Multiple pressure grade mixed working medium cryogenic throttling refrigeration system

A refrigeration system and mixed working medium technology, which is applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems of reduced pressure difference, reduced unit flow isothermal throttling effect, and large compressor pressure ratio

Active Publication Date: 2005-10-19

TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

View PDF1 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In addition, in order to achieve 210-230K refrigeration in the field of general cooling, two-stage compression and two-stage throttling refrigeration cycles are often used (Li Songshou et al., Refrigeration Principles and Equipment, Shanghai Science and Technology Press, 1988, pp.57-59), mainly The purpose is to solve the problem of excessive pressure ratio of the compressor when achieving low temperature

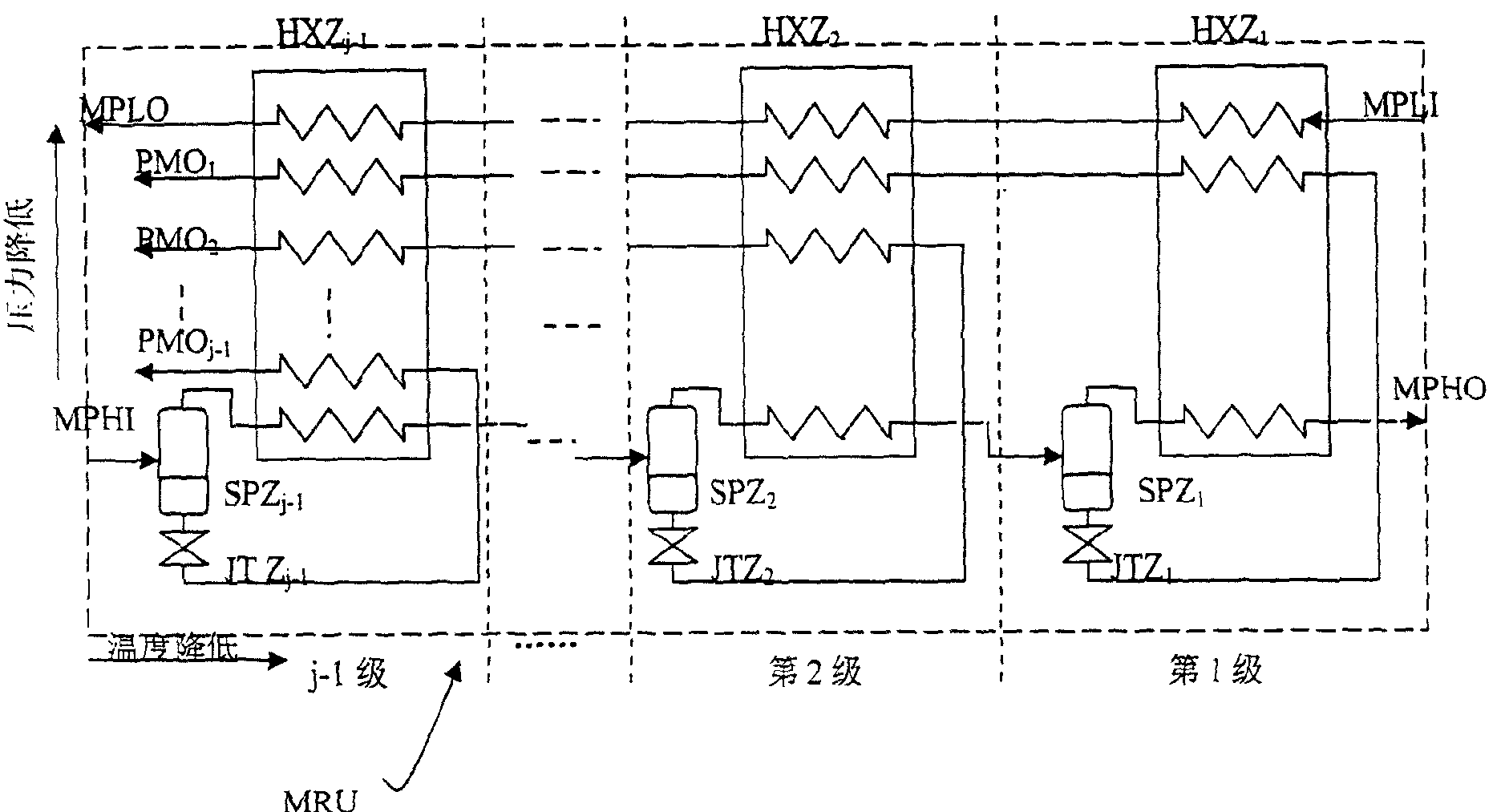

In addition, there are also two throttling cycles in the field of cryogenics (Chen Guobang et al., Machinery Industry Press, 1994, pp.328-329). Pure working fluid is used to reduce the temperature before the last stage of throttling, but the last stage of throttling The pressure before the flow has been throttled once, so that the pressure difference before and after the throttling is reduced, which will reduce the isothermal throttling effect of the unit flow rate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0047] project

Embodiment 2

[0049] project

Embodiment 3

[0051] project

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

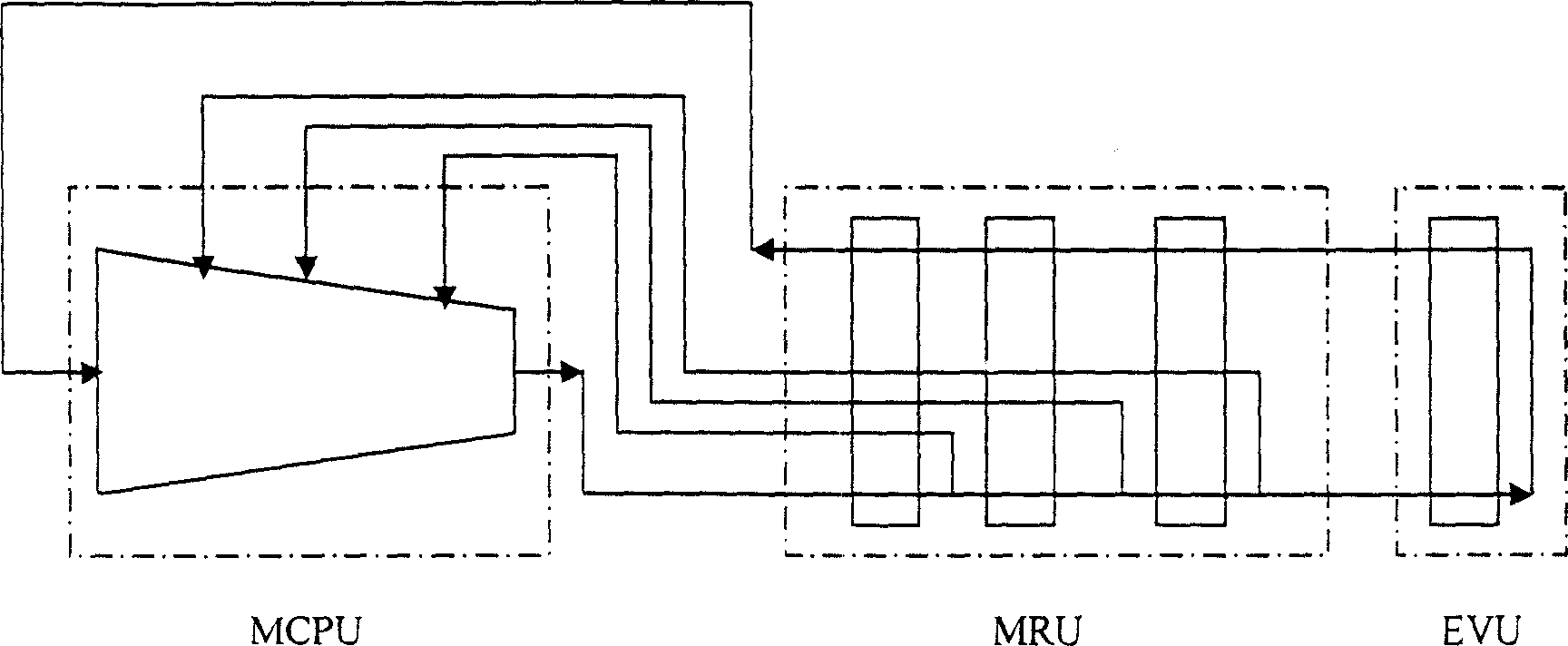

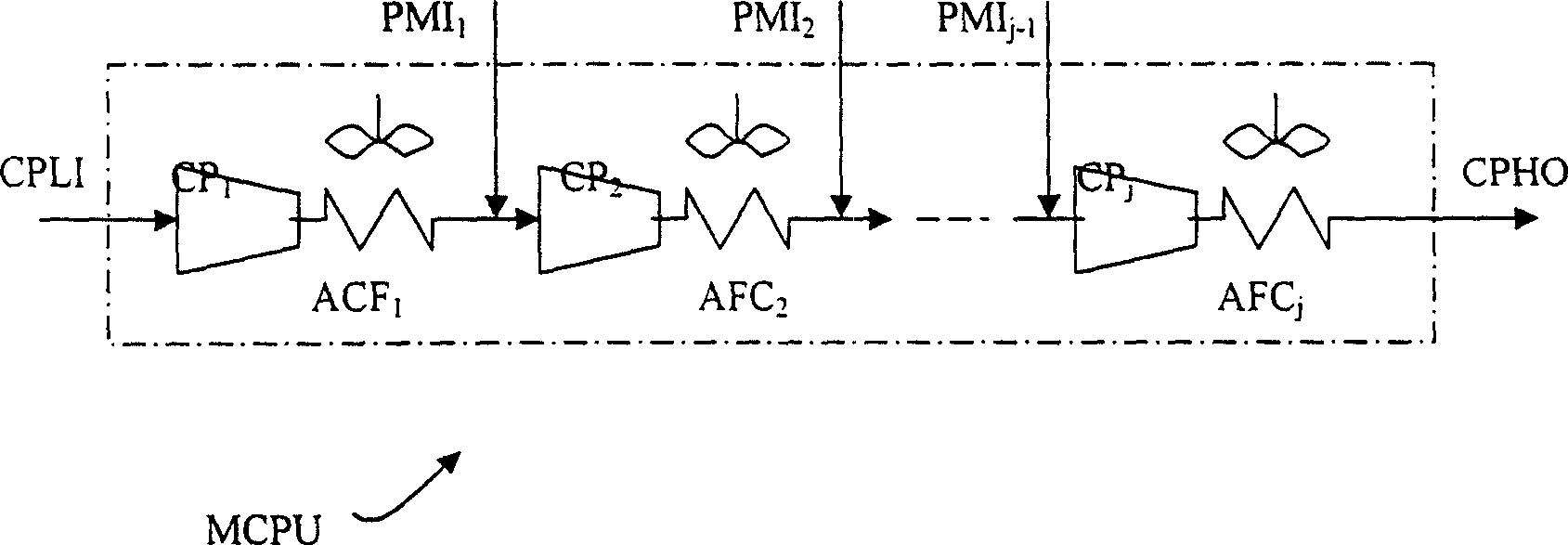

The multiple pressure stage mixed work medium cryogenic throttling refrigeration system consists of several stages of compressor set unit MCPU, back heating pre-cooling unit MRU and evaporator unit EVU. The connection mode includes connecting the high pressure outlet of MCPU to the high pressure inlet of MRU, connecting the low pressure inlet of MCPU to the low pressure outlet one MRU, connecting the high pressure outlet operate MRU to the inlet of EVU, and connecting the outlet of EVU to the low pressure inlet of MRU. The present invention adopts high efficiency multiple-element mixed work medium. The refrigeration system has lowered irreversible loss of compression and back heating process thermodynamically, reduced loss in the practical flow and heat exchange process, and thus high thermodynamic efficiency, and is especially suitable for large and middle scale low temperature refrigerating and gas liquefying fields.

Description

technical field [0001] The invention relates to the field of low-temperature refrigeration technology and gas liquefaction, in particular to a cryogenic throttling refrigeration system with multi-pressure stage mixed working medium. Background technique [0002] The cryogenic multi-component mixed working medium throttling refrigerator with heat recovery measures is widely used in the fields of energy, chemical industry and cryogenic engineering to realize device cooling and liquefaction of industrial gases. Among them, the application in the field of liquefied natural gas is the mixed working medium One of the most important manifestations of throttling refrigeration technology. The use of multiple mixtures of working fluids provides more freedom of choice in the design and operation of the refrigerator. Therefore, according to different cooling objects and application requirements, various refrigeration process systems have emerged, and there are no less than dozens of pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F25B1/10F25J1/02F25J3/02

CPCF25J1/0212F25J1/0022F25J1/0055F25J1/0097

Inventor 公茂琼吴剑峰

Owner TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com