Seal ring

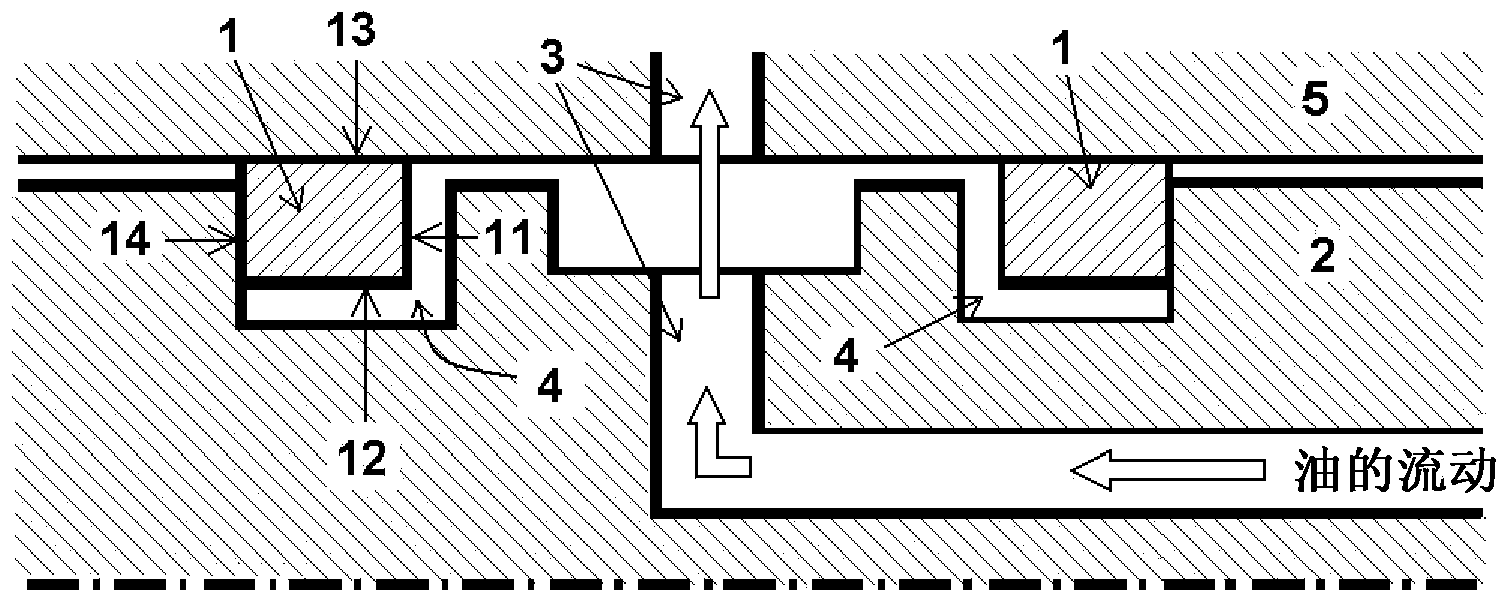

一种密封环、凹部的技术,应用在发动机的密封、机械设备、发动机元件等方向,能够解决油泄漏等问题,达到低泄漏、降低摩擦力、抑制泄漏的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

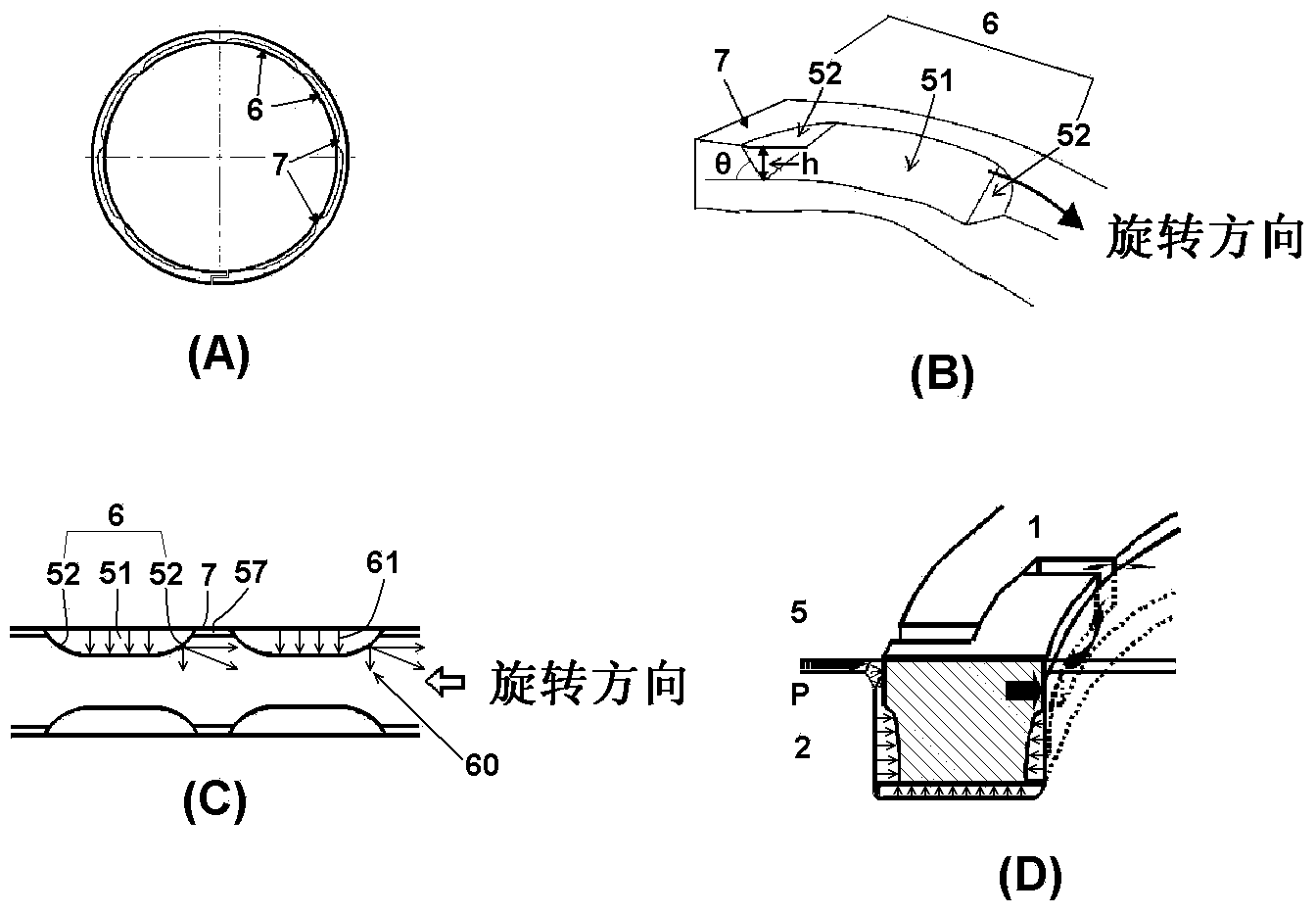

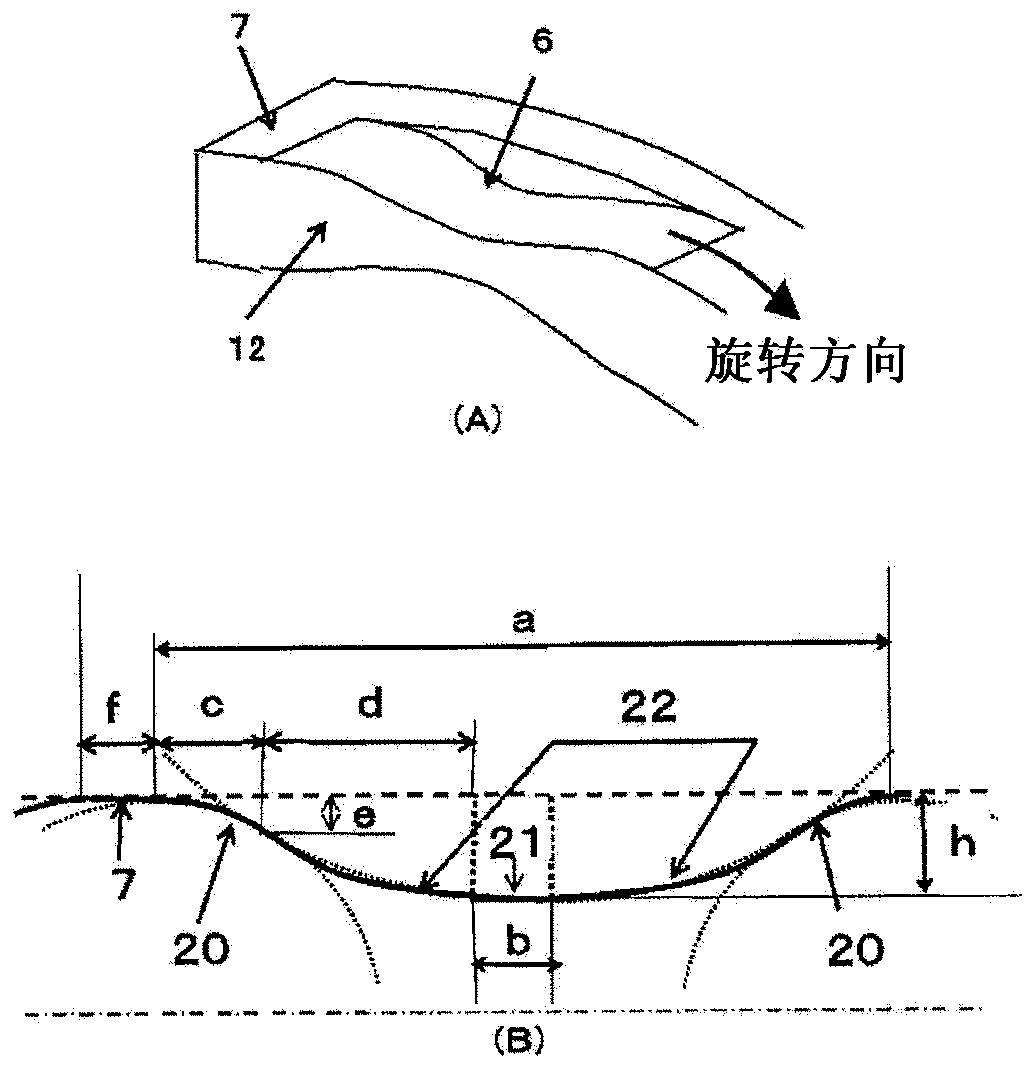

Embodiment 1)

[0043] Using PEEK material with carbon fiber added, through injection molding, a image 3 (A) The seal ring of the recessed part shape of the structure shown. Here, when the curvature of the throttle portion is R40, eight recesses with a depth of 0.22 mm and a circumferential width of 24 mm are formed on the contact side surface and the pressure receiving side surface, respectively. The outer diameter (nominal diameter) of the sealing ring is 67mm, the thickness (radial width) is 2.3mm, the width (axial width) is 2.32mm, and the interface is Figure 5 Three step openings shown. In addition, when the axial width of the seal ring is 100, the depth of the deepest part is 9.5; when the circumferential length of one recess is 100, the circumferential width of the deepest part is 16.9; When the sum is 100, the sag length of the R-curved surface of the throttle portion is 13.9, and the depth of the throttle portion is 15.0 when the depth of the deepest portion of the concave portio...

Embodiment 2~5)

[0053] In the same manner as in Example 1, a PEEK material with carbon fiber added was used by injection molding to manufacture a image 3 (A) The seal ring of the recessed part shape of the structure shown. Here, the curvature of the throttle portion was changed so that the depth h of the deepest portion was 0.03 mm (Example 2), 0.08 mm (Example 3), 0.12 mm (Example 4), and 0.41 mm (Example 5), respectively. . In addition, the outer diameter (nominal diameter) of the sealing ring is 67mm, the thickness (radial width) is 2.3mm, the width (axial width) is 2.32mm, and the interface is Figure 5 Three step openings shown. When the axial width of the seal ring is 100, the depths of the deepest portions of the respective examples are 1.3 (Example 2), 3.4 (Example 3), 5.2 (Example 4), and 17.7 (Example 5). The frictional force and oil leakage amount of the obtained seal ring were measured in the same manner as in Example 1.

[0054] Figure 7 In the graph, the results (·) of th...

Embodiment 6~10)

[0058] Using PEEK material with carbon fiber added, through injection molding, a Figure 4(A) The seal ring of the recessed part shape of the structure shown. An inner wall with a width of 0.3 mm and a circumferential length of 10 mm on one side was provided along the inner peripheral end from both ends of the recesses toward the center, and an oil introduction hole with a circumferential length of 4 mm was formed in the center. Here, the curvature of the throttling portion was changed, and the deepest portions h were manufactured to be 0.03 mm (Example 6), 0.08 mm (Example 7), 0.12 mm (Example 8), and 0.22 mm (Example 9). ), and a sealing ring of 0.41 mm (Example 10). In addition, the outer diameter (nominal diameter) of the sealing ring is 67mm, the thickness (radial width) is 2.3mm, the width (axial width) is 2.32mm, and the interface is Figure 5 Three step openings shown. The frictional force and oil leakage amount of each seal ring were measured in the same manner as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com