Expansion valve, refrigerant cycle system and air conditioner

A technology of expansion valve and valve needle, which is applied in the direction of refrigeration and liquefaction, fluid circulation arrangement, valve lift, etc., to achieve the effect of reducing throttling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

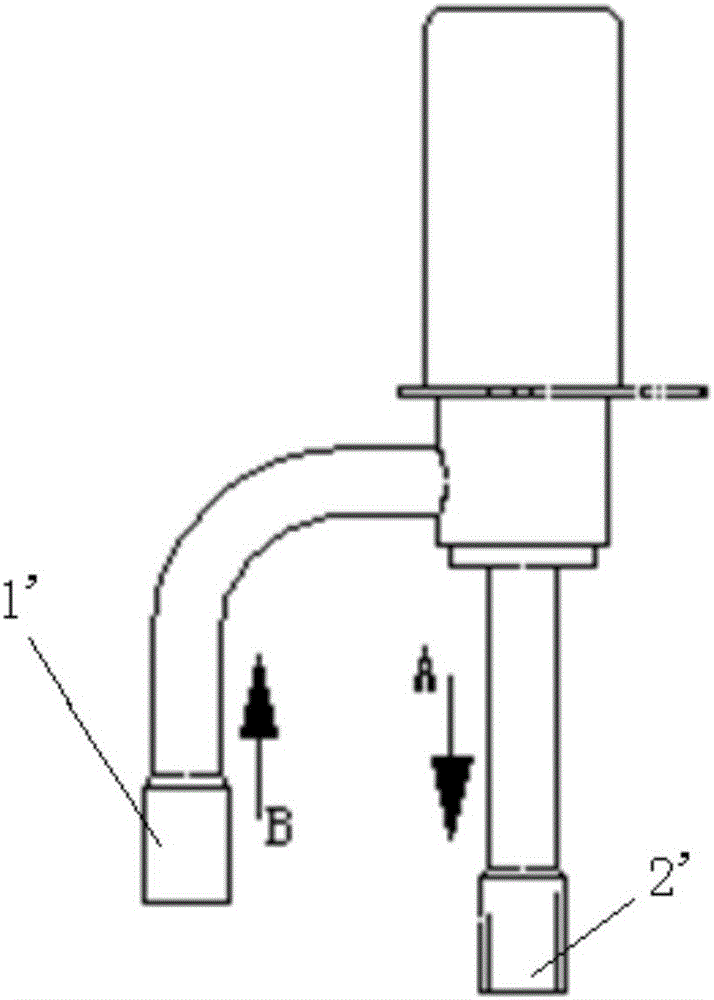

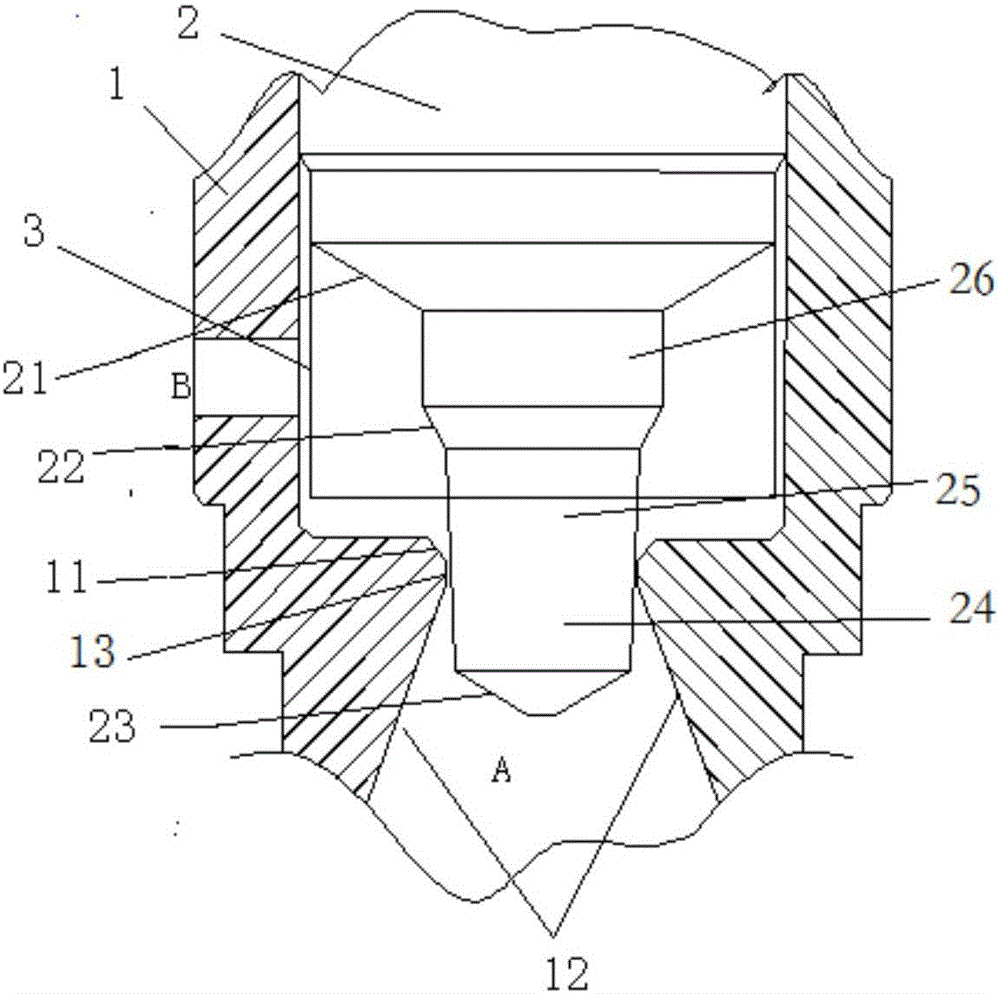

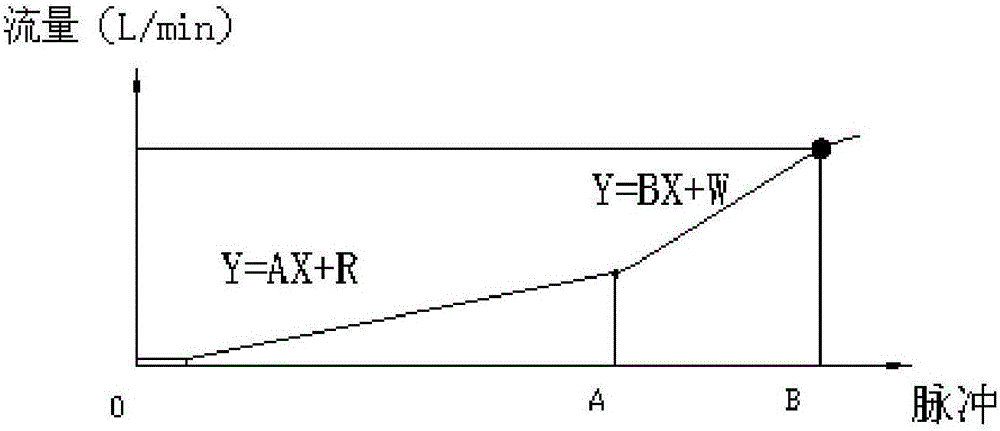

[0036] Such as figure 2 , 4 As shown in and 5, the expansion valve of this embodiment includes a valve body 1 and a valve needle 2 arranged in the valve body 1, the valve body 1 has a valve needle hole, and the valve needle 2 includes a flow regulating part for inserting into the valve needle hole, The cross section of the flow regulating part is reduced along the flow direction of the fluid in the expansion valve, and the valve needle 2 can move along the axial direction of the needle hole to change the gap between the flow regulating part and the valve needle hole. The flow regulating part Including the first valve needle section 24 and the second valve needle section 25 arranged along the above-mentioned flow direction, the first valve needle section 24 is located downstream of the second valve needle section 25 along the fluid flow direction, the cross section of the first valve needle section 24 The rate of change of is greater than the rate of change of the cross-secti...

Embodiment 2

[0081] Figure 6 A schematic structural diagram of the expansion valve according to the second embodiment of the present application is shown. Such as Figure 6 As shown, the structure of the expansion valve of this embodiment is different from that of Embodiment 1 in that: the valve needle hole includes a first port 12, and the upstream section of the first port 12 along the fluid flow direction in the expansion valve is connected to the equal-diameter section 13 , The equal-diameter section 13 extends to the end of the needle hole. That is to say, the valve needle hole of the present embodiment lacks the second port 11 compared with the valve needle hole of the first embodiment.

Embodiment 3

[0083] Figure 7 A schematic structural diagram of the expansion valve according to the third embodiment of the present application is shown. Such as Figure 7 As shown, the structure of the expansion valve of this embodiment is different from that of Embodiment 1 in that: the end surface of the downstream end of the valve needle 2 along the fluid flow direction in the expansion valve is a plane. That is to say, the valve needle 2 of this embodiment lacks the top 23 compared with the valve needle 2 of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com