A heat pump water heater system

A technology for heat pump water heaters and condensers, applied in lighting and heating equipment, fluid circulation arrangements, refrigeration components, etc., can solve problems such as low suction pressure, inability to change refrigerant volume synchronously, system performance degradation, etc., and achieve good throttling capacity , optimize the throttling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

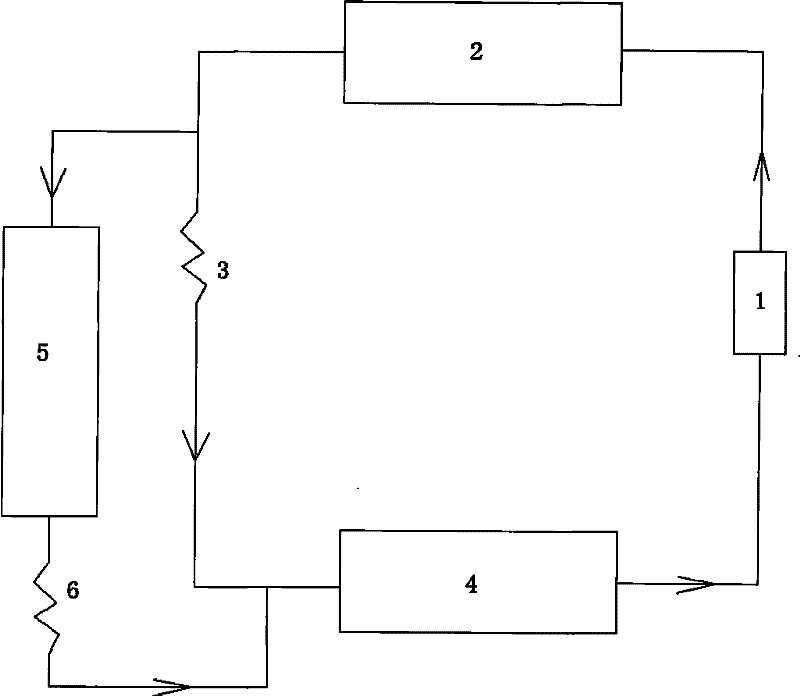

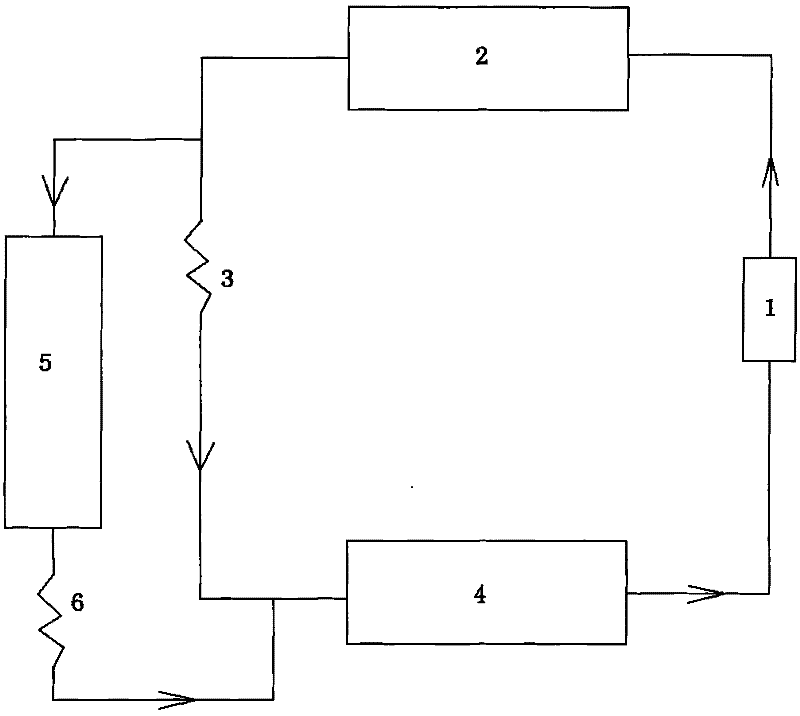

[0015] Such as figure 1 As shown, a heat pump water heater system includes a compressor 1, a condenser 2, a throttling device 3 and an evaporator 4, and the compressor 1 is connected to the condenser 2, the throttling device 3, and the evaporator 4 in sequence Returning to the compressor 1, it also includes a high-pressure accumulator 5 and an auxiliary throttling device 6. After the high-pressure accumulator 5 is connected in series with the auxiliary throttling device 1, it is connected in parallel at both ends of the throttling device 3 to achieve double throttling. The function of the heat pump water heater system using the rotary compressor has a wider throttling range and a better throttling effect. Both the throttling device 3 and the auxiliary throttling device 6 are capillary throttling devices.

[0016] The device composed of the high-pressure liquid accumulator 5 and the auxiliary throttling device 6 connected in series is connected in parallel at both ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com