Method for improving magnetic liquid sealing reliability

A magnetic liquid, reliable technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of magnetic liquid seal failure, no impact resistance, large pressure fluctuation of sealing medium, etc., to reduce leakage and use Long life and good throttling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

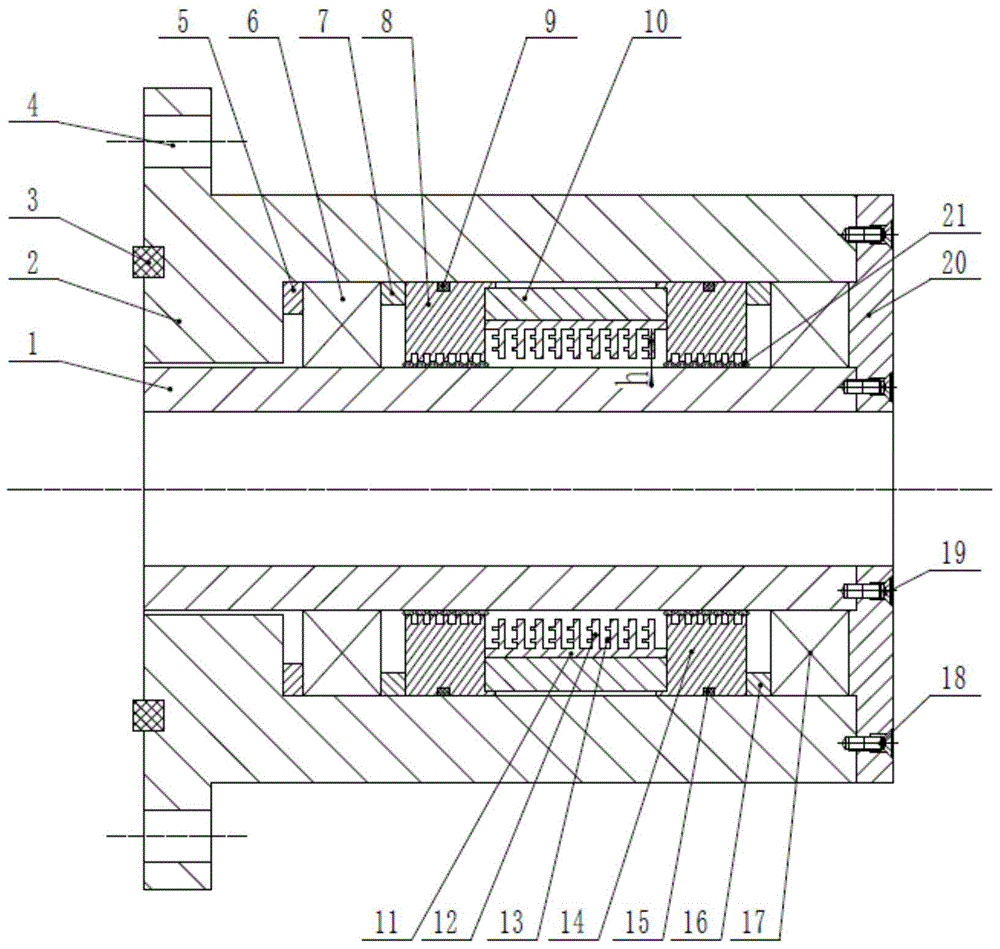

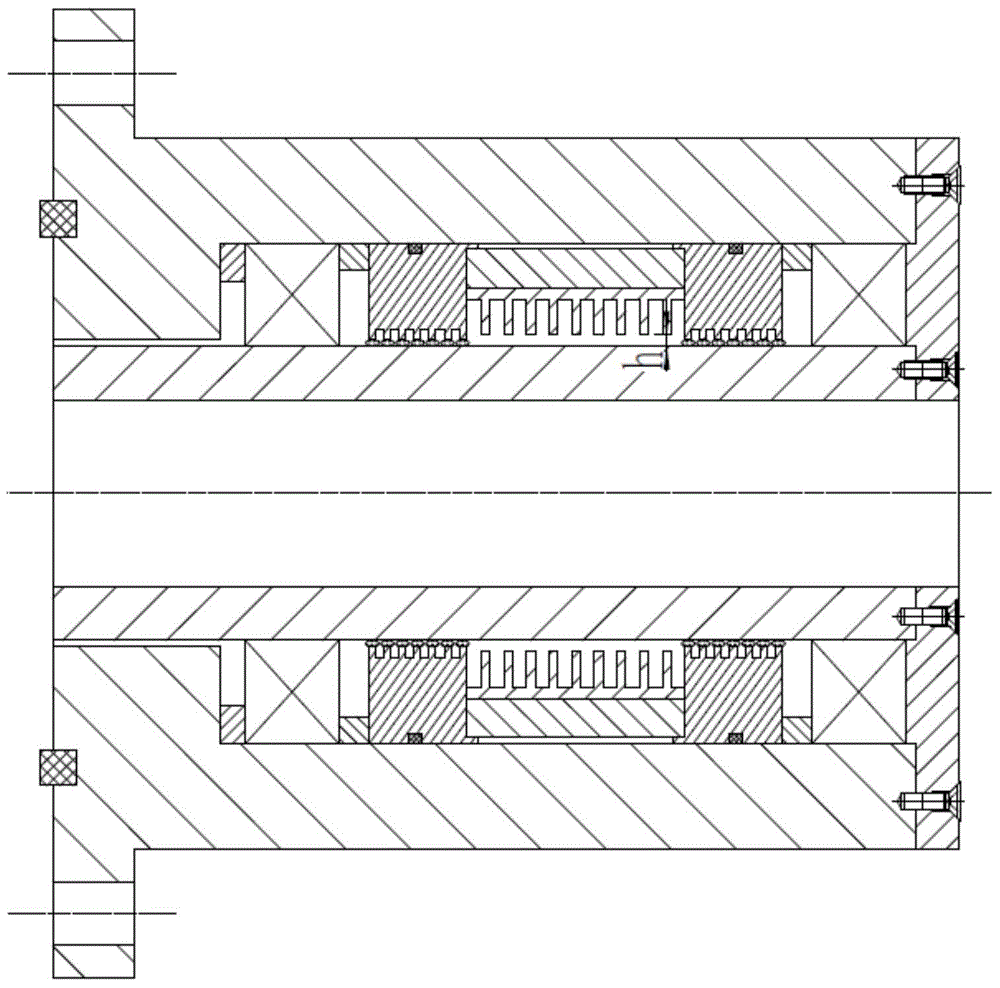

[0018] Utilize accompanying drawing to further illustrate the present invention:

[0019] Step 1 The left pole piece 8, the left seal ring 9, the magnet 10, the right pole piece 14, the right seal ring 15, and the shaft sleeve 1 are assembled into a magnetic liquid sealing assembly in sequence; the left seal ring 9 and the right seal ring 15 are respectively installed in in the grooves on the outer circular surfaces of the left pole piece 8 and the right pole piece 14;

[0020] The labyrinth seal ring 11 is sleeved on the inner ring of the magnet 10 to realize labyrinth seal with the shaft sleeve 1 .

[0021] Step 2 Arrange the positioning ring 5, the left bearing 6, the left magnetic isolation ring 7, the magnetic liquid seal assembly in step 1, the right magnetic isolation ring 16, and the right bearing 17 in the outer casing 2 in sequence, and then inject the magnetic liquid 21 into the outer casing 2. Set on the labyrinth seal ring 11 on the inner ring of the magnet 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com