Sealing structure for dynamic and static gaps of rotating machine

A technology of sealing structure and rotating machinery, applied in the direction of engine sealing, mechanical equipment, machine/engine, etc., can solve the problems such as the inability to ensure safe and stable operation, the lack of control structure design of the seal, the inability to effectively control the leakage volume, etc., and achieve good control. Flow effect, stable control of leakage, effect of preventing tooth root breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with technical scheme and accompanying drawing, the present invention is described in detail by taking nuclear main pump as embodiment.

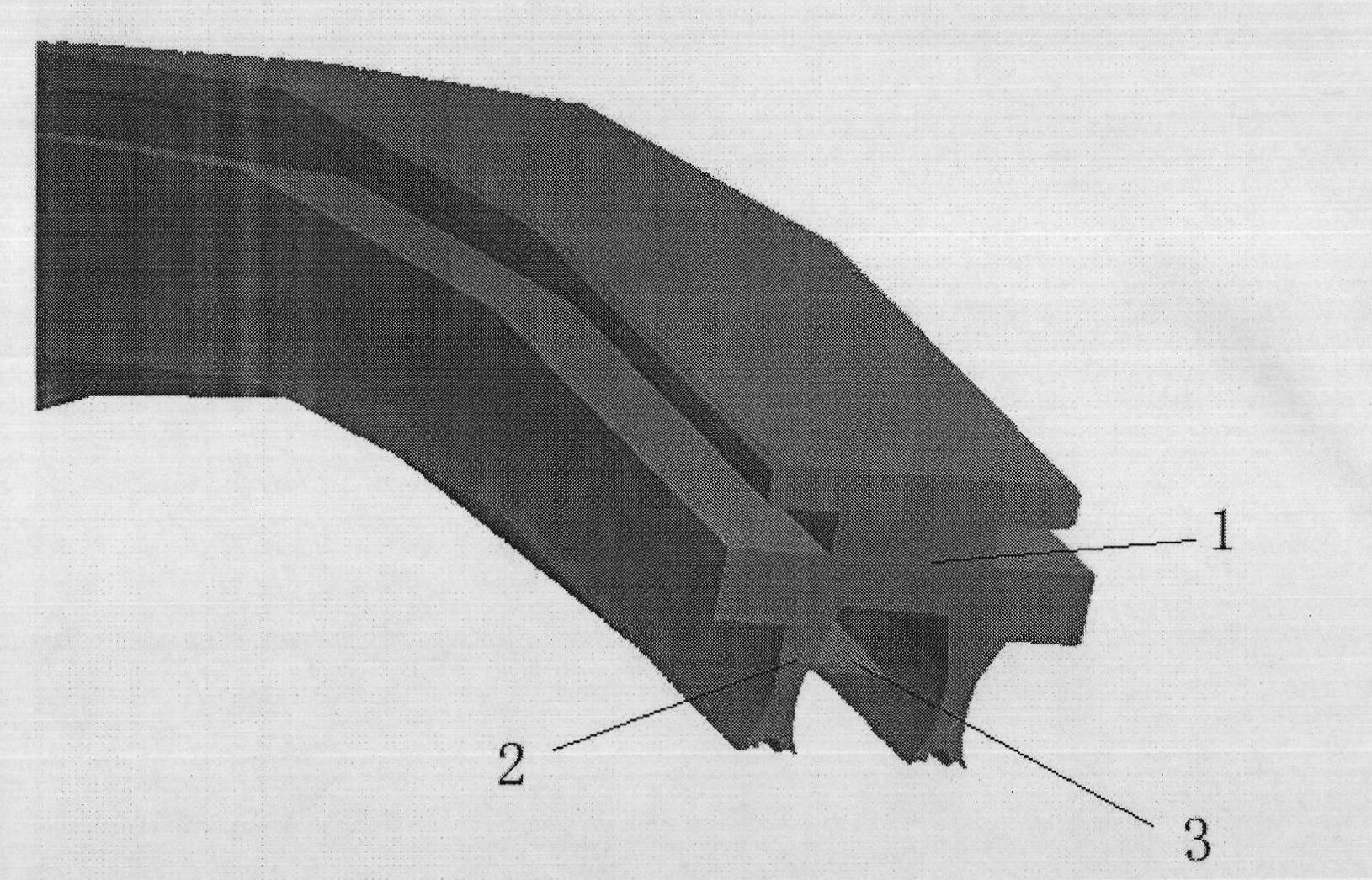

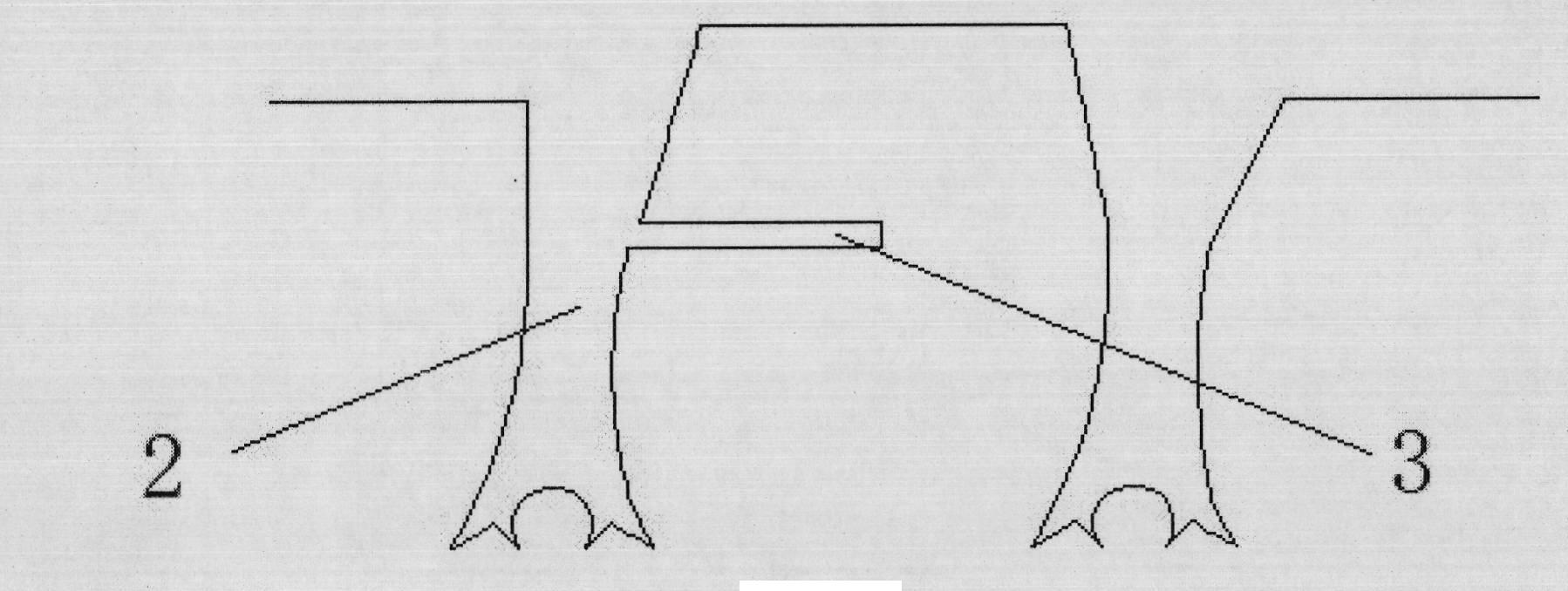

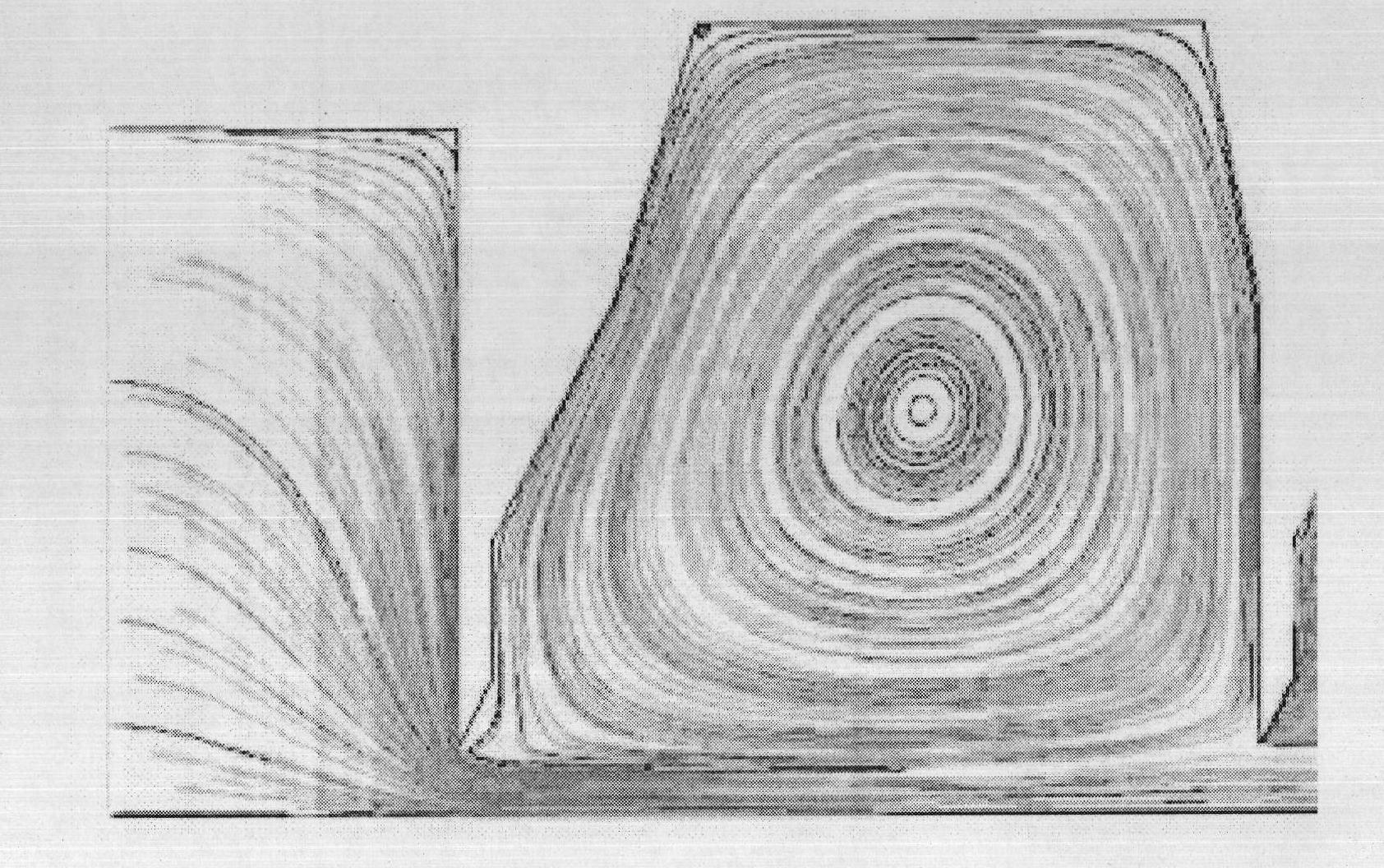

[0034] The sealing of the present invention is composed of two semicircular sealing rings, such as Figure 5 , can be installed in the dynamic and static clearance 4 between the impeller outlet and the guide vane of the nuclear main pump and the dynamic and static clearance 5 between the impeller inlet wheel cover and the inlet guide pipe, such as Image 6 , or installed in the gap between the heat shield and the shaft. The back arc of the sealing ring is installed along the sealing groove of the fixed part, and the inclined direction of the sealing teeth faces the direction of the incoming flow. The sealing structure of the present invention is mainly composed of a sealing ring 1 and a sealing tooth 2 .

[0035] The inner ring of the sealing ring can be provided with multiple sealing teeth, as shown in Figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com