Gas heater

A gas heater and gas technology, applied in the direction of machines/engines, oil supply devices, internal combustion piston engines, etc., can solve problems such as loose pipelines and reduced gas delivery efficiency, and achieve the effects of easy disassembly and reduced temperature range fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

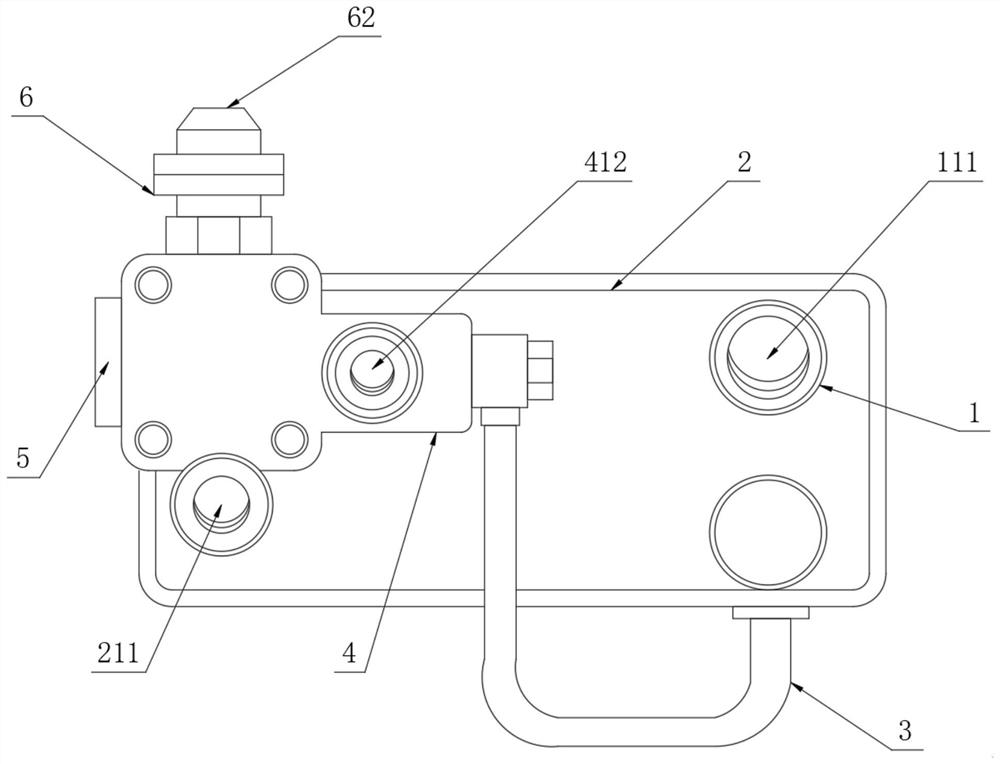

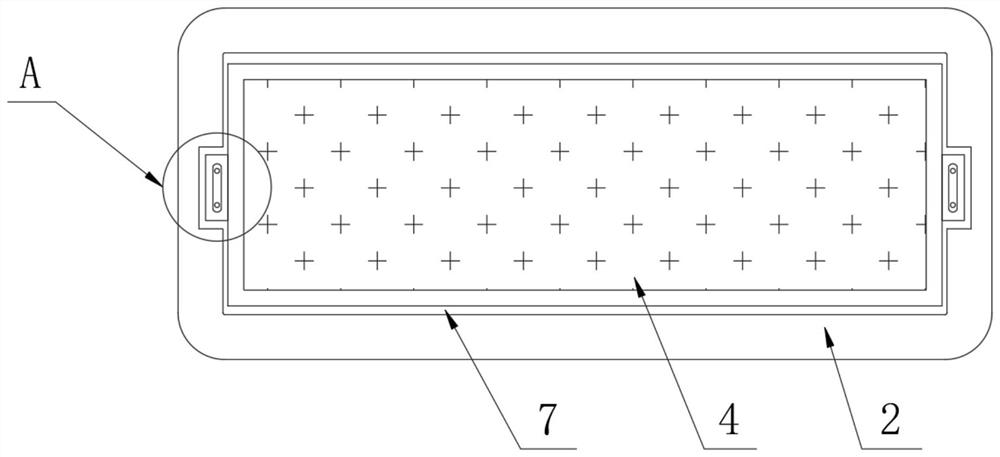

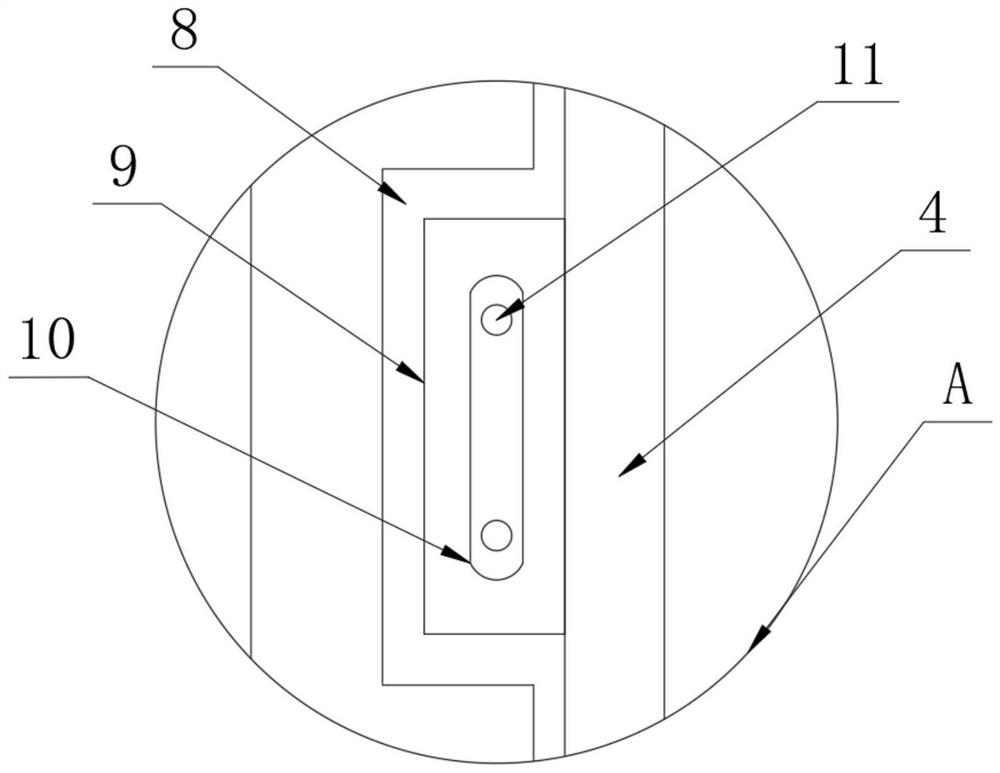

[0040] like Figure 1 to Figure 12 As shown, the embodiment of the present invention provides a gas heater, including an air inlet joint 1, a heat exchanger 2, an external water connection pipeline 3, a thermostat control valve 5, an air outlet joint 6, and a first gas inlet 111, the first gas outlet 112, the third gas inlet 41 and the fourth gas outlet 62, the valve block 4 is detachably installed on the heat exchanger 2, and the surface of the heat exchanger 2 is provided with an installation cavity 7 One side of the inside of the installation cavity 7 is provided with a connection groove 8, the inside of the connection groove 8 is clamped with a connection plate 9, and the surface of the connection plate 9 is detachably mounted with a connection ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com