Capillary tube flow testing device

A flow test device and capillary tube technology, which is applied in the direction of volume/mass flow generated by mechanical effects, fluid flow detection by measuring pressure difference, etc., can solve problems such as design errors and influences, and achieve the goal of improving authenticity and throttling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

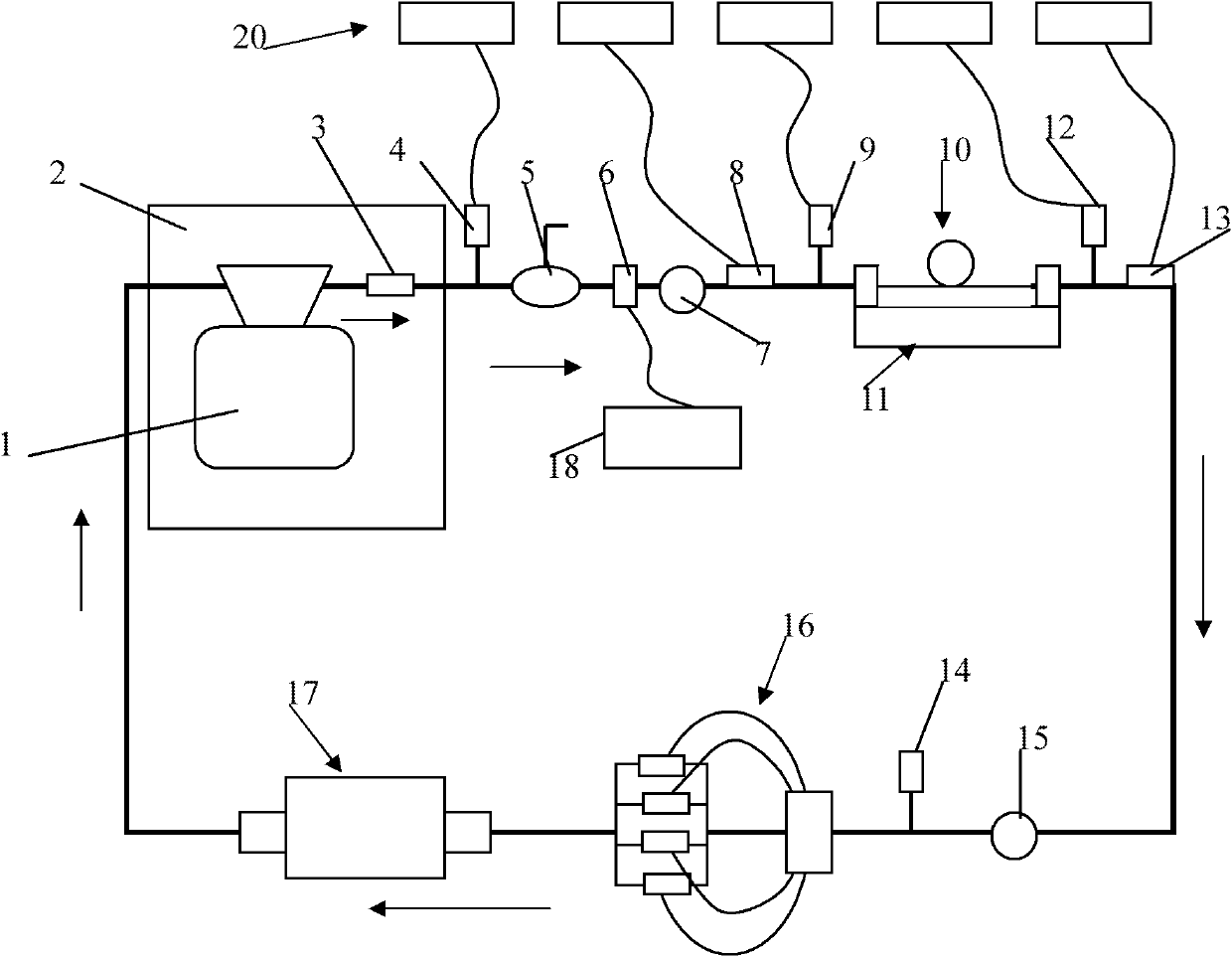

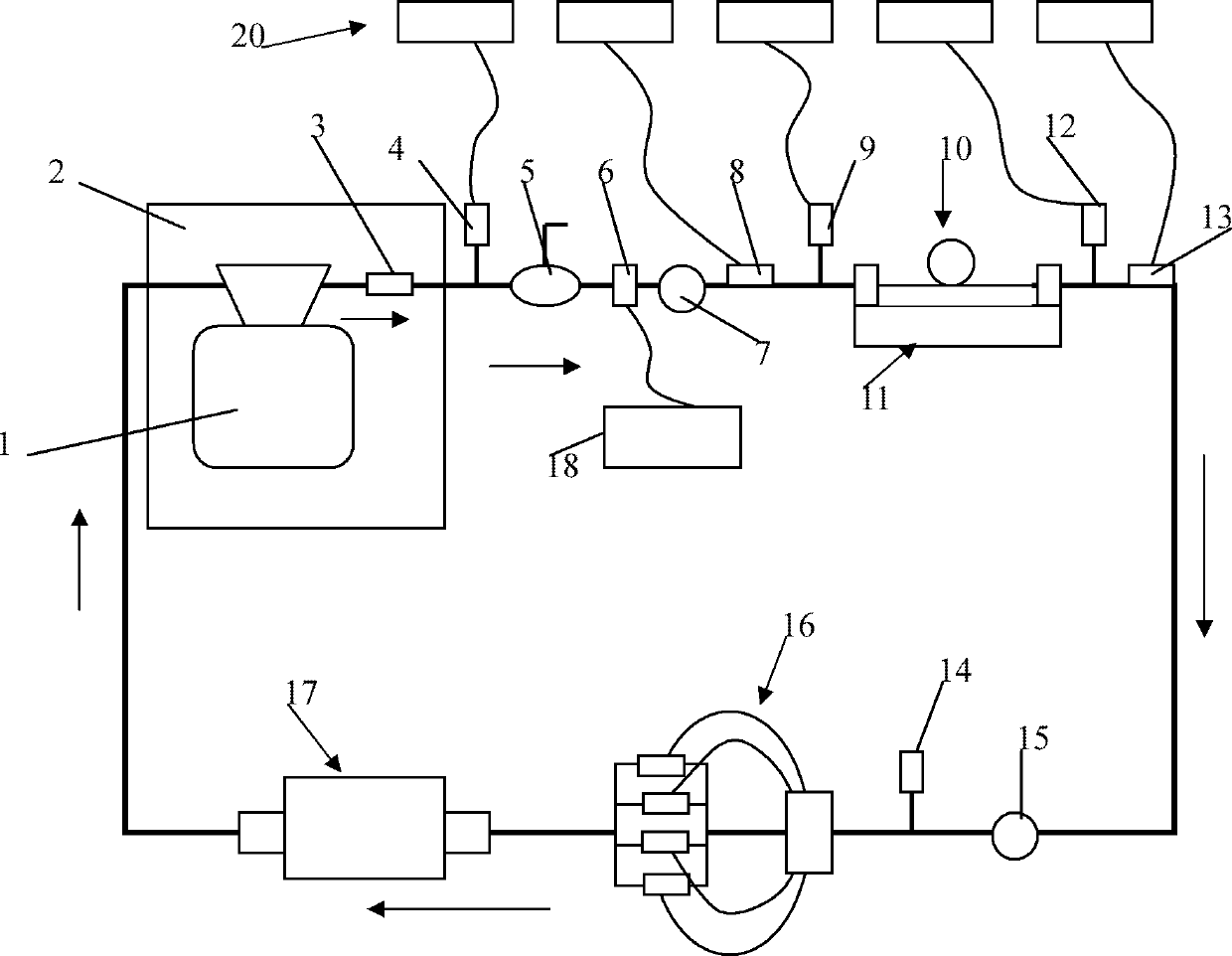

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0016] Such as figure 1 As shown, the capillary flow test device of the present invention includes: a refrigerant liquid storage tank 1 contained in a constant temperature box 2; a check valve 3 sequentially connected to the output port of the liquid storage tank 1 through a pipeline; The manual switch 4 at the rear of the one-way valve 3, the manual switch 4 can open or close the refrigerant flow path to start or terminate the flow test; the high-pressure regulator valve 7 connected in series behind the manual switch 4 in sequence; The capillary fixture 11 with the capillary 10 fixed; the inlet pressure sensor 9 and the outlet pressure sensor 12 respectively arranged in parallel on the refrigerant flow path near both ends of the capillary under test of the capillary fixture 11 ; Low-pressure stabilizing valve 15, self-balancing pressure contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com