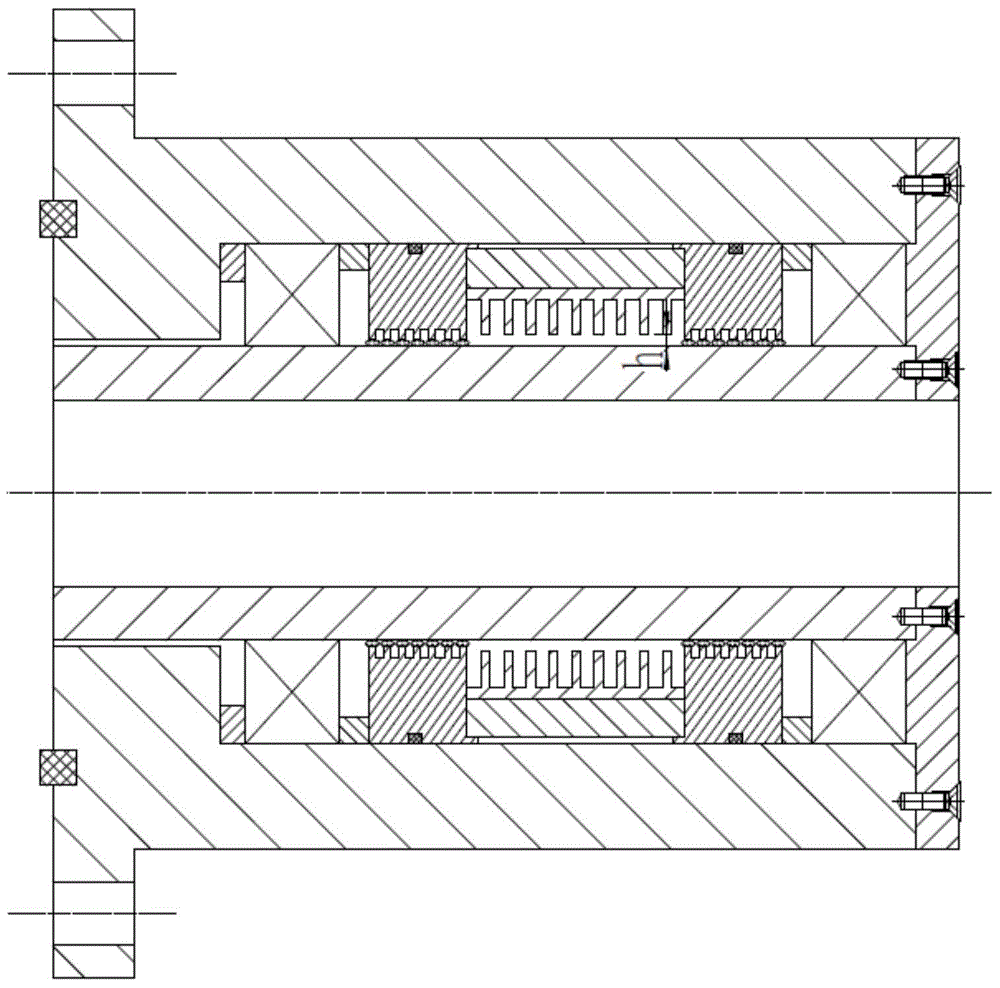

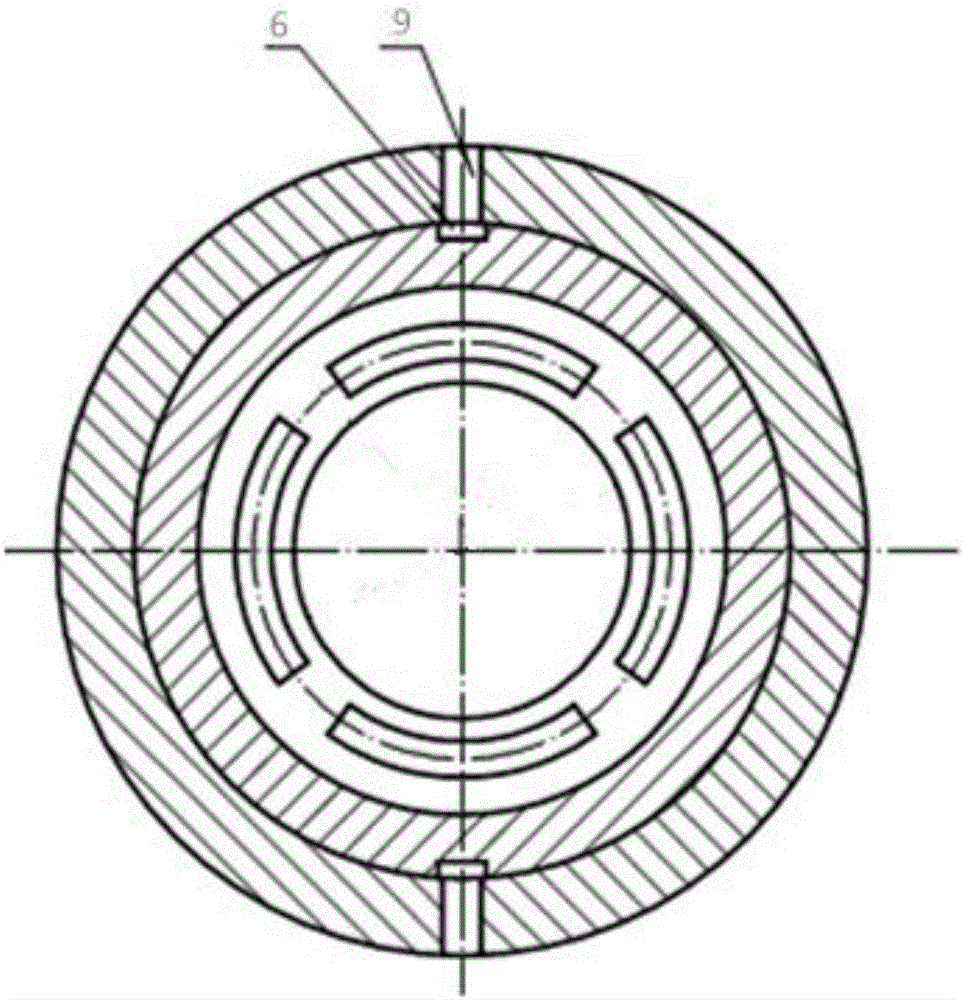

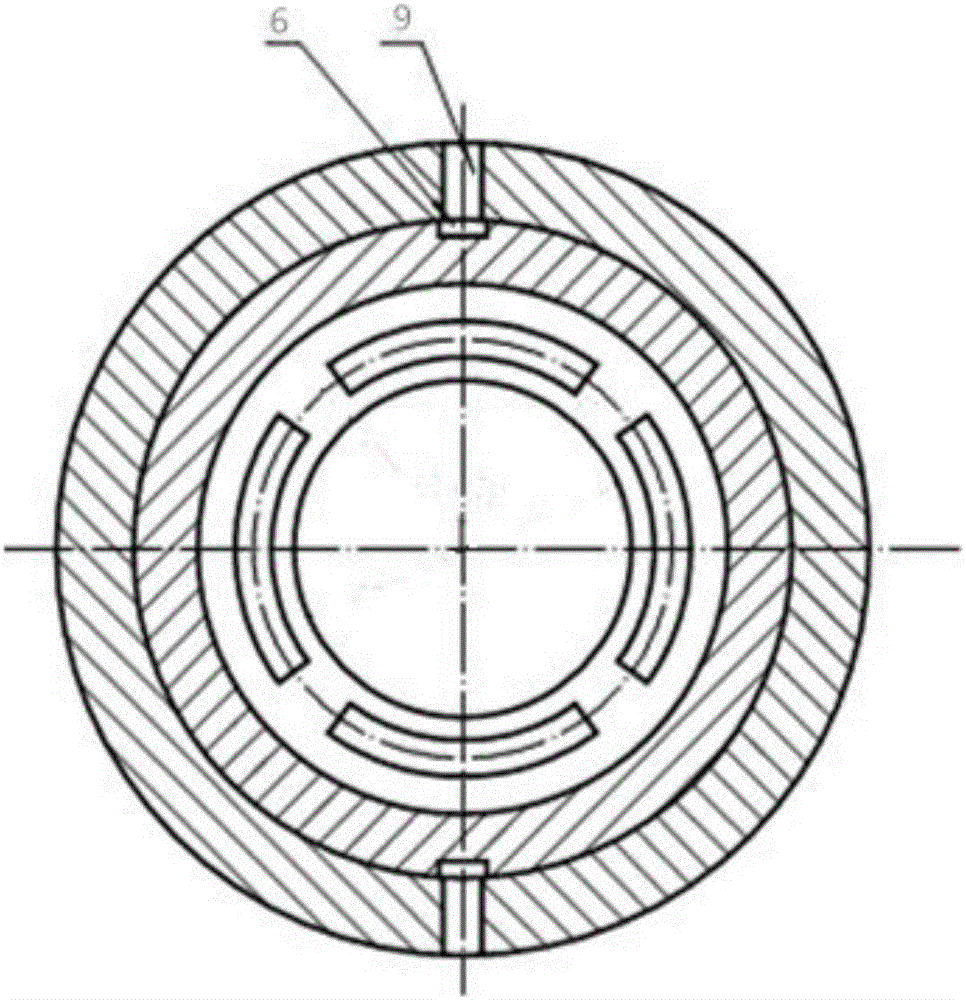

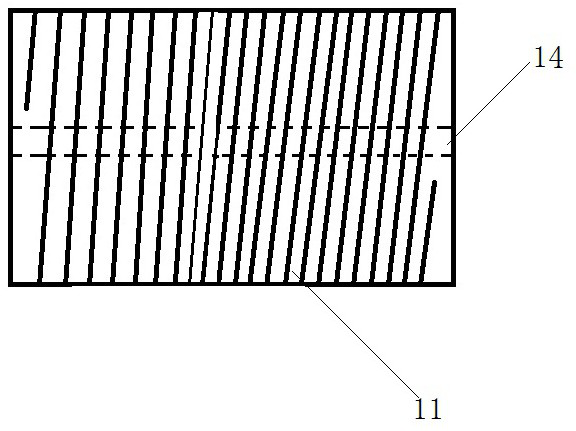

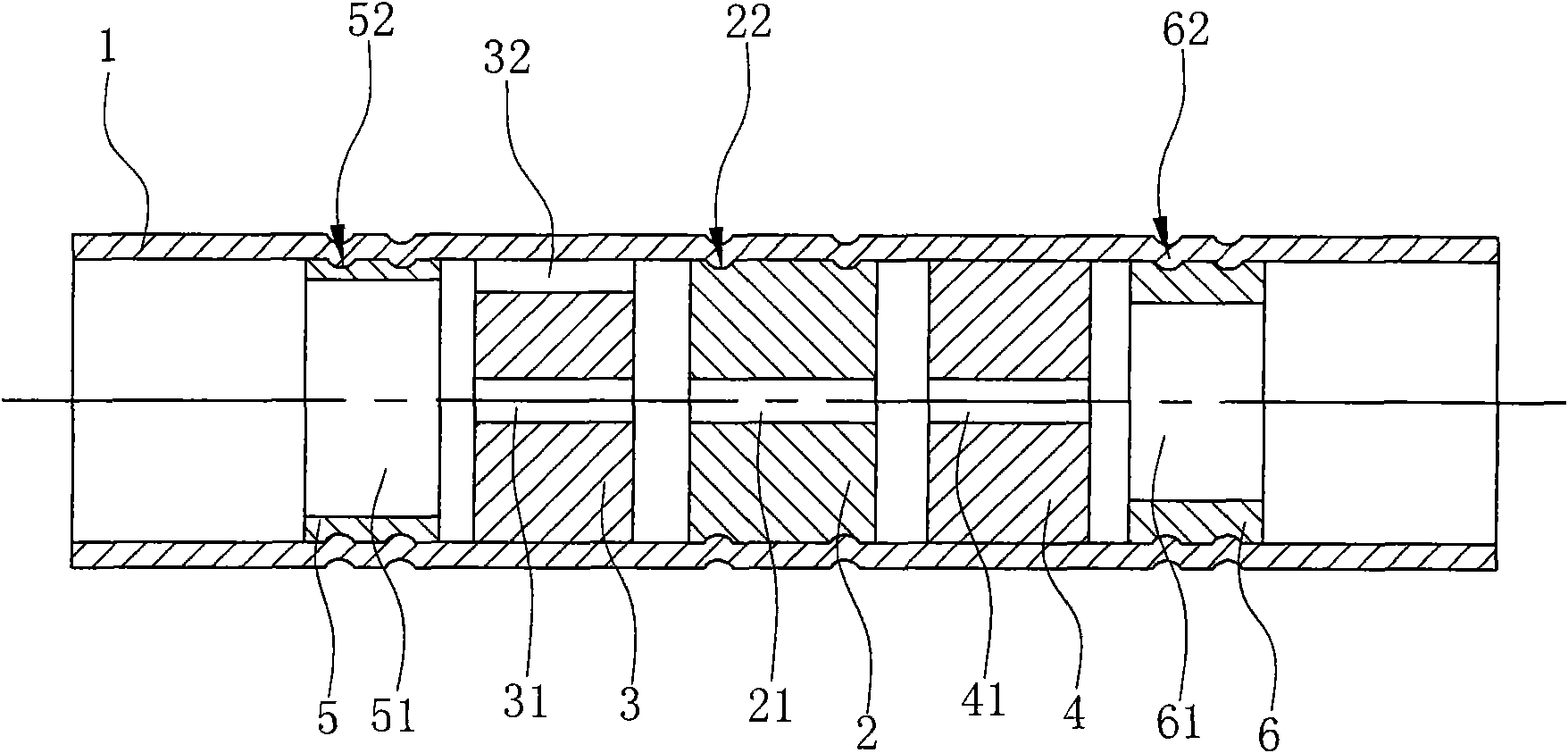

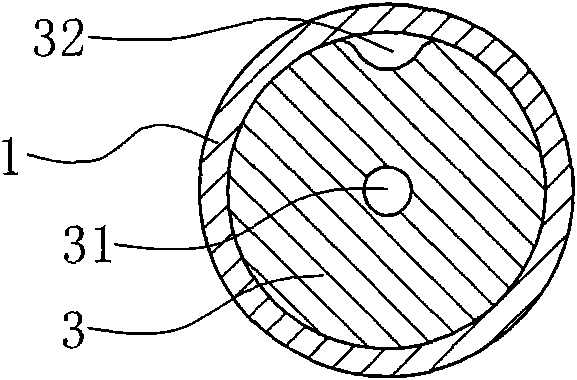

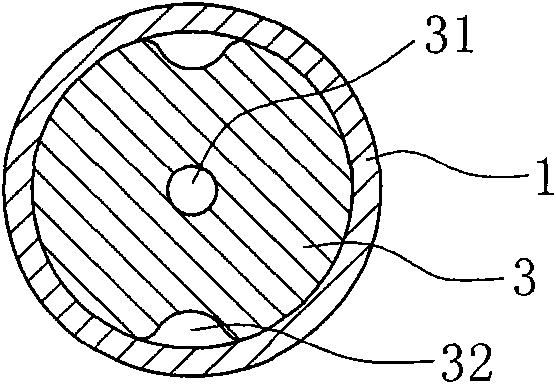

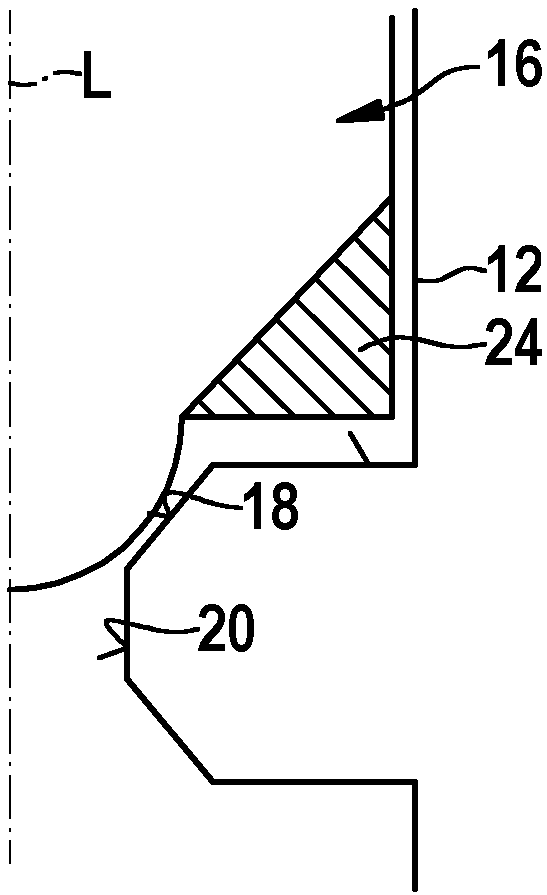

Liquid lubricated end face seal structure with cross-scale surface texture characteristic

ActiveCN101696728AImprove throttling effectEnhanced pumping effectEngine sealsPump componentsLubricationMicrometer

The invention discloses a liquid lubricated end face seal structure with a cross-scale surface texture characteristic, which comprises a moving ring and a static ring of a mechanical seal; and one side of an end face of the moving ring / static ring is a high pressure side, namely an upstream, while the other side is a low pressure side, namely a downstream. The liquid lubricated end face seal structure is characterized in that: a plurality of cross-scale texture face grooves are processed on the end face of the moving ring or the static ring of the mechanical seal; each cross-scale texture face groove consists of a millimeter deep groove and micrometer micropores; the deep groove is positioned at the upstream of the end face; the micropores are distributed on the periphery of the deep groove; seal weirs are arranged between the cross-scale texture face grooves; and a downstream of each cross-scale texture face groove is provided with an annular seal dam of a non-opened face groove. The liquid lubricated end face seal structure has the advantages of improving seal lubrication, improving the rigidity of a fluid film and the pressure and heat resistance of the mechanical seal, greatly strengthening the operational reliability, stability and leak tightness of the seal, and prolonging the service life of the seal.

Owner:ZHEJIANG UNIV OF TECH +1

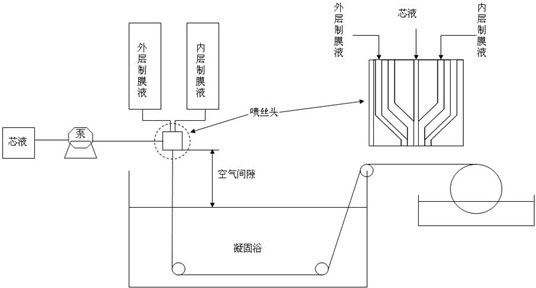

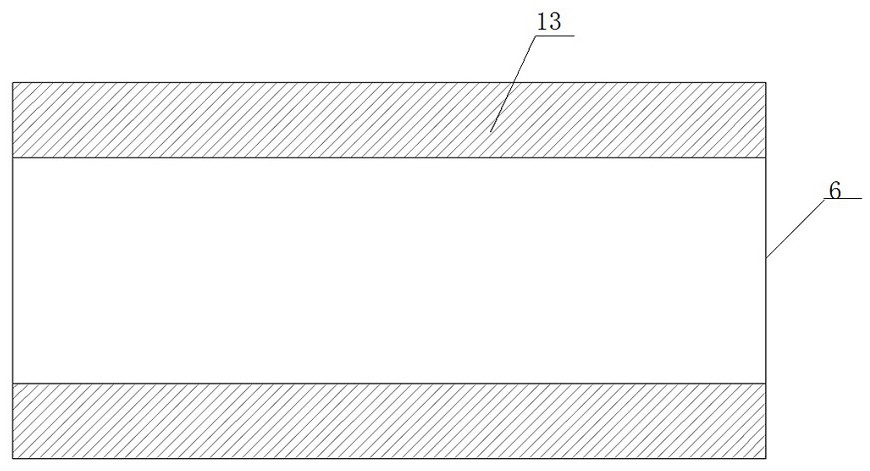

Positively charged polyvinyl chloride hollow fiber nanofiltration membrane and preparation method thereof

ActiveCN102210979ABacteria resistantWith acid and alkali resistanceSemi-permeable membranesFiberPolyvinyl chloride

The invention discloses a method for preparing a positively charged polyvinyl chloride (PVC) hollow fiber nanofiltration membrane. The positively charged PVC hollow fiber nanofiltration membrane has a two-layer structure consisting of a positively charged compact skin layer and an electrically neutral porous support layer; the pore diameter of micropores of the compact skin layer is 1-5nm, and the pore diameter of micropores of the porous support layer is 10-100nm; and the outer diameter of the membrane is 1.5-3.0mm, and the inner diameter of the membrane is 0.5-2mm, wherein the positively charged compact skin layer comprises main components of polyvinyl chloride and cationic copolymer; and the electrically neutral porous support layer comprises main components of polyvinyl chloride and an inorganic filler. The method for preparing the positively charged PVC hollow fiber nanofiltration membrane comprises the following steps of: co-extruding positively charged compact skin layer membrane preparing liquid and electrically neutral porous support layer membrane preparing liquid in a two-layer ring shape; and curing and forming hollow fibers by using a dry-wet spinning process. The prepared hollow fiber nanofiltration membrane has the advantages of easily controlled interception property, high strength, simple preparation process and the like, and is a high-performance, low-cost and long-life nanofiltration membrane material for water treatment.

Owner:HAINAN LITREE PURIFYING TECH CO LTD

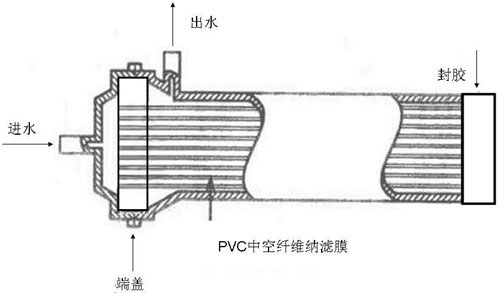

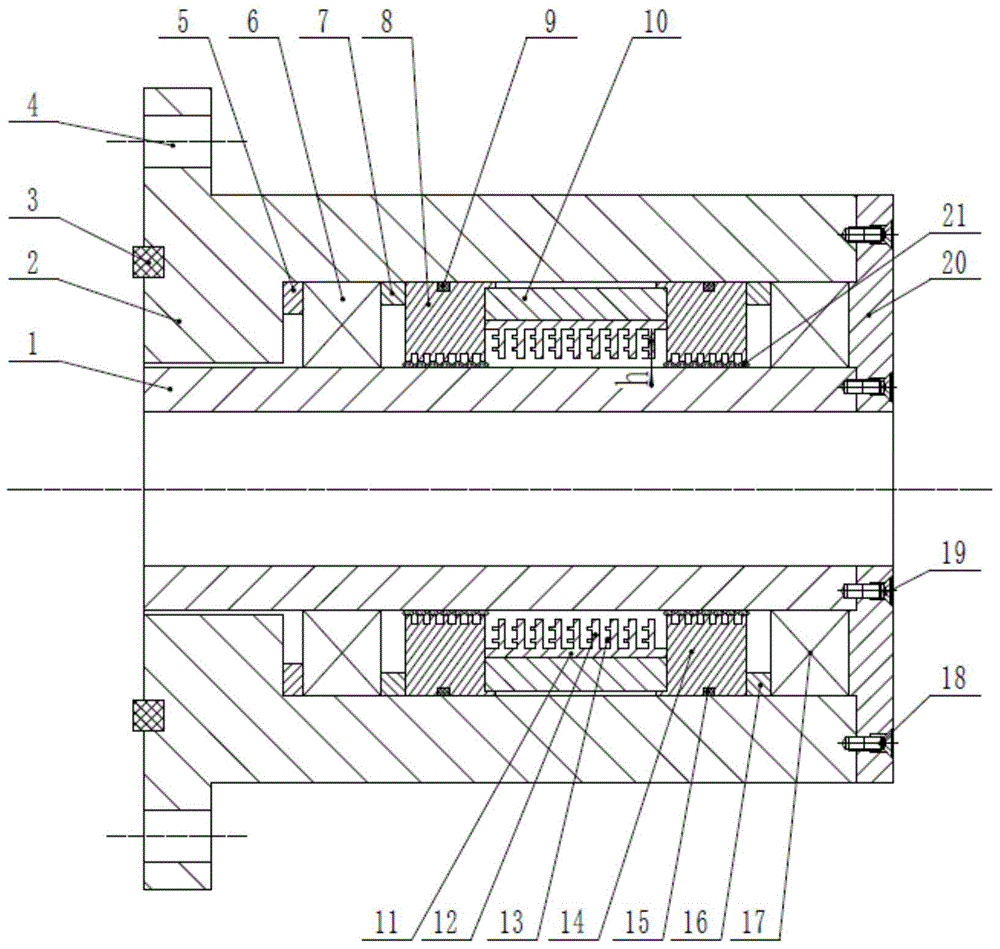

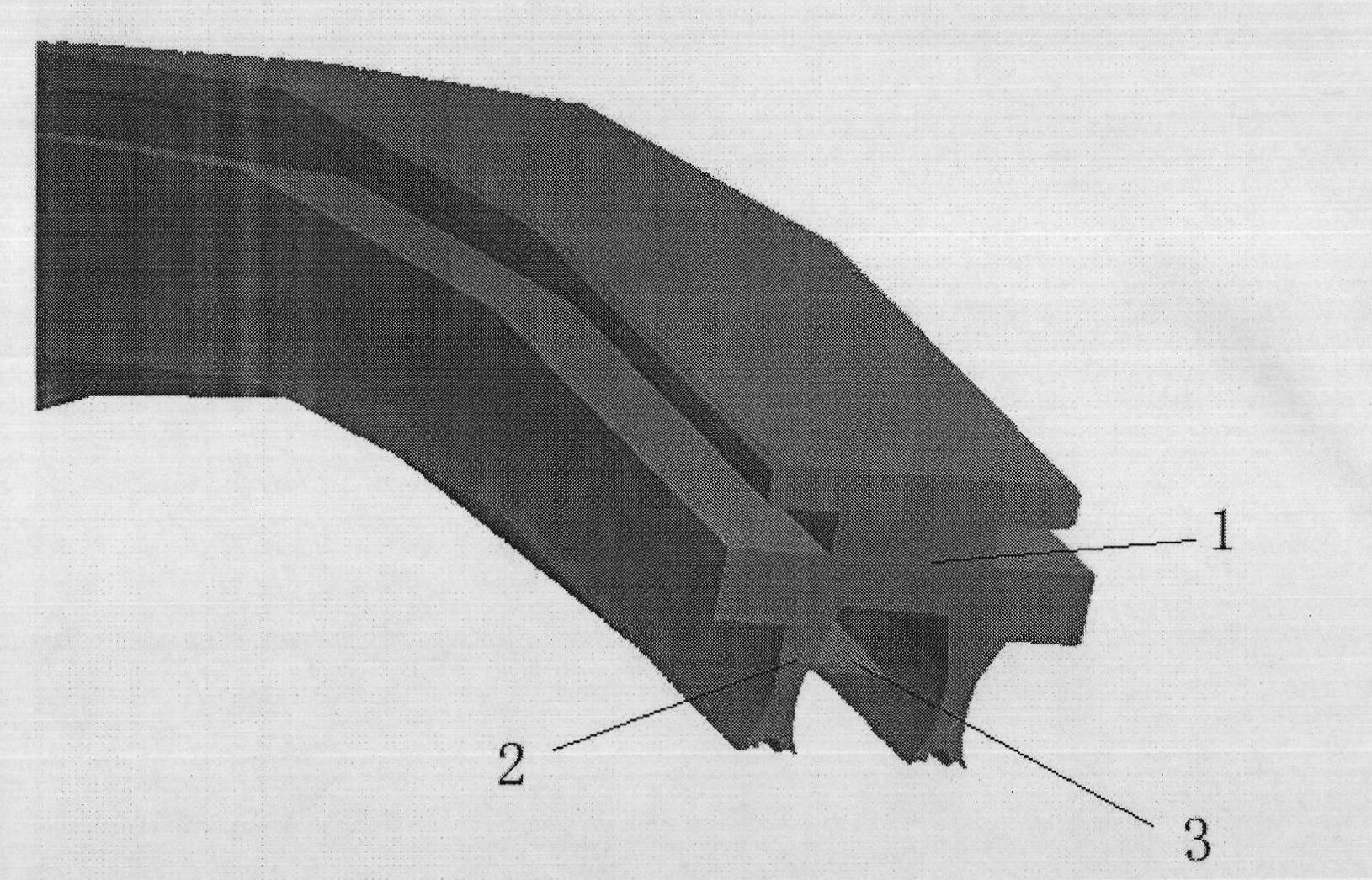

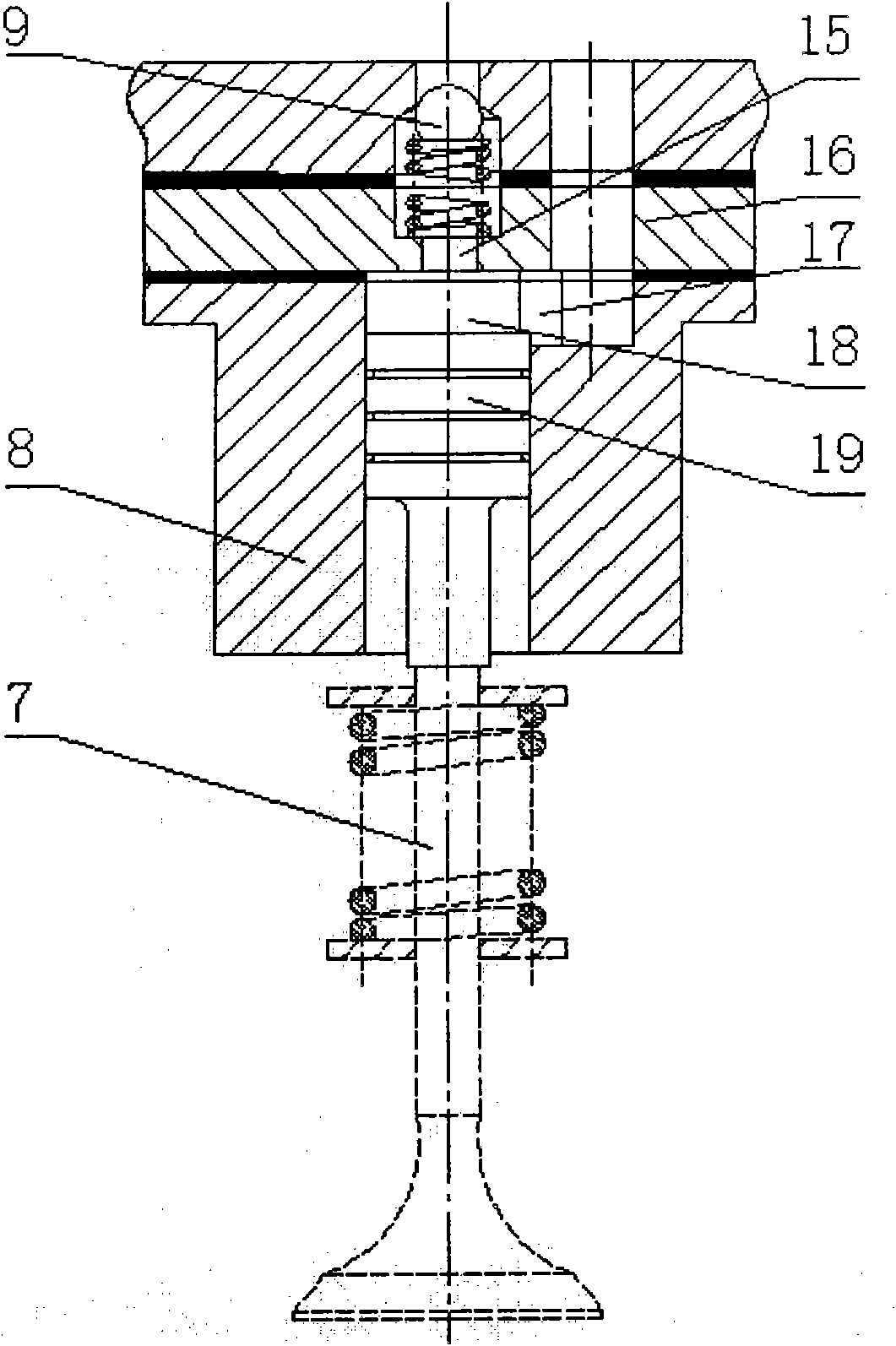

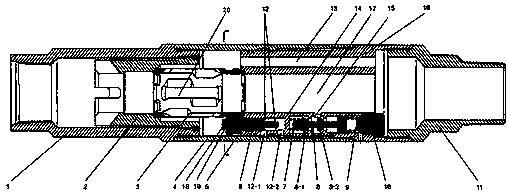

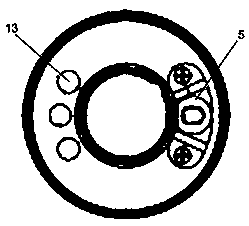

Magnetic liquid sealing device with pole shoes being provided with high teeth and low teeth

A magnetic liquid sealing device with pole shoes being provided with high teeth and low teeth. Positioning rings (5), left bearings (6), left magnetic separation rings (7), magnetic liquid sealing assemblies, right magnetic separation rings (13) and right bearings (14) are sequentially arrayed in outer covers (1). After magnetic liquid (17) is injected into inner rings of magnets (10), shaft sleeves (3) are arranged in inner holes of the above parts, then screws (20) are used for fixing end covers (18) on the outer covers (1), the outer circles of the right bearings (14) are compressed, and the end covers (18) and the shaft sleeves (3) are connected by screws (19). The characteristic that pole teeth are arranged on a common magnetic liquid sealing upper pole shoe is utilized, and pole teeth which are originally arranged on a magnetic liquid seal are replaced by high teeth in a labyrinth seal. The magnetic liquid sealing device with the pole shoes being provided with the high teeth and the low teeth is simple in structure, the impact resistance of the magnetic liquid seal is improved, and the magnetic liquid seal is made to be used in certain the severe proof pressure environments where pressure can be increased suddenly and sharply.

Owner:BEIJING JIAOTONG UNIV

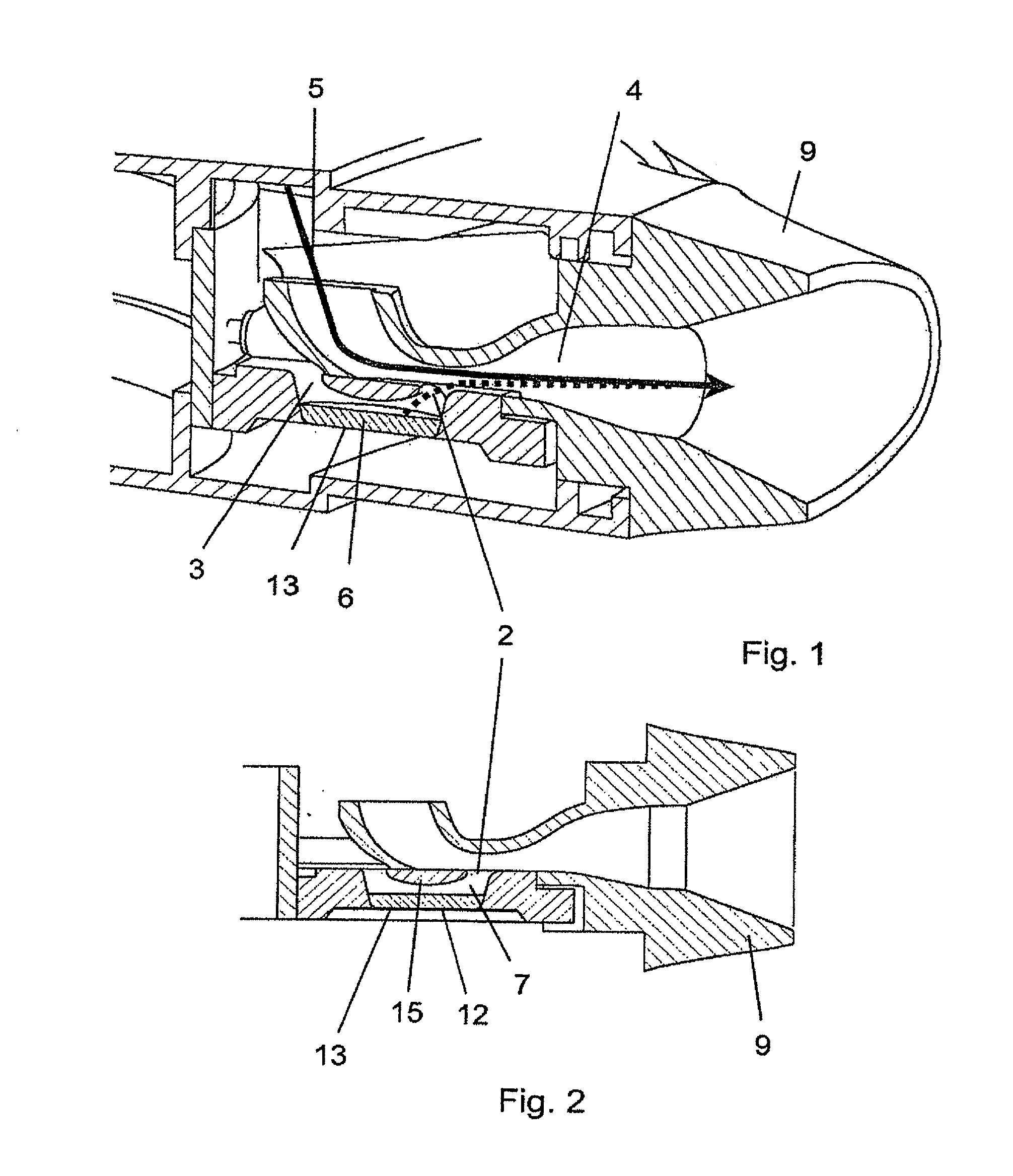

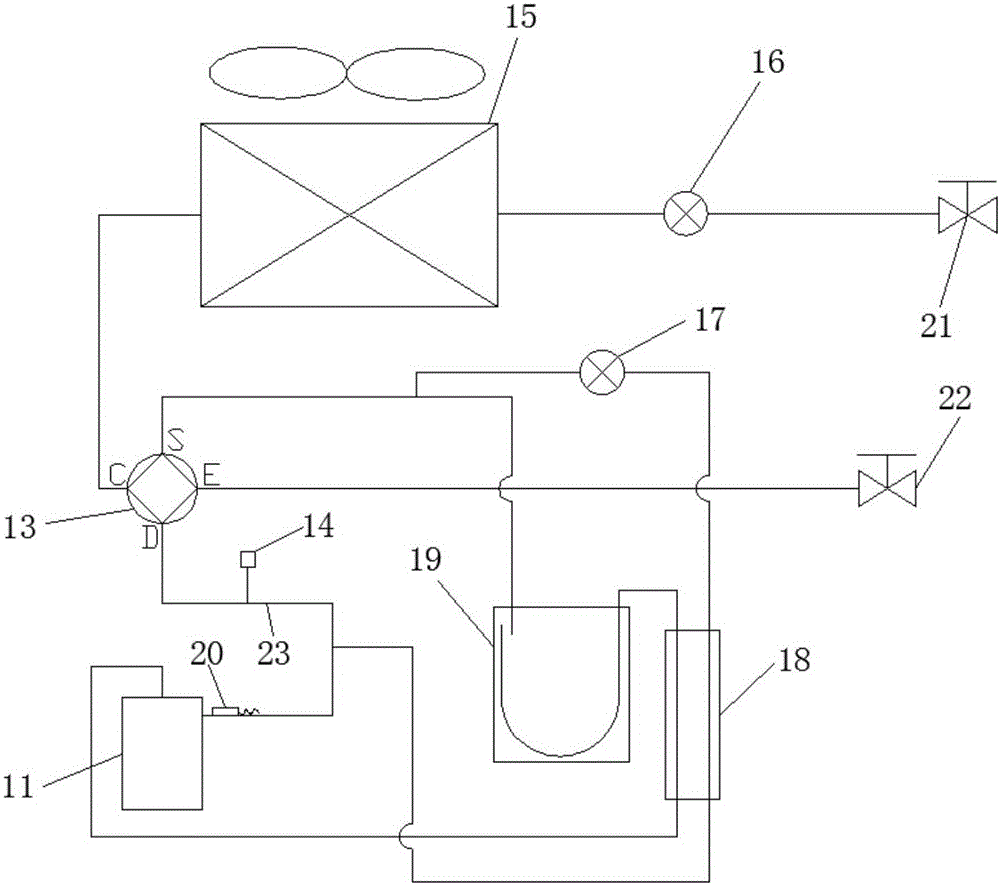

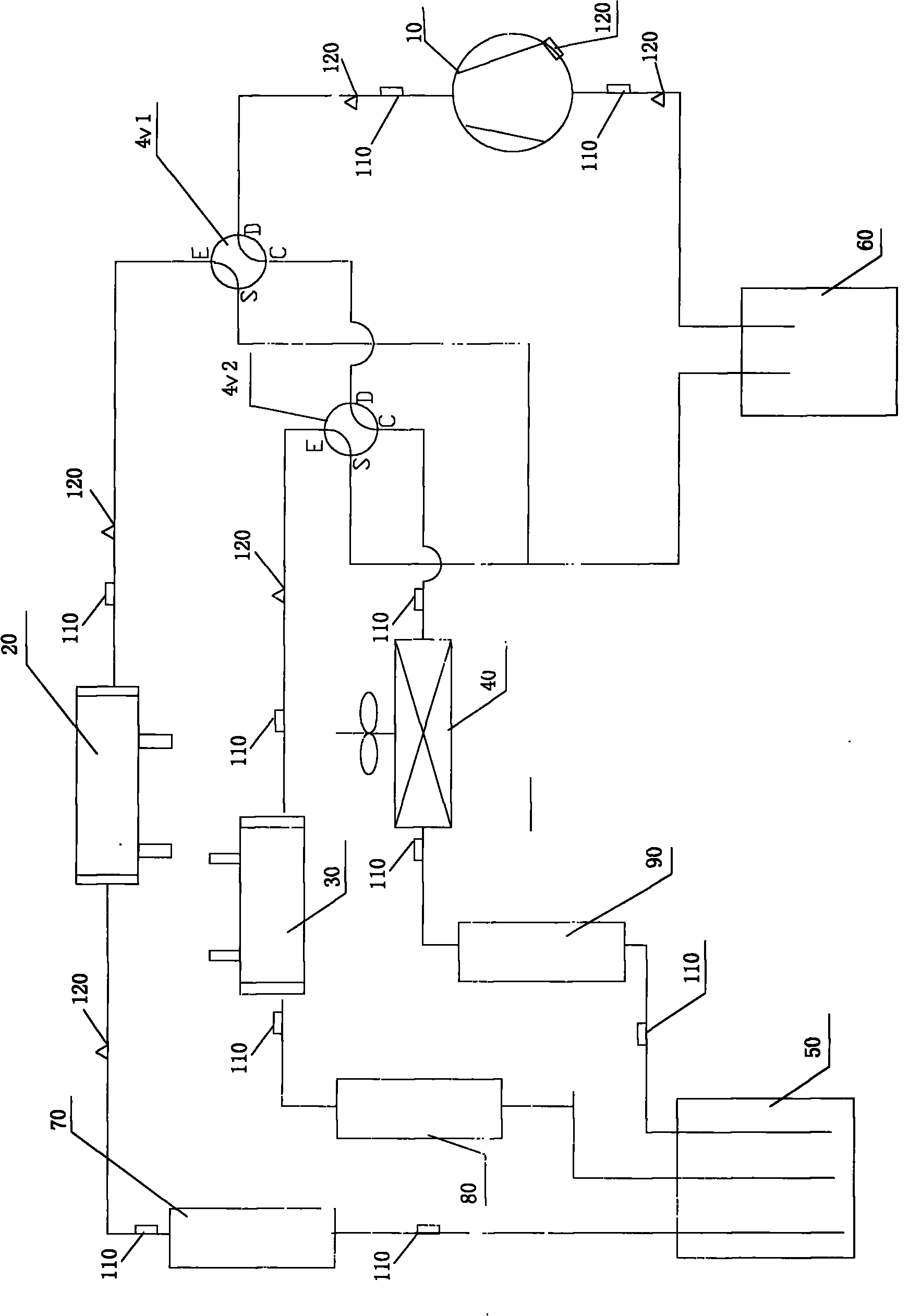

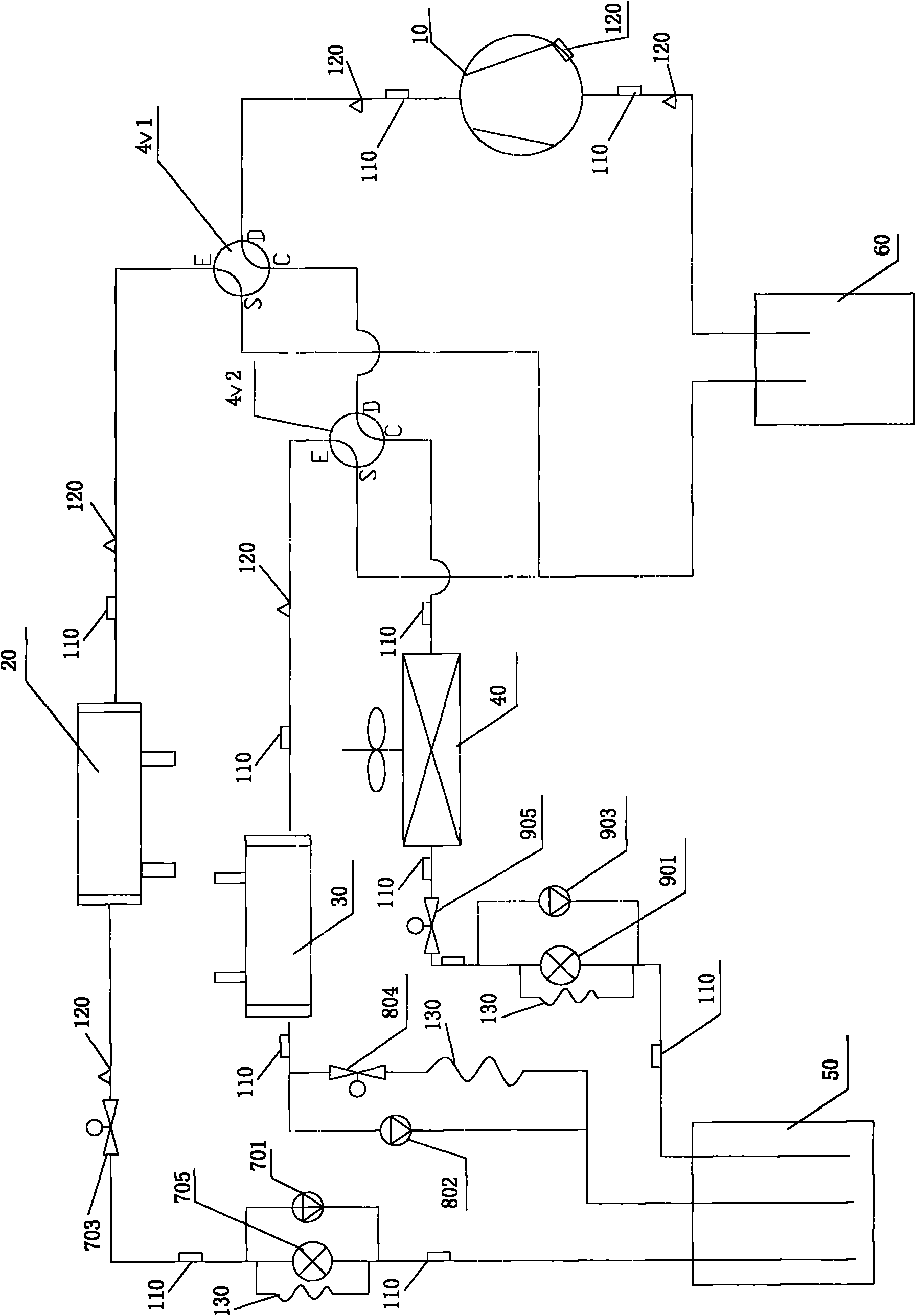

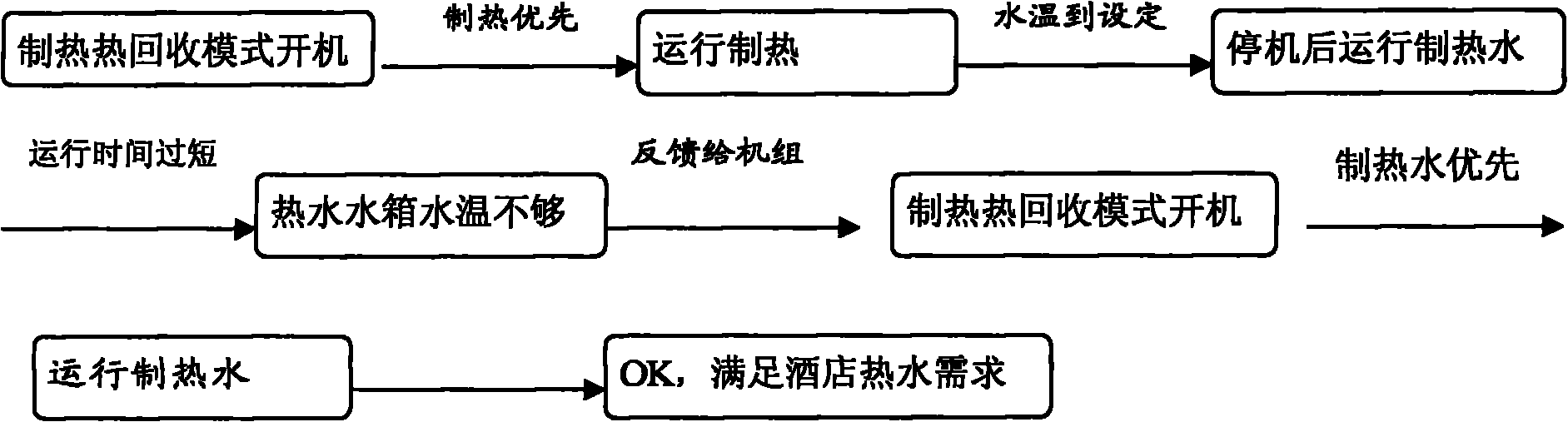

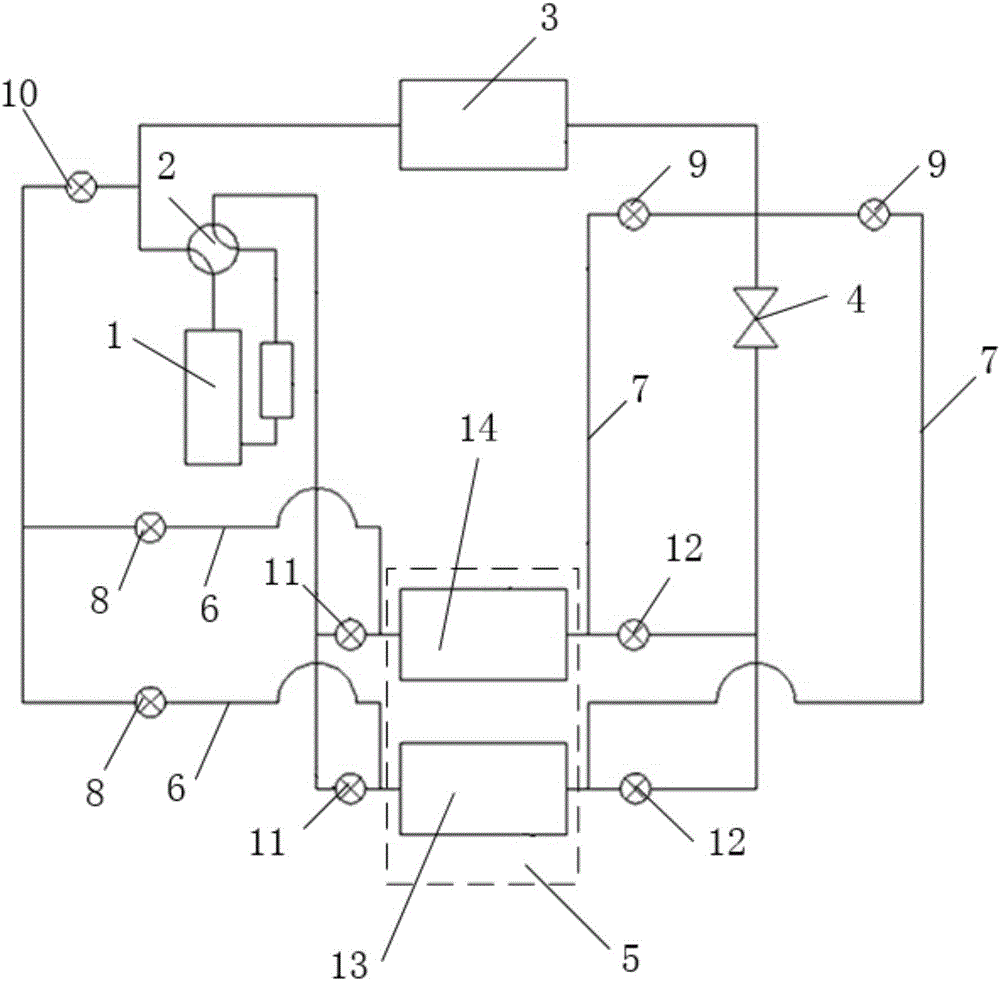

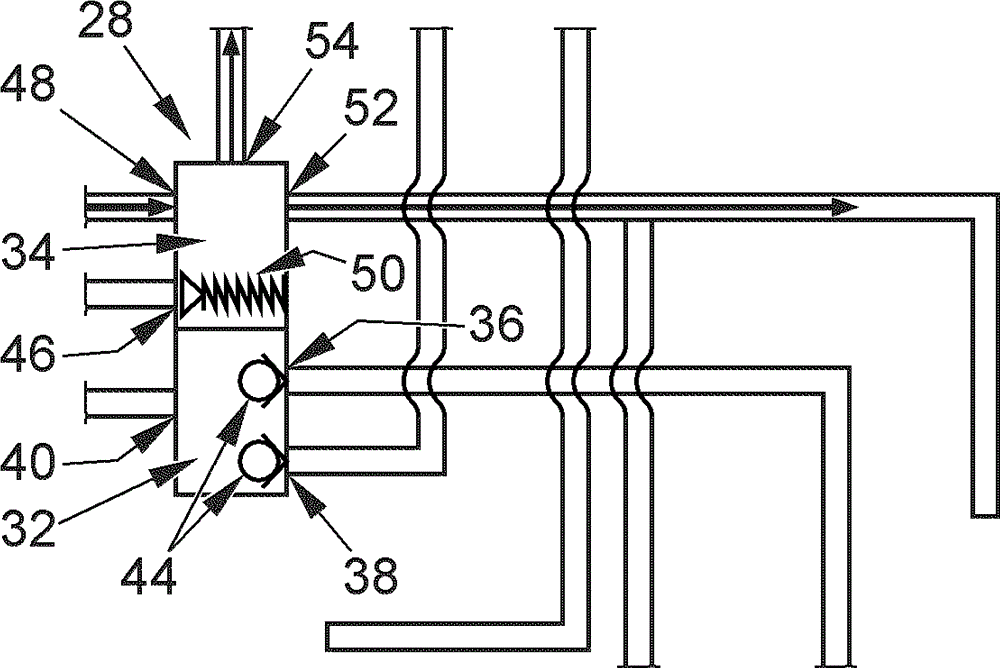

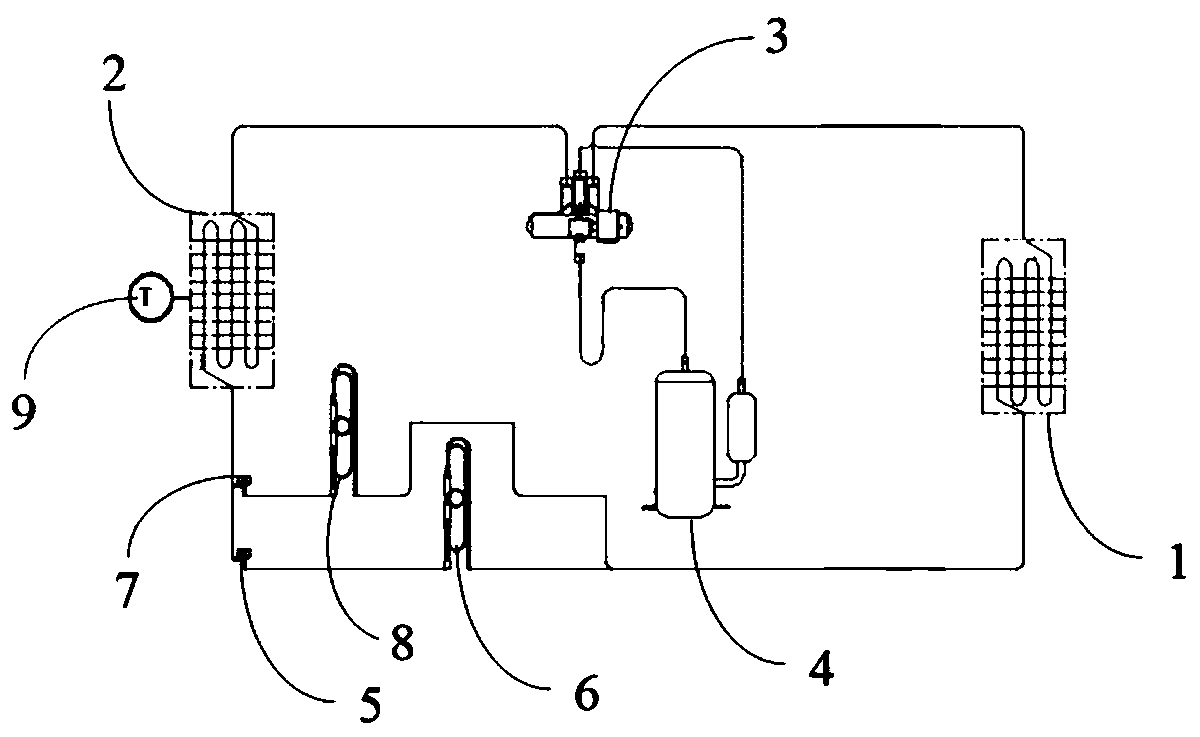

Heat reclamation module unit, air-conditioning unit and control method

ActiveCN102095294AGood throttling effectImprove matchSpace heating and ventilation safety systemsSpace heating and ventilation control systemsVapor–liquid separatorFour-way valve

The invention provides a heat reclamation module unit, which comprises a compressor, a first four-way valve, a second four-way valve, an air-conditioning water shell-tube heat exchanger, a first throttling device, a second throttling device, a third throttling device, a first heat exchanger, a hot water shell-tube heat exchanger, an air-liquid separator, a liquid storage tank and a connecting pipe; the D end of the first four-way valve is connected with the exhaust end of the compressor; the E end of the first four-way valve is connected with the output end of the air-conditioning water shell-tube heat exchanger; the S end of the first four-way valve is connected with the input end of the air-liquid separator; the C end of the first four-way valve is connected with the D end of the second four-way valve; the C end of the second four-way valve is connected with the input end of the first heat exchanger; the E end of the second four-way valve is connected with the output end of the hot water shell-tube heat exchanger; and the S end of the second four-way valve is connected with the input end of the air-liquid separator.

Owner:GREE ELECTRIC APPLIANCES INC

Seal ring

Owner:RIKEN CO LTD

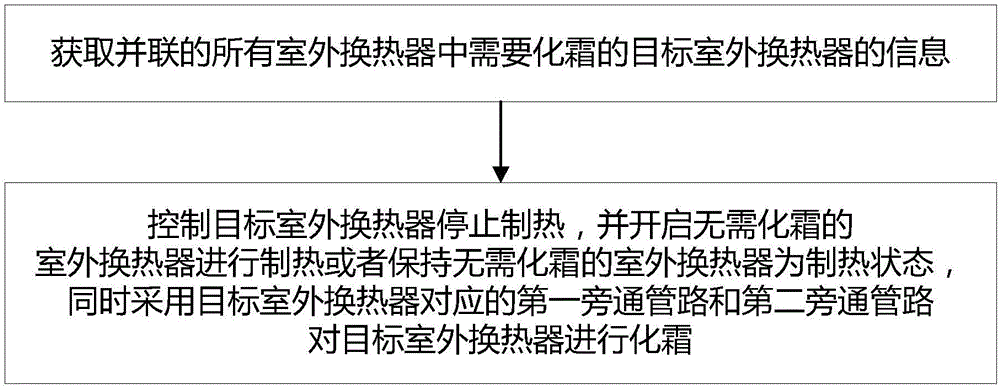

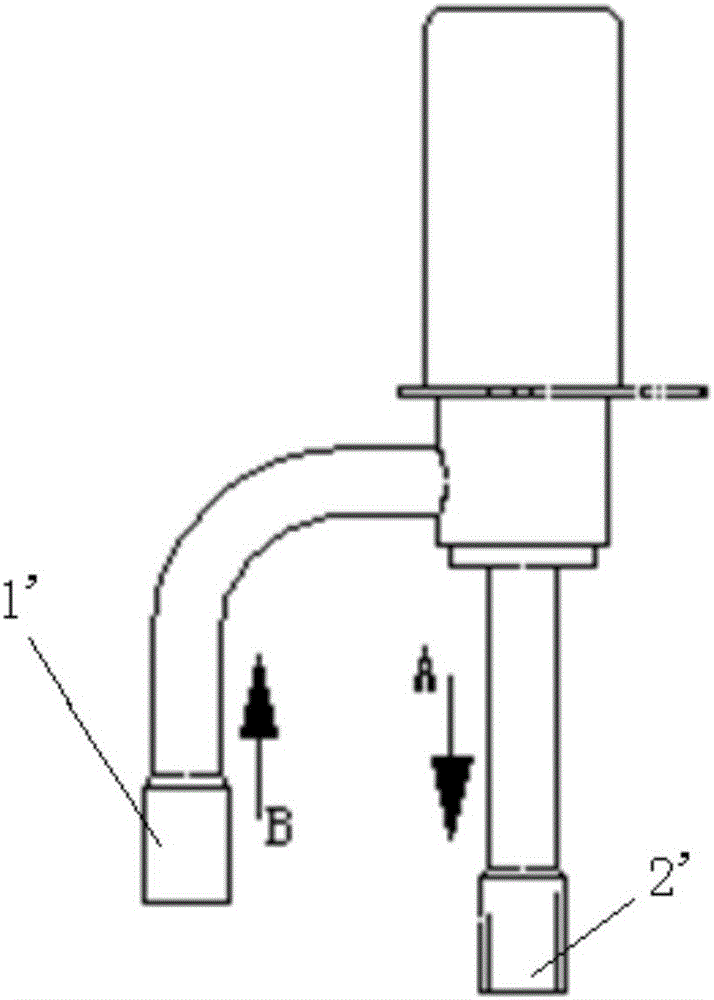

Air conditioner defrosting device, air conditioner defrosting control method and system and air conditioner

InactiveCN106524399AImprove operational reliabilityWill not cause large changes in suction and exhaust pressureMechanical apparatusSpace heating and ventilation safety systemsEngineeringDischarge pressure

The invention particularly relates to an air conditioner defrosting device, an air conditioner defrosting control method and a system and an air conditioner. Multiple parallel outdoor heat exchangers are provided; one or more outdoor heat exchangers can be selected for heating according to application environments of the air conditioner and user demands; when the outdoor heat exchangers need to defrost, the outdoor heat exchangers are defrosted by a hot air bypassing mode, and the other outdoor heat exchangers without needing defrosting are adopted to continuously heat, so that the indoor continuous heating in the defrosting process is realized, and the indoor comfort is prominently improved; and meanwhile, low-temperature gas after defrosting cooling in a bypass pipeline dose not directly enter a gas return port of a compressor, but enters a refrigerant circulating loop after being throttled by an electronic throttling part, so that the great change of the intake / exhaust pressure of the compressor cannot be caused, and the operation reliability of the compressor is improved.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD +1

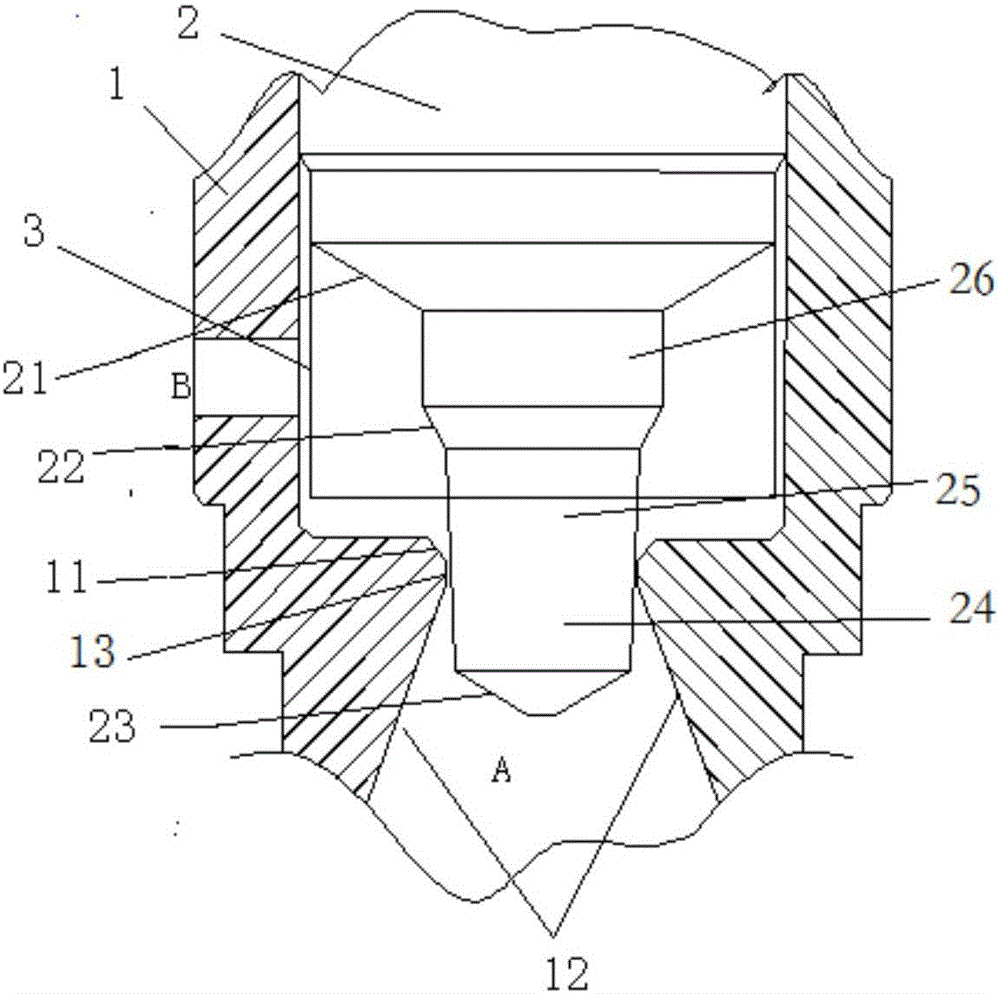

Expansion valve, refrigerant cycle system and air conditioner

InactiveCN105972233AGood throttling effectFluid circulation arrangementLift valveBiomedical engineering

The invention relates to an expansion valve, a refrigerant cycle system and an air conditioner. The expansion valve comprises a valve body (1) and a valve needle (2) arranged in the valve body (1), the valve body (1) is provided with a valve needle hole, the valve needle (2) is provided with a flow adjusting portion used for being inserted into the valve needle hole, the cross section of the flow adjusting portion is reduced in the flowing direction of fluid in the expansion valve, the valve needle (2) can move in the axial direction of the valve needle hole so as to change a gap between the flow adjusting portion and the valve needle hole, the flow adjusting portion comprises a first valve needle segment (24) and a second valve needle segment (25), the first valve needle segment (24) is located on the downstream portion of the second valve needle segment (25) in the flowing direction of the fluid, the change rate of the cross section of the first valve needle segment (24) is larger than that of the second valve needle segment (25). The expansion valve is beneficial for reducing the throttling function under the full-open state.

Owner:GREE ELECTRIC APPLIANCES INC

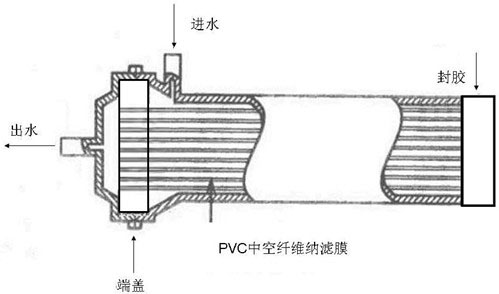

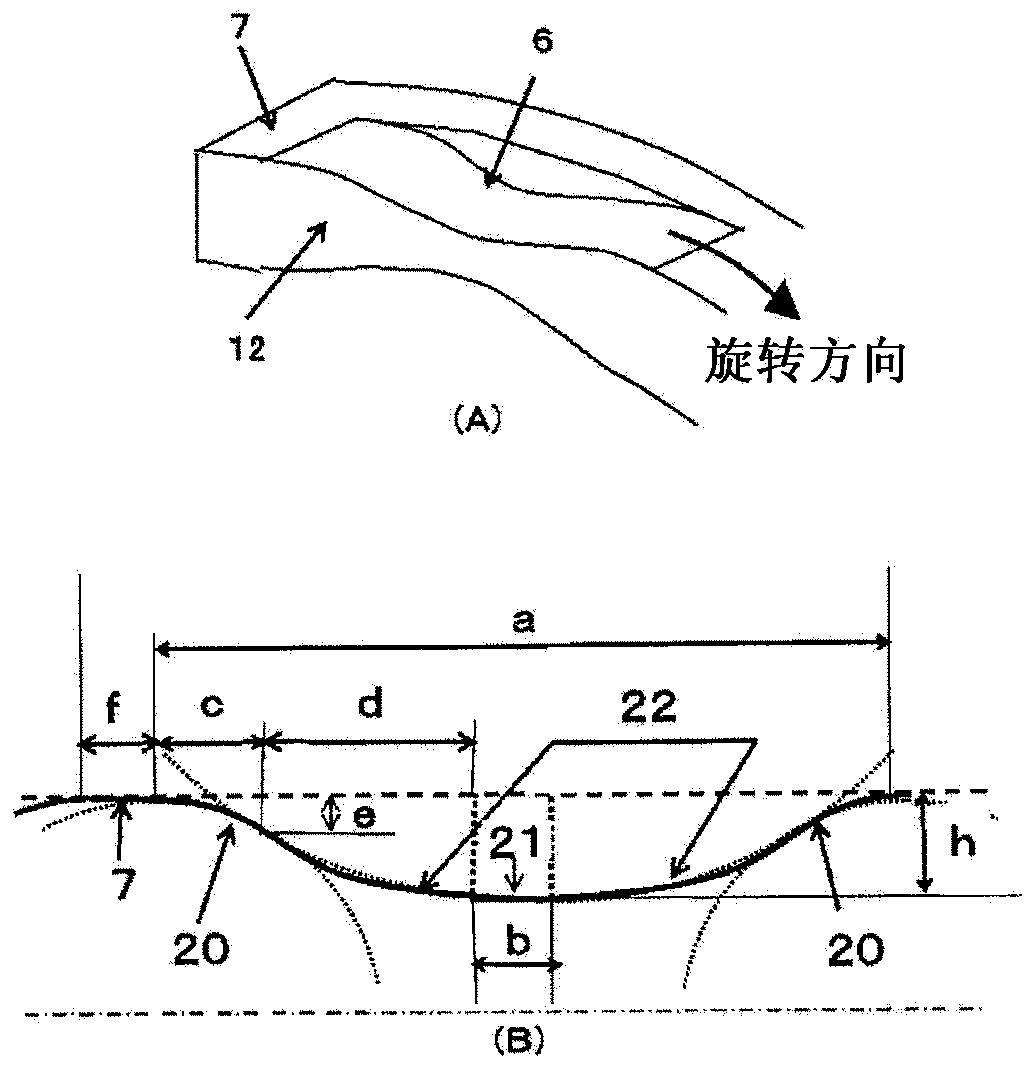

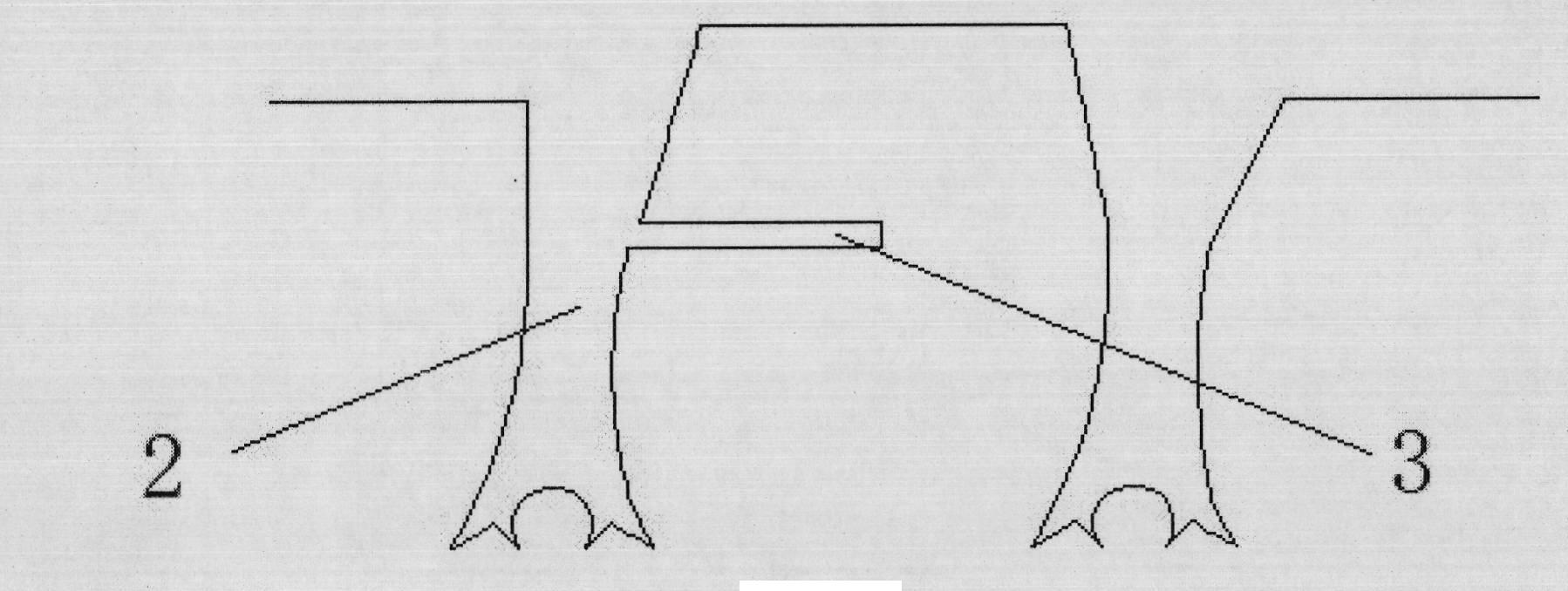

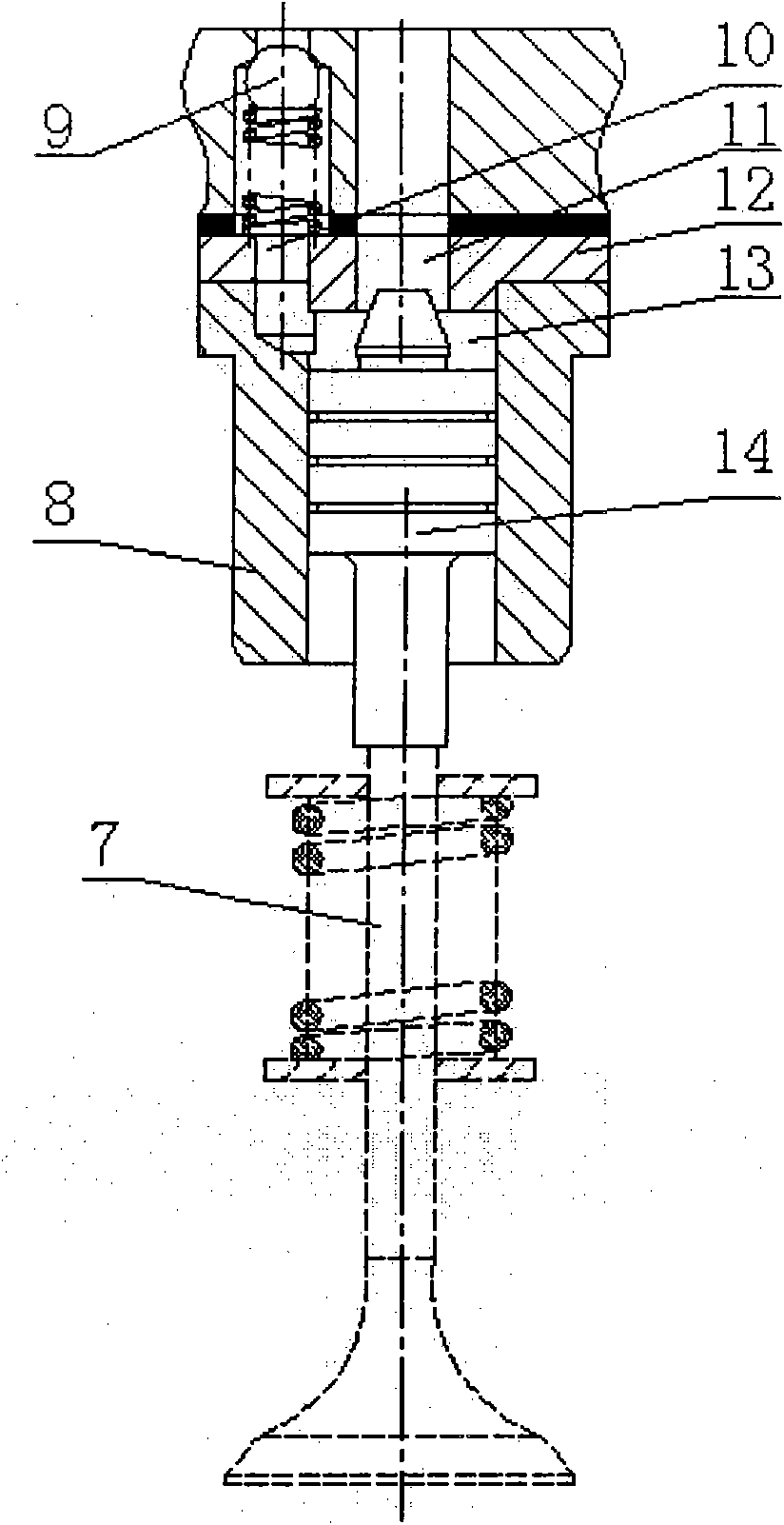

Method for improving magnetic liquid sealing reliability

The invention provides a method for improving magnetic liquid sealing reliability, and belongs to the field of mechanical engineering sealing. The method comprises the following steps that a left pole shoe (8), a left sealing ring (9), a magnet (10), a right pole shoe (14), a right sealing ring (15) and a shaft sleeve (1) sequentially form a magnetic liquid sealing assembly; the left sealing ring (9), the right sealing ring (15) and a labyrinth sealing ring (11) sleeve an inner ring of the magnet (10) and realize the labyrinth sealing with the shaft sleeve (1), a positioning ring (5), a left bearing (6), a left magnetic separation ring (7), the magnetic liquid sealing assembly, a right magnetic separation ring (16) and a right bearing (17) are sequentially arranged in an outer sleeve (2), then, magnetic liquid (21) is injected onto the labyrinth sealing ring (11) sleeving the inner ring of the magnet (18), then, the shaft sleeve (1) is arranged in an inner hole of a part, an end cover (20) is fixedly arranged on the outer sleeve (2) through screws (18), in addition, the outer ring of the right bearing (17) is rightly pressed, and a screw (19) is used for connecting the end cover (20) and the shaft sleeve (1). The method has the advantages that the axial length for the sealing is not increased, the structure is simple, and the magnetic liquid sealing impact-resistant capability is improved, so the magnetic liquid sealing can be used in the toxic and harmful gas medium environment with great pressure fluctuation, and the magnetic liquid sealing use reliability is improved.

Owner:BEIJING JIAOTONG UNIV

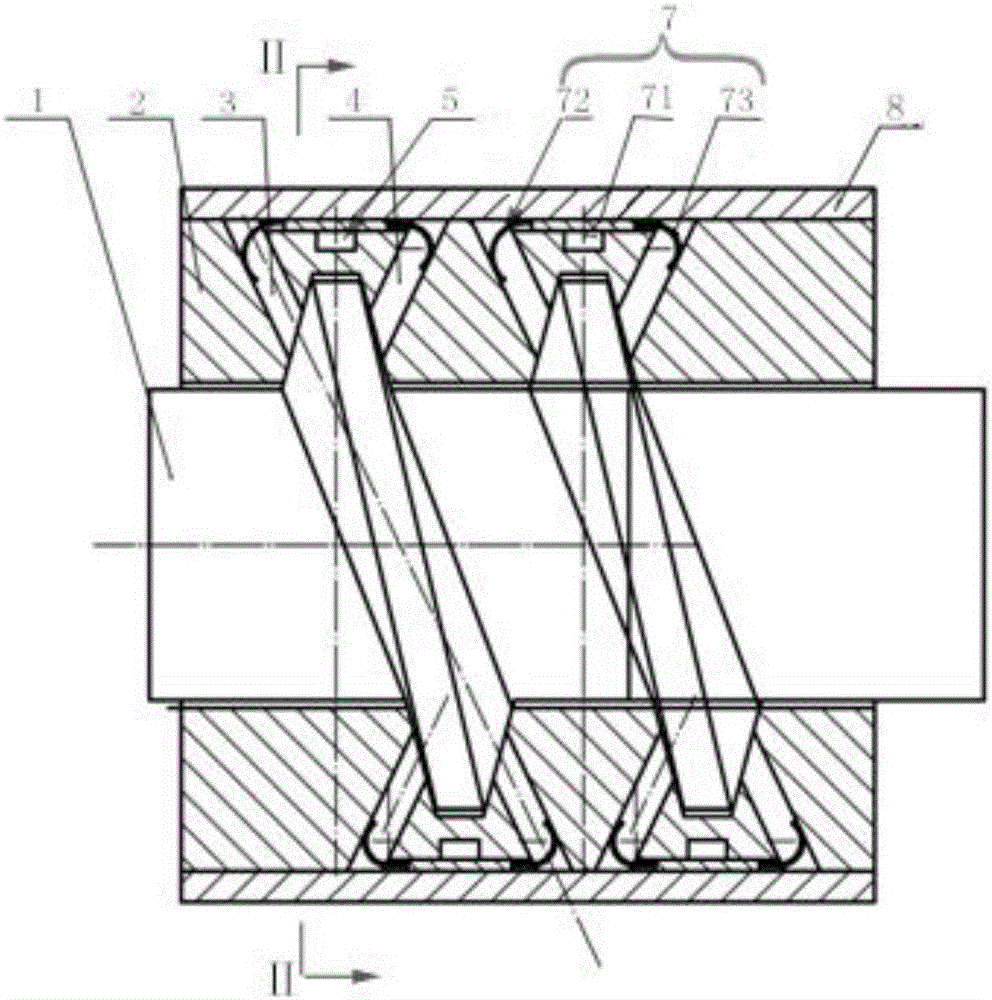

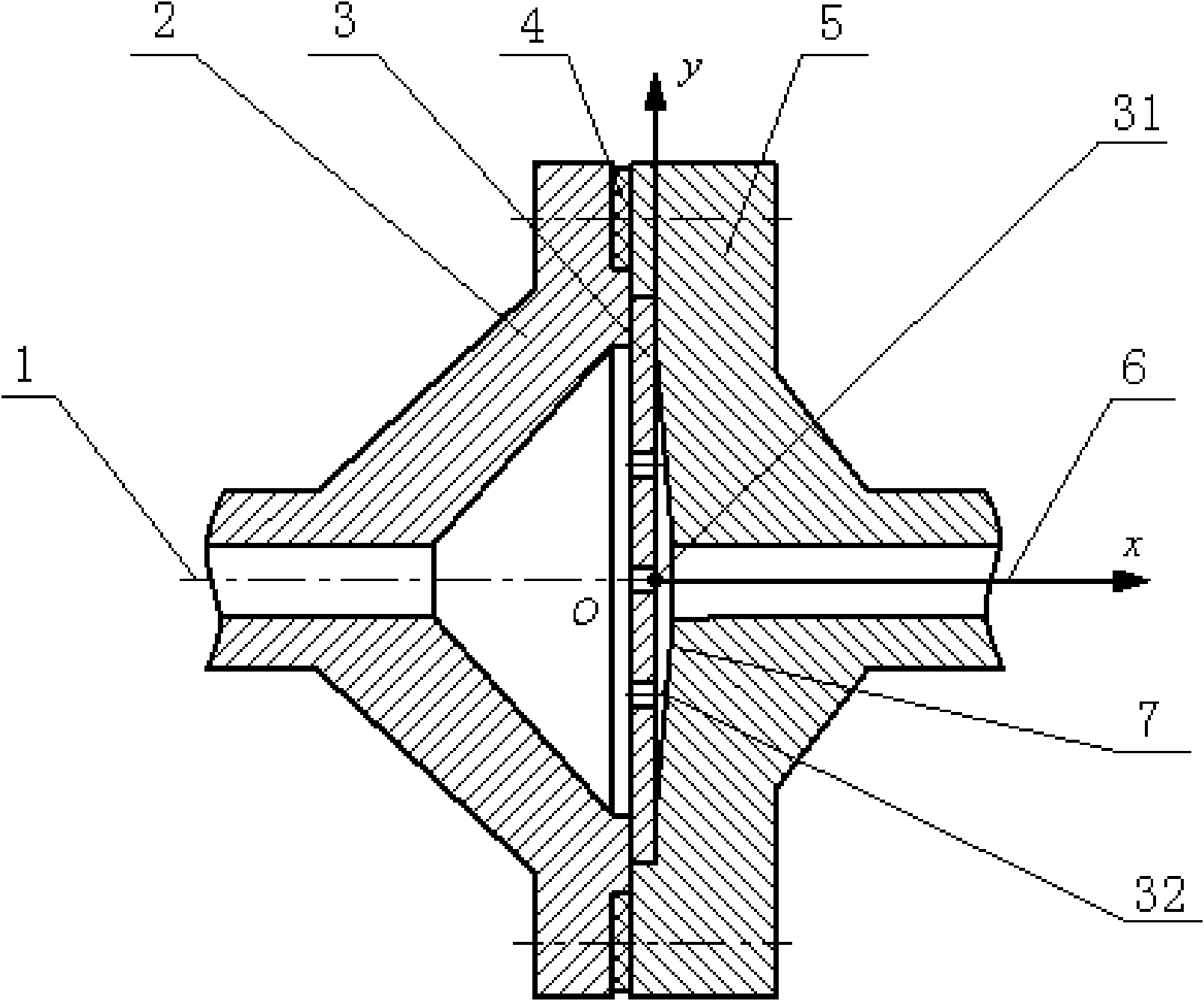

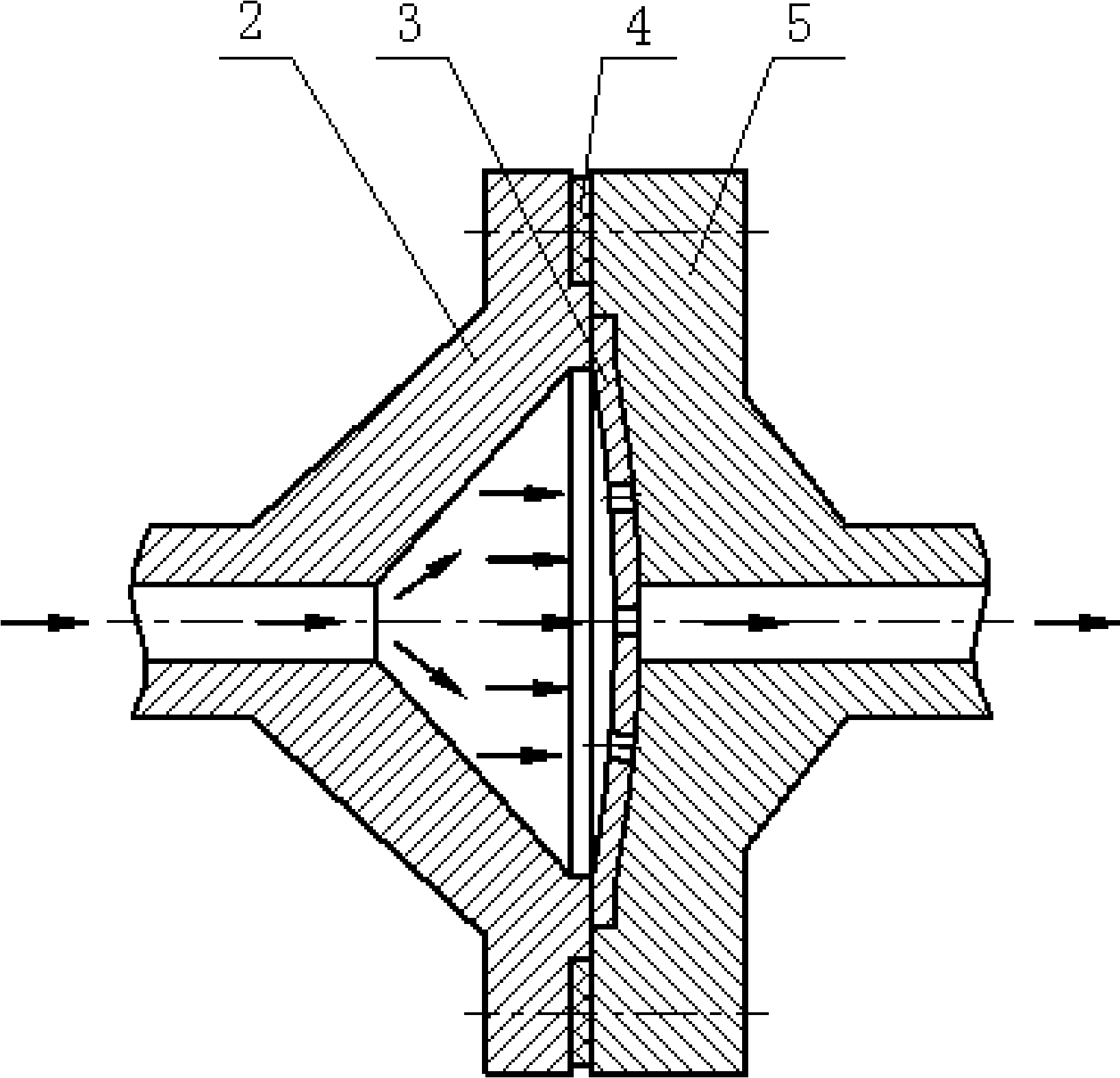

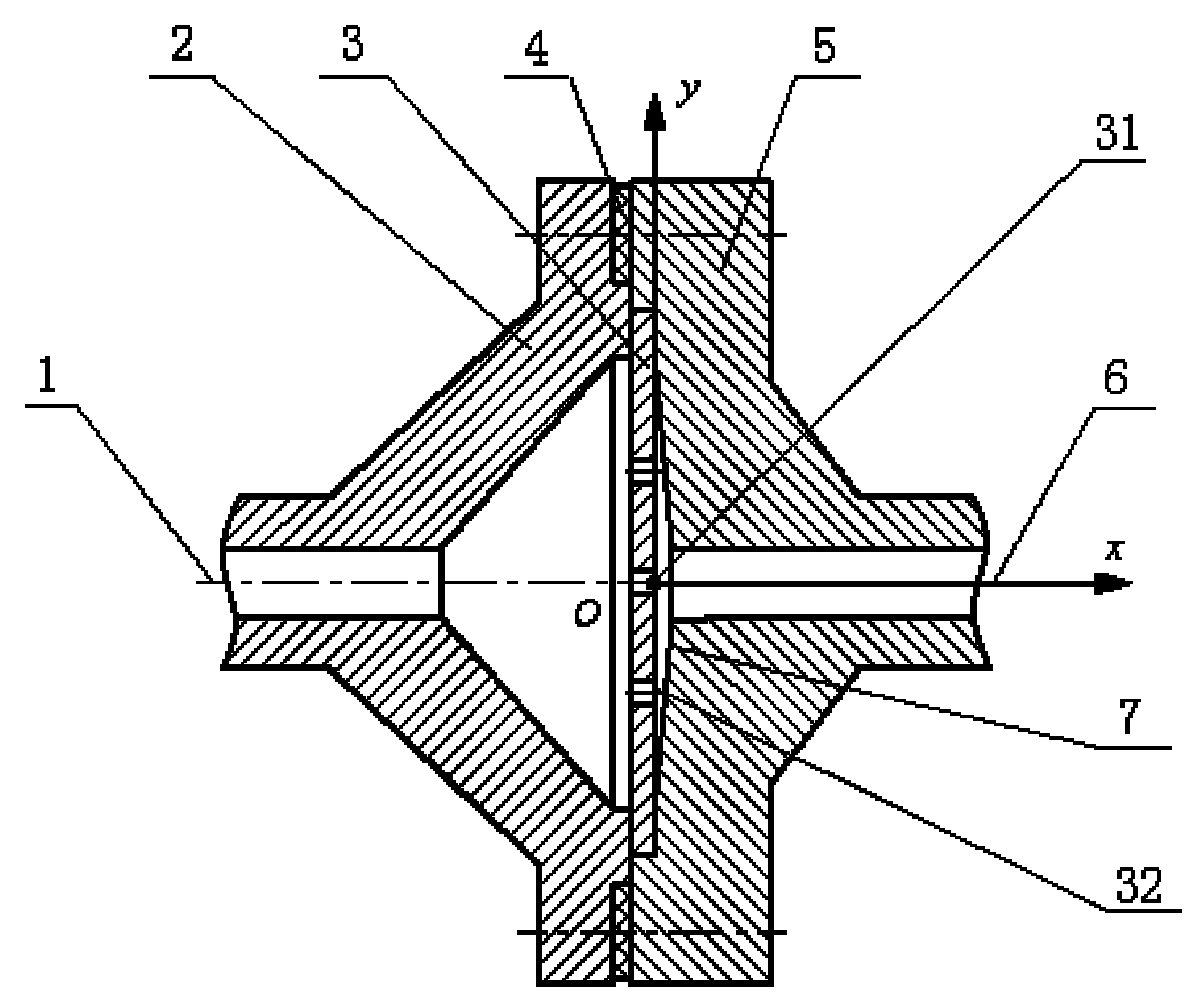

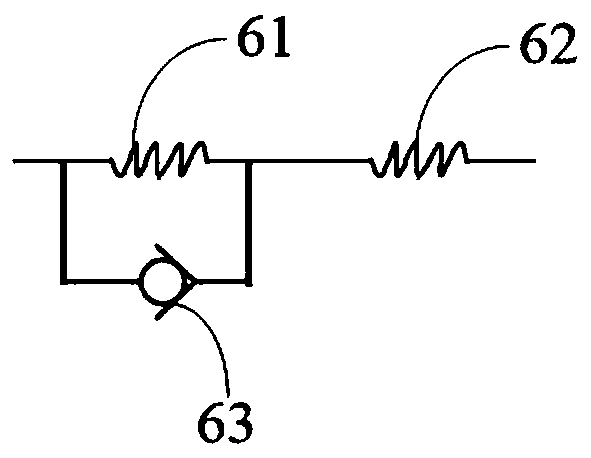

Hydrostatic nut pair with internal variable throttling function

InactiveCN105805255AGood throttling effectVariable flowGearingGear lubrication/coolingSpool valveElastic component

The invention discloses a hydrostatic nut pair with an internal variable throttling function and relates to the field of precision machinery automation equipment. The hydrostatic nut pair with the internal variable throttling function comprises a lead screw and a nut which are mutually matched, wherein a first oil cavity and a second oil cavity are formed in the two sides of each inner thread tooth surface of the nut, and the radial section projections of both the first oil cavity and the second oil cavity are fan trapezoids; through the corresponding first oil cavity and second oil cavity, a hydrostatic oil film of lubricating oil can be formed between the lead screw and each tooth side surface of the nut; a groove used for communicating with the corresponding first oil cavity and the corresponding second oil cavity is formed in each internal thread tooth of the outer circle of the nut; a movable throttling part is mounted in each groove, and comprises a slide valve, a first elastic component and a second elastic component; an oil supply groove communicating with each groove is formed in the outer circle of the nut; an external sleeve is mounted on the outer circle of the nut in a matched manner; and an oil supply hole communicating with the oil supply groove is formed in the external sleeve. By adoption of the hydrostatic nut pair provided by the invention, not only can an oil supply pipeline be simplified, but also the throttling performance can be improved.

Owner:SHANDONG UNIV

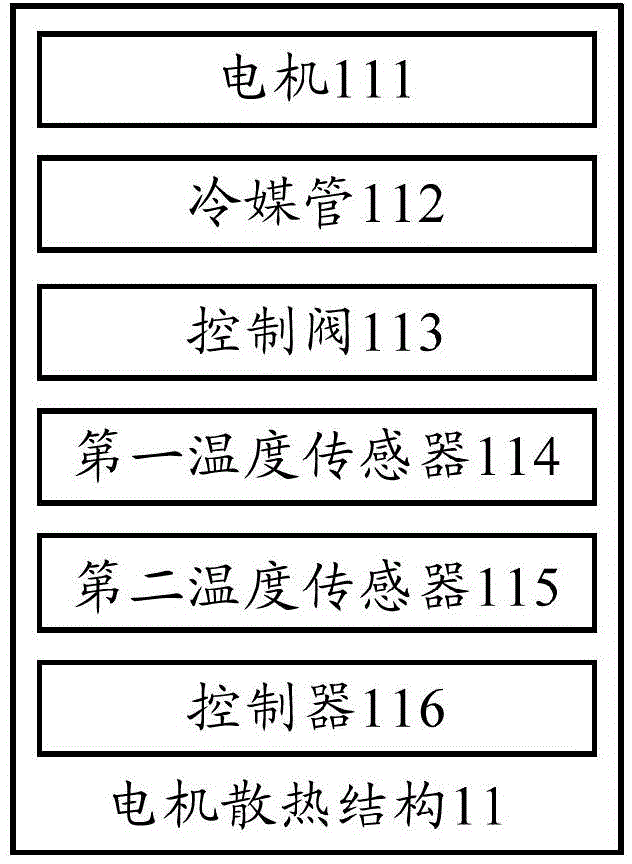

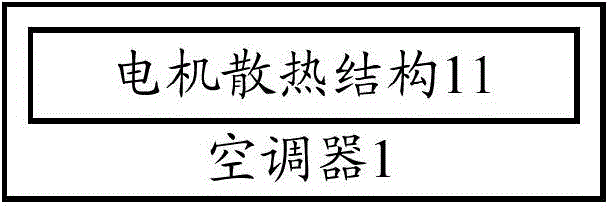

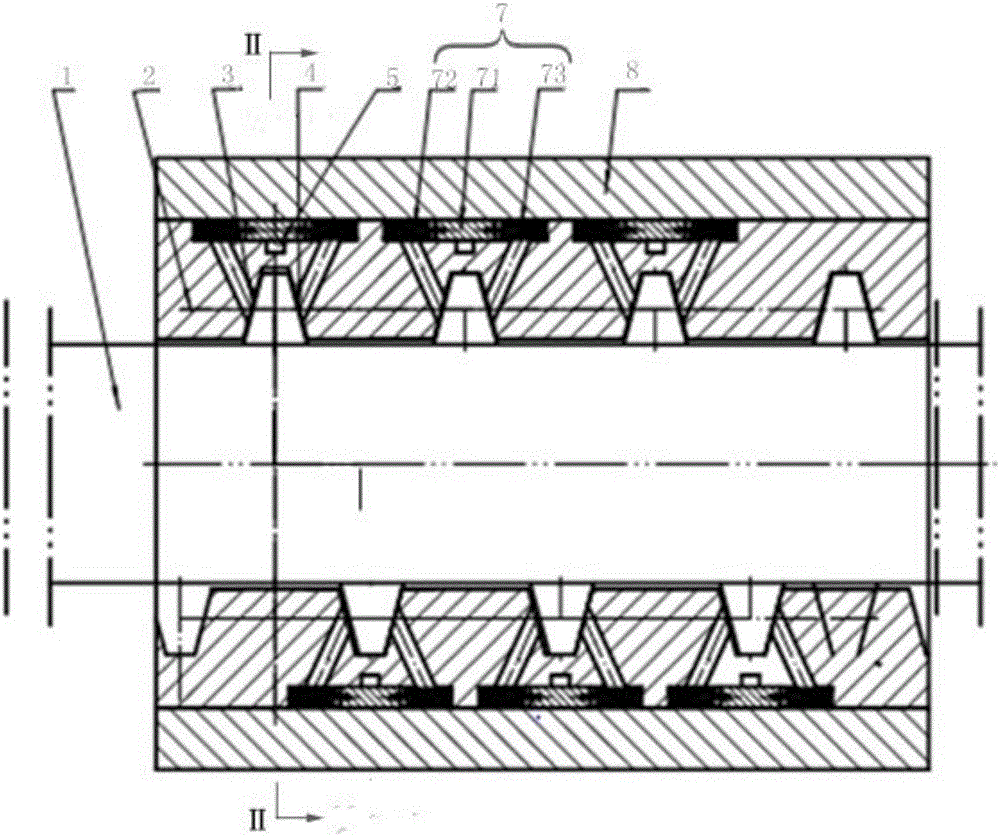

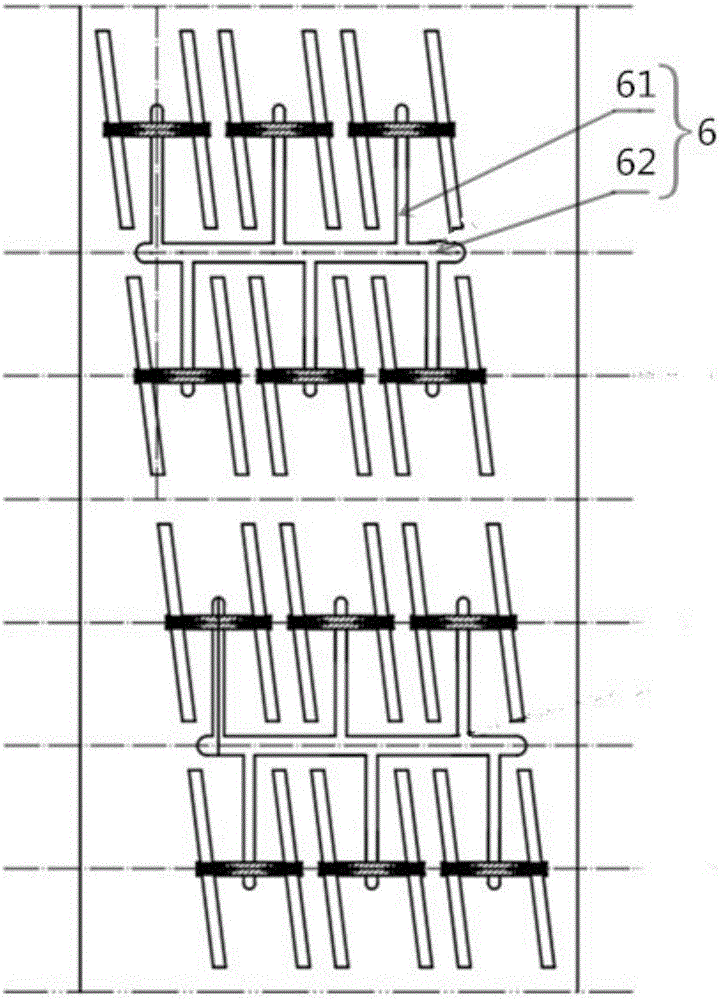

Motor cooling structure, air conditioner, and motor cooling method

ActiveCN104883005AImprove cooling effectReduce cooling effectSpace heating and ventilation safety systemsLighting and heating apparatusVapor–liquid separatorFour-way valve

The invention provides a motor cooling structure, an air conditioner, and a motor cooling method. The motor cooling structure includes a motor, a refrigerant pipe, a control valve, a first temperature sensor, a second temperature sensor, and a controller, the refrigerant pipe is arranged on the motor, the first end of the refrigerant pipe is connected with an outlet main pipeline of a condenser of the air conditioner, the second end of the refrigerant pipe is connected with a gas-liquid separator of the air conditioner, the control valve controls the opening and closing of the refrigerant pipe, when the refrigerant pipe is opened, refrigerant of the air conditioner enters into the refrigerant pipe via the first end through the outlet main pipeline and flows into the gas-liquid separator via the second end after passing through the motor, the first temperature sensor detects the outlet pipe temperature of a cooling branch, the second temperature sensor detects the outlet pipe temperature of a four-way valve, and the controller adjusts the opening degree of the control valve based on the difference of the outlet pipe temperature of the cooling branch and the outlet pipe temperature of the four-way valve. According to the invention, the motor cooling effect of the air conditioner is improved, and the energy efficiency of the motor can be maximally performed based on the normal operation of the air conditioner.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

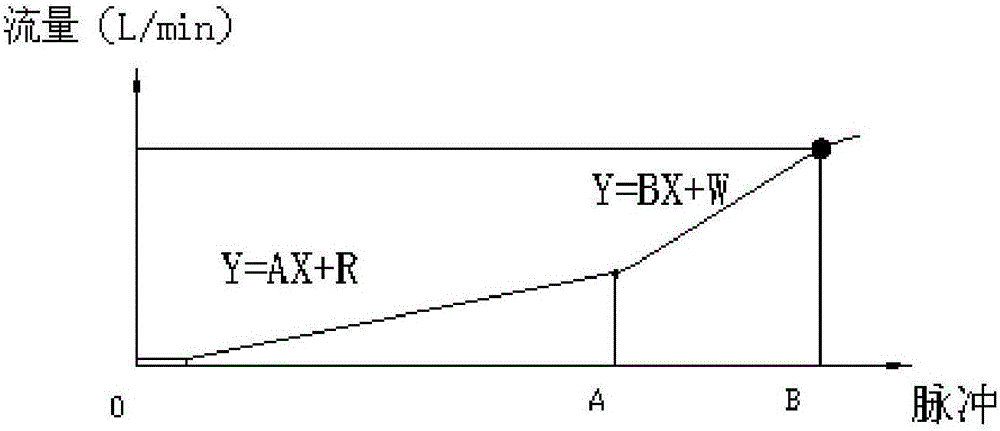

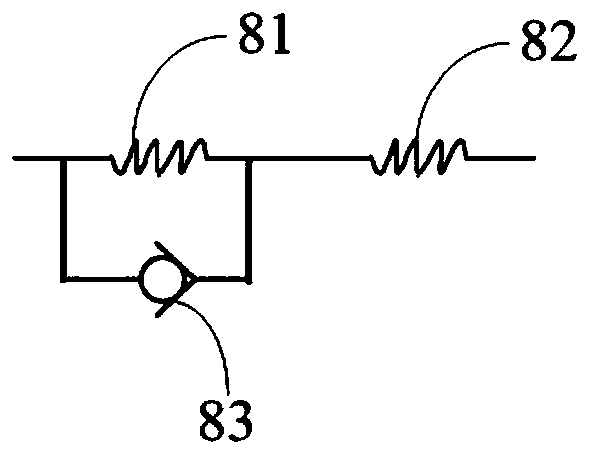

Built-in slide valve throttling static-pressure nut pair

InactiveCN105822739AGood throttling effectShorten the lengthGearingGear lubrication/coolingAutomationEngineering

The invention discloses a built-in slide valve throttling static-pressure nut pair, and relates to the field of precision mechanical automation equipment. The built-in slide valve throttling static-pressure nut pair comprises a lead screw and a nut which are matched with each other, wherein a first oil cavity and a second oil cavity are respectively formed in two sides of each inner thread surface of the nut; and by the first oil cavity and the second oil cavity, lubricating oil can form a static-pressure oil film between the lead screw and a thread side surface of the nut; a groove which communicates with the first oil cavity and the second oil cavity is formed in each inner thread on an excircle of the nut; a movable throttling component is mounted in each groove; oil supply grooves which communicate with the grooves are further formed in the excircle of the nut; a jacket is mounted on the excircle of the nut in a matched manner; and oil supply holes which communicate with the oil supply grooves are formed in the jacket. By the built-in slide valve throttling static-pressure nut pair, an oil supply pipeline can be simplified, and furthermore, the throttling performance can be improved.

Owner:SHANDONG UNIV

Capillary tube flow testing device

InactiveCN102706396AGood throttling effectLow mass flowVolume/mass flow by differential pressureDevice formLiquid storage tank

The invention discloses a capillary tube flow testing device, which comprises a refrigerant liquid storage tank, a one-way valve, a manual switch, a high pressure maintaining valve, a capillary tube clamp, an inlet pressure sensor, an outlet pressure sensor, a back pressure side lower pressure maintaining valve, a self-balancing type pressure control valve, a refrigerant recycling filling machine and a back pressure sensor. The refrigerant liquid storage tank is accommodated in a thermotank; the one-way valve is communicated with an output port end of the liquid storage tank via a pipeline; the manual switch and the high pressure maintaining valve are sequentially serially connected to the rear of the one-way valve; the capillary tube clamp is used for fixing a detected capillary tube; the inlet pressure sensor and the outlet pressure sensor are respectively parallelly connected to refrigerant flowing channels nearby two ends of the detected capillary tube fixed by the capillary tube clamp; the back pressure side low pressure maintaining valve, the self-balancing type pressure control valve and the refrigerant recycling filling machine are sequentially connected to the rear of the capillary tube clamp; and the back pressure sensor is parallelly connected to the rear of the low pressure maintaining valve. The capillary tube flow testing device forms a whole refrigerant loop and truthfully simulates the working state of the capillary tube, and calculates pressure difference of the refrigerant after the refrigerant passes through the capillary tube by controlling and measuring pressure and temperature, so that change of roughness of the capillary tube is detected, and the throttling effect of the capillary tube is improved according to the change.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

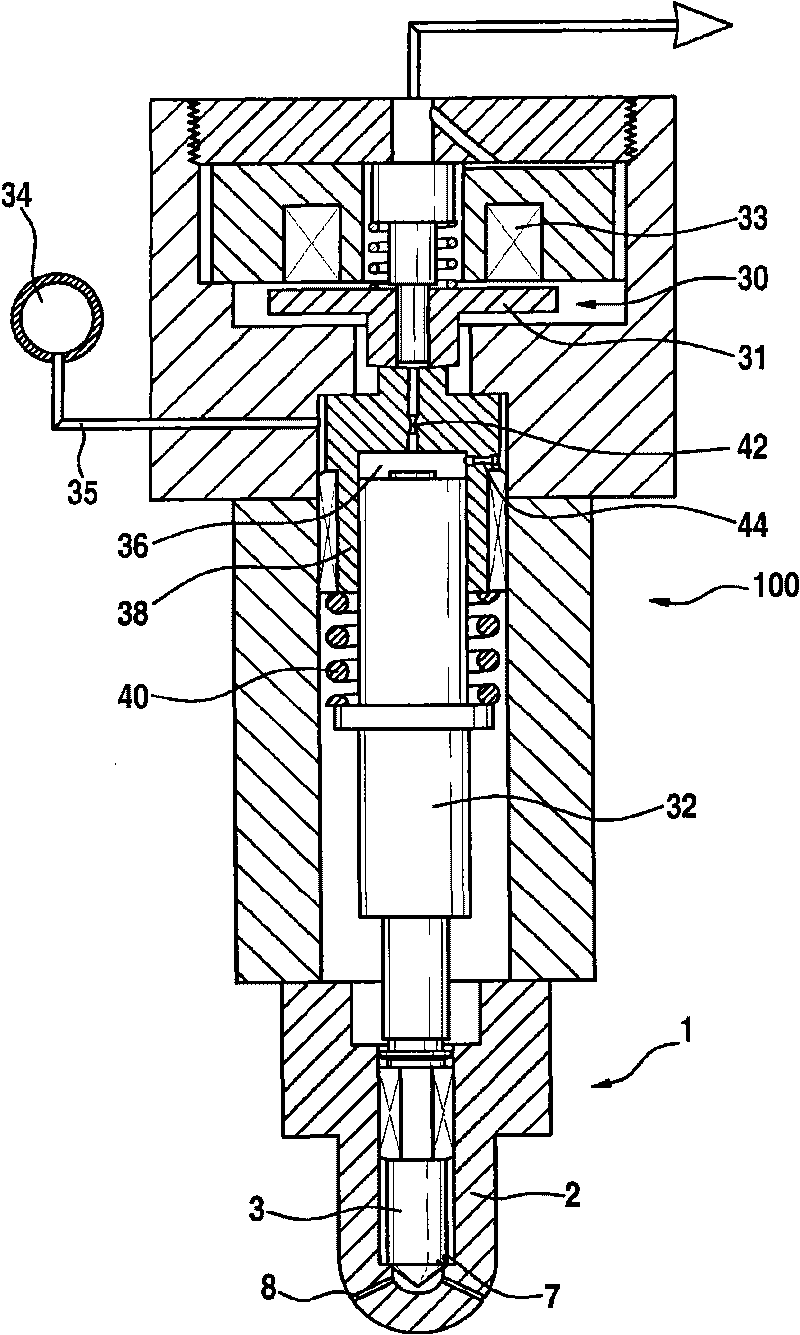

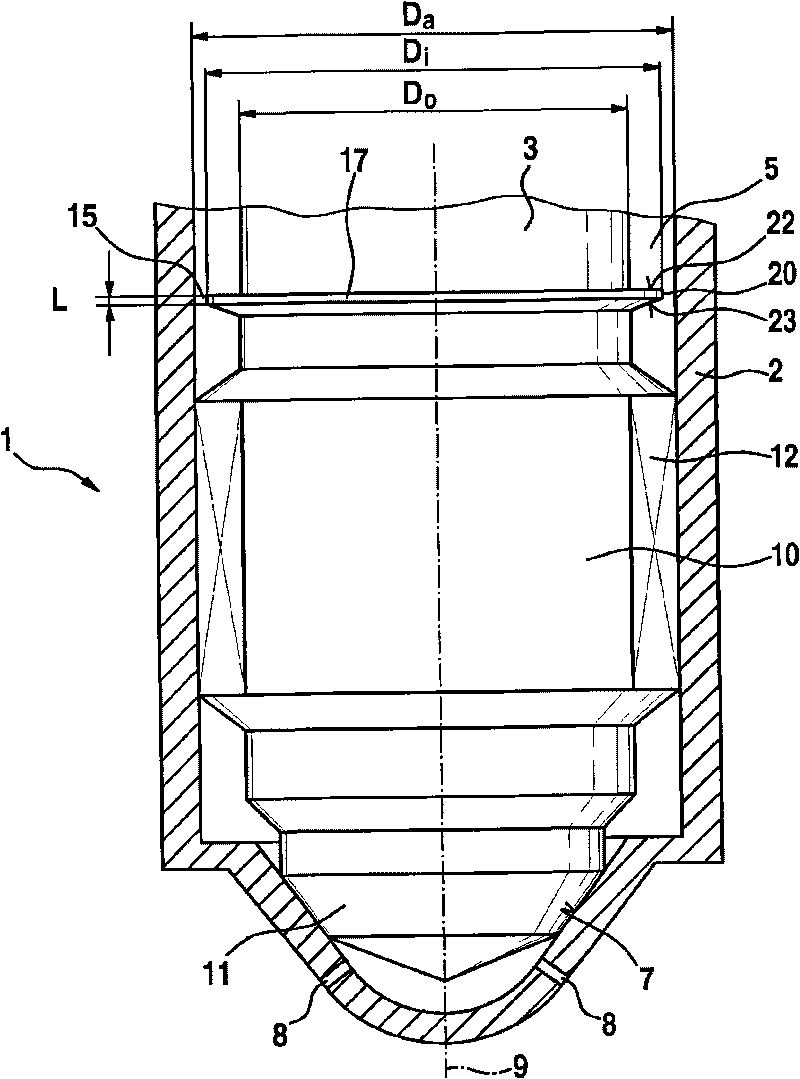

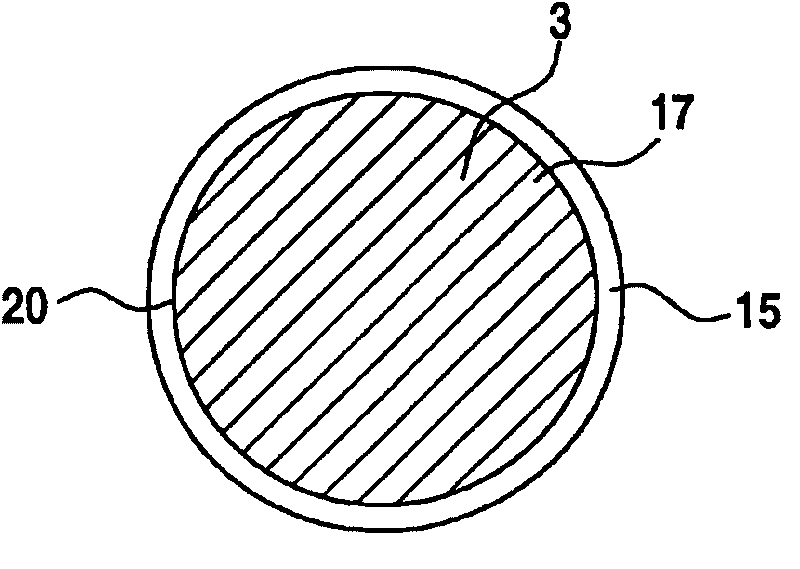

Throttle on a valve needle of a fuel injection valve for internal combustion engines

ActiveCN101743394AGuaranteed irrelevanceGood throttling effectFluid pressure injection controlMachines/enginesCombustionEngineering

Owner:ROBERT BOSCH GMBH

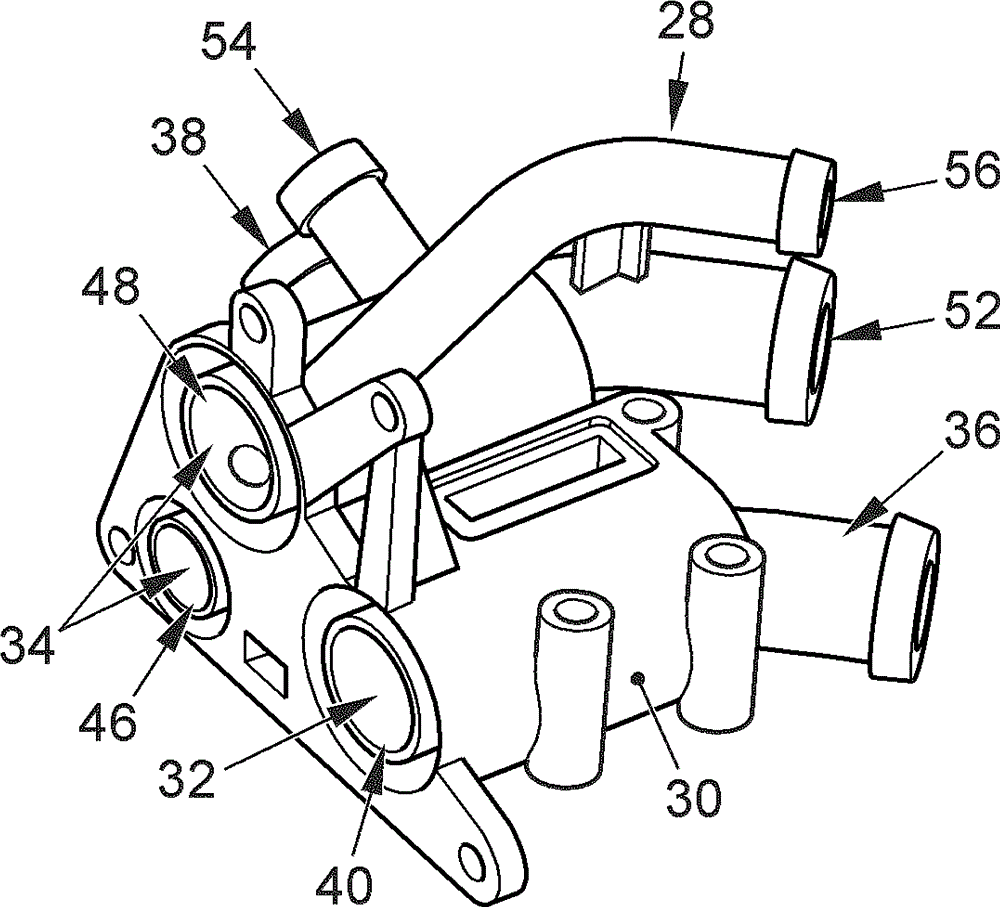

Cooling system

ActiveCN104653272ARegulate volume flowEasy to adjustLiquid coolingCoolant flow controlCoolant flowEngineering

Owner:VOLKSWAGEN AG

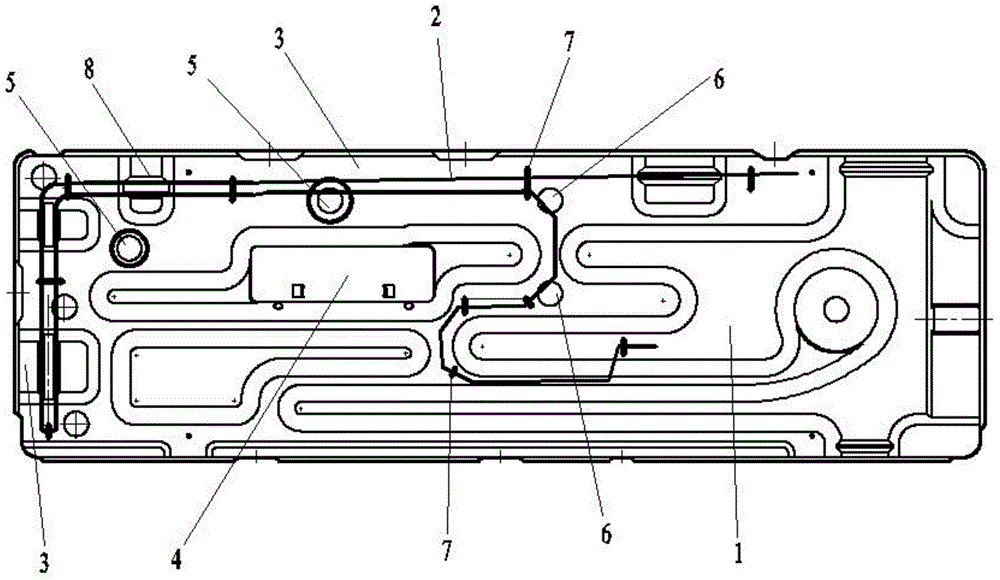

Outdoor unit of split wall-hanging type air-conditioner

InactiveCN104089344AGood throttling effectIncrease heating capacitySpace heating and ventilation safety systemsLighting and heating apparatusEngineeringRefrigeration

The invention discloses an outdoor unit of a split wall-hanging type air-conditioner. A throttling device is an electronic expansion valve and one-way valve combination device, the lengths and the specifications of an auxiliary refrigeration capillary tube and an auxiliary heating capillary tube can be adjusted according to requirements, and the best throttling effect is accordingly achieved; a chassis of the air-conditioner is of a novel structure, a groove position is additionally arranged on the basis of a chassis of an existing air-conditioner through optimization design, and the chassis can be fixed for electric heating. Compared with the prior art, the outdoor unit of the split wall-hanging type air-conditioner has the advantages that the heating amount can be improved, the low-temperature defrosting problem can be solved, and the outdoor unit can be suitable for common climate and ultra-low-temperature areas.

Owner:GUANGDONG CHIGO AIR CONDITIONING

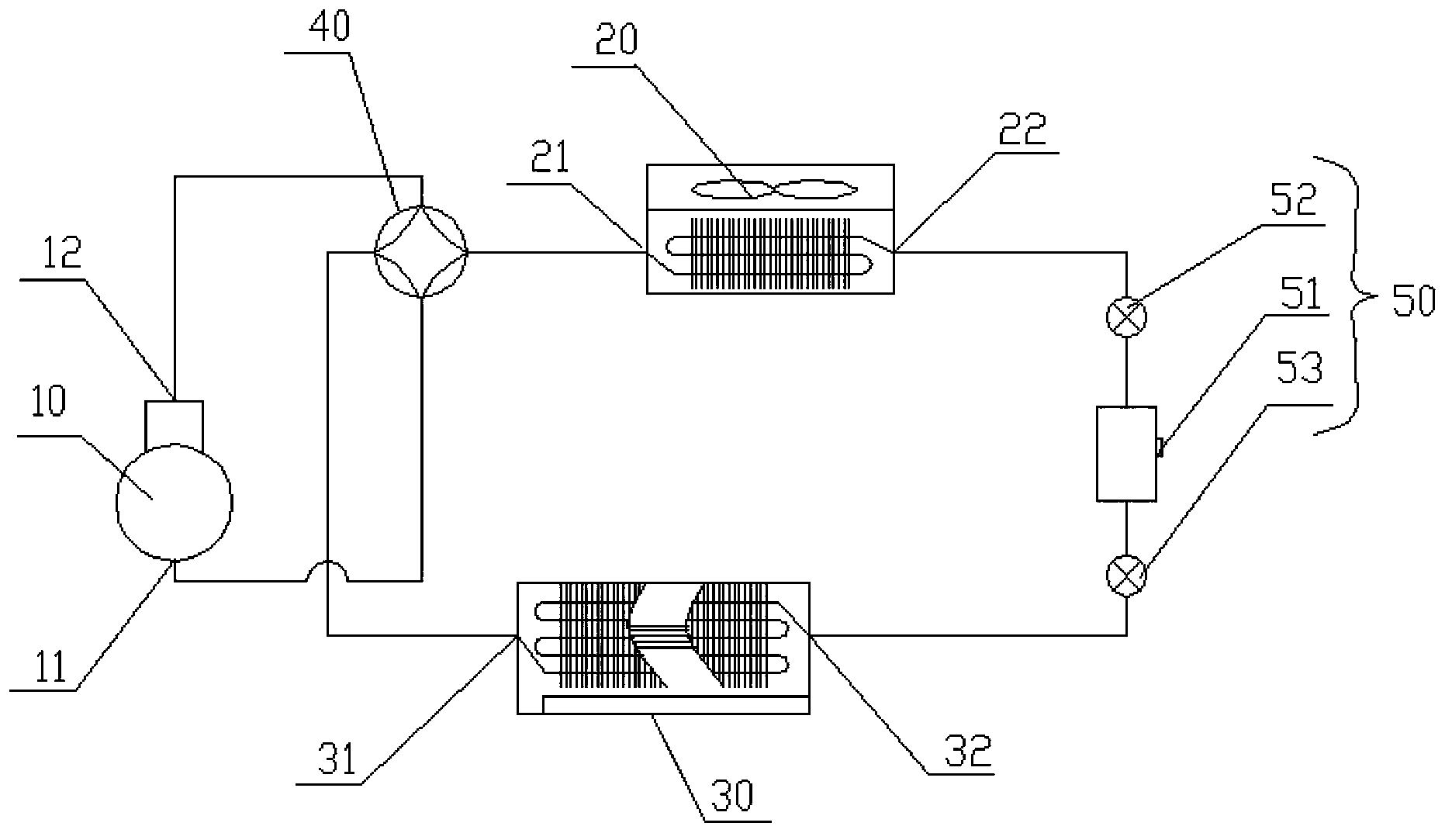

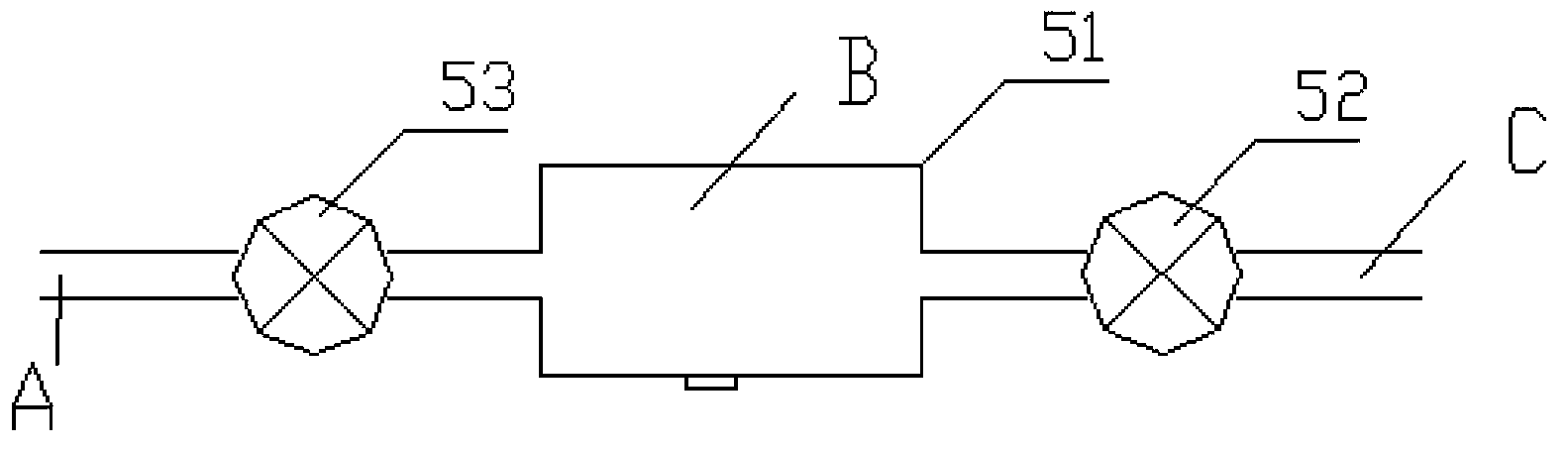

Air-conditioning system and method for adjusting refrigerant filling amount and refrigerant circulating volume

ActiveCN104344508AImprove performanceGuaranteed uptimeMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir conditioning

The invention discloses an air-conditioning system which comprises a compressor unit, an outdoor unit and an indoor unit. The indoor unit is provided with an indoor evaporator, a first expanding valve, a refrigerant adjusting storage device and a second expanding valve are sequentially connected between the outdoor unit and the indoor unit, refrigerant filling amount and refrigerant circulating volume in the compressor unit, the outdoor unit and the indoor unit are controlled through the second expanding valve and the first expanding valve, the performance of the air-conditioning system is improved by adjusting the refrigerant filling amount and the refrigerant circulating volume, the second expanding valve is serially connected with the first expanding valve, so that better throttling effect can be obtained as compared with a single expanding valve, the refrigerant circulating amount can be more accurately controlled, and the compressor unit can stably run at lower frequency, so that the running capacity range of the compressor unit is widened.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

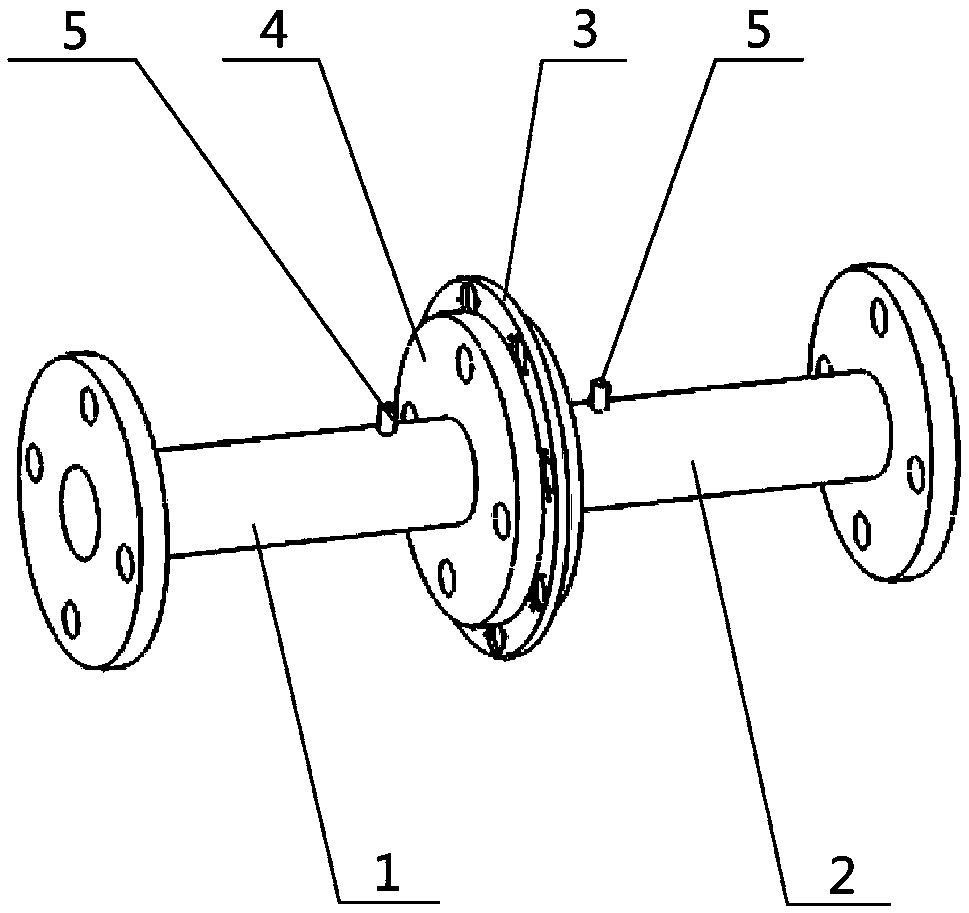

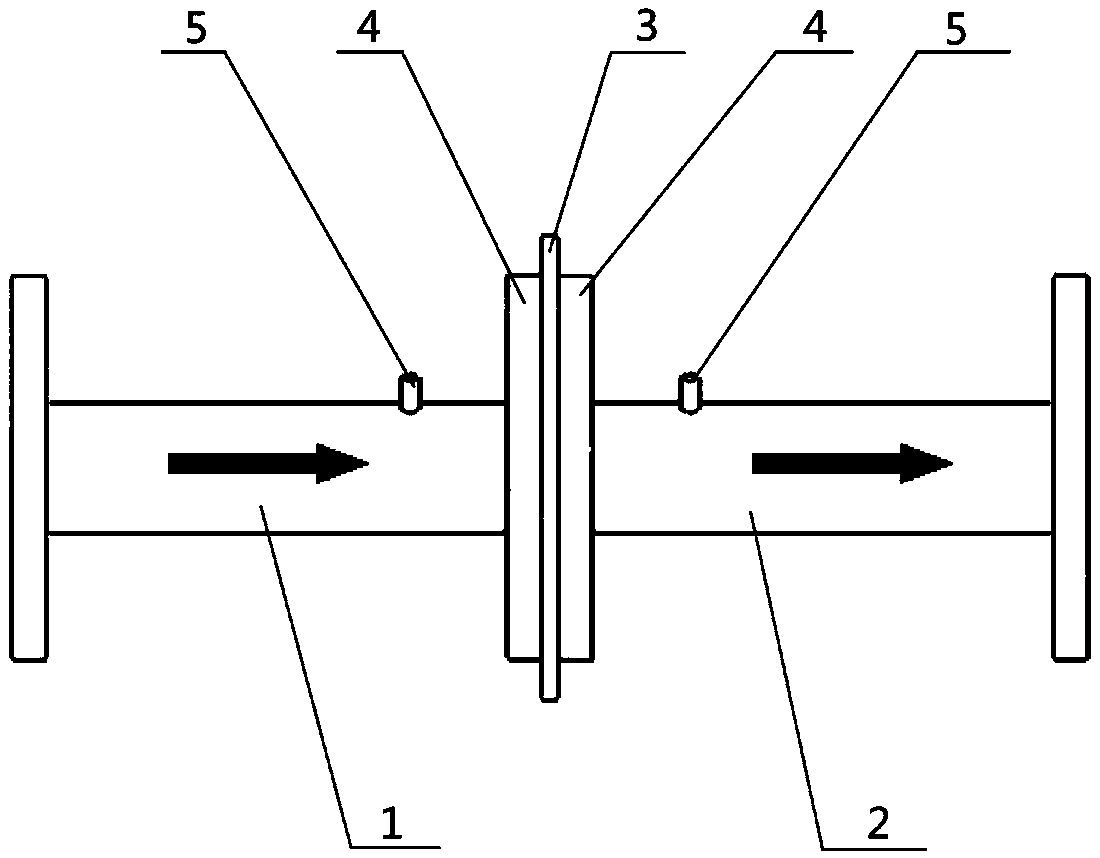

Air-impact protective throttle valve

InactiveCN101832423AAdjust throttling effectAdjust the differential pressure thresholdValve members for absorbing fluid energyStreamflowVALVE PORT

The invention discloses an air-impact protective throttle valve, which comprises a valve cover, a valve body, a throttle membrane and a gasket, wherein the inner cavity of the valve cover is in a gradually-opening valve chamber shape, and the throttle membrane is provided with a centre hole and several eccentric holes; the throttle membrane and the annular gasket are arranged between the valve cover and the valve body, the throttle membrane is in clearance fit with the valve cover and the valve body, and the gasket is compacted and arranged on the periphery part between the valve cover and the valve body; a joint face, matched with the throttle membrane, at the upper end of the valve body is set to be a concave surface; and the valve cover is provided with an air inlet, and the valve body is provided with an air outlet. The air-impact protective throttle valve can automatically reduce the flow area when impacted by burst airflows. The invention has the advantages of simple structure, low cost, good throttle effect and wide application.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

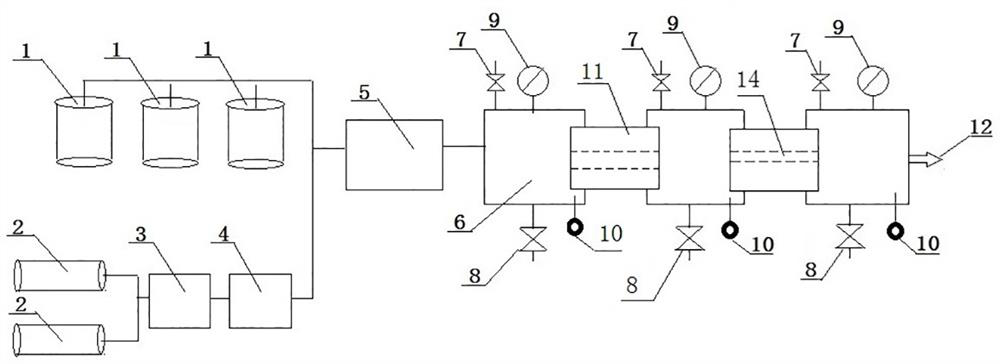

Gas well scaling simulation device and simulation method

PendingCN113006768AHigh simulation accuracyImprove heating efficiencySurveyMaterial thermal analysisThermodynamicsEngineering

The invention relates to a gas well scaling simulation device and simulation method. The gas well scaling simulation device comprises a gas storage device used for providing simulative gas, a liquid storage device used for providing simulative liquid, a gas-liquid mixer used for mixing the simulative gas and the simulative liquid to obtain experimental fluid and scaling simulation pipes; at least two scaling simulation pipes are sequentially connected in series to simulate a gas well; a throttling structure is arranged on any two corresponding adjacent scaling simulation pipes; the two corresponding adjacent scaling simulation pipes are in communication through a throttling channel to simulate the change that the pressure of gas well fluid is gradually reduced in the flowing direction of the gas well fluid; and each scaling simulation pipe is provided with a heating device used for adjusting the temperature of the scaling simulation pipe so as to simulate the change that the corresponding formation temperature is gradually reduced in the flowing direction of the gas well fluid. According to the technical scheme, the influence of the fluid pressure change in the gas well and the formation temperature change on gas well scaling is considered, and the environment in the whole gas well can be simulated from the overall macroscopic aspect.

Owner:CHINA PETROLEUM & CHEM CORP +1

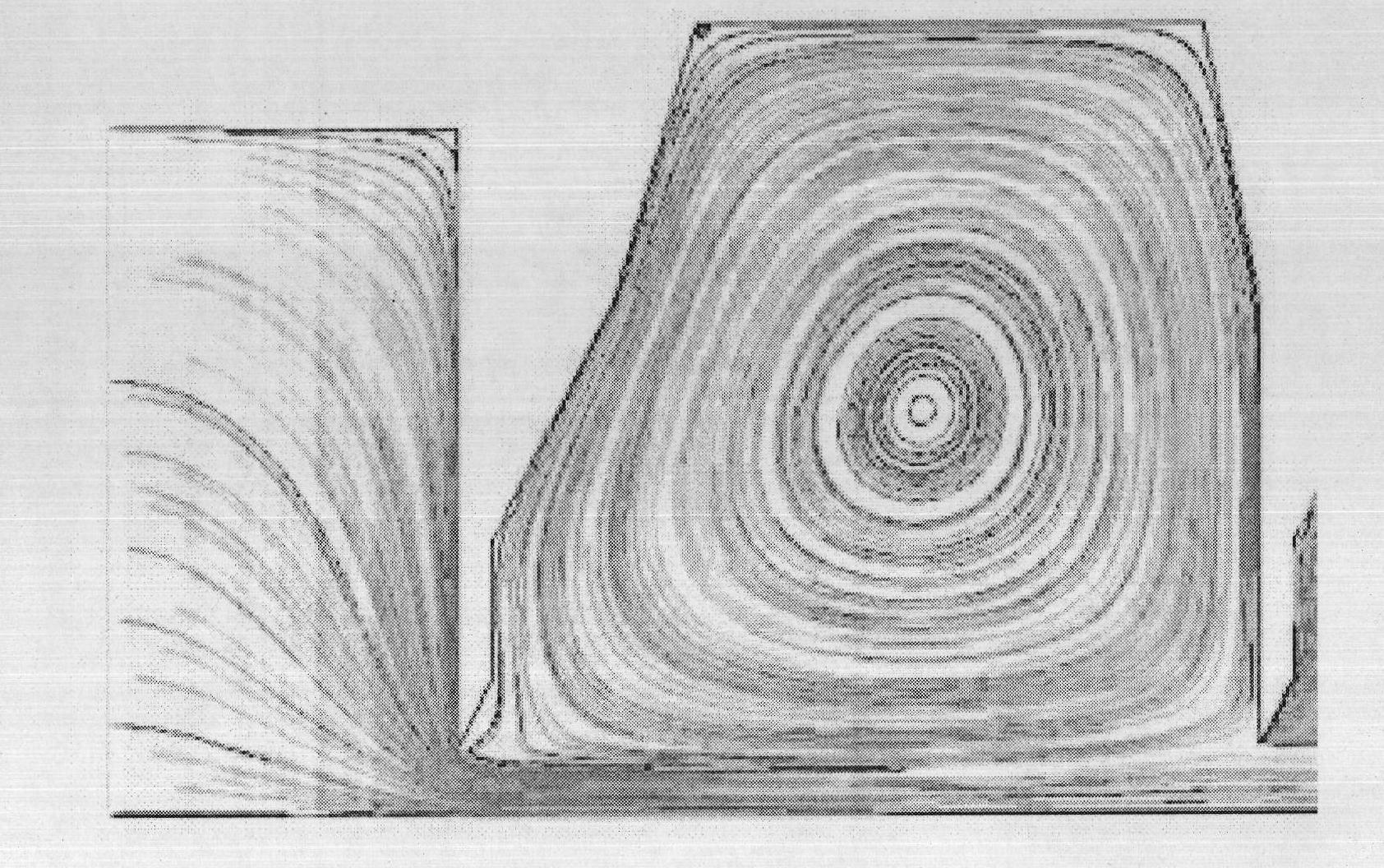

Sealing structure for dynamic and static gaps of rotating machine

ActiveCN101832392AAccelerated dissipationDissipate enoughEngine sealsPump componentsEngineeringHigh pressure

The invention relates to a sealing structure for dynamic and static gaps of a rotating machine. A transverse arm structure is arranged behind sealing tooth, and a claw-shaped structure is adopted on the top of the sealing tooth; the depth of a sealing cavity is increased, and the thicknesses of the root and the top of the sealing tooth are widened; oblique sealing tooth are applied; and both the windward side and the leeside of the sealing tooth adopt an arc surface modeling. The sealing structure is used for controlling the leakage of high-temperature and high-pressure fluid along the dynamic and static gaps and avoiding the condition that large-flow leakages influence the stable operation and the safe operation of parts of a next stage. Under the working medium conditions of high pressure, high temperature, high speed and large flow of a nuclear main pump, shown as a numerical simulation result, the sealing structure can reduce the leakage quantity by 13.8 percent compared with an ordinary straight-toothed labyrinth seal with the same gaps, can temporarily stabilize and control the leakage quantity under the extreme working condition of back flowing and has safety, durability and good throttling effect.

Owner:DALIAN UNIV OF TECH

Throttle pipe of household air conditioner

InactiveCN101571334ASimple structureGood throttling effectValve members for absorbing fluid energyFluid circulation arrangementEngineeringCapillary action

The invention relates to a throttle pipe of a household air conditioner. The throttle pipe comprises a tubular valve body, and a stationary valve core and dynamic valve cores are arranged in the valve body. The throttle pipe is characterized by only one stationary valve core which only has a capillary core channel penetrating an axle center thereof; and two dynamic valve cores, namely a first dynamic valve core and a second dynamic valve core respectively, wherein, the first dynamic valve core is provided with a first capillary core penetrating an axle thereof, and peripheral surface of the first dynamic valve core is opened with at least one groove throughout the peripheral surface, and the second dynamic valve core is only provided with one second capillary core penetrating the axle center thereof; and the throttle pipe further comprises a first block component and a second block component with channels, the first dynamic valve core is positioned between the first block component and the stationary valve core, and the second dynamic valve core is positioned between the second block component and the stationary valve core. The dynamic valve core directly slides in the valve body, and the structure of the stationary valve core is simpler in relation to structure of a valve seat in a throttle valve, and the stationary valve core is also provided with the capillary core channels, which ensure better throttling effect.

Owner:金仁召

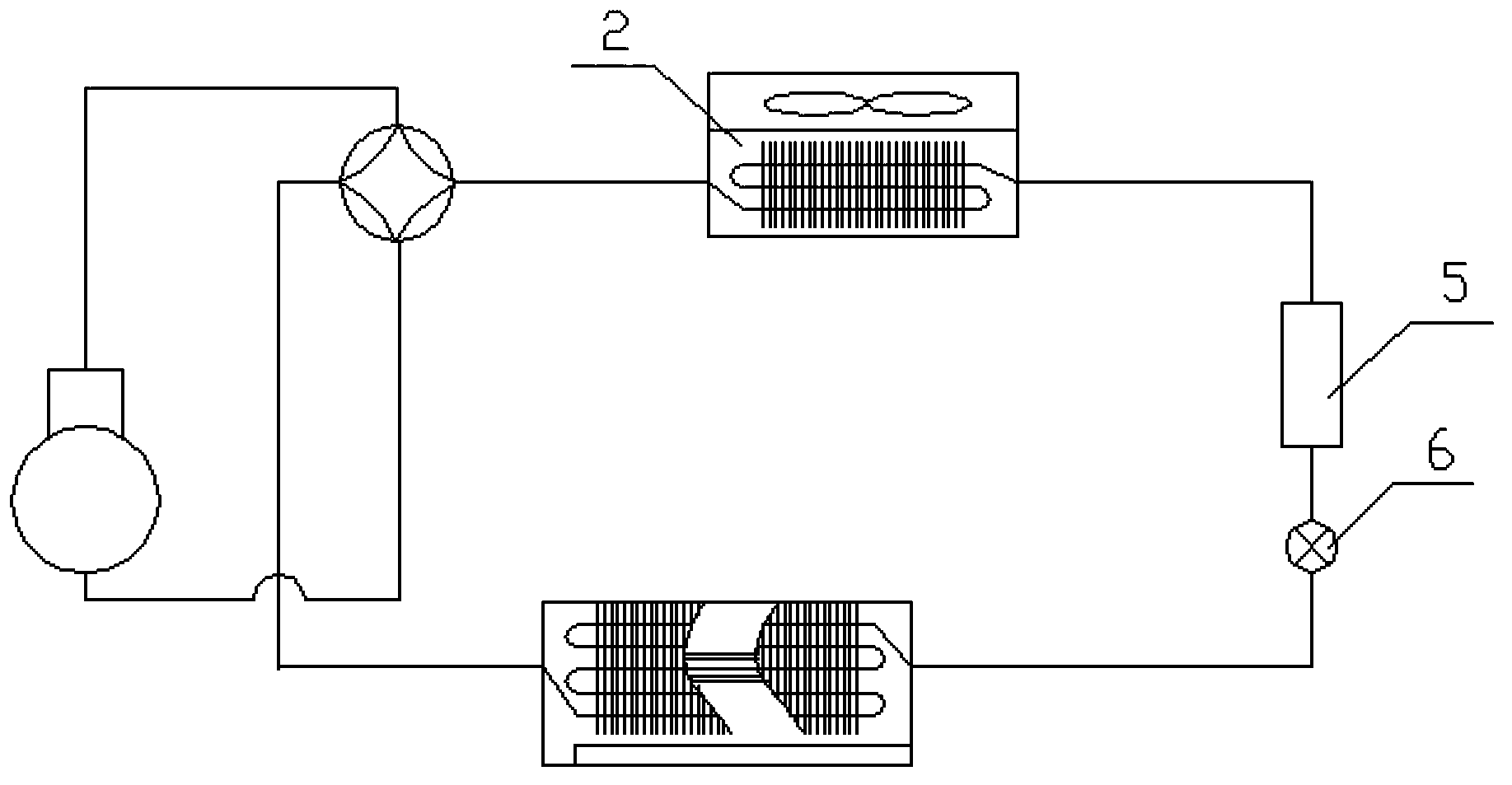

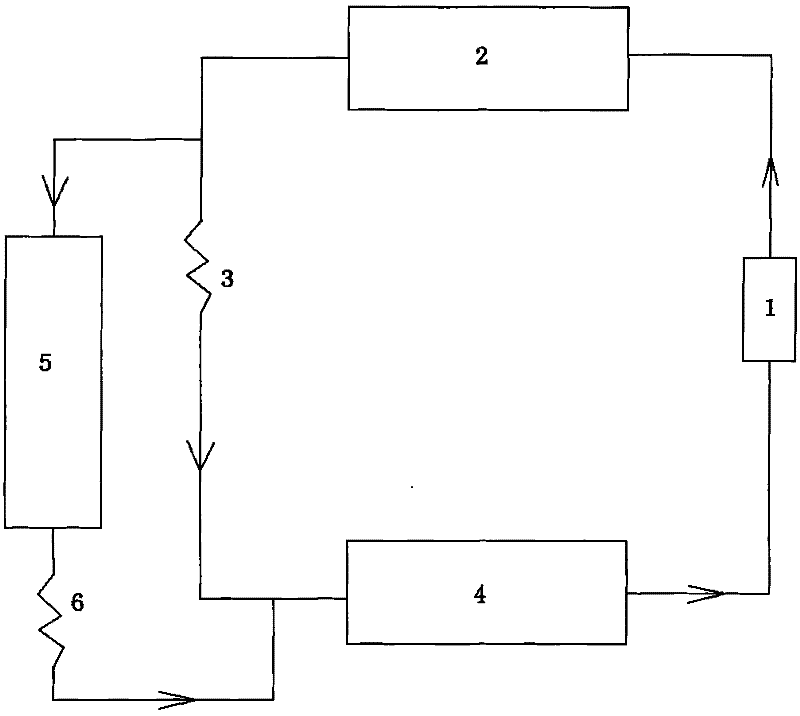

A heat pump water heater system

InactiveCN102261773AWiden the throttling rangeGood throttling effectFluid circulation arrangementEngineeringHigh pressure

The invention relates to a heat pump water heater system. The system includes a compressor, a condenser, a throttling device and an evaporator. The compressor is sequentially connected to the condenser, the throttling device, and the evaporator and returns to the compressor. It also includes a high-pressure storage liquid device, auxiliary throttling device, after the high-pressure liquid reservoir and auxiliary throttling device are connected in series, they are connected in parallel at both ends of the throttling device to perform double throttling control. Compared with the prior art, the invention has the advantages of wide throttling range, good throttling effect and the like.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

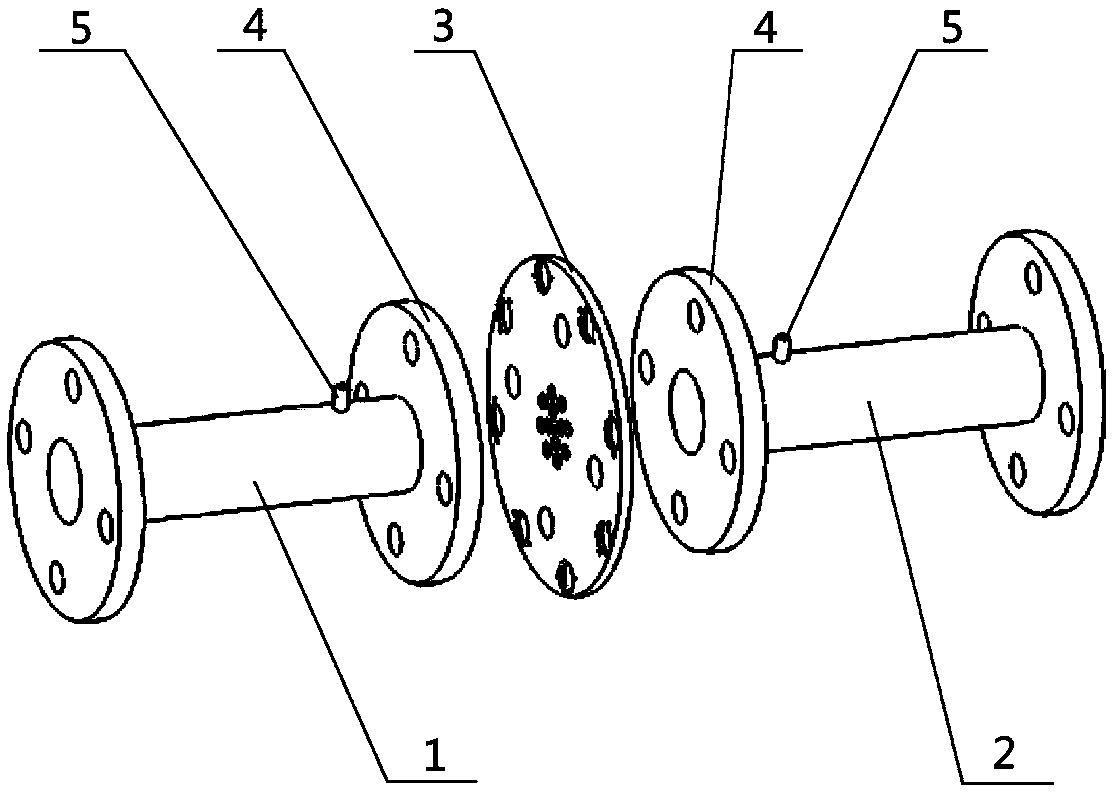

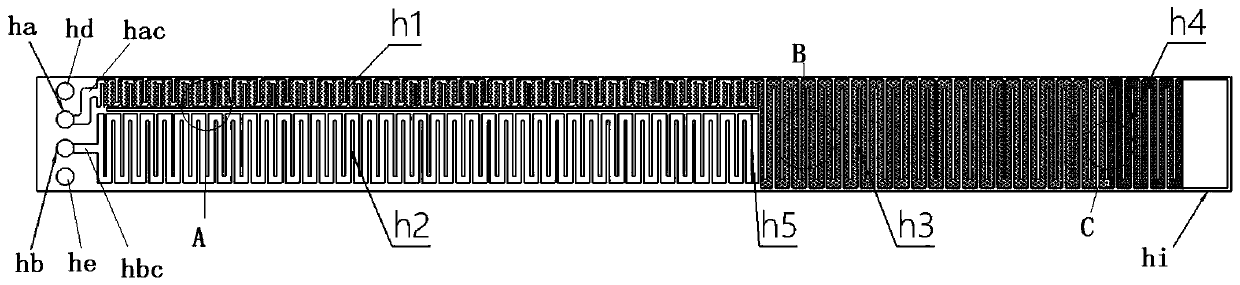

Two-phase flow parameter detection method based on porous throttling and acoustic emission technology

ActiveCN108931270AEliminate or reduce vibration noiseEliminate or attenuate inherent noiseMeasurement devicesAcoustic emissionDifferential pressure

The invention provides a two-phase flow parameter detection method based on the porous throttling and acoustic emission technology. The method realizes the combined measurement of porous orifice platebased on differential pressure measurement and acoustic emission technology based flow noise measurement, and solves the problem of noise interference when the two-phase flow is measured by using theacoustic emission. According to the detection method of the invention, the vibration noise of a pipeline itself and the inherent noise of the power source such as a water pump air compressor, and thenoise source from other parts can be eliminated or weakened. At the same time, the method makes full use of the advantages of the porous orifice plate and the acoustic emission technology in the respective measurement modes through a reasonable design, so that the two measurement means are more reasonable and effective in the combination mode, and the two-phase flow quantitative measurement basedon the acoustic emission technology can be realized.

Owner:HEBEI UNIVERSITY

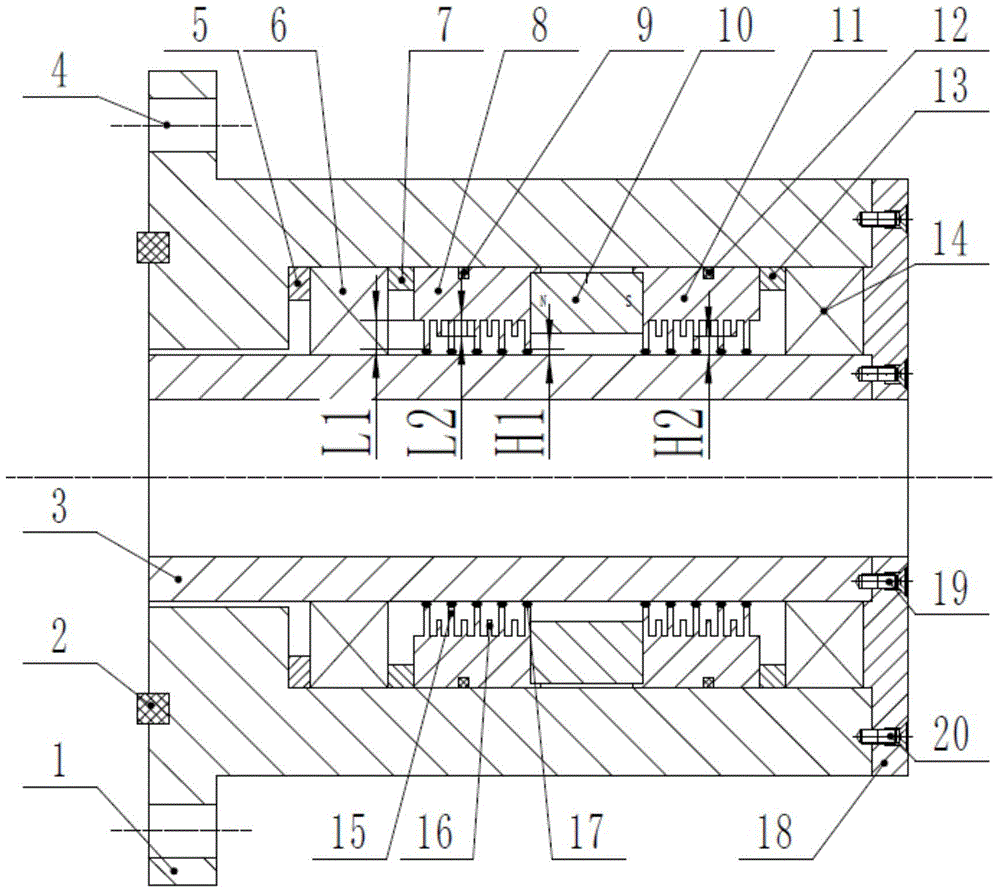

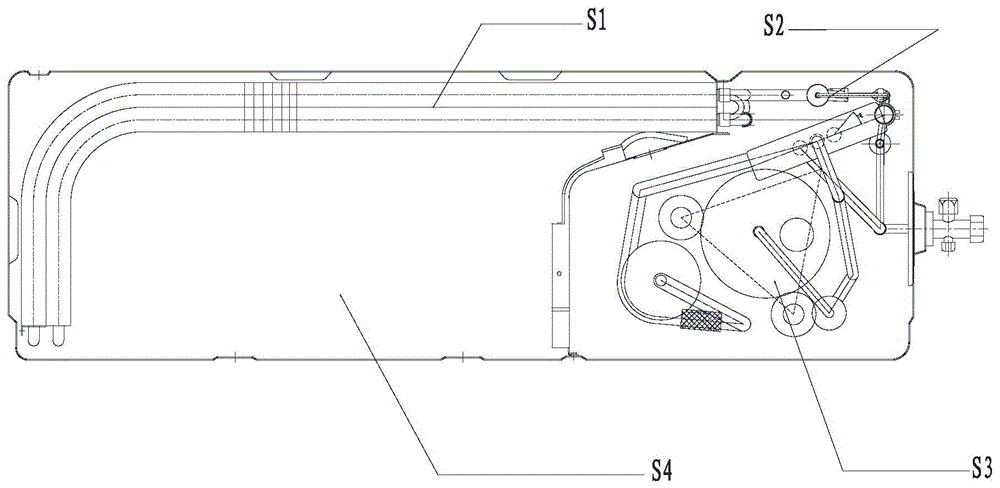

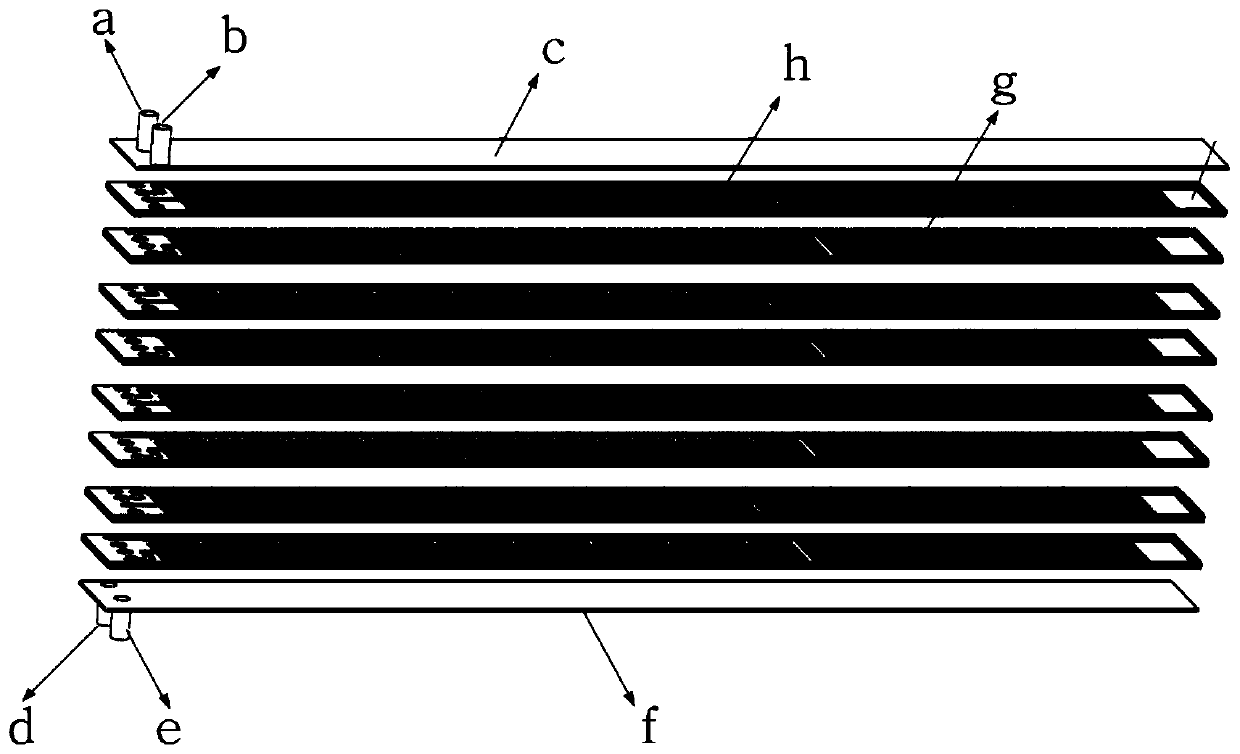

Multistage single-side pre-cooling laminated microchannel throttling heat exchanging refrigerator

The invention discloses a multistage single-side pre-cooling laminated microchannel throttling heat exchanging refrigerator. The multistage single-side pre-cooling laminated microchannel throttling heat exchanging refrigerator comprises sequentially stacked upper cover plates, multiple upper sheet bars and multiple lower sheet bars which are stacked up and down in a stagger manner, and a lower cover plate. Each upper sheet bar comprises an outlet and inlet segment, a channel segment and an evaporation cavity, wherein the channel segment comprises a first flowing channel, a second flowing channel, a third flowing channel and a fourth flowing channel, the first flowing channel comprises multiple straight channels in the length direction of the channel segment, one end of the first flowing channel communicates with a high-pressure inlet groove, the other end of the first flowing channel communicates with the third flowing channel, the second flowing channel is provided with an inwards-concaved S channel, one end of the second flowing channel communicates with a low-pressure outlet groove, the third flowing channel and the fourth flowing channel both comprise multiple straight channelsin the length direction of the channel segment, the straight channels are inwards-concaved rectangular grooves, the inwards-concaved depths are smaller than the thickness of the upper sheet bars, oneend of the third flowing channel communicates with the first flowing channel, the other end of the third flowing channel communicates with the fourth flowing channel, one end of the fourth flowing channel communicates with the third flowing channel, and the other end of the fourth flowing channel communicates with the evaporation cavity.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Air valve seating control device for hydraulic drive air valve mechanism of engine

InactiveCN102146820ASeated smoothlyReasonable circulation areaMachines/enginesNon-mechanical valveEngineeringPiston

The invention relates to an air valve seating control device for a hydraulic drive air valve mechanism of an engine, which mainly comprises a hydraulic piston, a hydraulic oil channel, a one-way valve, a hydraulic piston cavity, a variable throttling channel and the like. The hydraulic piston cavity is provided with a main oil channel of the variable throttling channel and a bypass oil channel with the one-way valve and is communicated with a hydraulic system; and the hydraulic piston is used for driving an air valve to move. The air valve seating control device adopts the one-way valve to lead the hydraulic drive air valve mechanism to have different hydraulic circulation areas in the opening and closing process of the air valve; with the adoption of the variable throttling channel, the throttling circulation areas can be changed along with the air valve lift in the closing process of the air valve, and the air valve seating speed of the hydraulic drive air valve mechanism of the engine is furthermore controlled to realize the soft landing of the air valve.

Owner:SHANDONG UNIV

Valve device for throttling a pressure medium flow, and damping device for damping pressure pulsations

ActiveCN108137030AThrottling characteristics are simpleReduce loadValve members for absorbing fluid energyVehicle sub-unit featuresMechanicsThrottle

Owner:ROBERT BOSCH GMBH

Fixed-frequency air-conditioner and control method and control device thereof and storage medium

InactiveCN110500740AGood throttling performanceImprove energy efficiencyMechanical apparatusSpace heating and ventilation safety systemsOutdoor temperatureEngineering

The invention discloses a fixed-frequency air-conditioner, a control method of the fixed-frequency air-conditioner, a control device of the fixed-frequency air-conditioner and a computer readable storage medium. The fixed-frequency air-conditioner comprises an indoor heat exchanger, an outdoor heat exchanger, an outdoor temperature sensor arranged on the outdoor heat exchanger, a four-way valve, acompressor, a first electromagnetic valve, a first throttling part, a second electromagnetic valve and a second throttling part, wherein the first electromagnetic valve and the first throttling partare mutually connected in series, and the second electromagnetic valve and the second throttling part are mutually connected in series. The length of a capillary pipe in the first throttling part is smaller than that of a capillary pipe in the second throttling part, a first refrigerant circulating loop and a second refrigerant circulating loop are formed, the first electromagnetic valve is used for controlling the first refrigerant circulating loop to be opened and closed, and the second electromagnetic valve is used for controlling the second refrigerant circulating loop to be opened and closed. The fixed-frequency air-conditioner solves the technical problem that an existing fixed-frequency air-conditioner provided with a single throttling assembly according to the rated working condition is low in energy efficiency under the working condition of low-temperature refrigerating or low-temperature heating.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

Bridge type concentric constant pressure water distributor

The invention discloses a bridge type concentric constant pressure water distributor. The bridge type concentric constant pressure water distributor comprises an upper joint, a positioning platform, aconcentric adjusting sleeve, an outer protective casing, an adjusting mechanism, a main structure and a lower joint. The outer protective casing is connected to one end of the upper joint, the main structure is connected to the other end of the outer protective casing, and the lower joint is connected to the other end of the main structure. One end of the positioning platform is installed insidethe upper joint in a sleeved mode, and the main structure is connected to the other end of the positioning platform. One end of the concentric adjusting sleeve is installed inside the positioning platform in a sleeved mode, and the main structure is connected to the other end of the concentric adjusting sleeve. The upper joint, the positioning platform, the concentric adjusting sleeve, the outer protective casing, the main structure and the lower joint are centrally penetrated and coaxially arranged, the adjusting mechanism is installed and pressed tightly between the main structure and the outer protective casing in a sleeved mode, and the concentric adjusting sleeve meshes with one end of the adjusting mechanism. The design combining electric direct adjustment of downhole flow and a constant pressure control technology is adopted in the bridge type concentric constant pressure water distributor, the flow control effect is improved, and the voltage stabilization and constant voltage control are realized.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com