Heat reclamation module unit, air-conditioning unit and control method

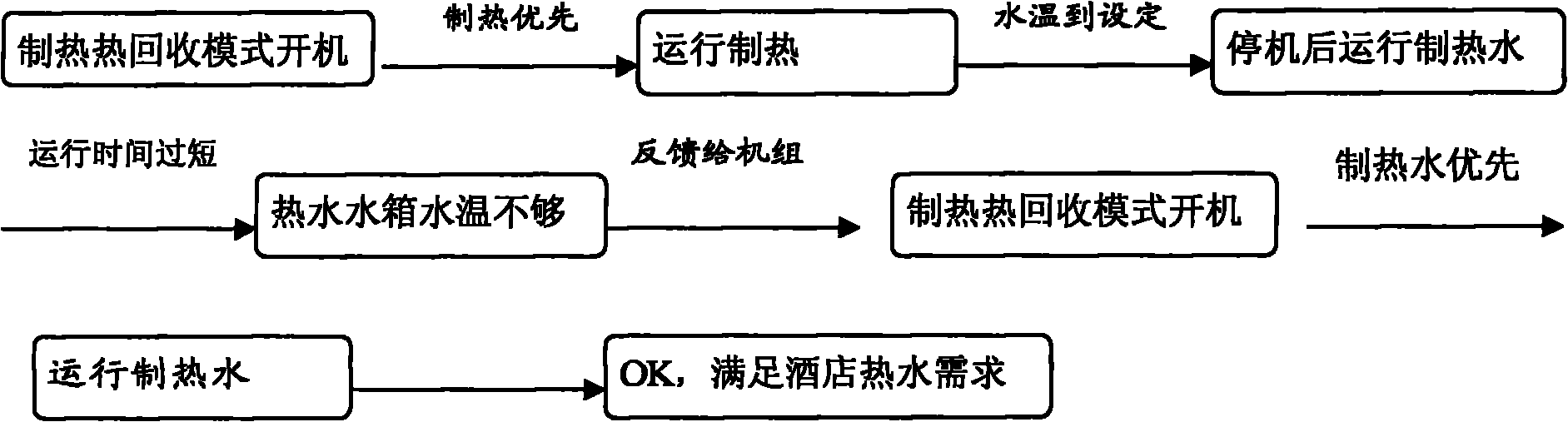

A heat recovery and unit technology, applied in the field of heat exchange, can solve problems such as the inability to achieve optimal matching of heating and heating water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

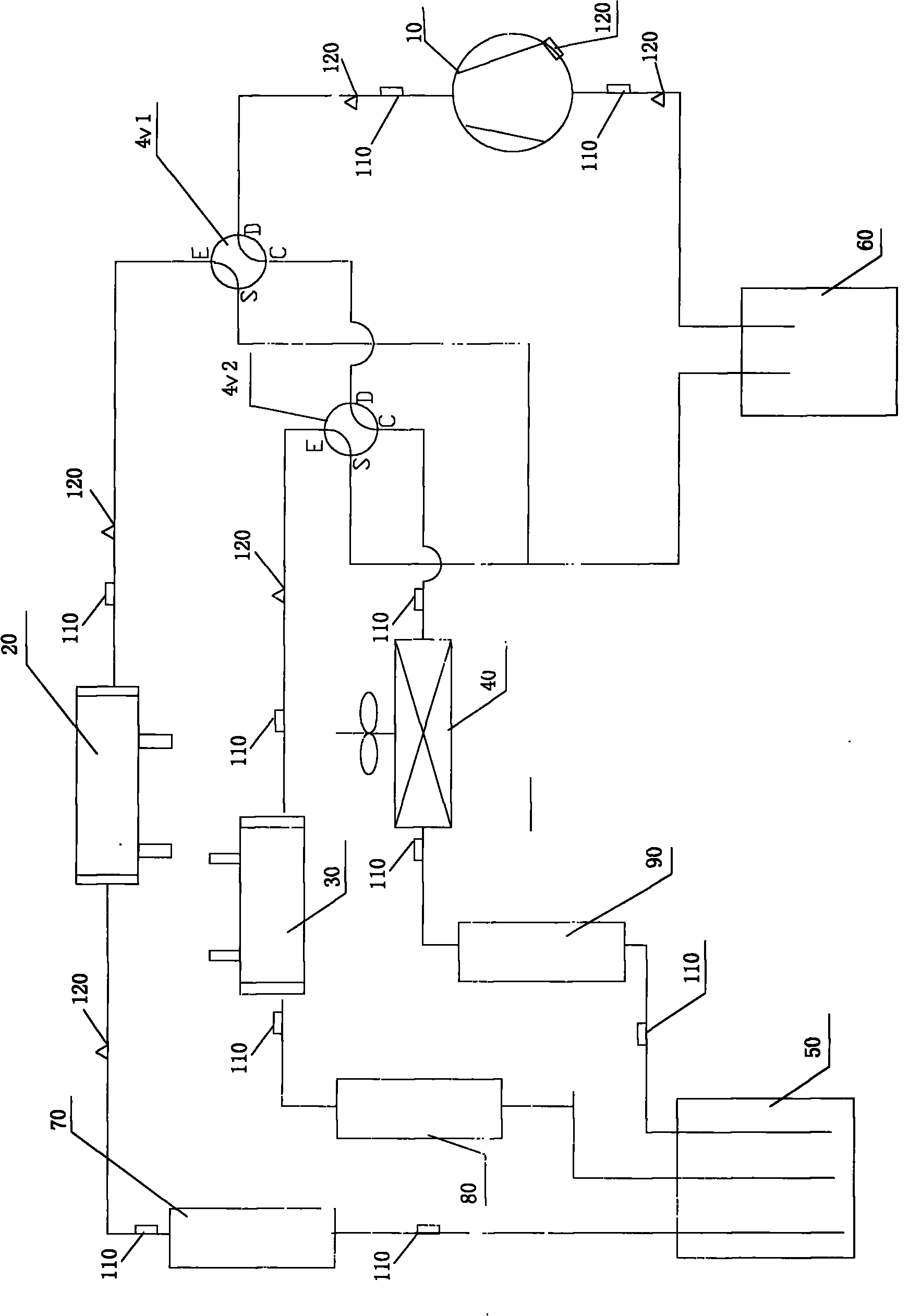

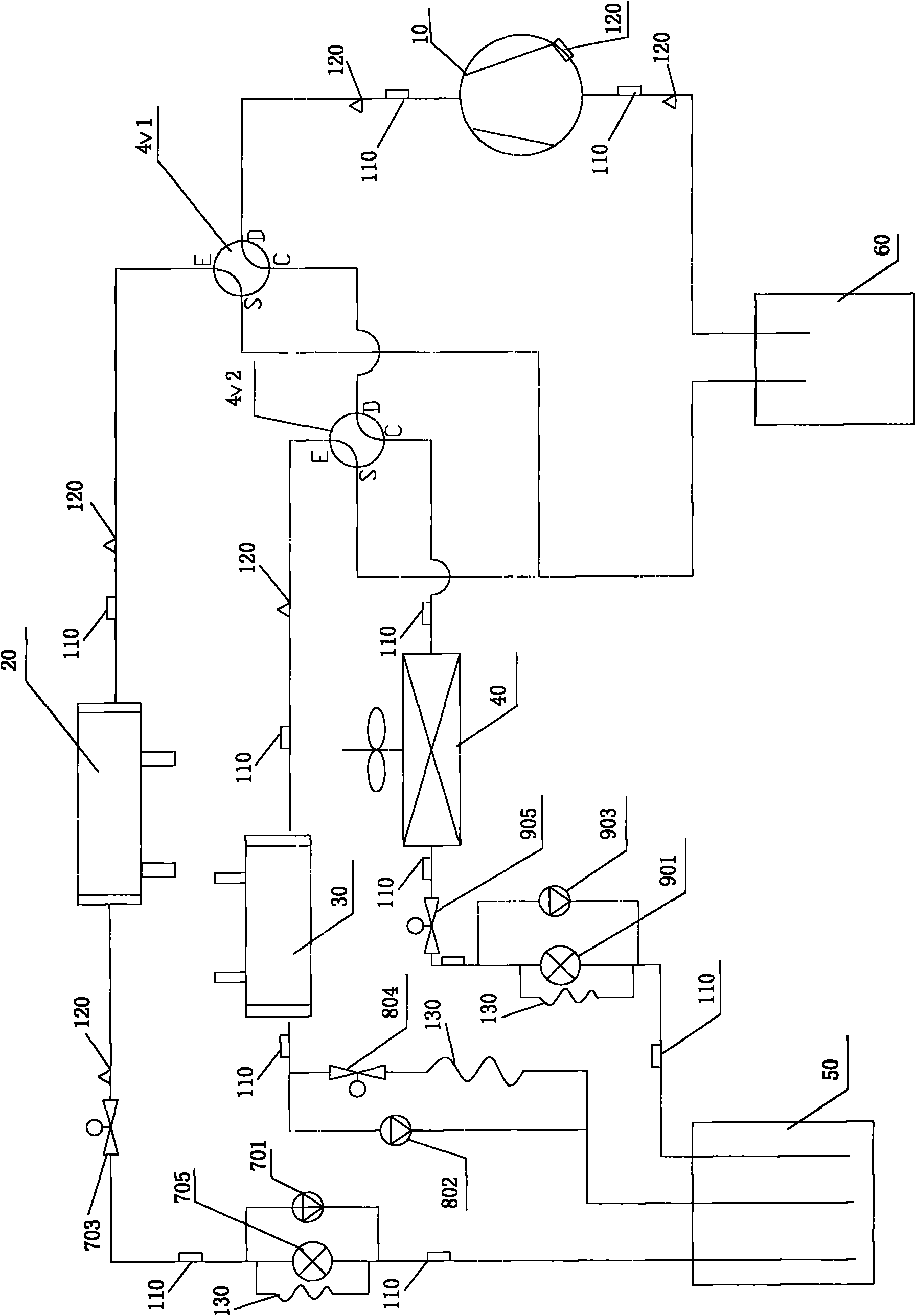

[0032] figure 1 It schematically shows a pipeline connection structure of a heat recovery modular unit according to an embodiment of the present invention. like figure 1 As shown, the heat recovery module unit 1 according to this embodiment includes: a compressor 10, a first four-way valve 4V1, a second four-way valve 4V2, an air-conditioning water shell-and-tube heat exchanger 20, a first throttling device 70, The second throttling device 80, the third throttling device 90, the first heat exchanger 40, the hot water shell-and-tube heat exchanger 30, the gas-liquid separator 60, the liquid storage tank 50, the connecting pipe 100, and the connecting pipe is used for the above-mentioned Interconnections between components. Of course, the heat recovery module unit 1 may use the gas-liquid separator 60 and the liquid storage tank 50,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com