Double-sealing filling sleeve compensator

A sleeve compensator, injection-filled technology, applied in the field of compensators, can solve the problems of endangering the life safety of staff, complicated production process, low processing efficiency, etc., and achieve the goal of eliminating hidden danger of leakage, good safety and improving sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

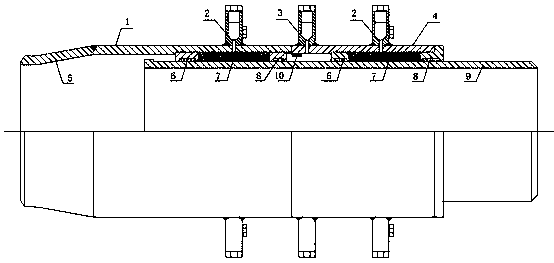

[0023] see Figure 1~2 , in the embodiment of the present invention, a double-seal filling type sleeve compensator, including a lower cylinder 1, one end of the lower cylinder 1 is provided with a small head 5, and the other end of the lower cylinder 1 is sleeved with an upper cylinder 4. The upper ends of the inner walls of the lower cylinder 1 and the upper cylinder 4 are provided with annular steps, and the inner sides of the annular steps are respectively provided with guide bushes 6 closely connected with the inner walls of the lower cylinder 1 and the upper cylinder 4, and the lower cylinder The outer walls of the body 1 and the upper cylinder 4 are both annularly distributed with no less than three filling nozzles 2, and the inner sides of the lower cylinder 1 and the upper cylinder 4 are provided with a gland ring 8 at the end far away from the guide bush 6. The inside of cylinder 1 and upper cylinder 4 are filled with sealing packing 7 between the guide bearing bush 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com