Patents

Literature

139results about How to "Implement Feedback Control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

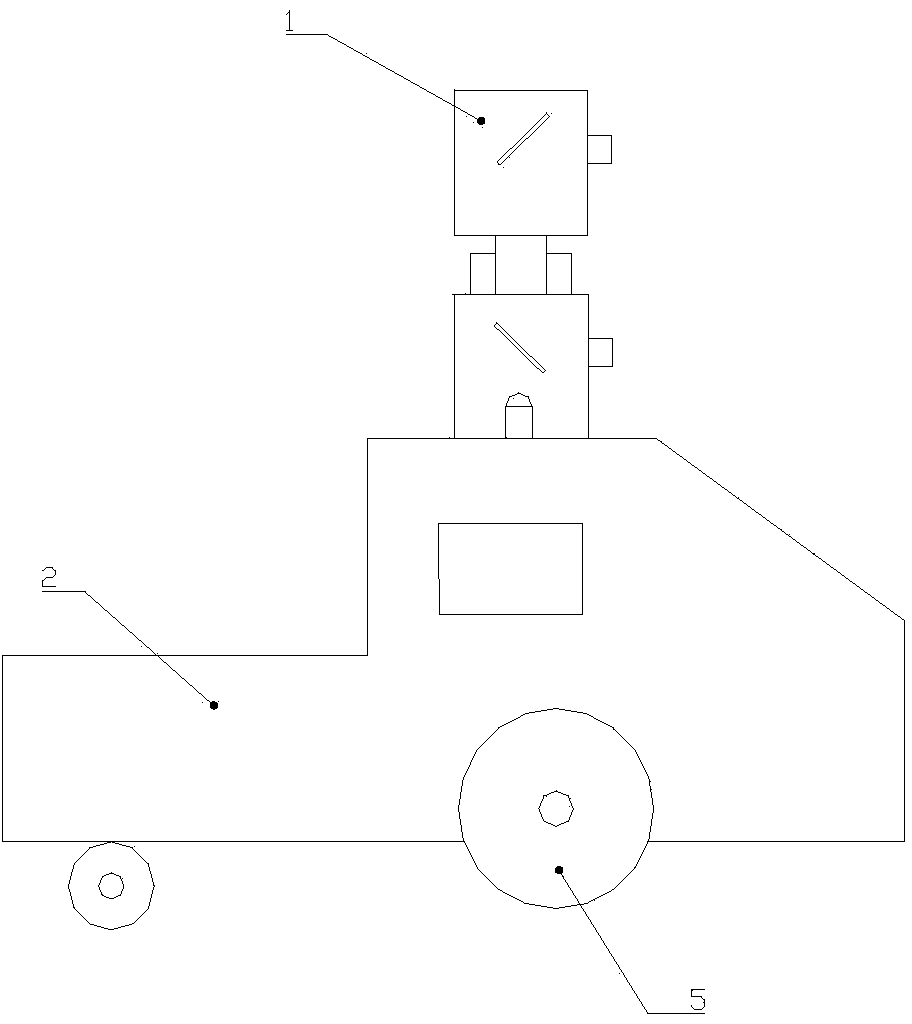

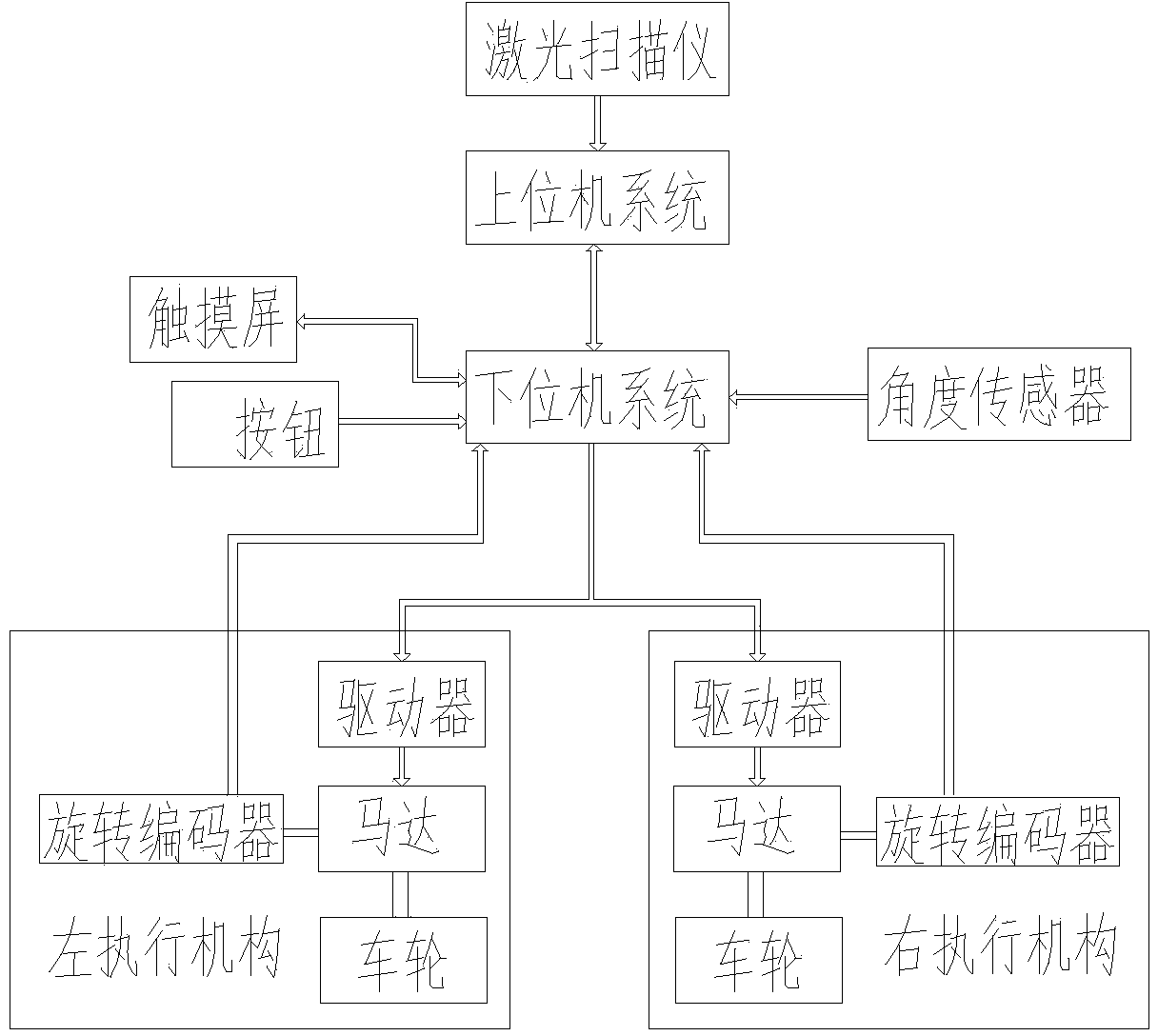

Non-baffle-board laser AGV and navigation method thereof

ActiveCN103777637AImplement Feedback ControlRealize autonomous navigationElectromagnetic wave reradiationPosition/course control in two dimensionsElectricityLaser scanning

The invention discloses a non-baffle-board laser AGV and relates to the technical field of transportation equipment. The non-baffle-board laser AGV can achieve positioning and obstacle avoidance without baffle boards and comprises a laser scanner, a vehicle body, an upper computer system, a lower computer system, an actuator and an input-output device, wherein the laser scanner is electrically connected with the upper computer system, the upper computer system is electrically connected with the lower computer system, the input-output device is connected with the lower computer system, and the actuator is rotatably connected to the lower portion of the vehicle body and is used for driving the non-baffle-board laser AGV to run.

Owner:SUZHOU AGV ROBOT CO LTD

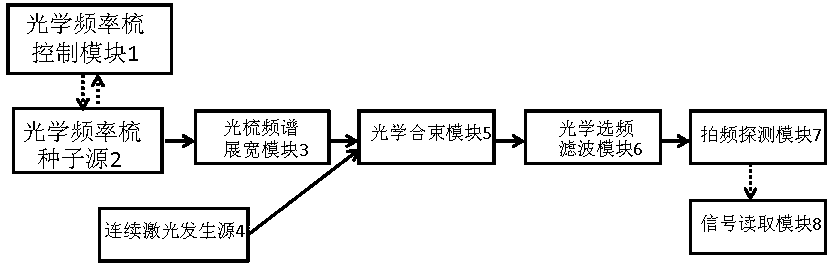

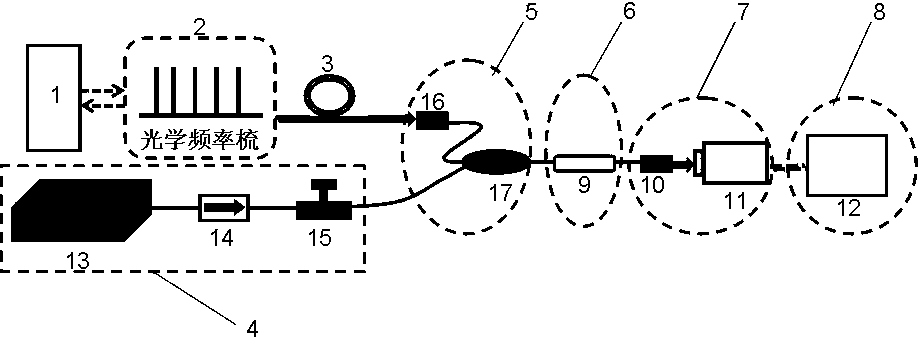

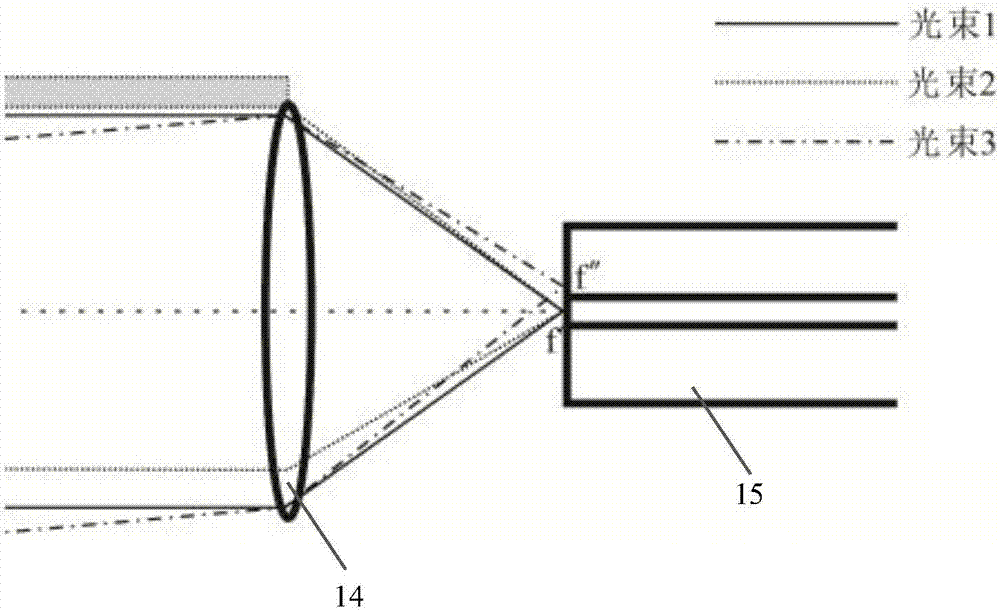

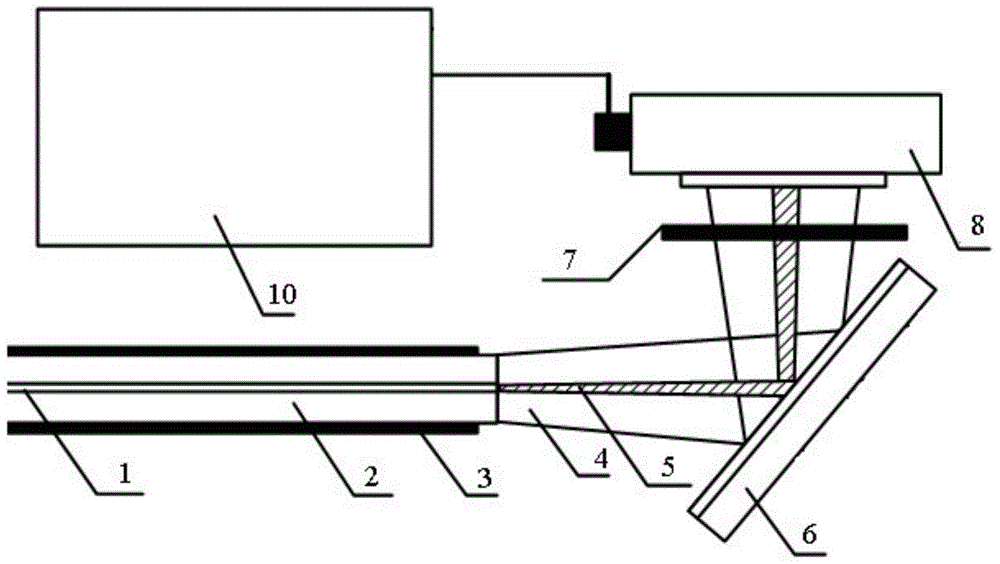

Continuous laser device spectral line width measurement device based on optical frequency comb

ActiveCN103712689AWide range of availableRealize measurementSpectrum investigationMeasurement deviceSpectral width

The invention discloses a continuous laser device spectral line width measurement device based on an optical frequency comb. The continuous laser device spectral line width measurement device is characterized by comprising an optical frequency comb control module, an optical frequency comb seed source, an optical frequency comb spectrum broadening module, a continuous laser generating source, an optical beam combining module, an optical frequency selecting filtering module, a beat frequency detecting module and a signal reading module. The spectrum of the precisely-controlled optical frequency comb is broadened, output light of the precisely-controlled optical frequency comb and output light of the continuous laser generating source together enter the optical beam combining module, the light spots of two outgoing laser beams coincide, and then the two laser beams together enter the optical frequency selecting filtering module, two laser beams obtained through filtering pass through the beat frequency detecting module, the sizes of light spots are changed through shaping, and the light spots are concentrated on a detector, beat frequency signals are obtained through coherent combination, and the output spectral width of the continuous lasers to be measured can be contained through the signal reading module. The continuous laser device spectral line width measurement device is stable in structure and high in practicability, the measurement process is rapid and simple, and the output spectral width of one or more wave length continuous lasers can be obtained in real time.

Owner:SHANGHAI LANGYAN OPTOELECTRONICS TECH +1

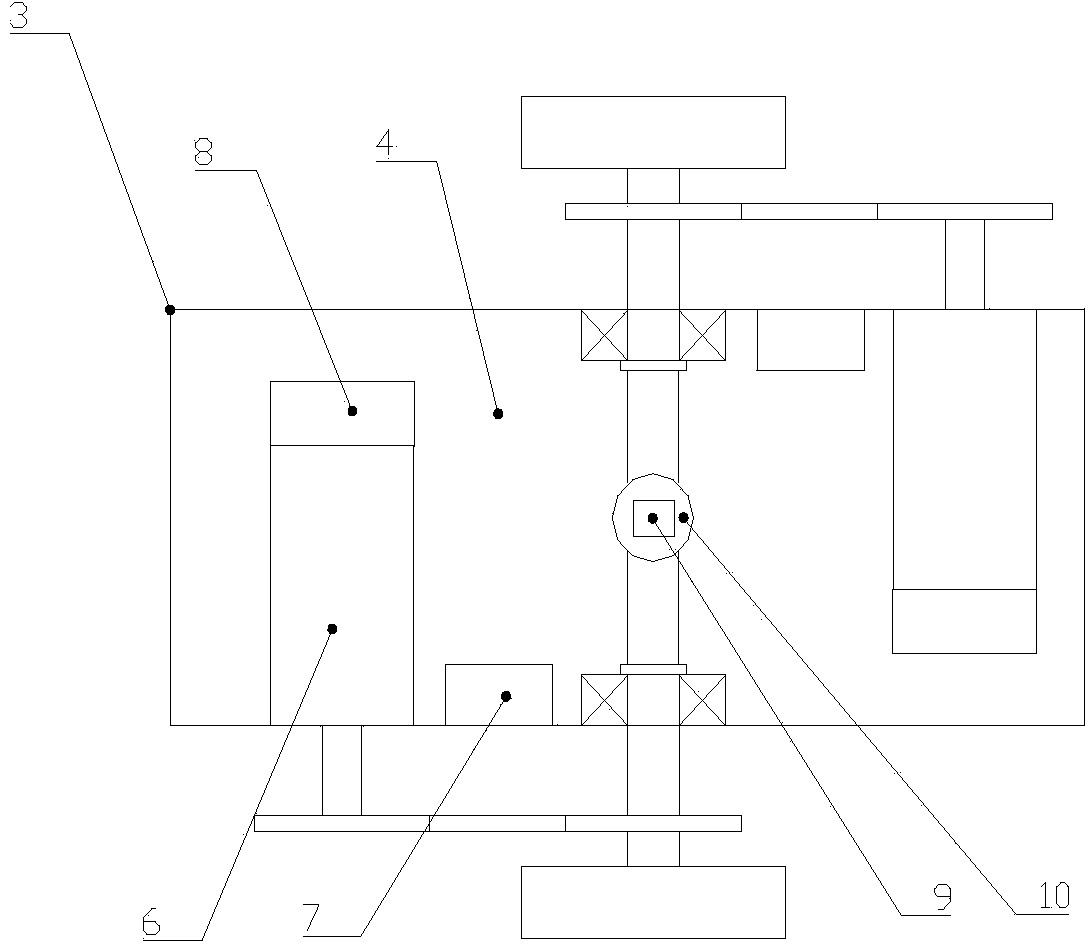

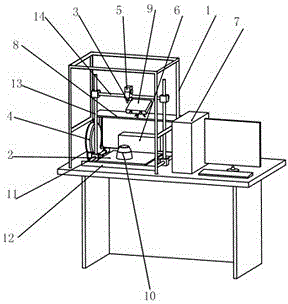

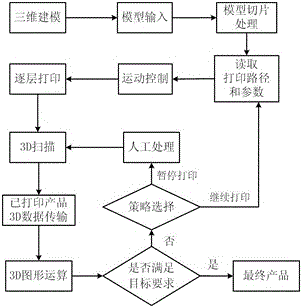

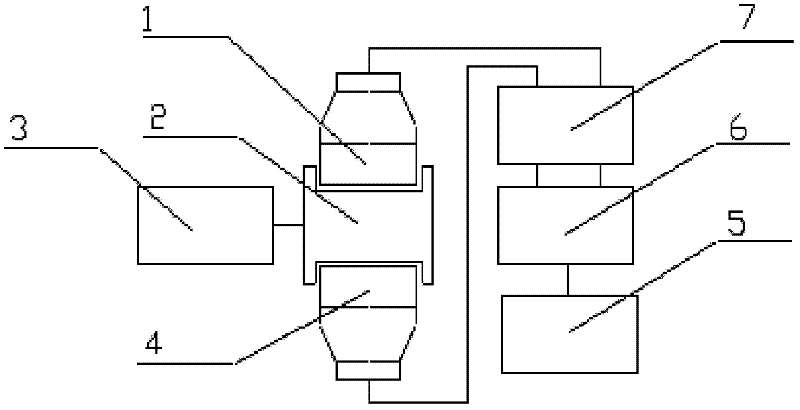

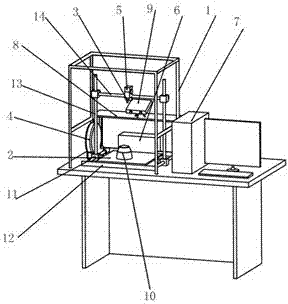

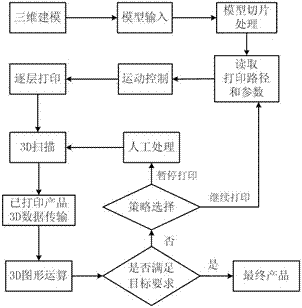

3D printing machine with three-dimensional figure feedback system and printing method of 3D printing machine

InactiveCN105666877AHigh precisionImprove printing efficiencyAdditive manufacturing apparatusGraphicsControl system

The invention discloses a 3D printing machine with a three-dimensional figure feedback system and a printing method of the 3D printing machine. The 3D printing machine comprises a rack, a printing platform, a printing spray head, a material box, a feeding device, a drive device, a control system, a computer, a support mounted on the outer side of the drive device and a 3D scanner which is arranged on the support and used for scanning a printed article. In the product forming process, the 3D scanner is used for scanning a semi-finished workpiece or a blank, the three-dimensional profile of the workpiece is obtained and compared with a three-dimensional model of a target product through graphics operation, the motion path and printing parameters of the printing machine are adjusted according to a result, and therefore feedback control of the printing process is achieved, and the 3D printing forming precision and the printing efficiency are improved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

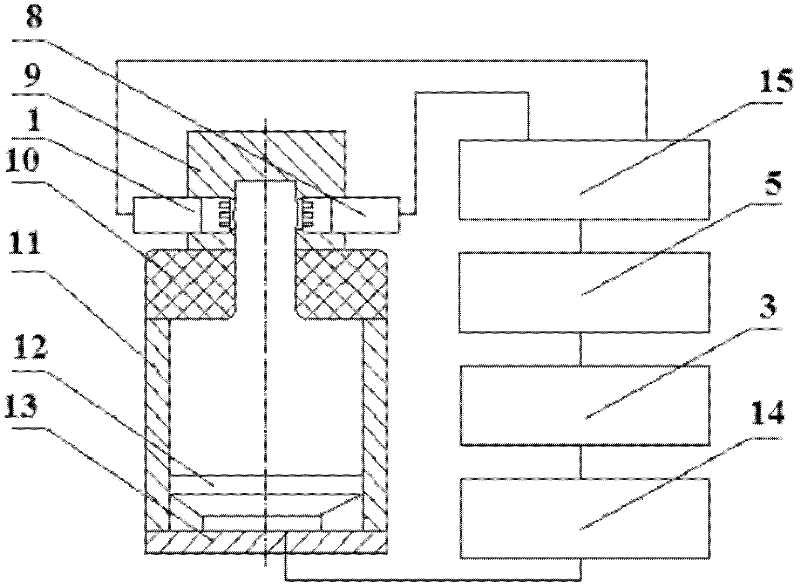

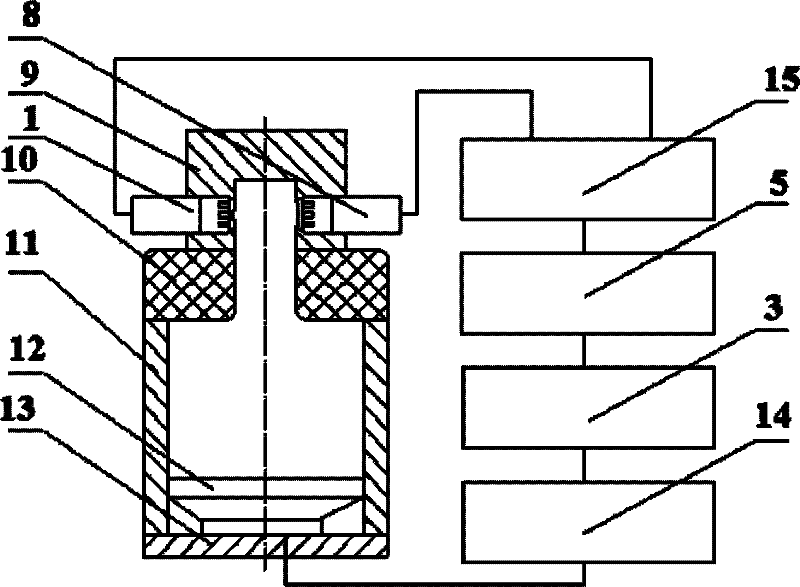

Device and method for detecting high sound pressure-phase shifting characteristic of microphone

ActiveCN102655628ASolving the Calibration Problem of Sensitivity Nonlinear Phase ShiftImplement Feedback ControlElectrical apparatusSound sourcesPhase difference

The invention provides a device and a method for detecting a high sound pressure-phase shifting characteristic of a microphone. A variable-section closed space is formed by an equal-phase coupling cavity, a variable-section reflection end cover, a standing wave tube and a bottom reflection end cover; a loudspeaker in the standing wave tube is connected with a power amplifier; the power amplifier is connected with a signal source; the signal source is connected with a computer; a reference microphone and a calibrated microphone are respectively arranged on the side wall of the equal-phase coupling cavity and are connected with a signal amplifier; and the signal amplifier is connected with the computer. The method comprises the following steps of: controlling the signal source by the computer, and driving the loudspeaker in the standing wave tube to send a sound wave signal by the power amplifier; and performing cross-spectrum analysis on a signal which is acquired by the reference microphone and the calibrated microphone, so as to obtain a phase difference of the calibrated microphone relative to the reference sensor under a certain condition. A sound source has high sound pressure of 94 to 160 decibels according to a standing wave sound field theory, and the distortion degree is less than 1 percent; and therefore, the phase shifting characteristic of the phase sensitivity of the microphone is calibrated under a high sound pressure environment.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH +1

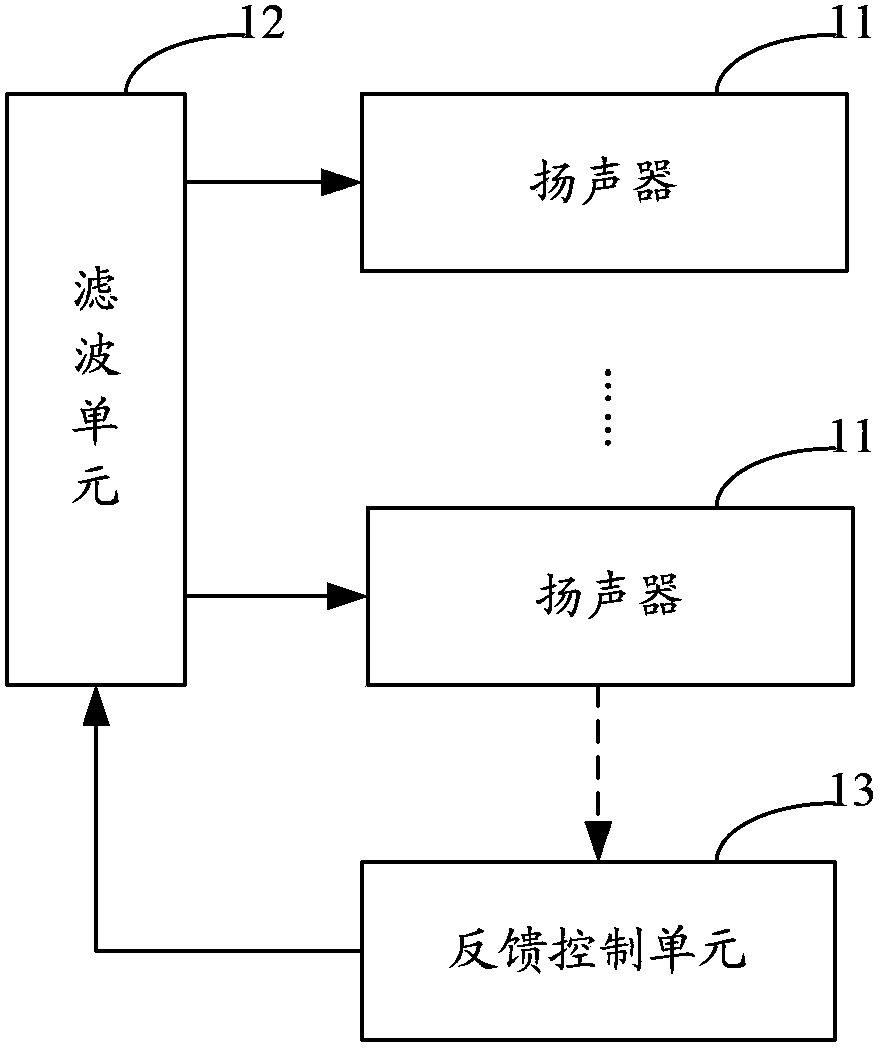

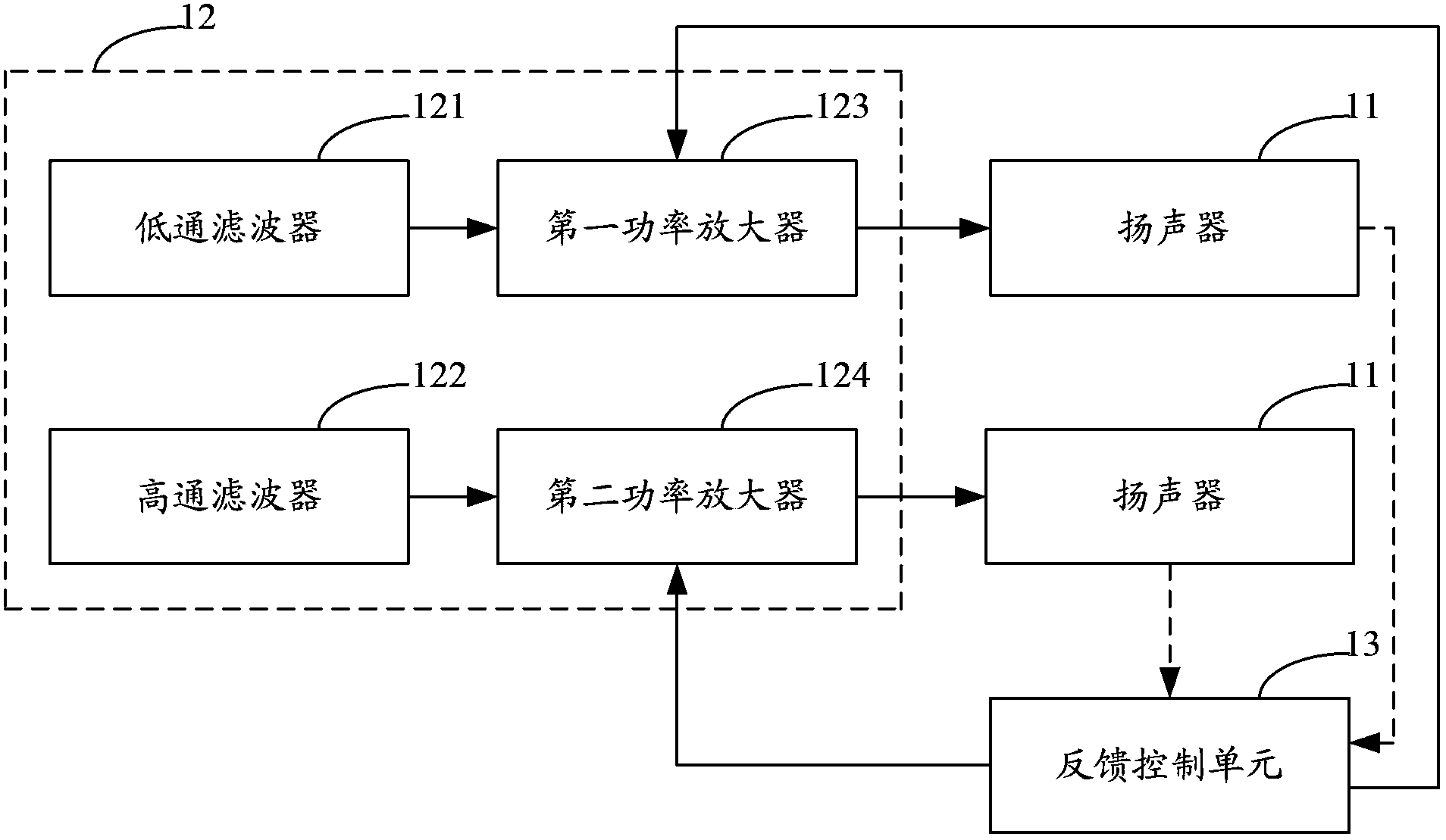

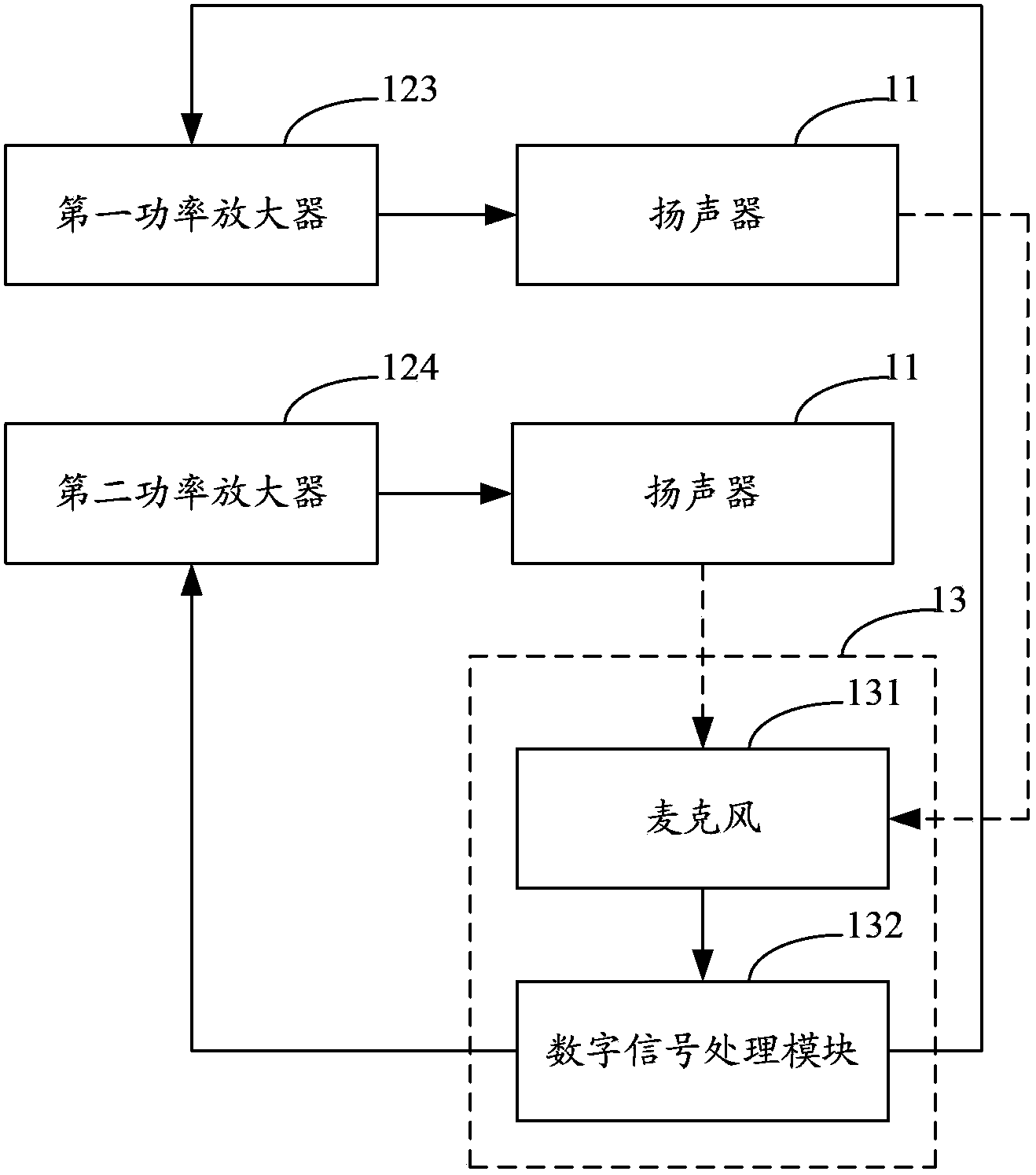

Audio signal playing system and electronic device

InactiveCN103428607AConsistent loudnessEnhance listening experienceTransducer acoustic reaction preventionFrequency response correctionMagnificationAudio signal flow

The invention relates to the technical field of signal processing, and provides an audio signal playing system and an electronic device. The system comprises two or more than two loudspeakers which are used for respectively playing audio signals of different frequencies, a filtering unit which is used for filtering the input audio signals, and carrying out amplifying and outputting to the corresponding loudspeakers, and a feedback control unit which is used for collecting the audio signals played by two or more than two loudspeakers, identifying the power sizes of the audio signals in different frequencies, and then adjusting the magnification factor of the corresponding frequency of each audio signal filtered by the filtering unit according to the identifying results. The feedback control of the audio playing strength of each loudspeaker is realized, so that the loudness of each loudspeaker is consistent. The audio playing effect of the system is optimized. The audio signal playing system and the electronic device can enable an audience to acquire a good listening experience and are conducive to the promotion and the application of a product.

Owner:HUAWEI TECH CO LTD

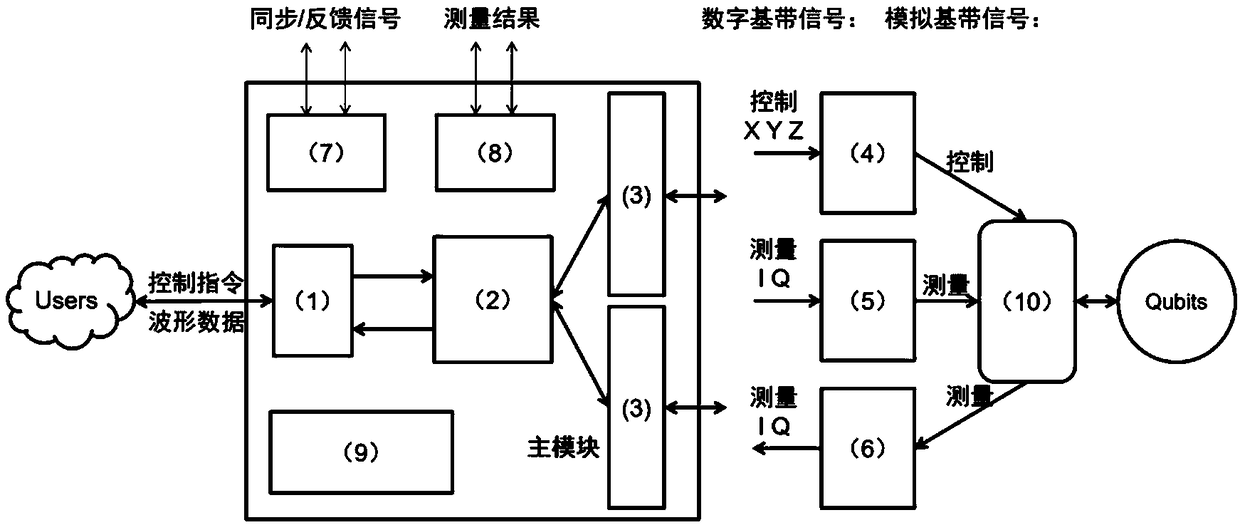

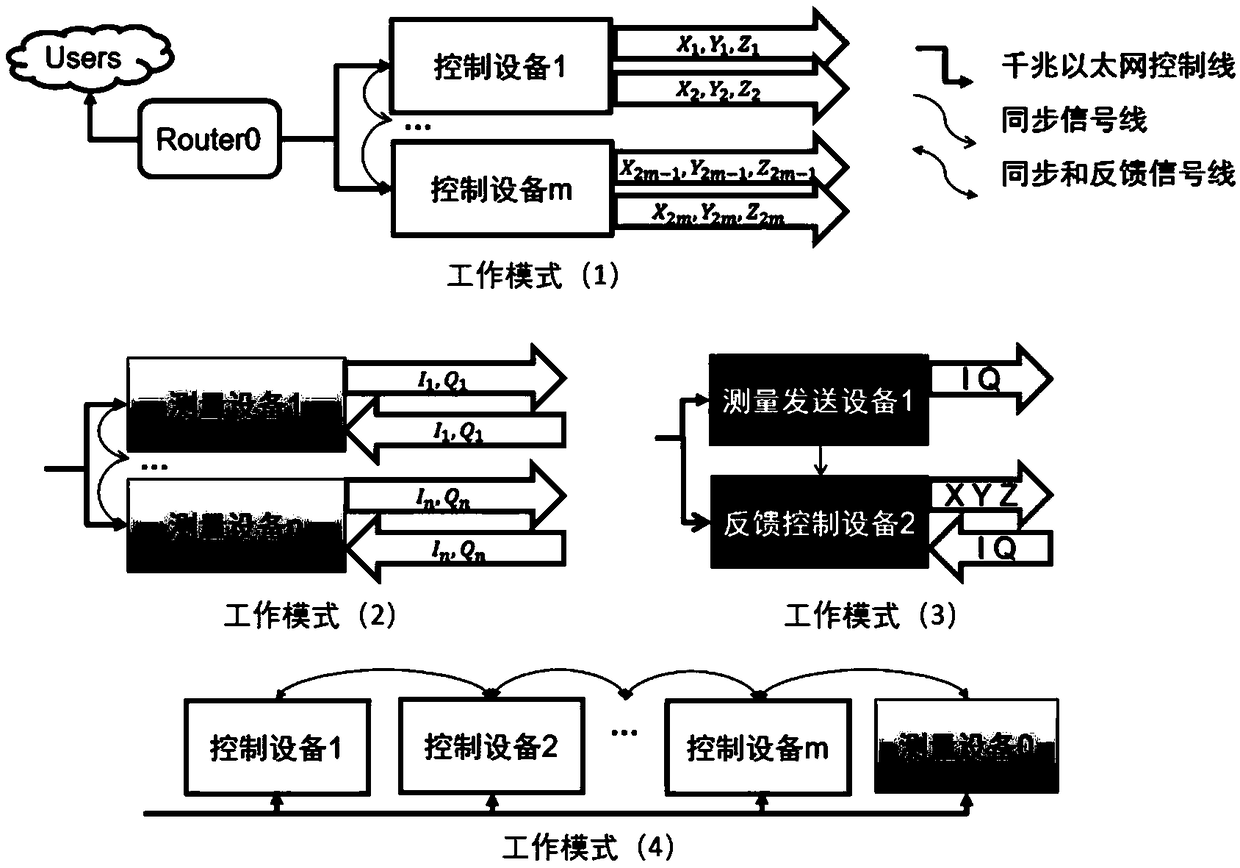

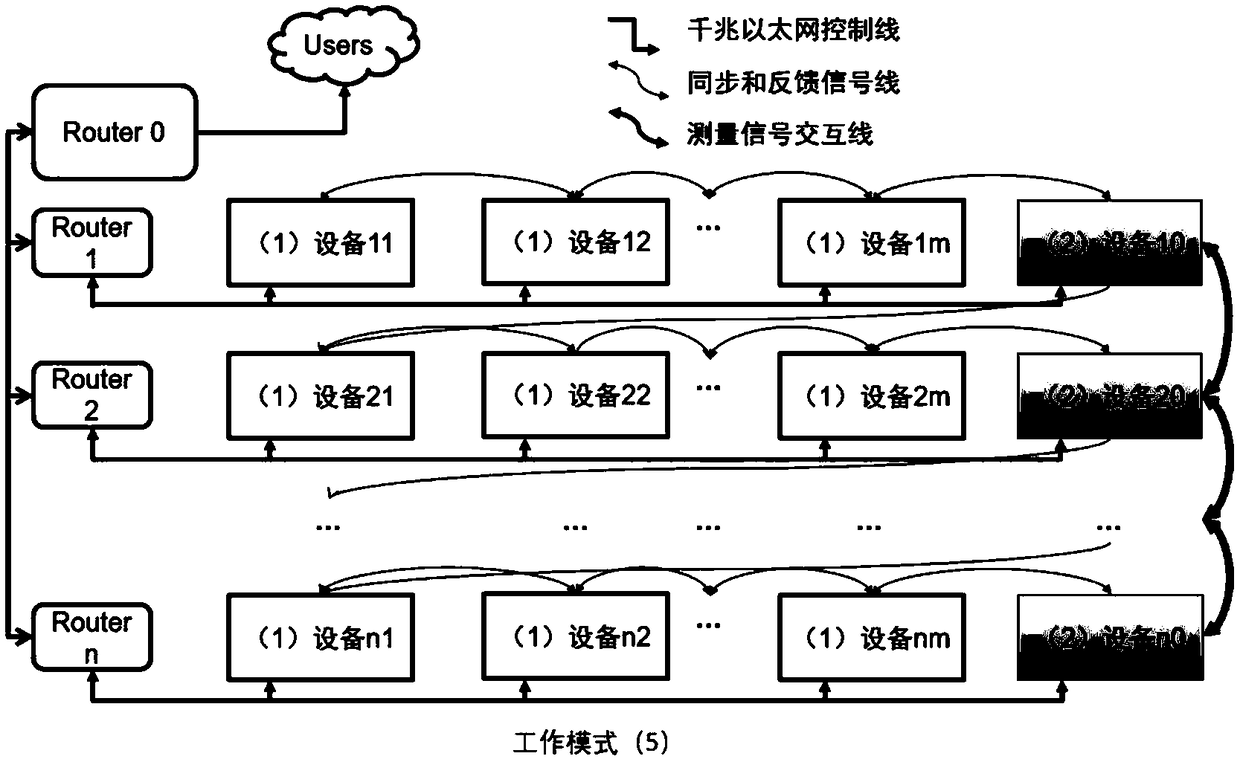

Scalable low-latency feedback control device for quantum bits

ActiveCN109217939AEnabling Quantum MeasurementsImplement Feedback ControlPhotonic quantum communicationDigital signal processingFeedback control

The invention discloses a scalable low-latency feedback control device for quantum bits. The device realizes the feedback control of the quantum states of multiple quantum bits by means of digital signal processing technology and a quantum mechanical principle based on a high-speed microwave baseband signal transceiving hardware circuit board. The quantum feedback control device designed in the present invention is different from the feedback control applied in the classic field, and can generate synchronous microwave pulses for operating superconducting quantum bits, can accurately define thenumber of times, the time and the strength of quantum measurement, demodulates measurement signals in real time, deploys a quantum feedback algorithm on an FPGA, and has extremely low feedback delayand excellent scalability so as to accurately control a system integrating multiple quantum bits and to satisfy a requirement for running a measurement-based quantum error correction algorithm on a quantum chip.

Owner:ZHEJIANG UNIV

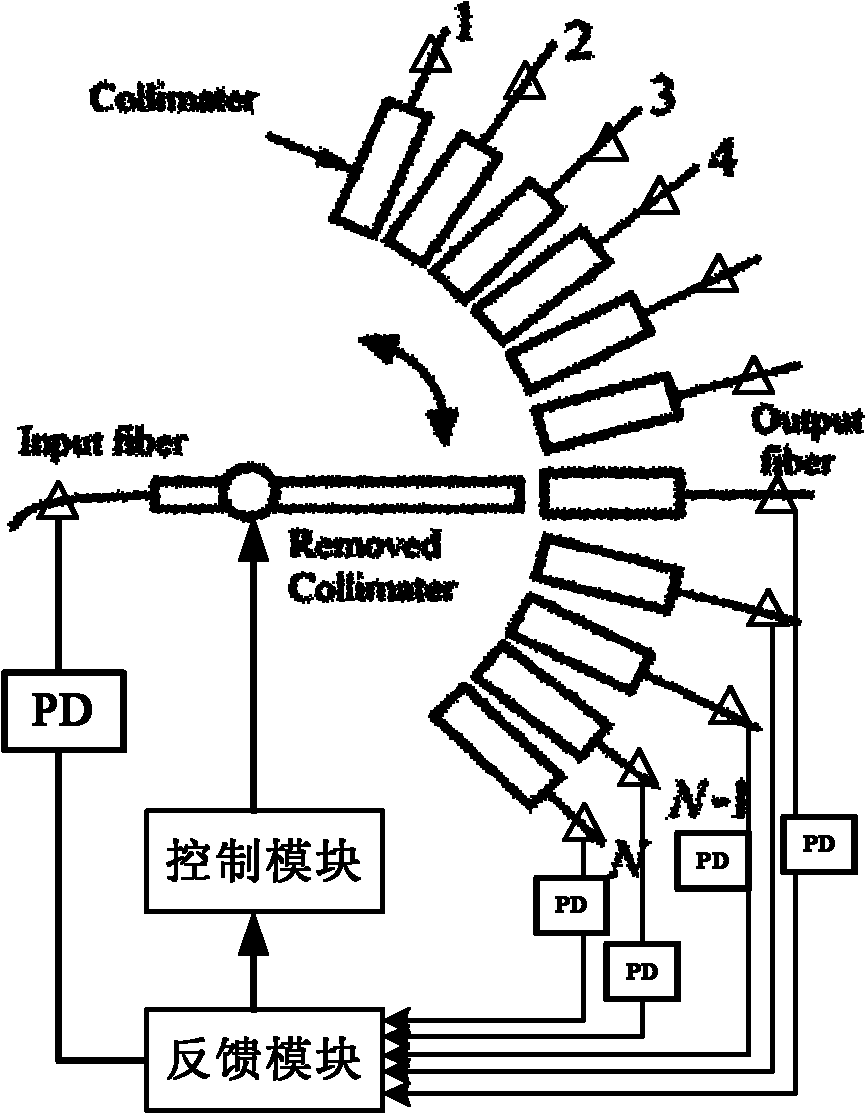

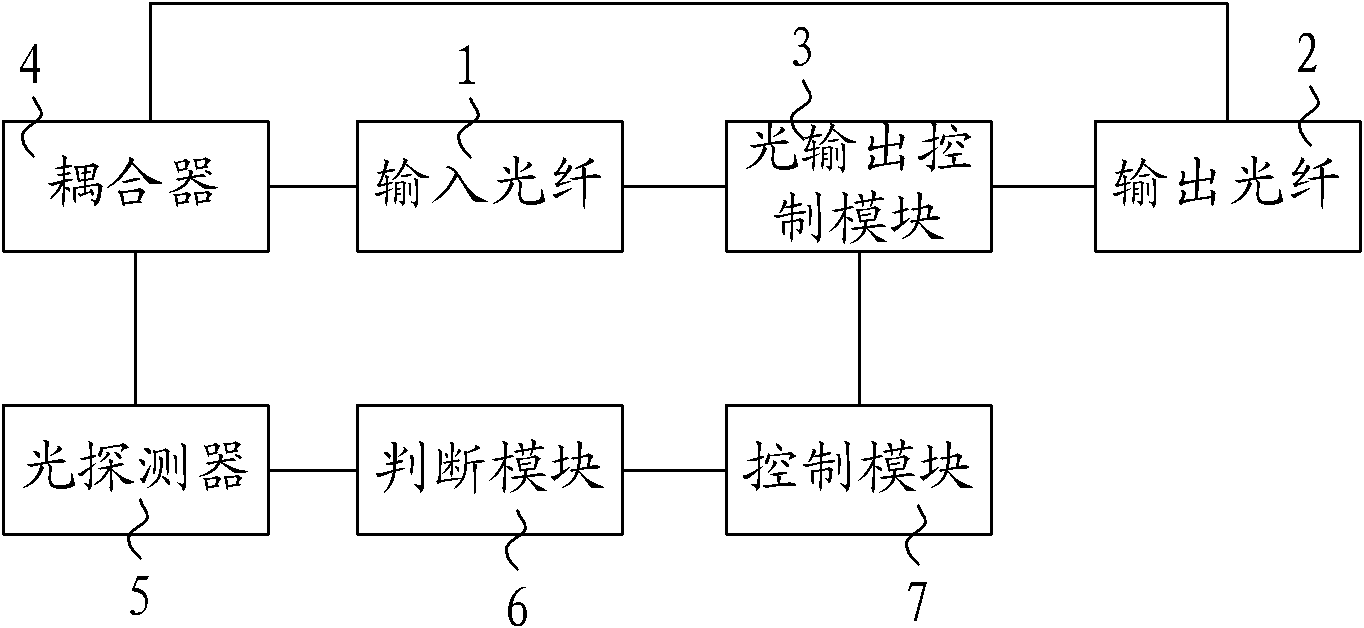

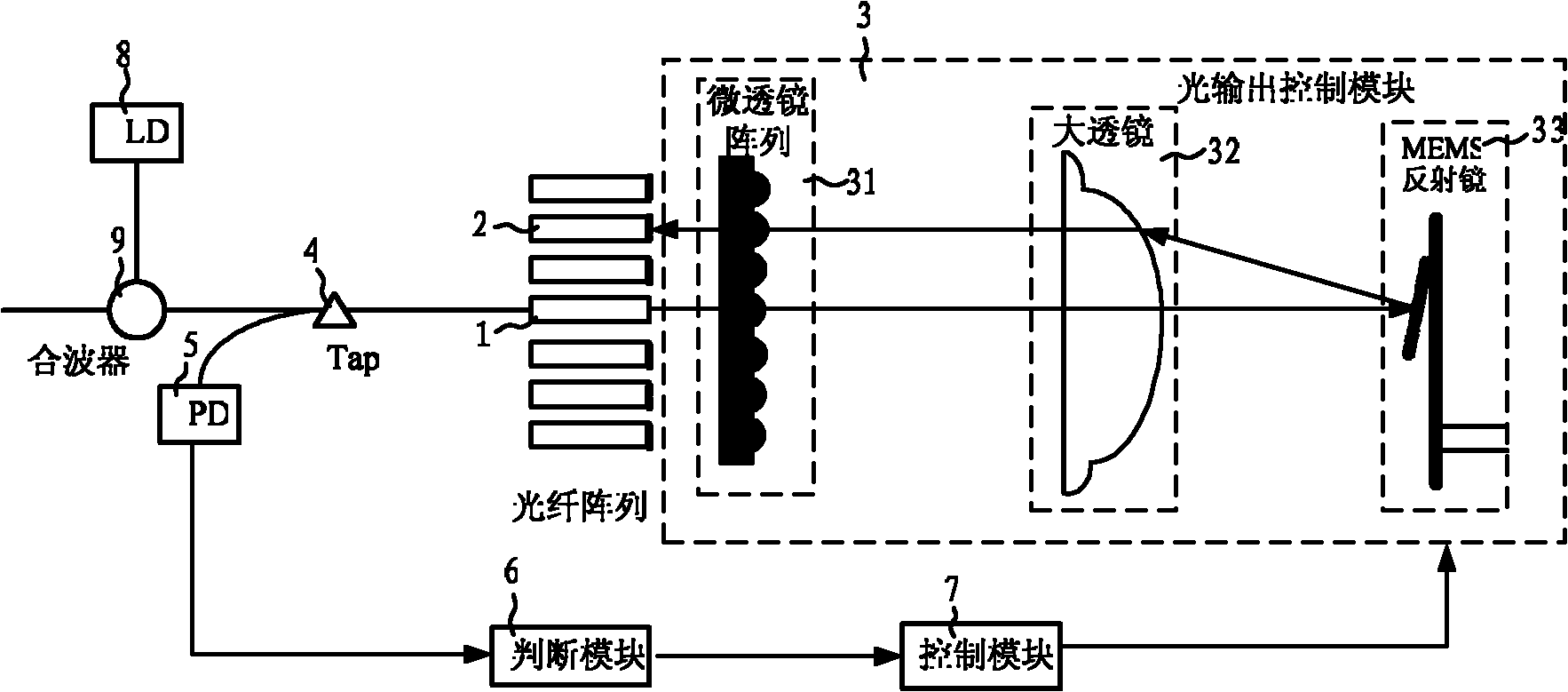

Optical switch system and signal light feedback control method

InactiveCN102135647AMitigating the impact of optical performanceImplement Feedback ControlCoupling light guidesLight controlPhotodetectorLight energy

The invention discloses an optical switch system and a signal light feedback control method. The optical switch system comprises an input optical fiber, an output optical fiber and an optical output control module, wherein a reflecting film is coated on an end face of the output optical fiber; and the optical switch system also comprises a coupler, a photodetector, a judging module and a control module, wherein the coupler is connected with the input optical fiber; the reflecting film is used for reflecting the signal light which is output from the optical output control module to the output optical fiber and reflecting the reflected output signal light in the coupler along an original path; the coupler is used for splitting the output signal light and extracting the signal light in a first preset ratio from the output signal light and inputting the signal light into the photodetector; and the judging module is used for comparing light energy of the output signal light which is detected by the photodetector with light energy of the input signal light which is initially acquired. The invention also provides a signal light feedback control method. Compared with the prior art, the invention greatly reduces the cost.

Owner:HUAWEI TECH CO LTD

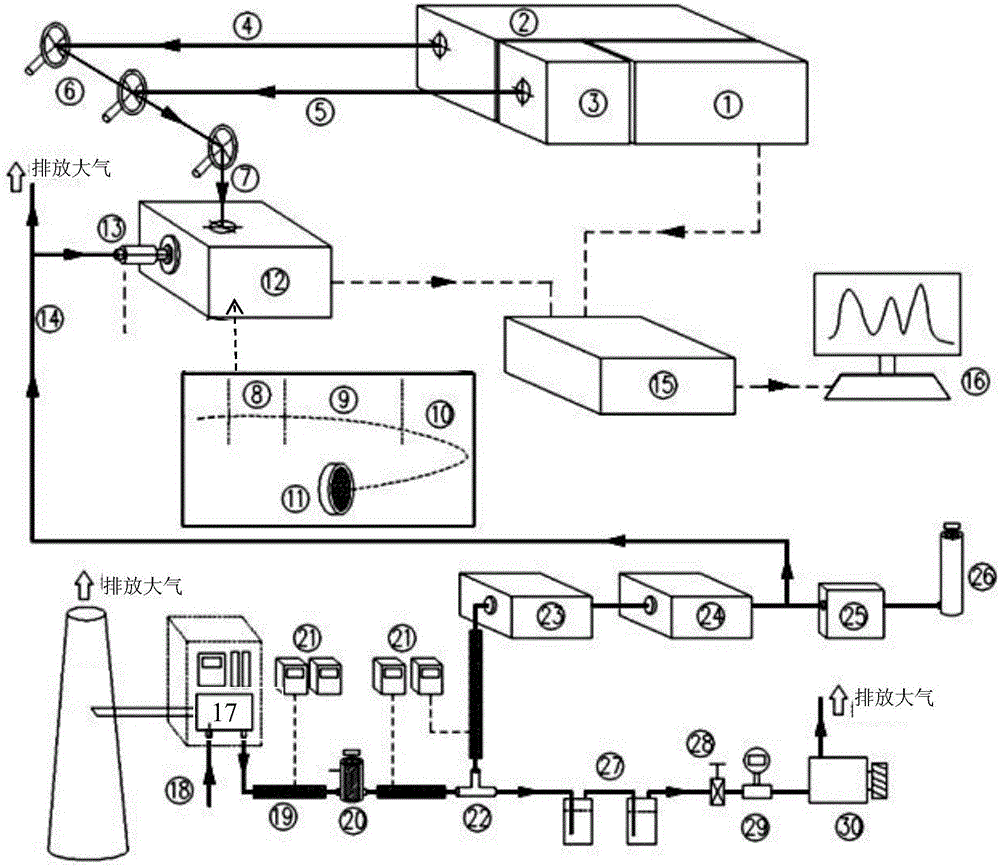

System for on-line detection of dioxin type trace organic pollutants in actual smoke

ActiveCN105954441ARespond quicklyRapid and timely discharge concentrationComponent separationBottleMass spectrometric

The invention relates to a trace organic pollutant detection technology and aims at providing a system for on-line detection of dioxin type trace organic pollutants in actual smoke. A sampling device of the system is connected with a thermal desorption instrument and a sampling pump module respectively through a pipeline, and a heat tracing pipeline is arranged on the pipeline. A laser device can simultaneously output two types light beams of deep ultraviolet wavelength and tunable ultraviolet visible waveband, an optical lens set is arranged between a flight time mass spectrometer and the laser device, two beams of laser are combined and then enter a laser window of the flight time mass spectrometer. A sample inlet pipeline of the flight time mass spectrometer is connected with a calibration gas storage bottle and the thermal desorption instrument respectively. The system integrates a thermal desorption technology and flight time mass-spectrometric technique, overcomes the shortcomings of a sample detection technology, can rapidly reflect the dioxin discharge concentration of smoke in time and is high in precision and large in information amount. The system composition can be adjusted according to actual demands, the adaptation can be improved. Detection results can represent the combustion conditions in a furnace, and the incineration process control can be optimized.

Owner:浙江富春江环保科技研究有限公司

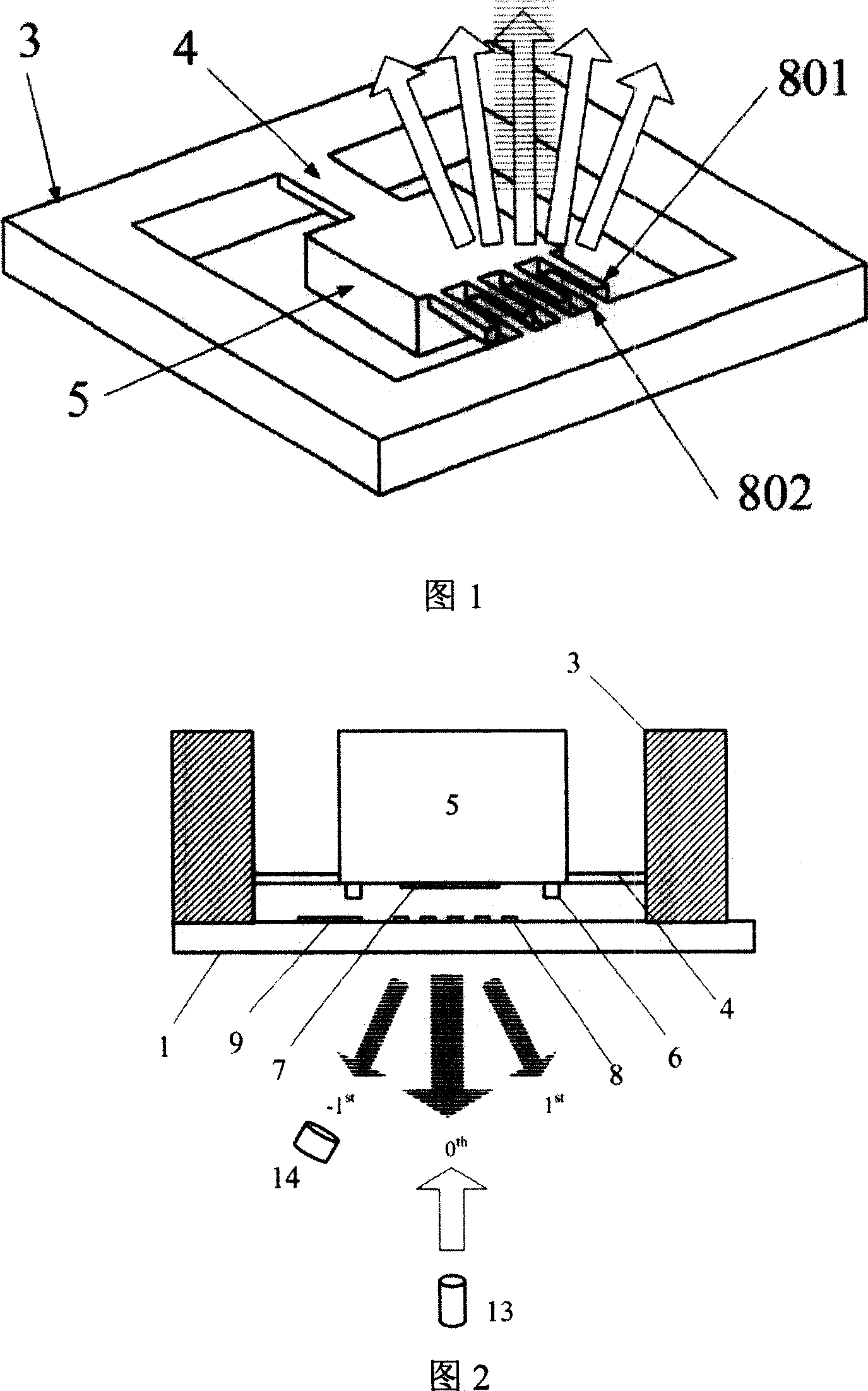

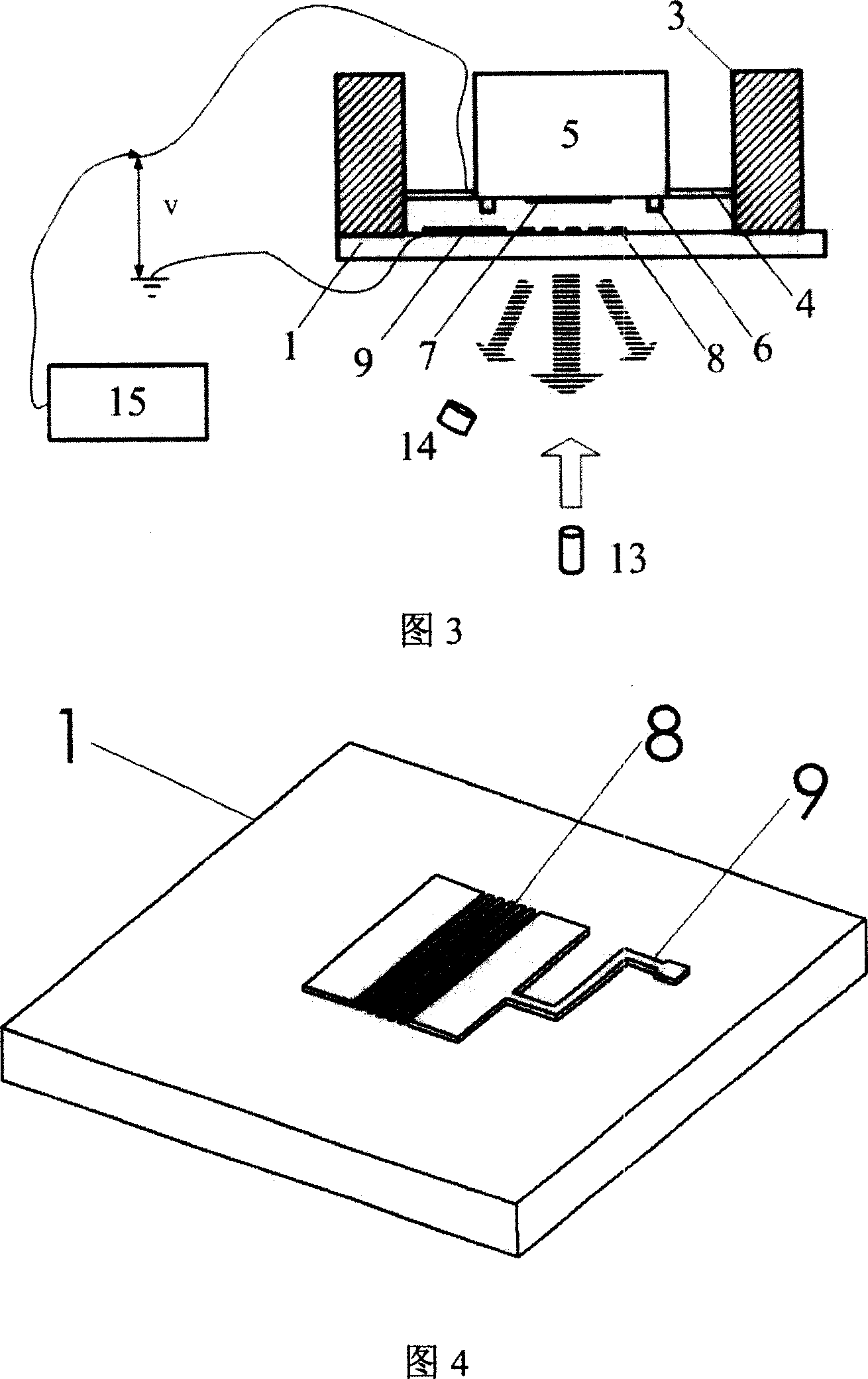

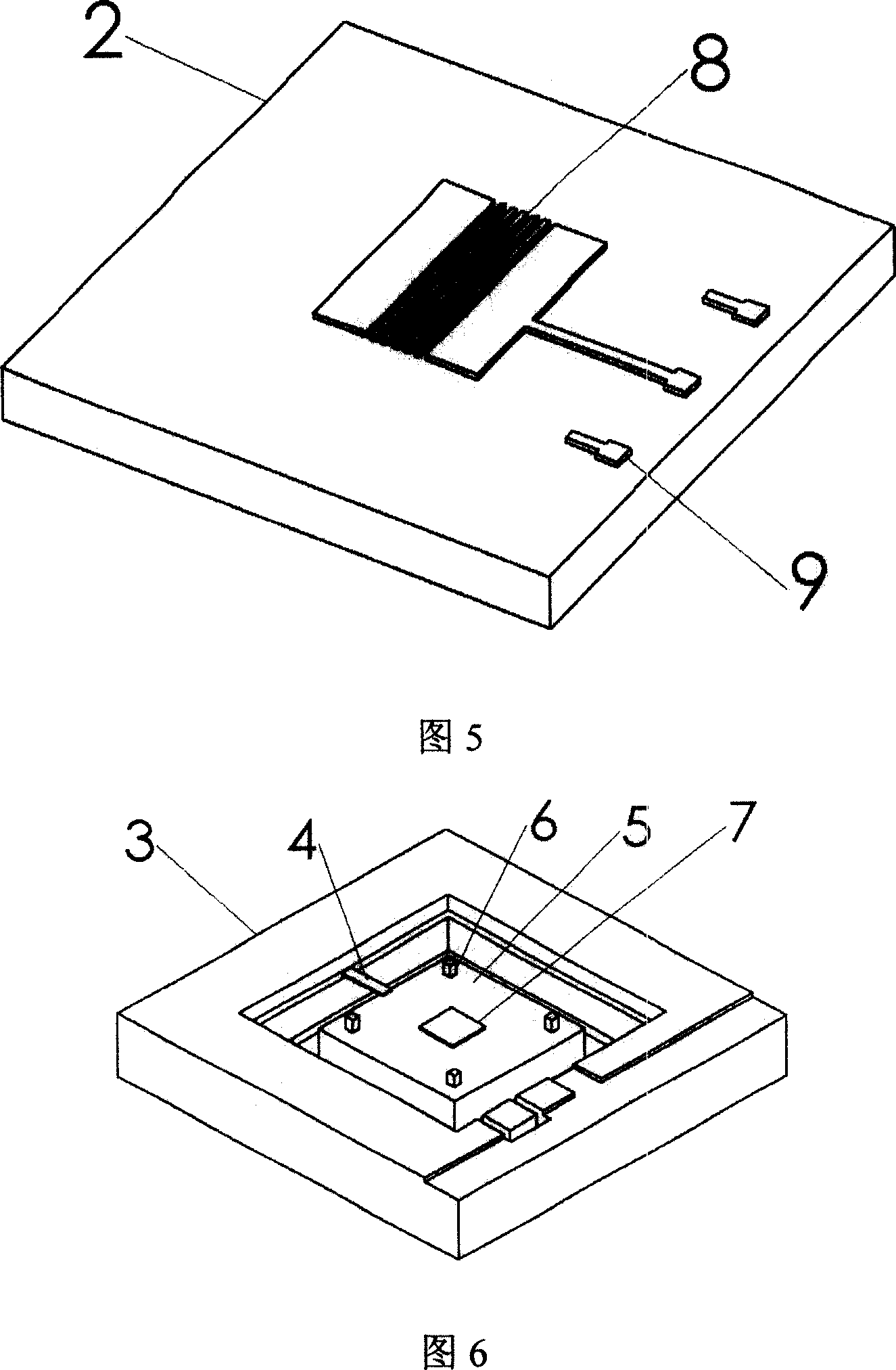

Integrated optic grating interference micro mechanical acceleration sensor and its producing method

InactiveCN1987486ASmall sizeReduce the difficulty of implementationTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesPhotovoltaic detectorsLight spot

The acceleration sensor includes parts: metal grating and electrode setup on surface of the first sheet glass; mass block setup on silicon chip, N pieces of male tab setup on the mass block, and a layer of reflection plane deposited on male tabs; girder or membrane of supporting mass block, and the other end of the mass block connected to the bonding top of table-board formed from silicon chip; the face, where the metal grating and electrode are located, of the first sheet glass is opposite to the reflection plane on mass block, and the position of grating is opposite to the position of silicon island and integrated together through bonding technique; tiny gap is formed between mass block and glass so as to form sensing unit of the sensor; photoelectric detection circuit is connected to electrode of the sensing unit. By using sensibility of light intensity of grating diffracted light spot dependent on distance between grating surface and reflection plane, to implement measuring acceleration.

Owner:TSINGHUA UNIV

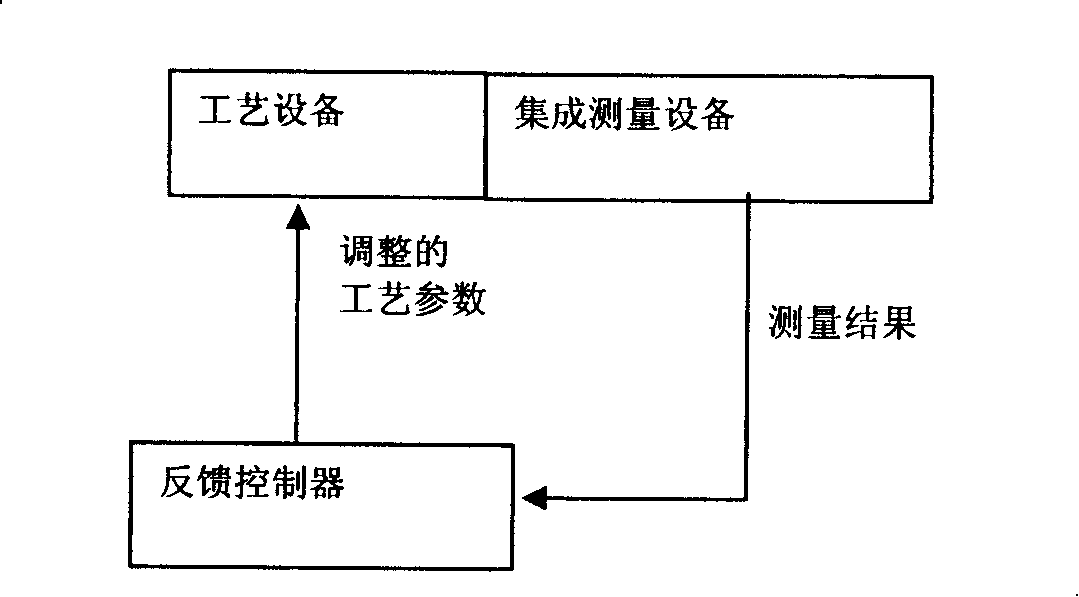

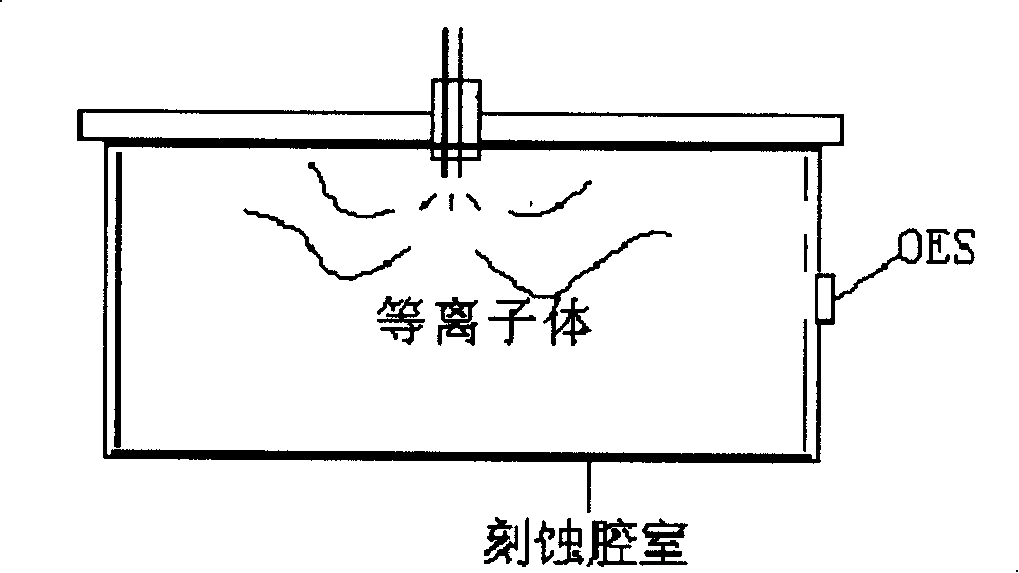

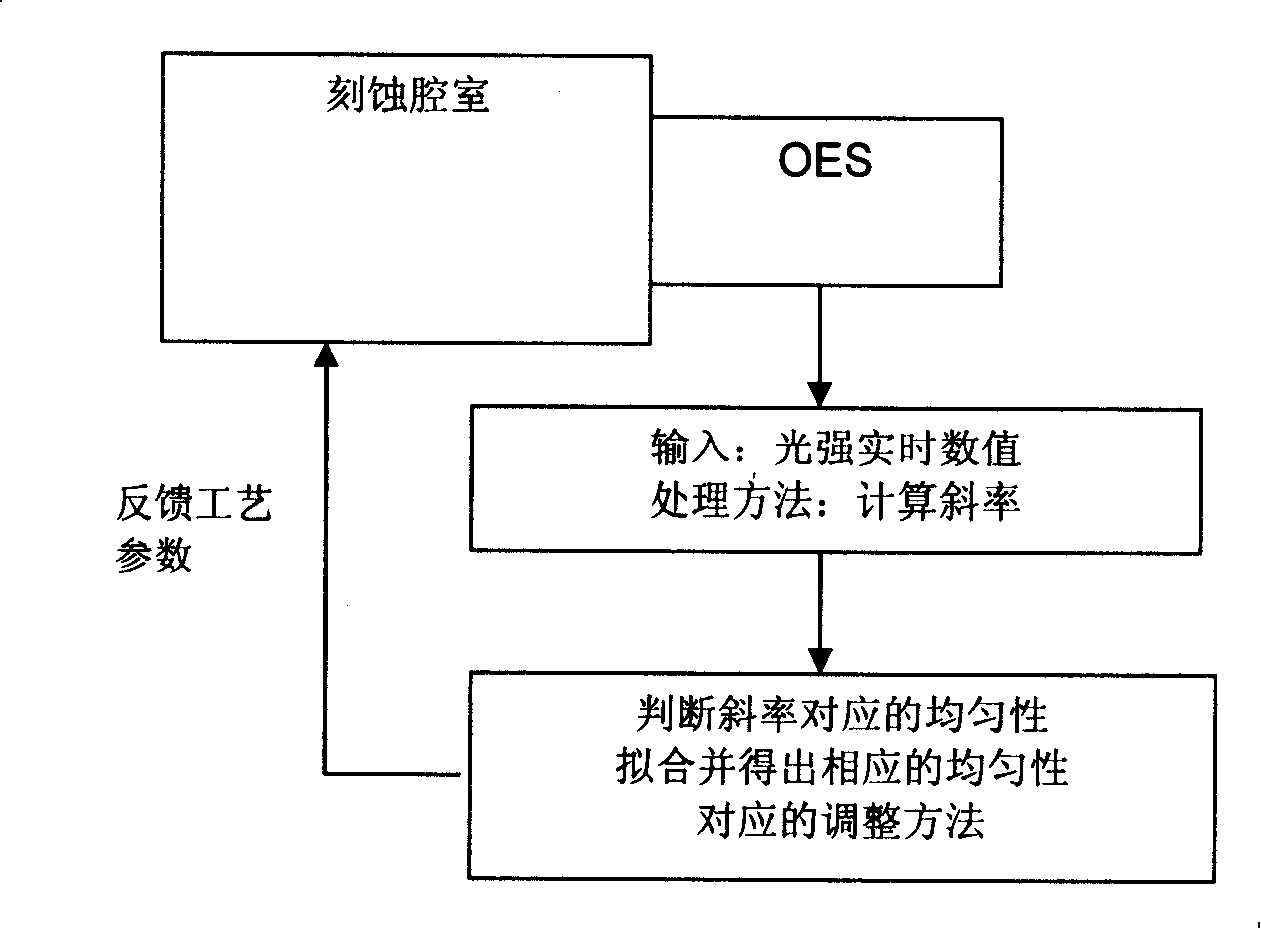

Method for controlling semiconductor silicon dies etching technique

InactiveCN101207004AImplement Feedback ControlReduce processing complexitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingFeedback controlSilicon chip

The invention discloses a feedback control method of a semiconductor silicon chip etching process. Plasma spectral information of the plasma in an etching cavity is detected through the prior optical emission spectra OES on the etching cavity which is used for the end-control to the etching process when an end point of the etched silicon chip is detected. The detected spectrum information is processed, and according to the processing result, the adjustable quantity of the etching process parameter is determined, and the process parameter is adjusted, to realize the feedback control of the etching process to the semiconductor silicon chip. Additionally integrated online check-up equipment is saved, a complex feedback control is carried on, the control process is simple, the control is precise, and the cost is low.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

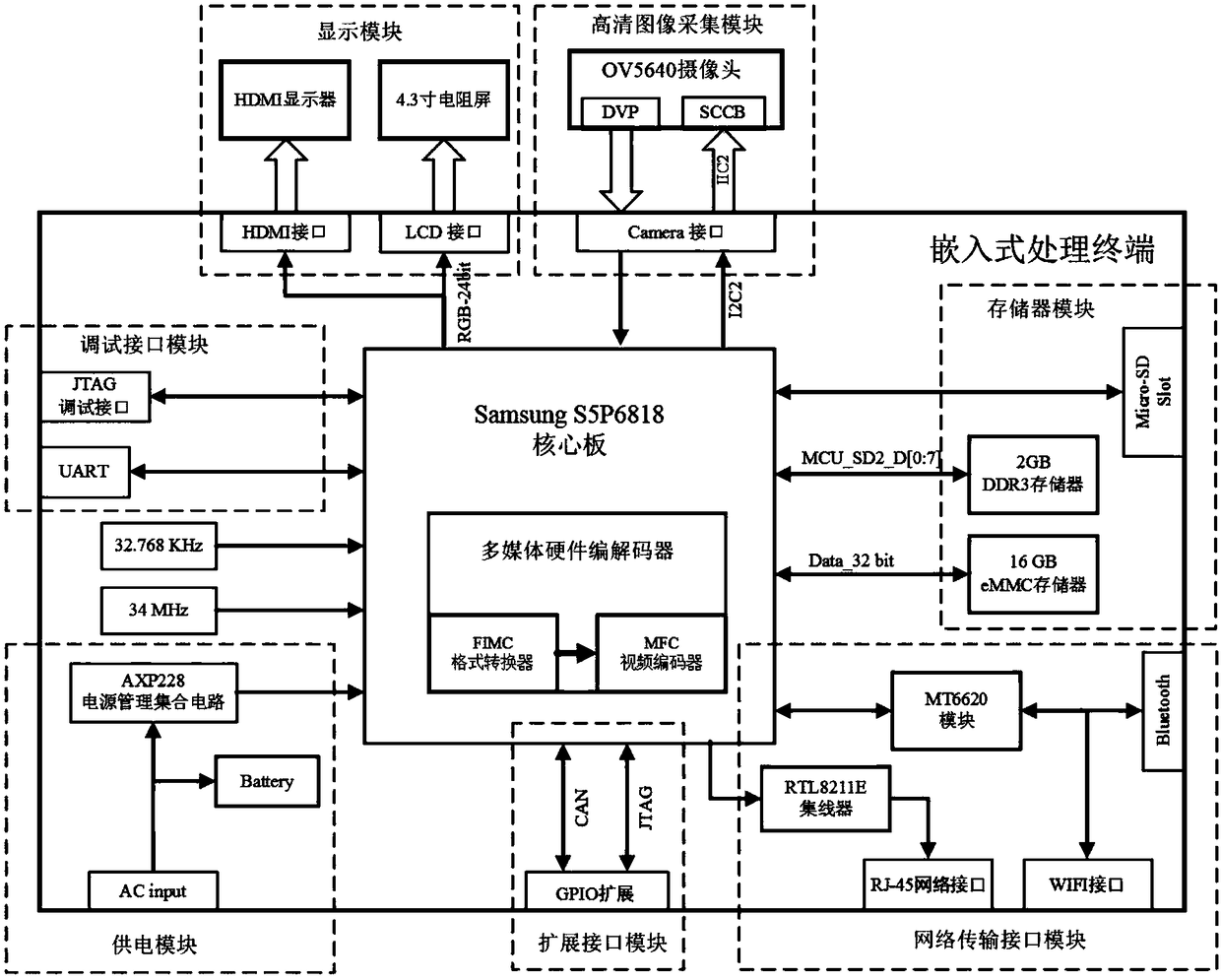

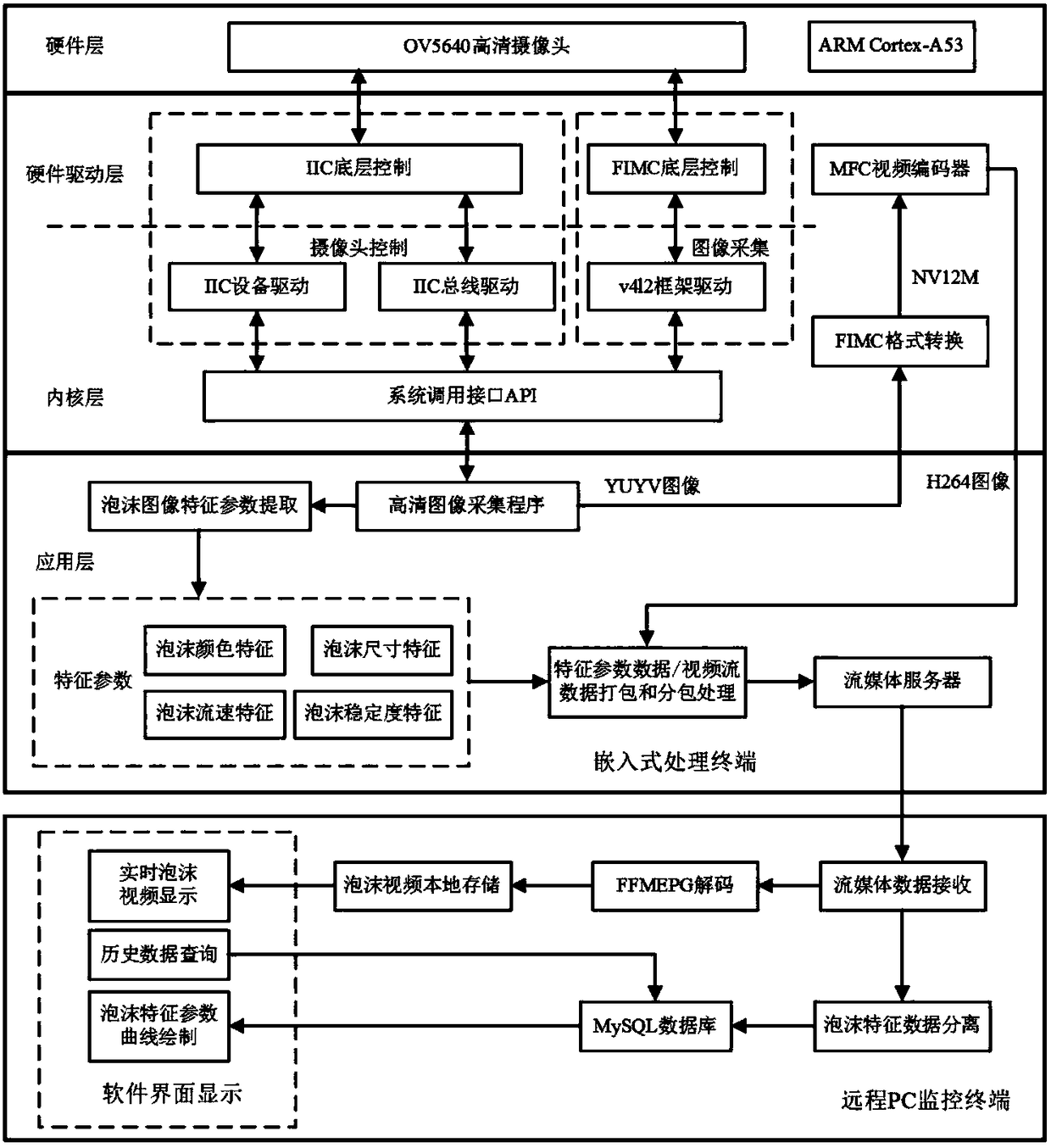

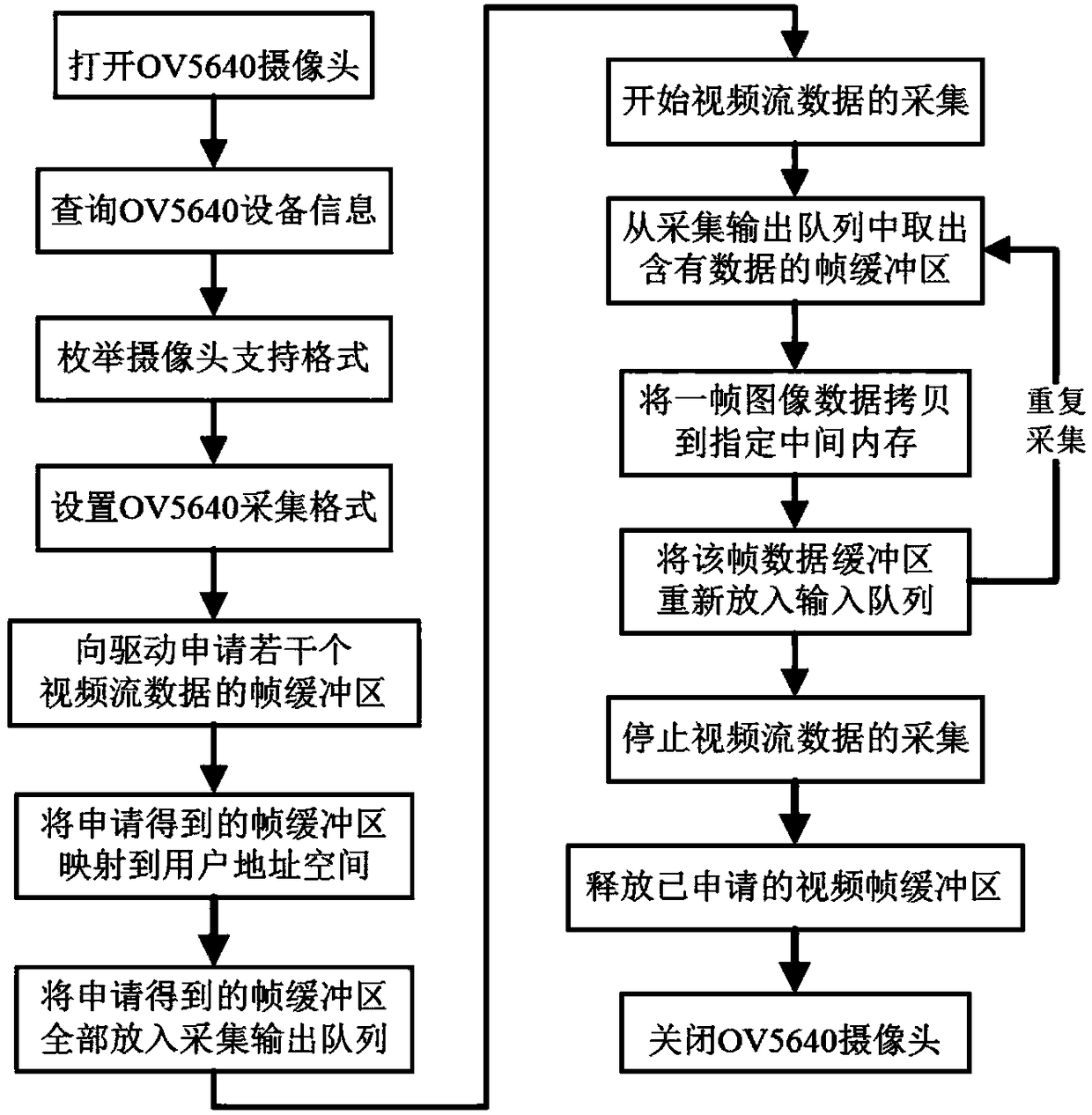

Embedded high-definition video acquisition and data stream transmission system

ActiveCN108616722AGuaranteed service efficiencyImplement Feedback ControlClosed circuit television systemsDigital video signal modificationComputer hardwareStreaming data

The invention discloses an embedded high-definition video acquisition and data stream transmission system. Based on a Samsung S5P6818 core board, an OV5640 camera integrated board card is adopted to acquire high-definition image data, a multimedia hardware codec integrated in the core board is adopted to carry out compressed encoding on the image, an algorithm processing algorithm is used to extract image features, and a real-time video and a feature parameter data stream are published in a local area network through a streaming media server built on the board. Thus, a remote PC client can receive the video streaming data and the image feature parameter data, and through decoding, display and local storage, functions such as historical query are supported.

Owner:CENT SOUTH UNIV

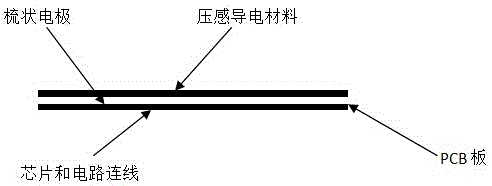

Pressure-distributed sensor and intelligent sickbed monitoring system and monitoring method thereof

ActiveCN105049511ATimely monitoringImplement Feedback ControlData processing applicationsTransmission systemsArduinoEngineering

The invention discloses a pressure-distributed sensor, and an intelligent sickbed monitoring system and an intelligent sickbed monitoring method. In terms of a long-term bedridden patient, terminals such as a mobile phone, a tablet personal computer, and so on could help the patient to finish a series of movements of rising back, turning over, pumping legs, and to prompt the patient to turn over according to the data obtained by the pressure-distributed sensor so as to prevent the generation of chronic pressure sores, and use a camera to monitor the state of the patient. The system is composed of power-driven sickbeds, Arduino, an inertial sensor, the pressure-distributed sensor, a Raspberry Pi, the camera, a server and a Web end. The inertial sensor could obtain the posture angle of the sickbed and transmit the angle data to the Raspberry Pi to achieve the feedback control of a linear motor. The Raspberry Pi is used as data terminal of the single intelligent sickbed while the server is used as a data control terminal of a plurality of intelligent sickbeds and could be used for monitoring the sickbeds via the Web end and monitoring the physiological status of the patient and the states of the intelligent sickbeds.

Owner:ZHEJIANG UNIV

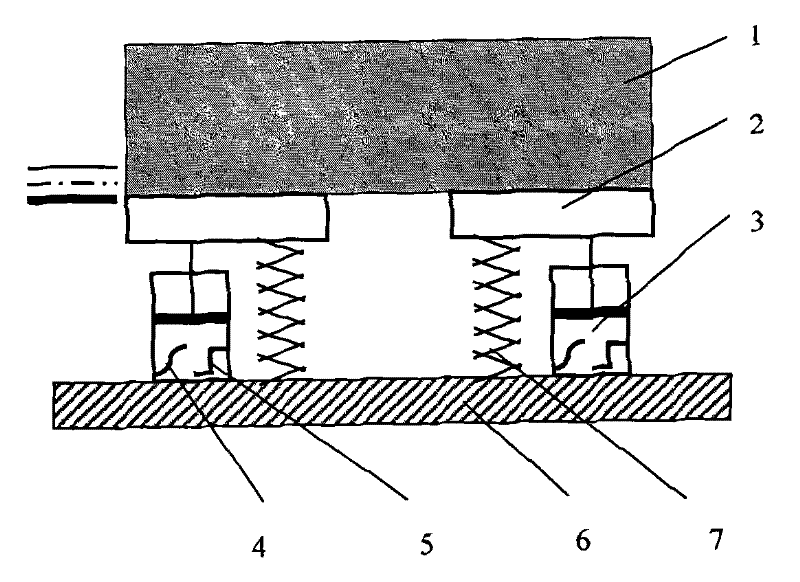

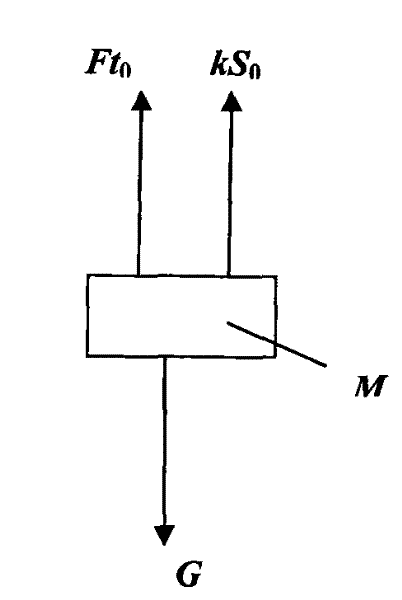

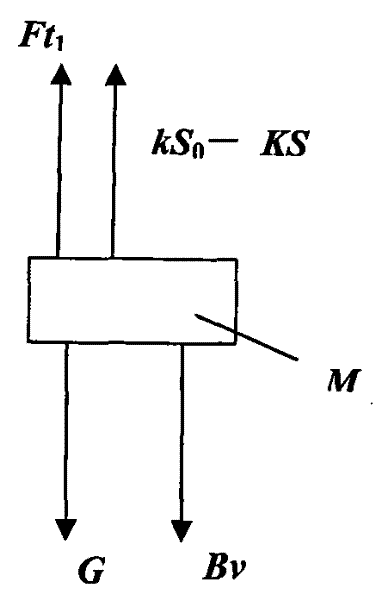

Device and method for detecting friction force of continuous casting crystallizer on line

InactiveCN102126001AImplement Feedback ControlImplement transient detectionCasting parameters measurement/indication devicesEngineeringForce analysis

The invention provides a device and method for detecting the friction force of a continuous casting crystallizer on line. The vibrating system of the detecting device comprises hydraulic cylinders (3) each of which is provided with a pressure sensor (4) and a displacement sensor (5), wherein the two hydraulic cylinders are arranged on the two sides below a vibrating table in a bilaterally symmetrical mode; and signals detected by the two sensors are sequentially processed by a programmable controller (8), an analogue / digital (A / D) data acquisition card (9), an industrial personal computer (IPC) (10) and a communication card (11), and are transmitted to a server (12) for data storage. The detecting method comprises the following steps of: measuring the comprehensive rigidity and the equivalent damping of the vibrating system through particle swarm optimization (PSO), performing force analysis on the vibrating system, establishing force equations when the vibrating system keeps still at a vibrating balance position and in a null vibrating state and a throwing state, and calculating the difference between throwing output force and null vibrating output force so as to acquire the friction force of the crystallizer. By using the device and the method, the friction force of the continuous casting crystallizer can be accurately and reliably detected in real time on line.

Owner:BAOSHAN IRON & STEEL CO LTD +1

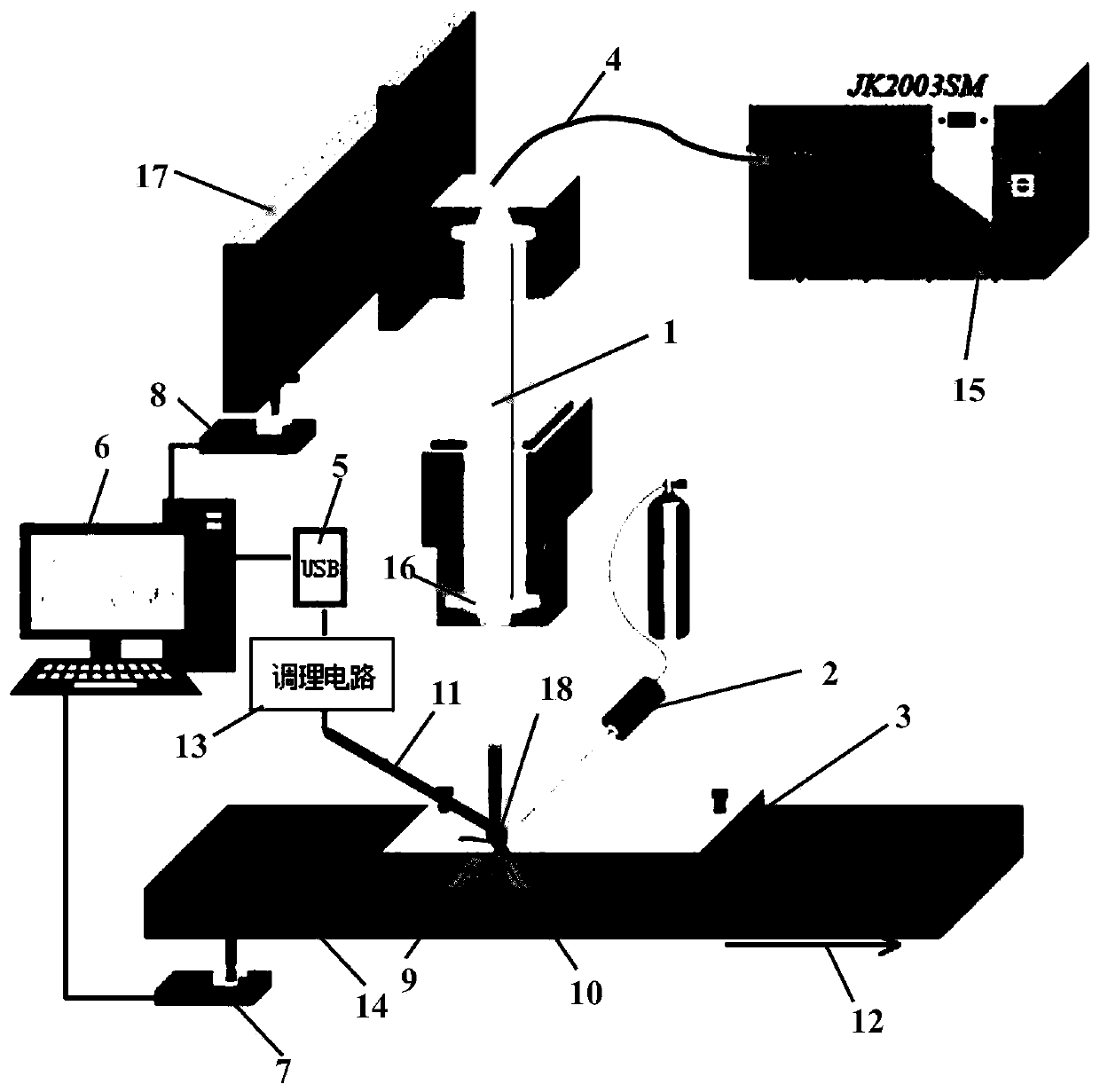

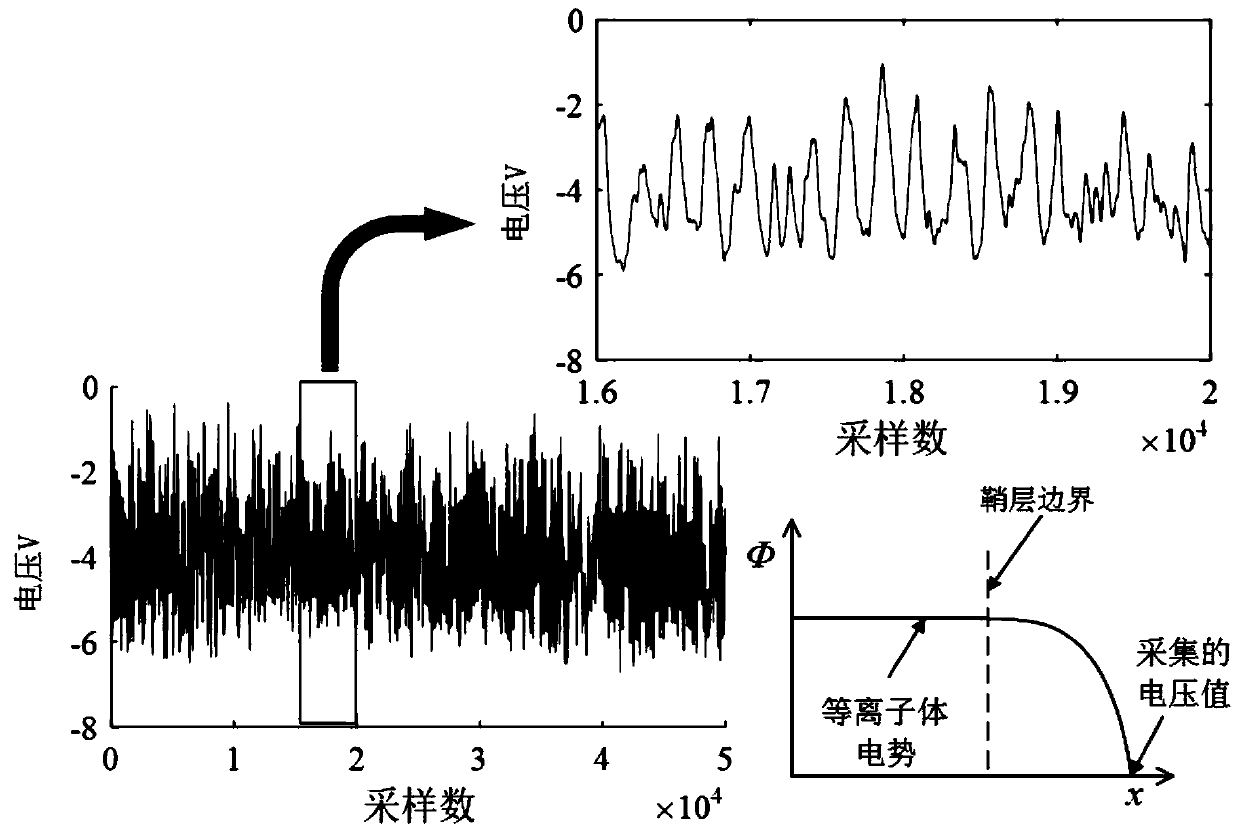

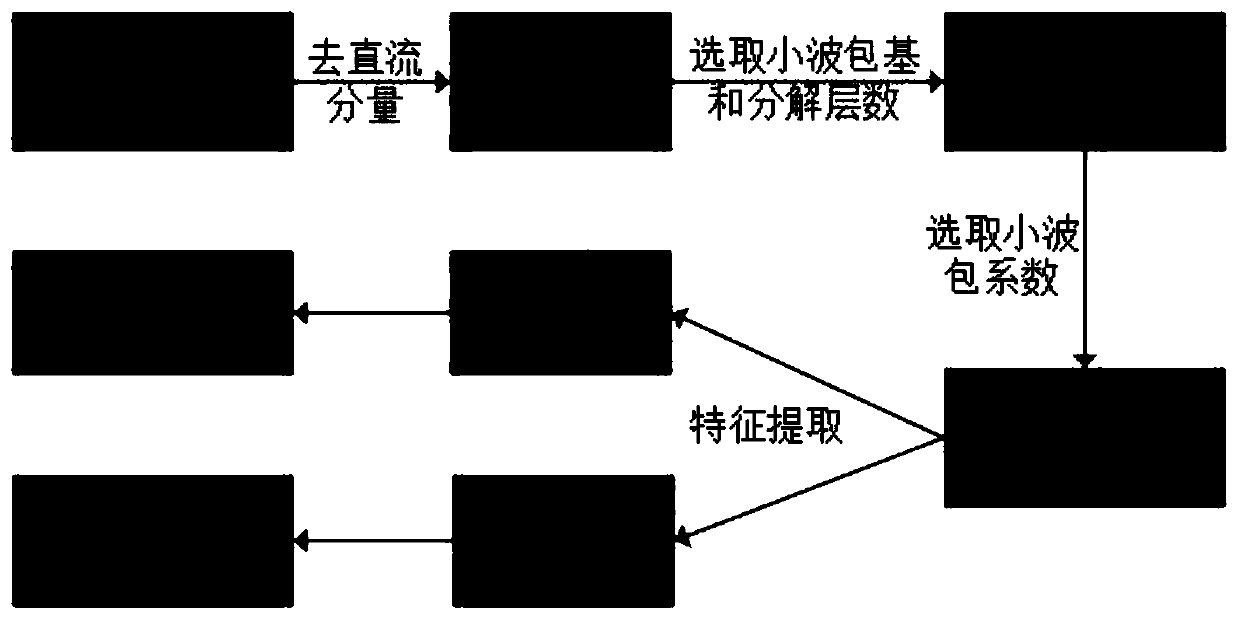

Laser deep penetration welding intelligent monitoring system and method based on plasma electric signals

InactiveCN109940305AImplement Feedback ControlLow running costWelding apparatusDecompositionNetwork model

The invention discloses a laser deep penetration welding intelligent monitoring system and method based on plasma electric signals. The system comprises three portions, namely, a laser welding subsystem, a motion control subsystem and an electric signal acquisition subsystem, so that the quality judgment of weld joints is realized. The method comprises the following steps that the electric signalsof the laser plasma are measured on line, and the electric signal voltage data are acquired in real time; the denoised signals undergo ensemble empirical mode decomposition; sample data of each weldjoint is selected; the node number of an input layer, a hidden layer, a sum layer and an output layer of the probability neural network to be established is determined; by taking the training sample data as input of the probability neural network, a probability neural network model is established, probability neural network training is performed, the judgment result of the probability neural network is compared with the actual weld joint state, and the probability neural network model is verified; and the prediction accuracy of the probability neural network model is verified. According to thelaser deep penetration welding intelligent monitoring system and method, the welding state can be identified in a high-precision mode, the feedback control of the welding quality can be realized, andthe operation cost is greatly reduced.

Owner:TIANJIN UNIV

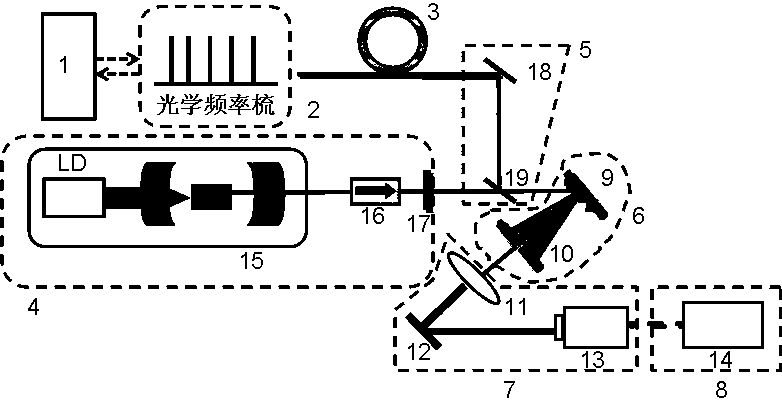

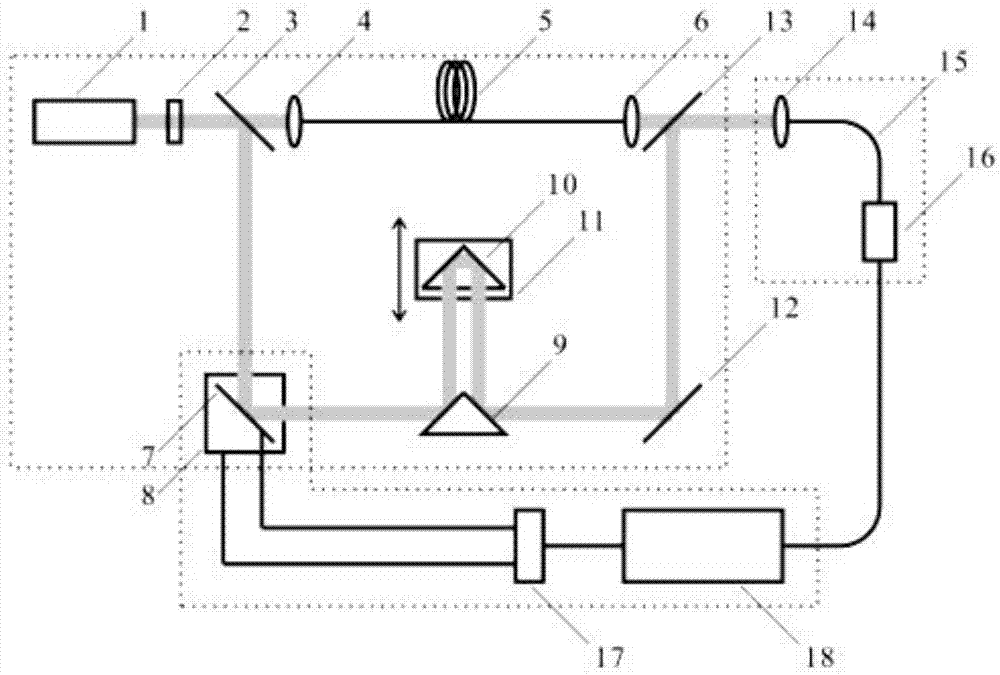

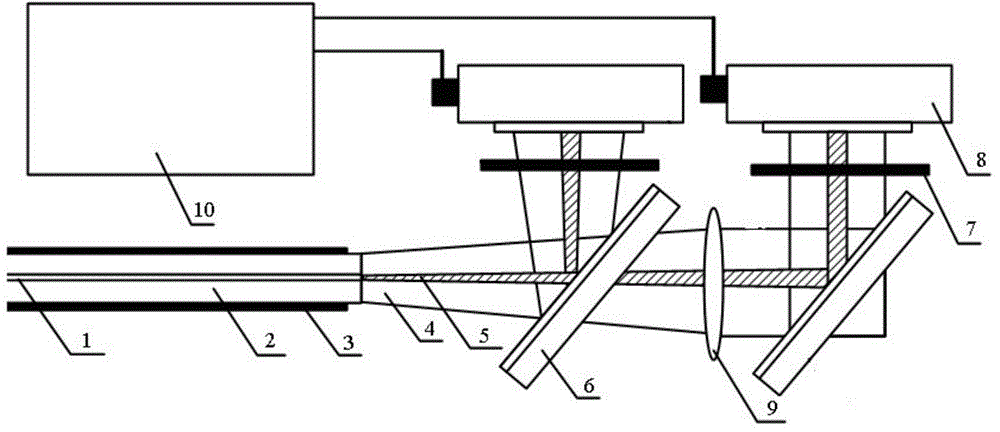

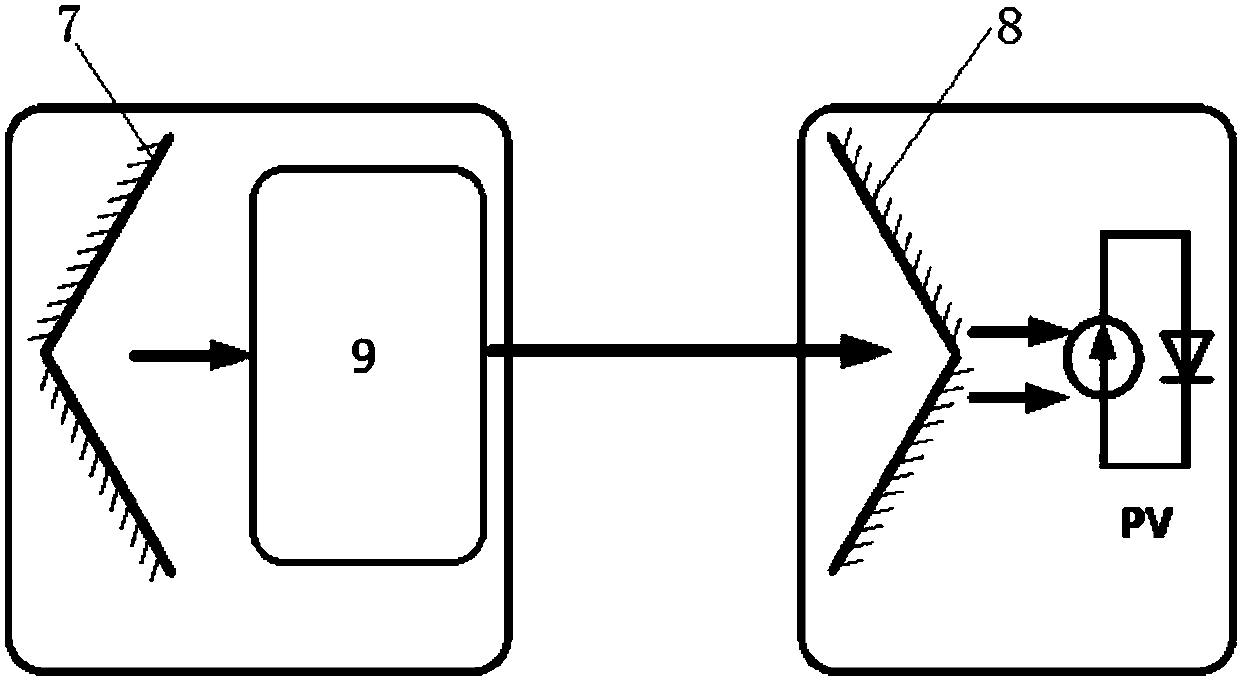

Optical fiber coupling-based CARS (Coherent Anti-Stokes Raman Scattering) beam space stability test control system and method

ActiveCN108007571AImplement Feedback ControlAvoid spaceRadiation pyrometrySpectrometry/spectrophotometry/monochromatorsMicro imagingControl system

The invention discloses an optical fiber coupling-based CARS (Coherent Anti-Stokes Raman Scattering) beam space stability test control device and method. the system is composed of three parts of a CARS micro excitation source (100), a beam space stability detection device (200) and a beam feedback control system (300), wherein space beams outputted by the CARS micro excitation source (100) pass through the beam space stability detection device (200) to monitor the space state in real time, the space beams are adjusted through the beam feedback control system (300), and finally, the CARS microexcitation source 100 outputs beam space stability test and control. In comparison with the prior art, the space state of a pump beam remains stable when an adjustable space light delay line changes,the problem that a space light path needs to be adjusted frequently in a CARS micro imaging system to ensure space overlapping between the pump light and the Stokes light can be avoided, the operationprocess is simplified, and the detection efficiency is improved.

Owner:TIANJIN UNIV

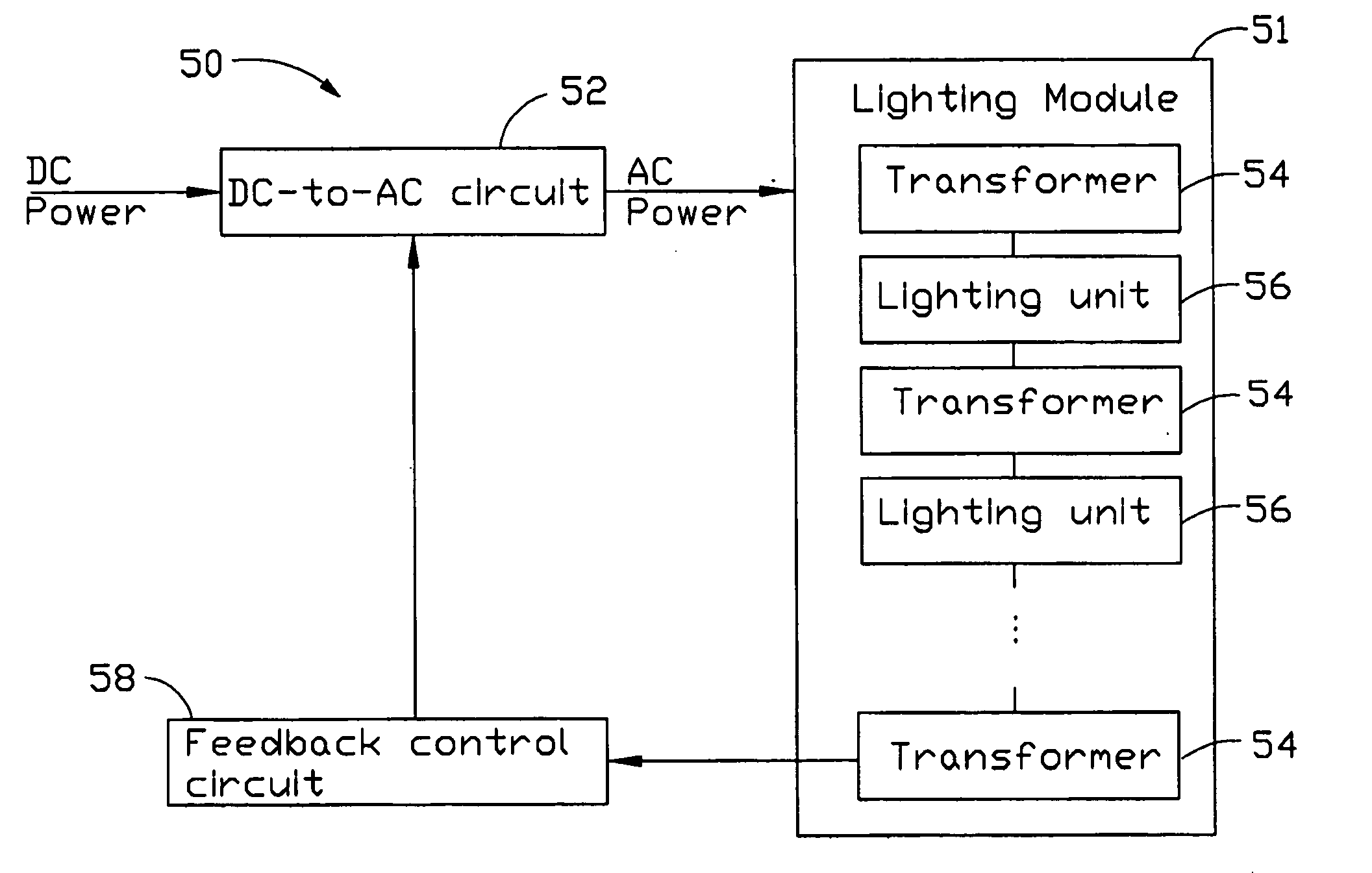

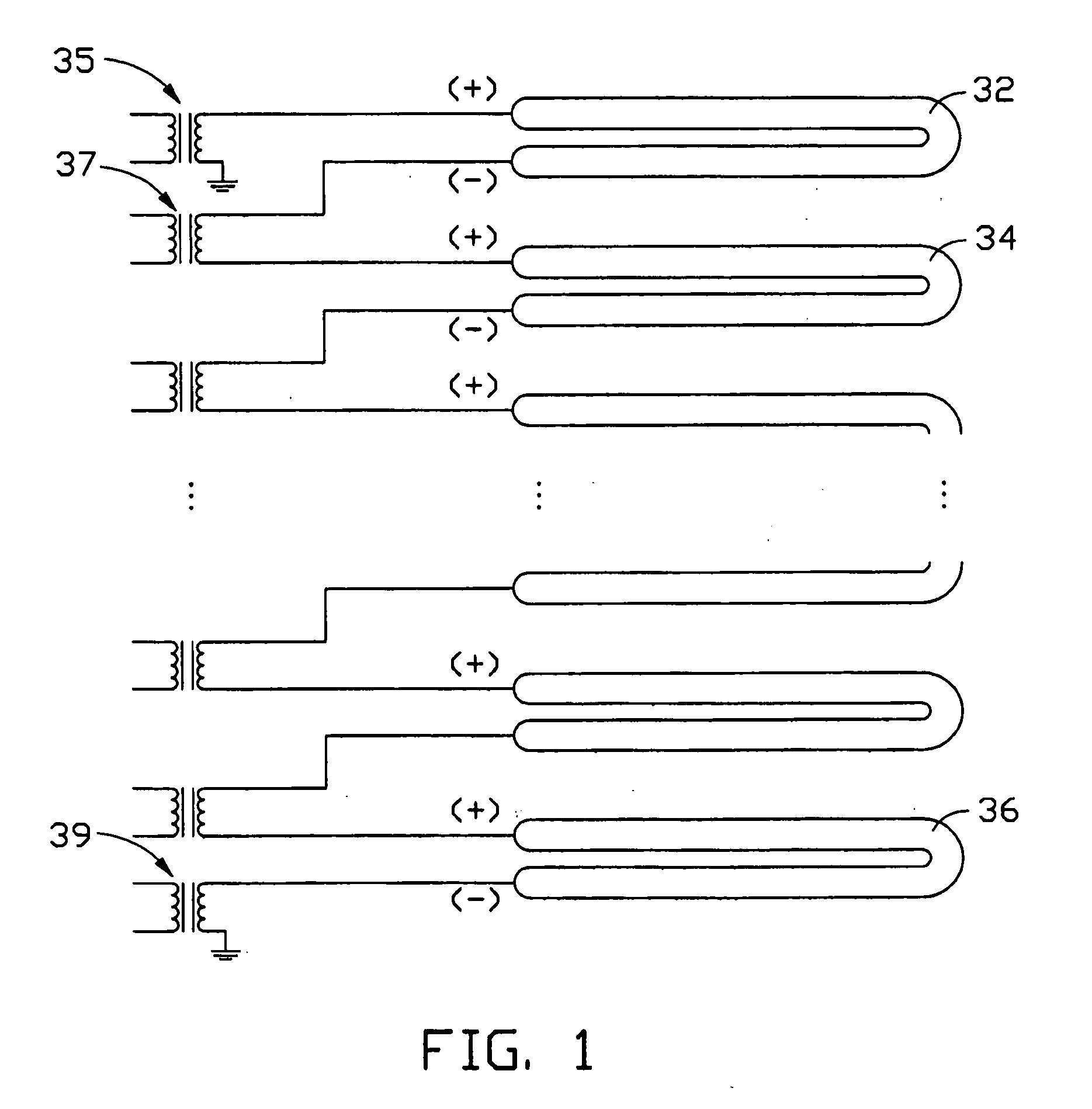

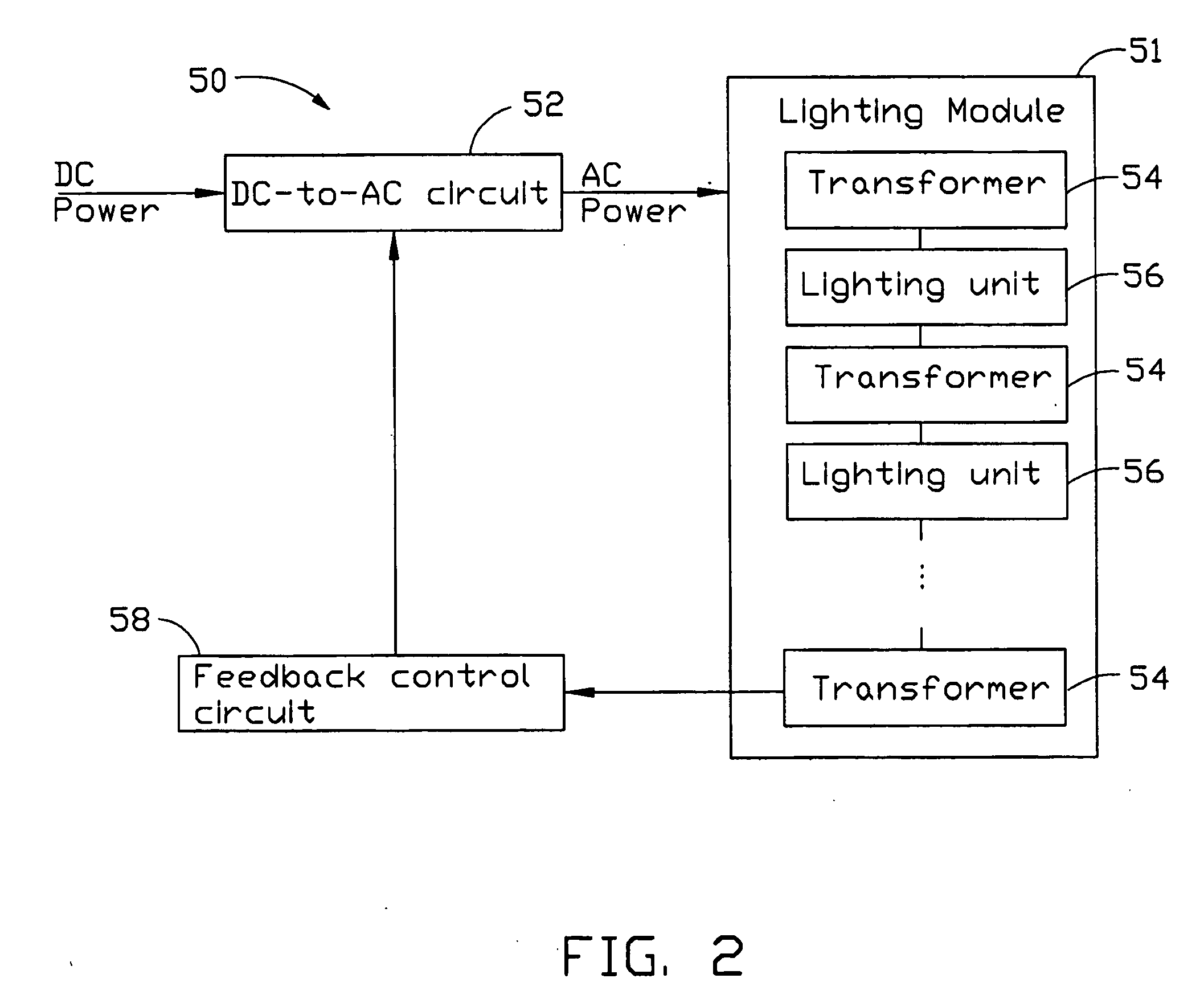

Lighting apparatus formed by serially-Driven lighting units

InactiveUS20050156542A1Implement Feedback ControlReduce in quantityElectrical apparatusStatic indicating devicesLight equipmentTransformer

A lighting apparatus includes a lighting module, a feedback control circuit, and a DC-to-AC circuit. The lighting module comprises a first lighting unit, a second lighting unit, a first transformer, a second transformer and a third transformer. A first end of a first port of the first transformer is connected to a first end of the first lighting unit, a first end of a first port of the second transformer is connected to a second end of the first lighting unit, a second end of the first port of the second transformer is connected to a first end of the second lighting unit, and a first end of a first port of the third transformer is connected to a second end of the second lighting unit. The lighting apparatus uses serial connection of the lighting units to reduce the number of transformers and still have the feedback control circuit.

Owner:HON HAI PRECISION IND CO LTD

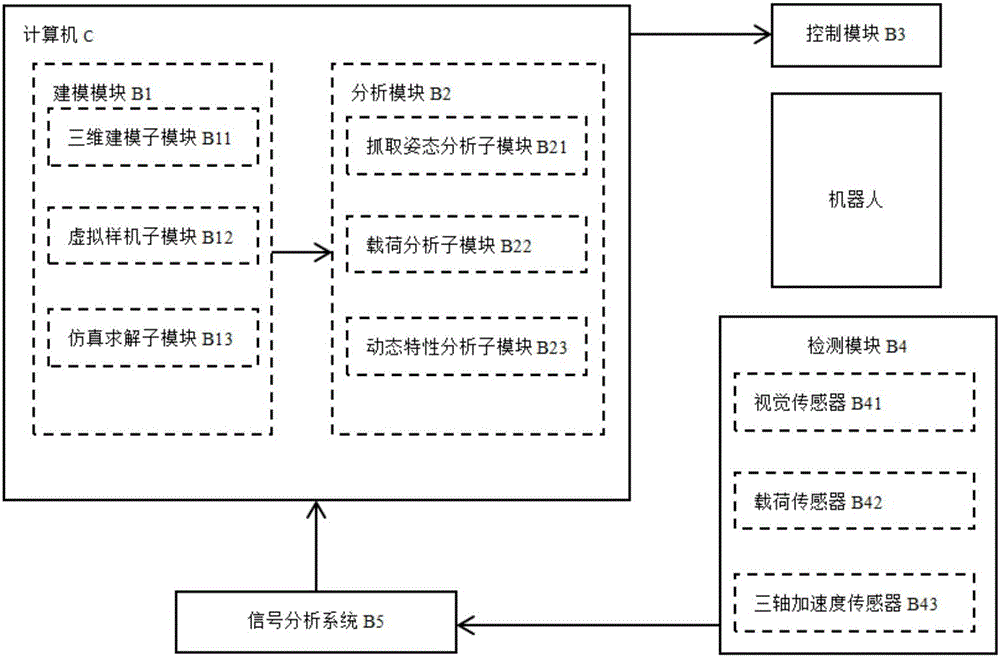

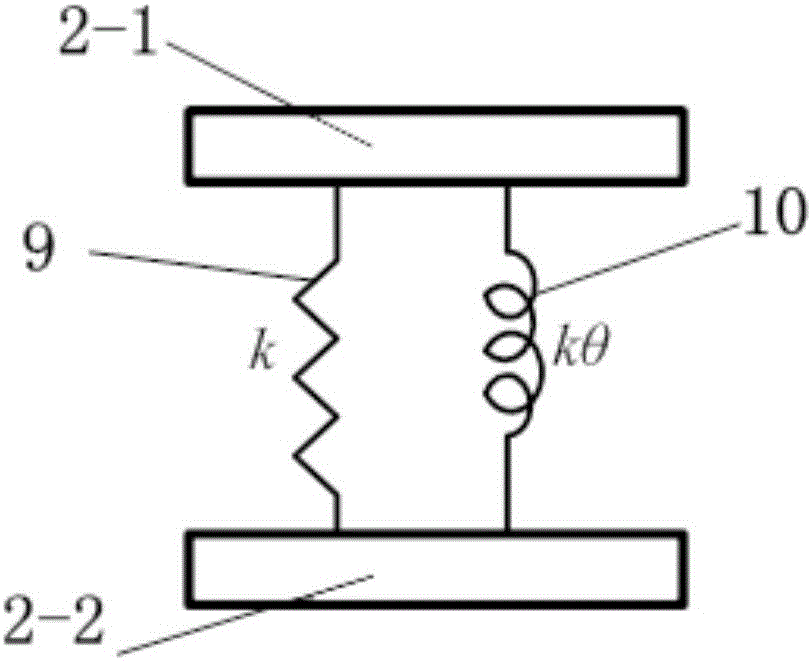

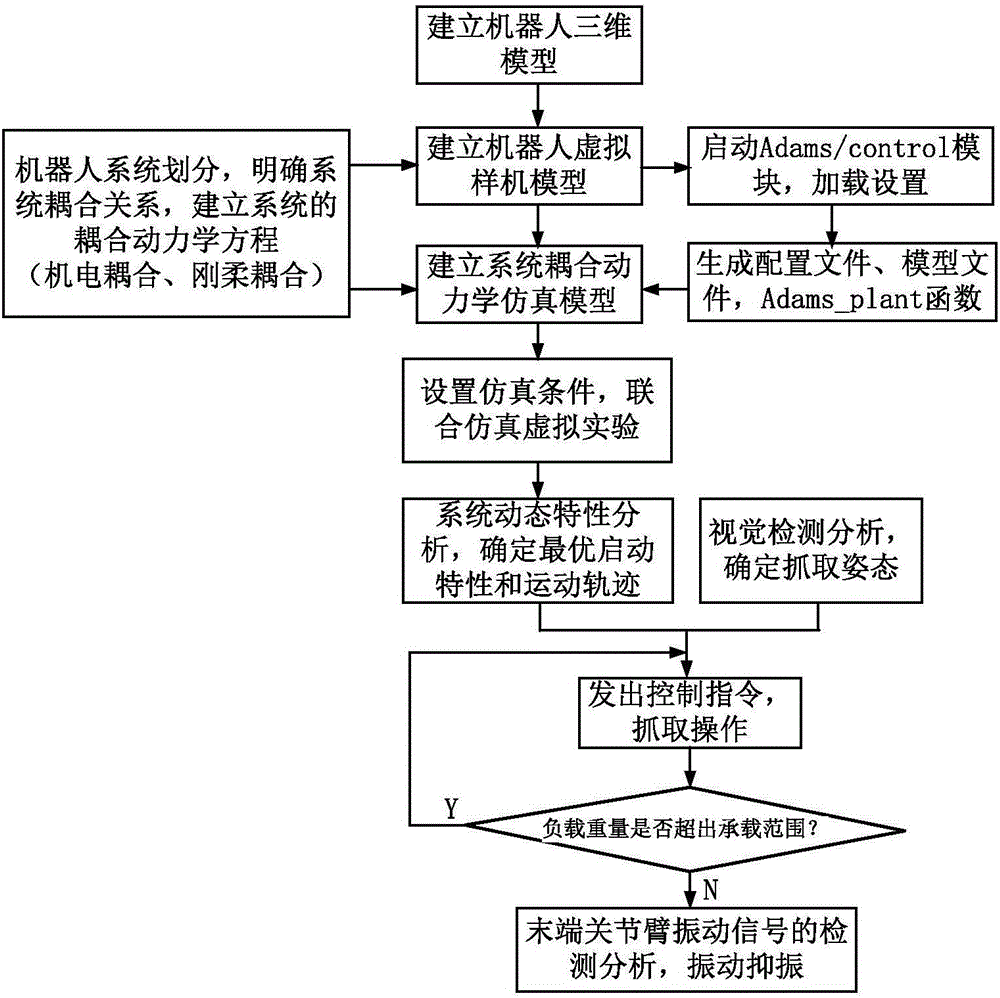

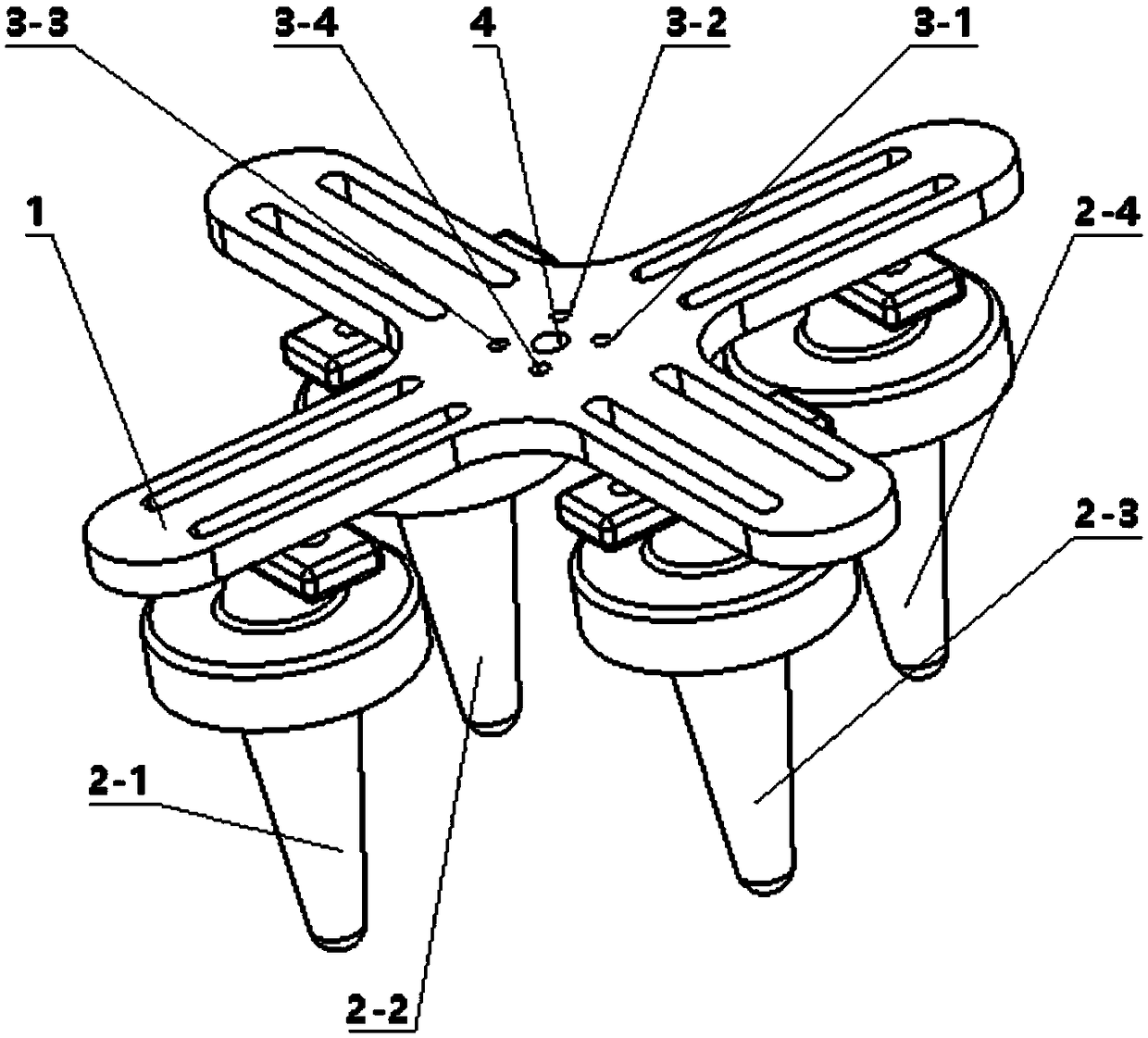

System and method for analyzing and controlling coupled dynamic characteristics of robot

ActiveCN106625684AEasy to analyzeConducive to integrated designProgramme-controlled manipulatorRobotic systemsCoupling

The invention provides a system and method for analyzing and controlling coupled dynamic characteristics of a robot. The analysis and control system comprises a computer, wherein a modeling module B1 and an analysis module B2 are arranged in a computer C; and a signal analysis system B5, a detection module B4 and a control module B3 are arranged between the computer C and the robot. According to the method, coupling factors existing in the robot system can be considered, the analysis result precision of the dynamic characteristics is high, and the problems of errors, even mistakes, caused by neglecting of the coupling factors can be effectively solved. Meanwhile, feedback control of the coupled dynamic characteristics of the system can be realized, and comprehensive analysis and integrated design of the robot system can be facilitated. The system disclosed by the invention is based on system modularization and is easy to realize and simple in operation, the complicated theoretical modeling calculation process is avoided, the analysis difficulty is reduced, and the problem that errors are easily caused due to lots of calculations and solutions can be effectively solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

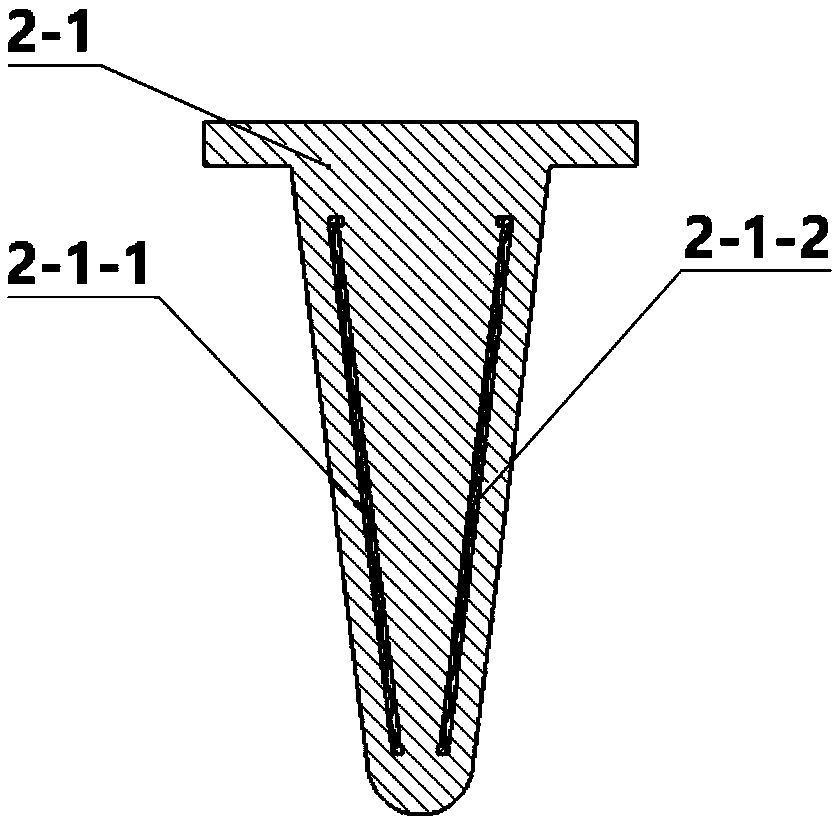

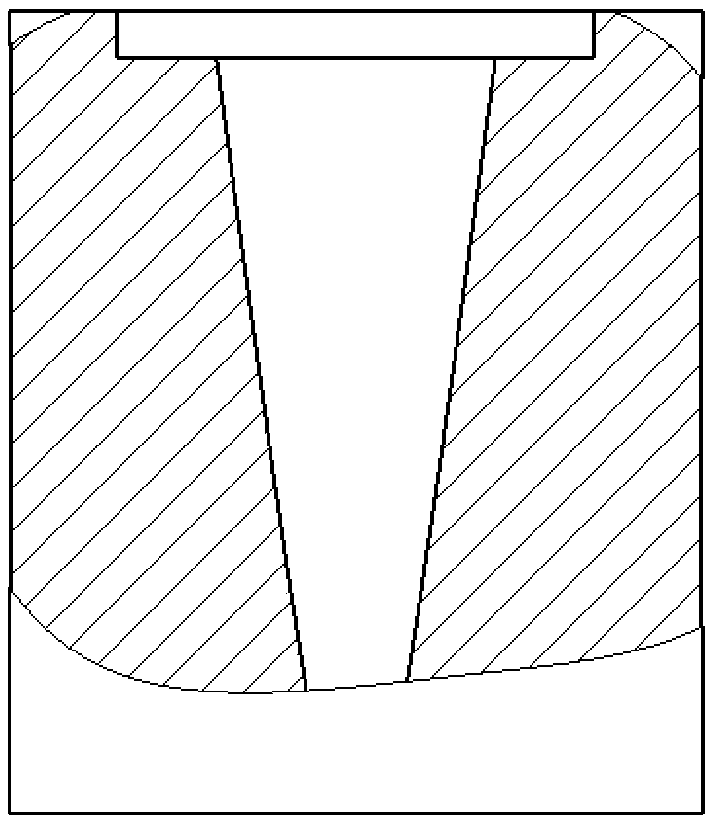

Soft mechanical arm based on SMA springs

InactiveCN109176589ASimple drive structureNo pollution in the processGripping headsMicrocontrollerMicrocomputer

The invention discloses a soft mechanical arm based on SMA springs. The soft mechanical arm comprises a platform. Multiple mechanical arm fingers are arranged below the platform. Each mechanical arm finger comprises a silica gel outer shell. Each silica gel outer shell is internally provided with a soft sensor and the corresponding two SMA springs. Every two SMA springs are arranged in the corresponding silica gel outer shell at the set angle from top to bottom. The top end of each SMA spring is provided with a lead wire. The SMA springs are connected with a control circuits through the lead wires. The extending-and-contracting state of the SMA springs is controlled through the control circuit, and thus, work of the mechanical arm fingers is achieved. The control circuit comprises a singlechip microcomputer, a PWM electronic switch control panel and a voltage-controlled current source, wherein the single chip microcomputer is provided with multiple analog input ports. The STM32 singlechip microcomputer is used for achieving a PWM control constant flow source circuit and outputting the specific frequency and PWM waveforms of specific duty ratios. The PWM electronic switch controlpanel is used for converting PWM signals into the voltage. The voltage-controlled current source controls the current to change through voltage changes. By means of the soft mechanical arm, gripping control of the soft mechanical arm can be achieved.

Owner:GUANGZHOU UNIVERSITY

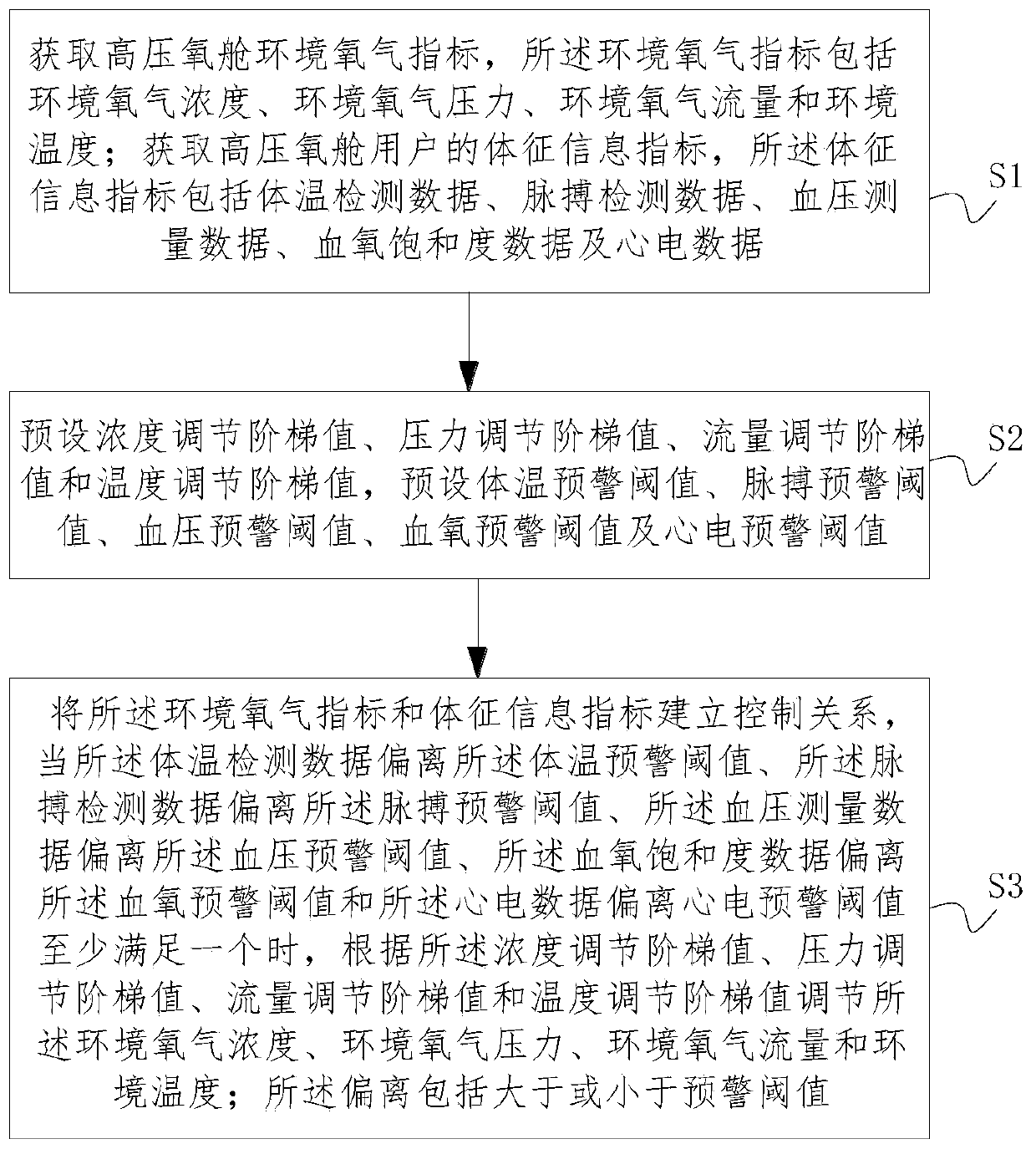

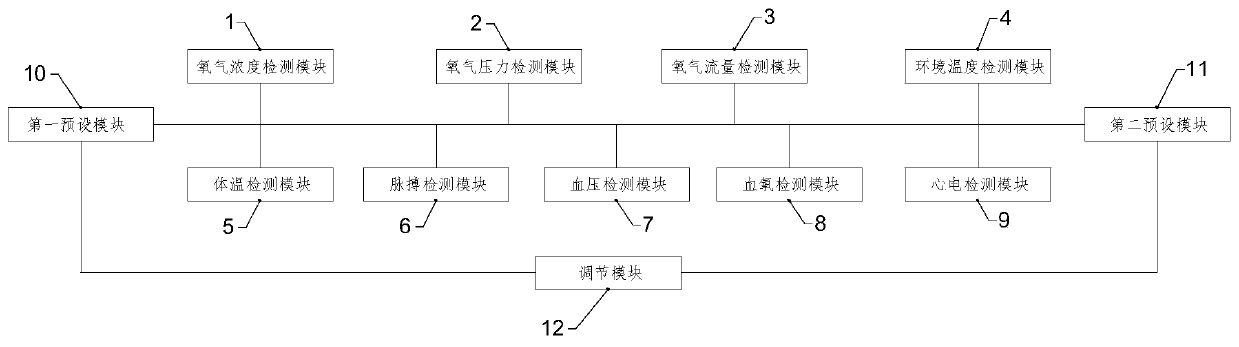

Hyperbaric oxygen chamber equipment operation monitoring method and system

InactiveCN110063859AImprove operational efficiencyRealize automatic compensationBreathing protectionMeasurement devicesFeedback controlAmbient oxygen

The embodiment of the invention discloses a hyperbaric oxygen chamber equipment operation monitoring method and system. The method comprises the steps that a hyperbaric oxygen chamber environmental oxygen index and a physical information index of a user are obtained, the control relationship is established between the environmental oxygen index and the physical information index, and when at leastone of the conditions that temperature detection data deviates from a body temperature early warning threshold value, pulse detection data deviates from a pulse early warning threshold value, blood pressure measurement data deviates from a blood pressure early warning threshold value, blood oxygen saturation data deviates from a blood oxygen early warning threshold value, and electrocardio data deviates from an electrocardio early warning threshold value is met, the environmental oxygen concentration, environmental oxygen pressure, environmental oxygen flow and environmental temperature are adjusted according to a concentration regulation step value, a pressure regulation step value, a flow regulation step value and a temperature regulation step value; deviations include greater or less than the early warning threshold value. Accordingly, by judging the oxygen pressure, concentration and flow in the hyperbaric oxygen chamber environment, equipment operation parameter real-time monitoring and feedback control is achieved, occurrence of dangerous accidents is avoided, the equipment operation is more efficient, and energy consumption is lowered.

Owner:烟台宏远氧业股份有限公司

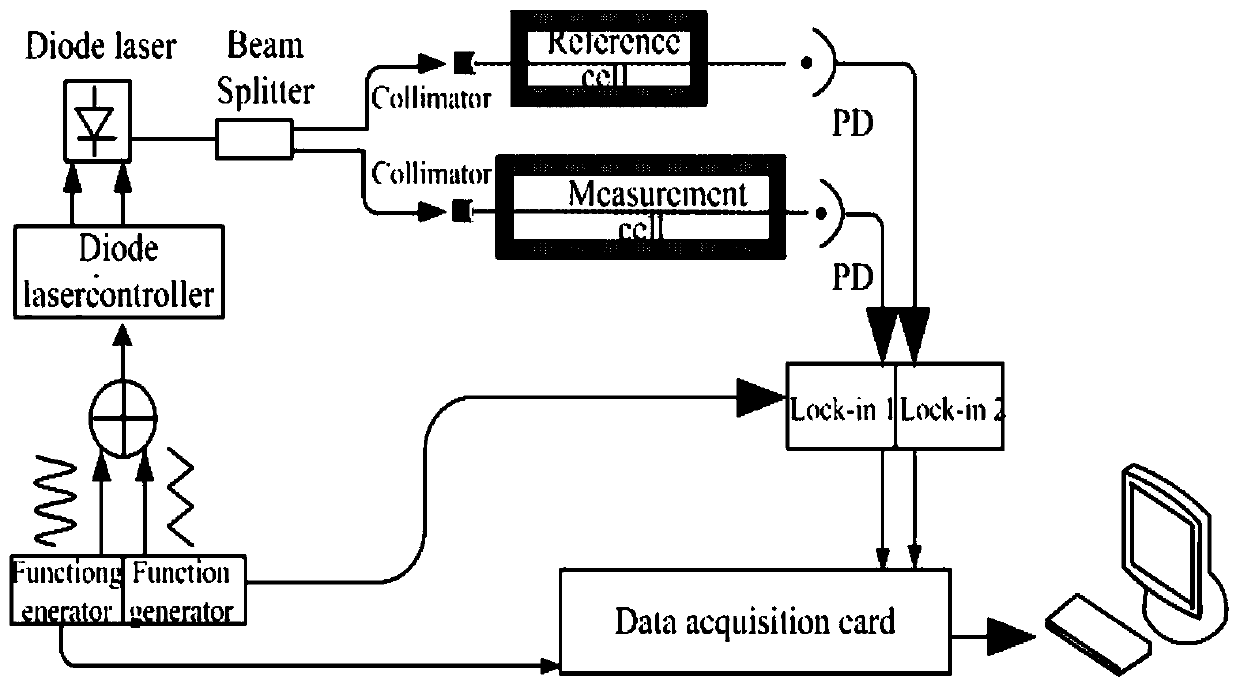

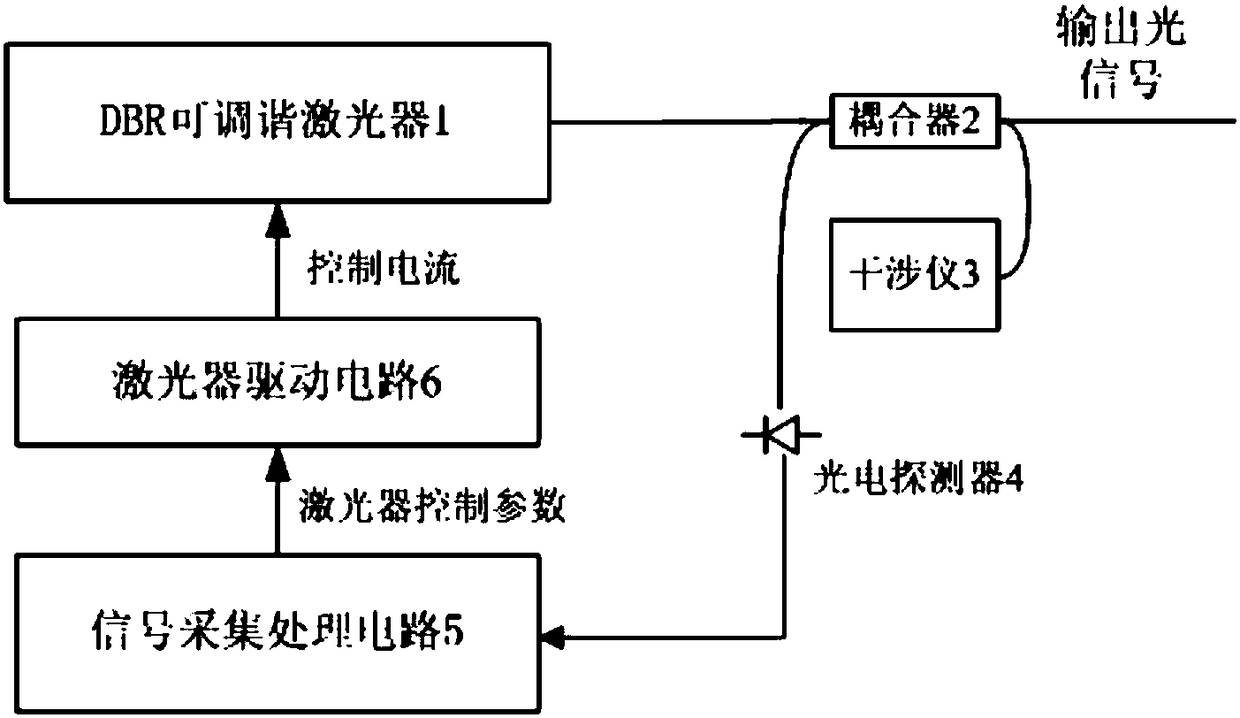

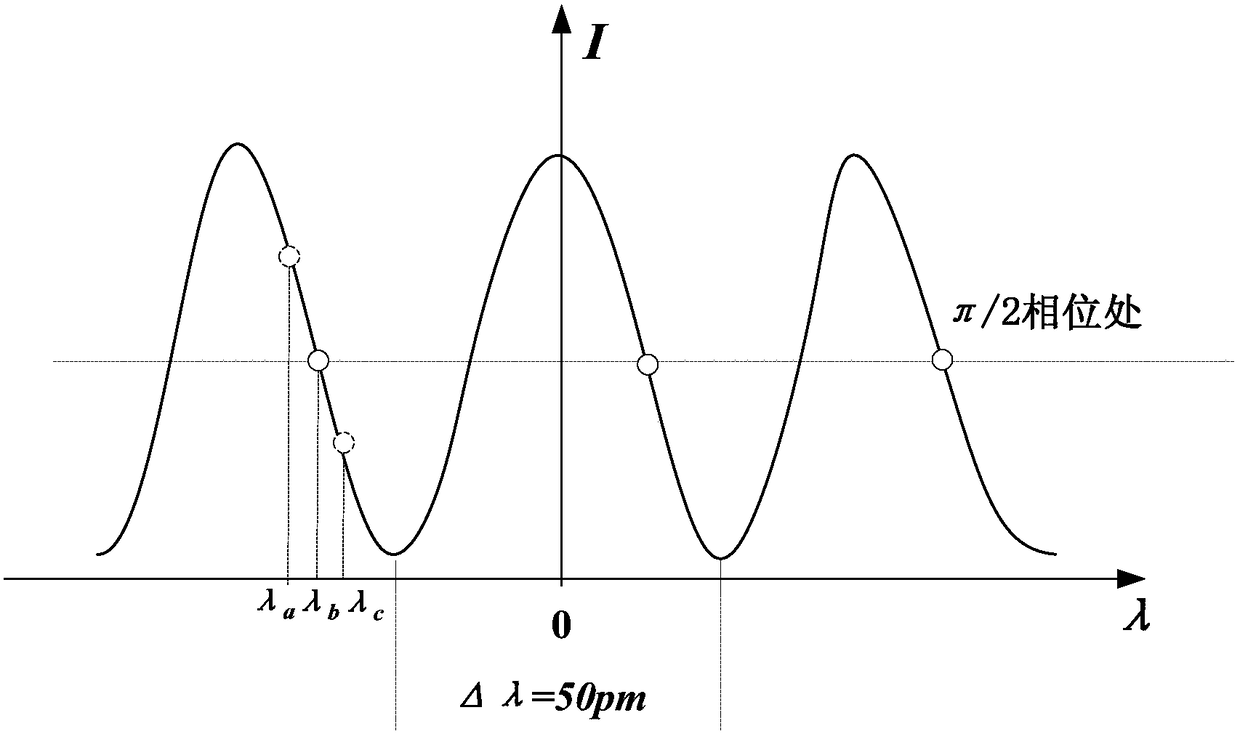

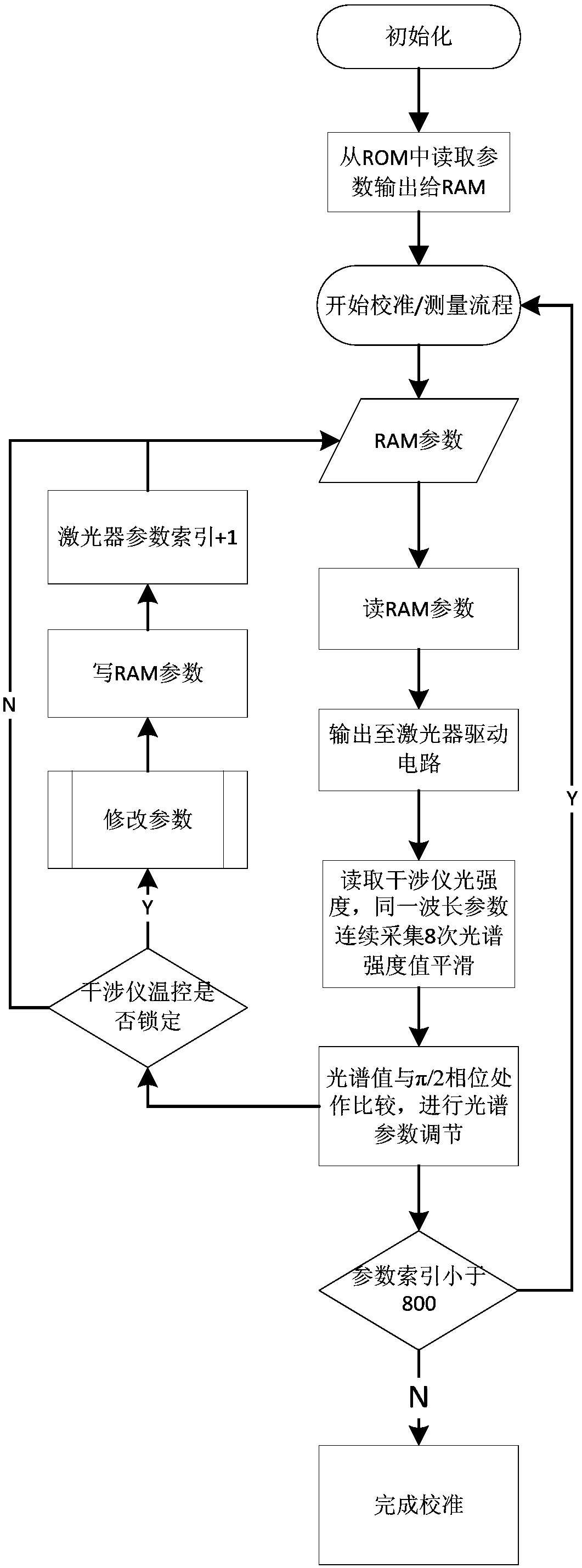

On-line wavelength calibration device and method of DBR (distributed bragg reflector) tunable laser

ActiveCN108123366AReduce wavelength control errorAccurate control errorLaser detailsSemiconductor lasersTunable laserFeedback control

The invention discloses an on-line wavelength calibration device and a method of a DBR (distributed bragg reflector) tunable laser. The device comprises a coupler, an interferometer, a photoelectric detector, a signal acquisition and processing circuit and a laser driving circuit. A reflection spectrum of the interferometer is of a cosine type; output wavelengths of the DBR tunable laser are set at a pi / 2 phase of the reflection spectrum of the interferometer; when an optical signal acquired by the signal acquisition and processing circuit deviates from the pi / 2 phase, a newly generated control parameter of the DBR tunable laser is transmitted to the laser driving circuit; and the laser driving circuit changes control current of the DBR tunable laser, so that the output wavelengths of theDBR tunable laser are locked at the pi / 2 phase of the reflection spectrum of the interferometer all the time. According to the device and the method, the interferometer is introduced for monitoring and feedback control of the wavelengths of the DBR tunable laser, and a wavelength control error during long-term usage of the DBR tunable laser can be effectively decreased.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Printing method of 3D printer with three-dimensional graphic feedback system

InactiveCN105666877BHigh precisionImprove printing efficiencyAdditive manufacturing apparatus3D object support structuresControl systemThree dimensional graphics

The invention discloses a 3D printing machine with a three-dimensional figure feedback system and a printing method of the 3D printing machine. The 3D printing machine comprises a rack, a printing platform, a printing spray head, a material box, a feeding device, a drive device, a control system, a computer, a support mounted on the outer side of the drive device and a 3D scanner which is arranged on the support and used for scanning a printed article. In the product forming process, the 3D scanner is used for scanning a semi-finished workpiece or a blank, the three-dimensional profile of the workpiece is obtained and compared with a three-dimensional model of a target product through graphics operation, the motion path and printing parameters of the printing machine are adjusted according to a result, and therefore feedback control of the printing process is achieved, and the 3D printing forming precision and the printing efficiency are improved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

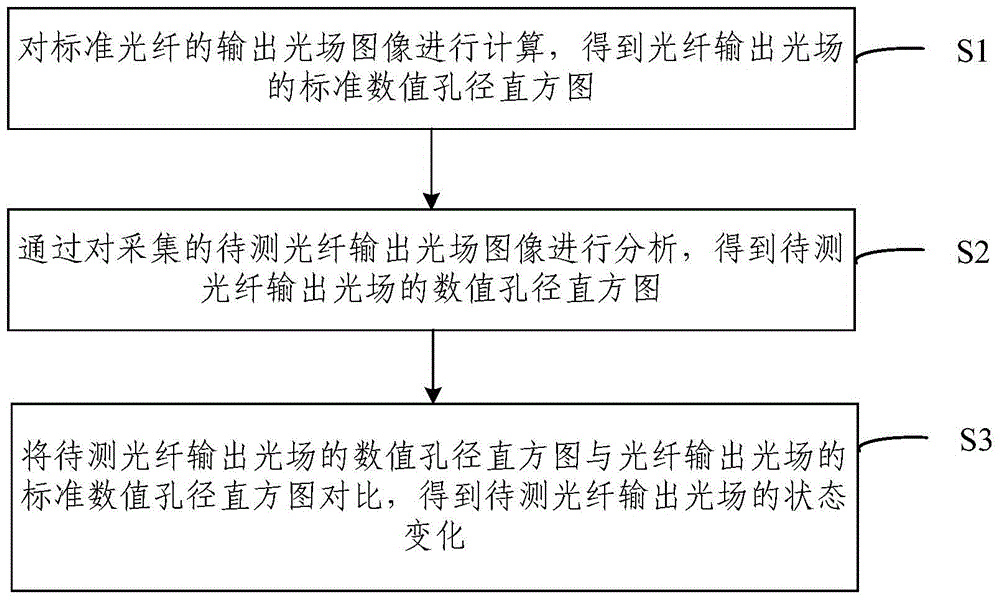

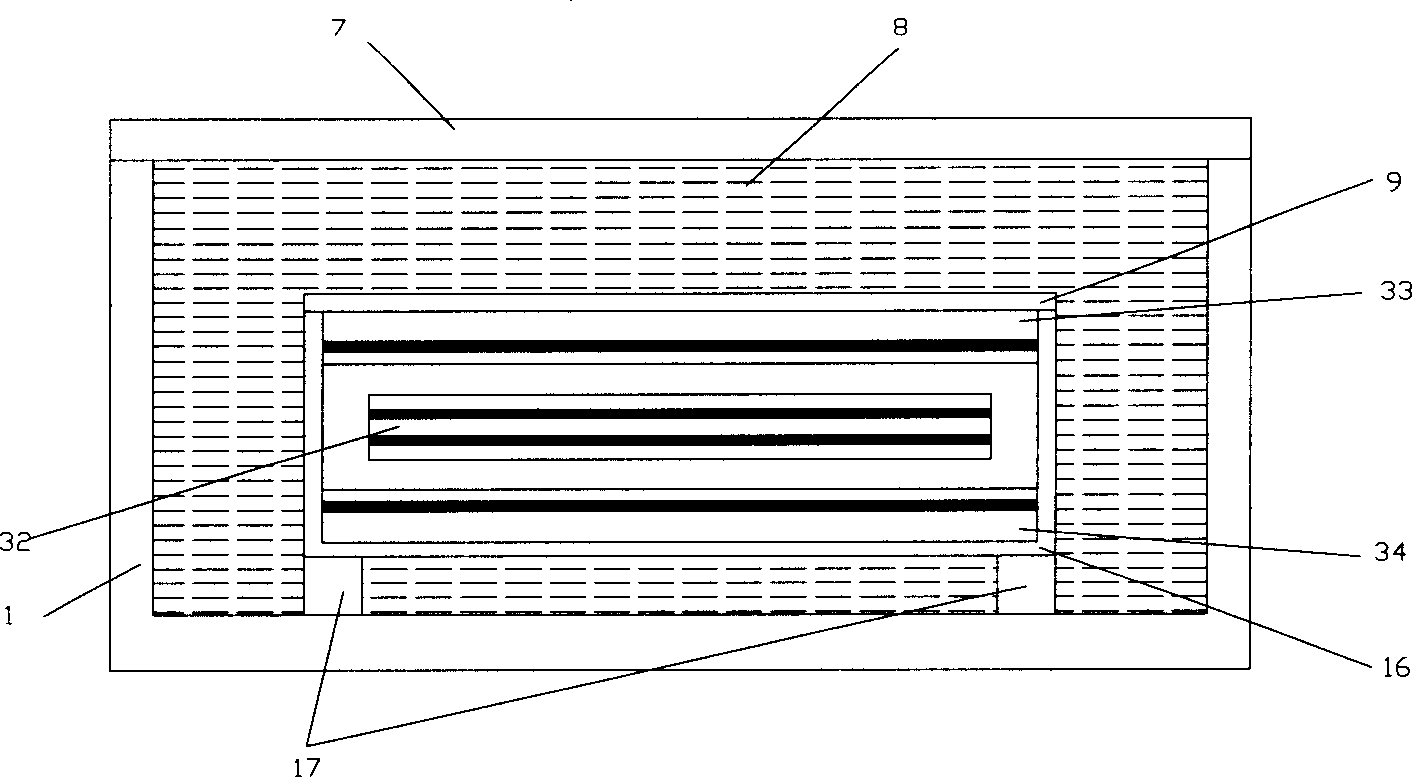

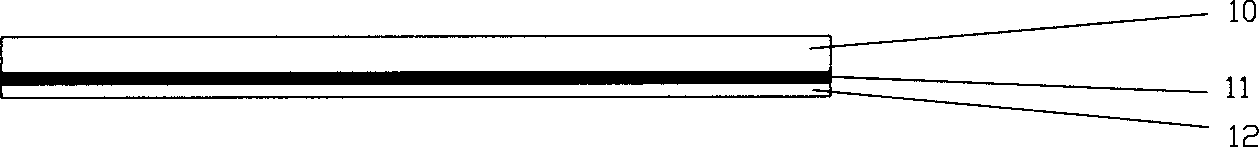

Fiber state detection method and system

ActiveCN104089756ARealize real-time monitoring and feedback controlImplement Feedback ControlTesting optical propertiesPhysicsHistogram

The invention discloses a fiber state detection method and system, and relates to the technical field of fiber detection. The method comprises: performing calculating on a standard fiber output light field image to obtain a standard value aperture histogram of a fiber output light field; through analyzing an acquired image of a fiber output light field to be detected, obtaining a value aperture histogram of the fiber output light field to be detected; and comparing the value aperture histogram of the fiber output light field to be detected with the standard value aperture histogram of the fiber output light field to obtain a state change of the fiber output light field to be detected. According to the invention, for the structural characteristics and optical waveguide characteristics of a multi-wrapping-layer fiber, the method is designed to realize detection of the state of the multi-wrapping-layer fiber. The method is applied to detection of fiber defects, bending states, loss parameters and the like, and can also realize real-time monitoring and feedback control of the multi-wrapping-layer fiber at the same time.

Owner:北京同方华光系统科技有限公司

High-temperature superconductive and permanent magnet microgyrorotor with stabilized hung

A micro-gyroscope of permanent magnet rotor stably suspended by high temperature superconductor is prepared by setting gyroscope bottom shell on piqued nitrogen Dewar through support column; forming top and bottom stators of gyroscope by high temperature superconductor, silicon nitride insulation material and stator driving detection moment layer; forming gyroscope rotor by two layers of rotor driving detection moment layer, two layers of cylindrical silicon nitride insulation material and cylindrical permanent magnet material .

Owner:SHANGHAI JIAO TONG UNIV

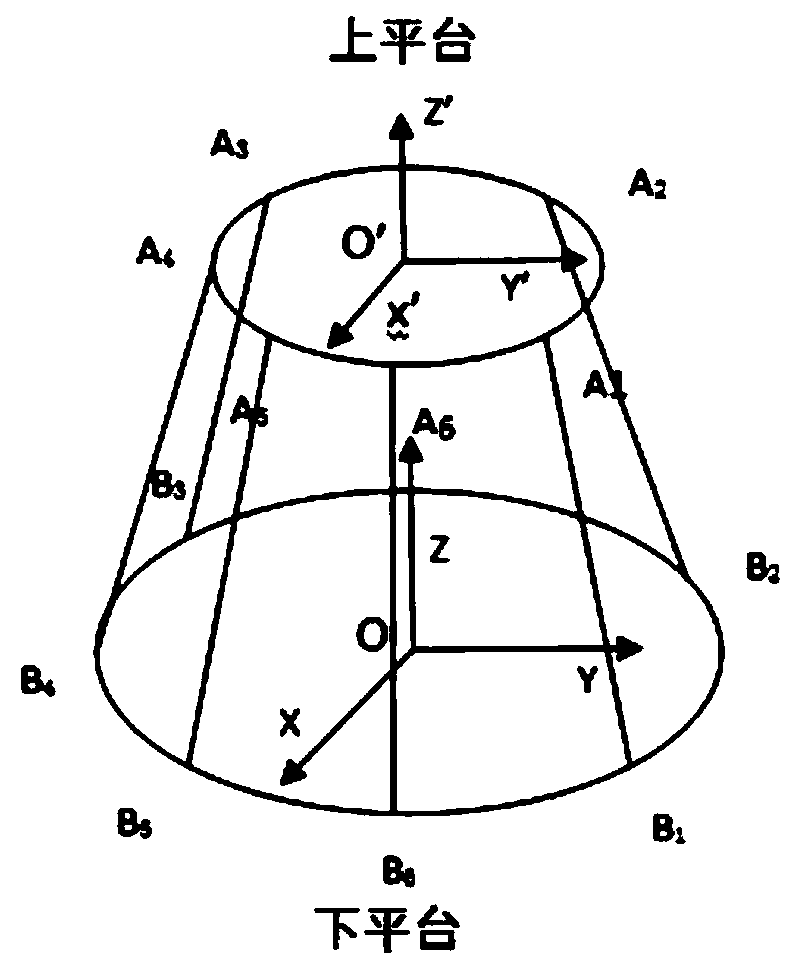

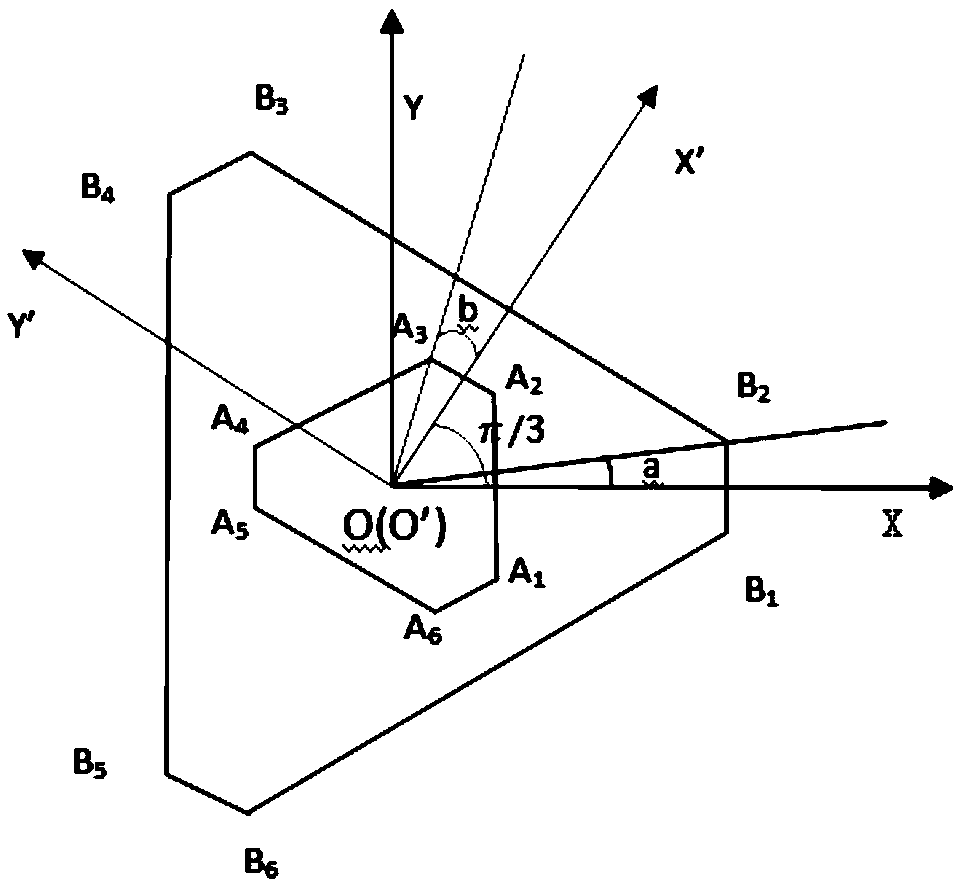

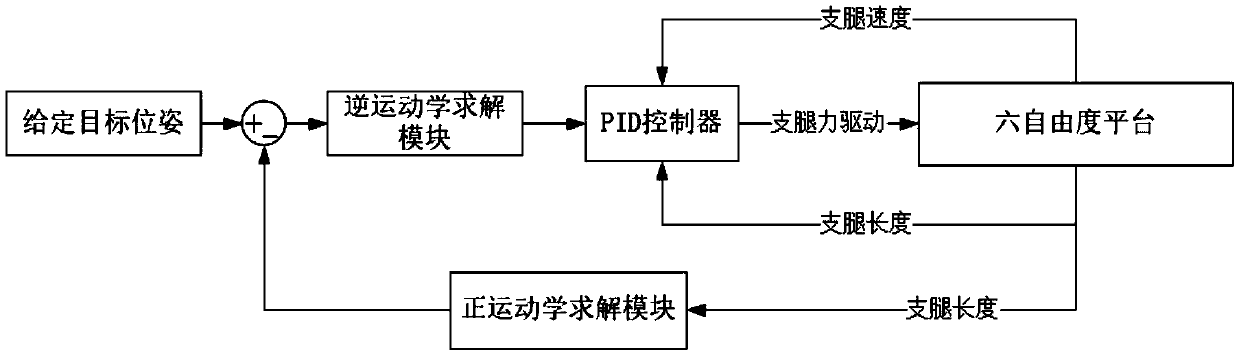

Six-degree-of-freedom platform positioning control method

InactiveCN109613819AImplement Feedback ControlHigh positioning accuracySimulator controlControllers with particular characteristicsClosed loop feedbackFeedback control

The invention belongs to the field of mechanical automation and astronomy, and concretely discloses a six-degree-of-freedom platform positioning control method and equipment. The method includes the establishment of a simulation model and the control of a six-degree-of-freedom platform, by establishing and configuring the six-degree-of-freedom platform simulation model and parameters thereof, a six-degree-of-freedom platform PID control algorithm module based on forward kinematics solution is established in simulink, by combining a mechanical system dynamics automatic analysis model, the jointmotion simulation control is realized, and then the precise positioning control of the six-degree-of-freedom platform is realized. The method and the equipment based on the method realize the controladjustment of the six-degree-of-freedom platform based on the workspace control strategy, can realize the closed-loop feedback control of the platform positioning by using the forward kinematics based on the discrete Newton iterative solution, simplify the control algorithm and improve the positioning accuracy of the platform.

Owner:HUAZHONG UNIV OF SCI & TECH

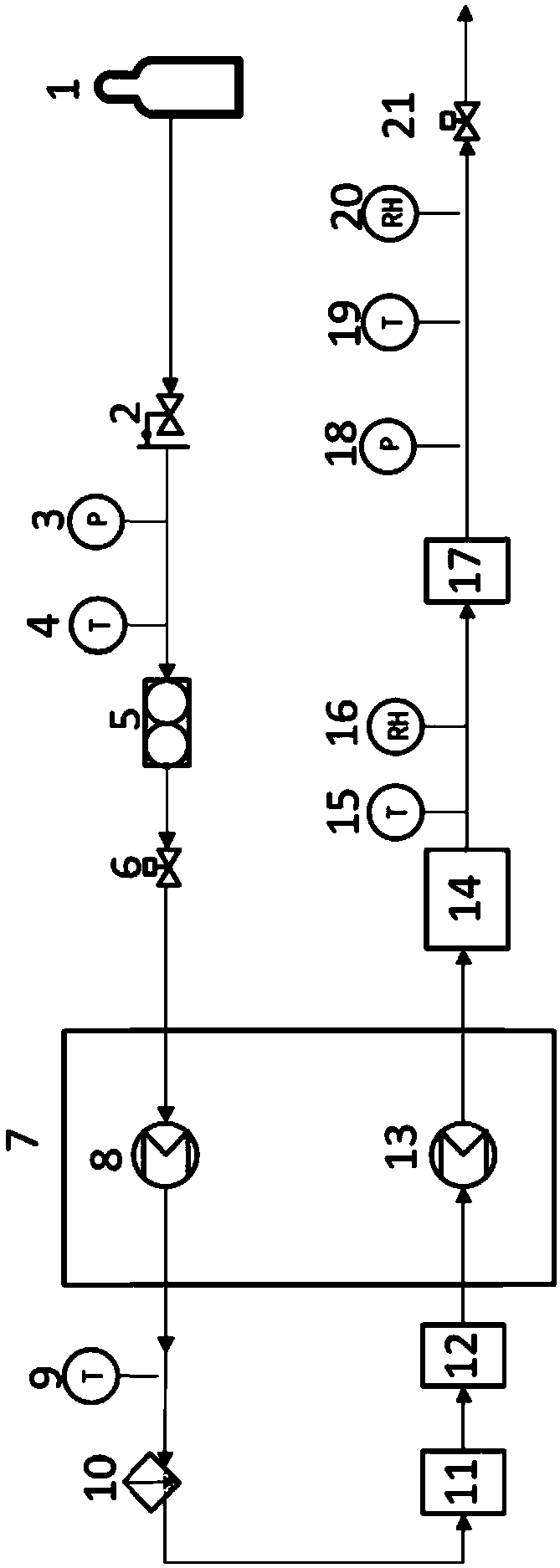

High-flow-rate low-temperature gas temperature-humidity control device

PendingCN108155401AReduce moisture contentReduce the amount of icingFuel cellsWater contentProcess engineering

The invention relates to a high-flow-rate low-temperature gas temperature-humidity control device. The high-flow-rate low-temperature gas temperature-humidity control device comprises a gas source, adecompression apparatus, a liquid thermostat, a first dehumidifying apparatus and a second dehumidifying apparatus, wherein the gas source is used for providing high-pressure gas; an input end of thedecompression apparatus is connected with the gas source and used for adjusting the gas pressure and the flow rate of the high-pressure gas; a first heat exchanger and a second heat exchanger are arranged inside the liquid thermostat; the first dehumidifying apparatus comprises a first dewatering assembly and a first pipeline heater; and the second dehumidifying apparatus comprises a second dewatering assembly and a second pipeline heater. Compared with the prior art, two heat exchangers are provided, the corresponding dewatering assembly and pipeline heater are arranged behind each heat exchanger, and the pipeline heater is arranged behind the dewatering apparatus, so that the water content in the gas can be greatly reduced, the possible icing amount is reduced, and a fuel cell is prevented from being damaged.

Owner:TONGJI UNIV

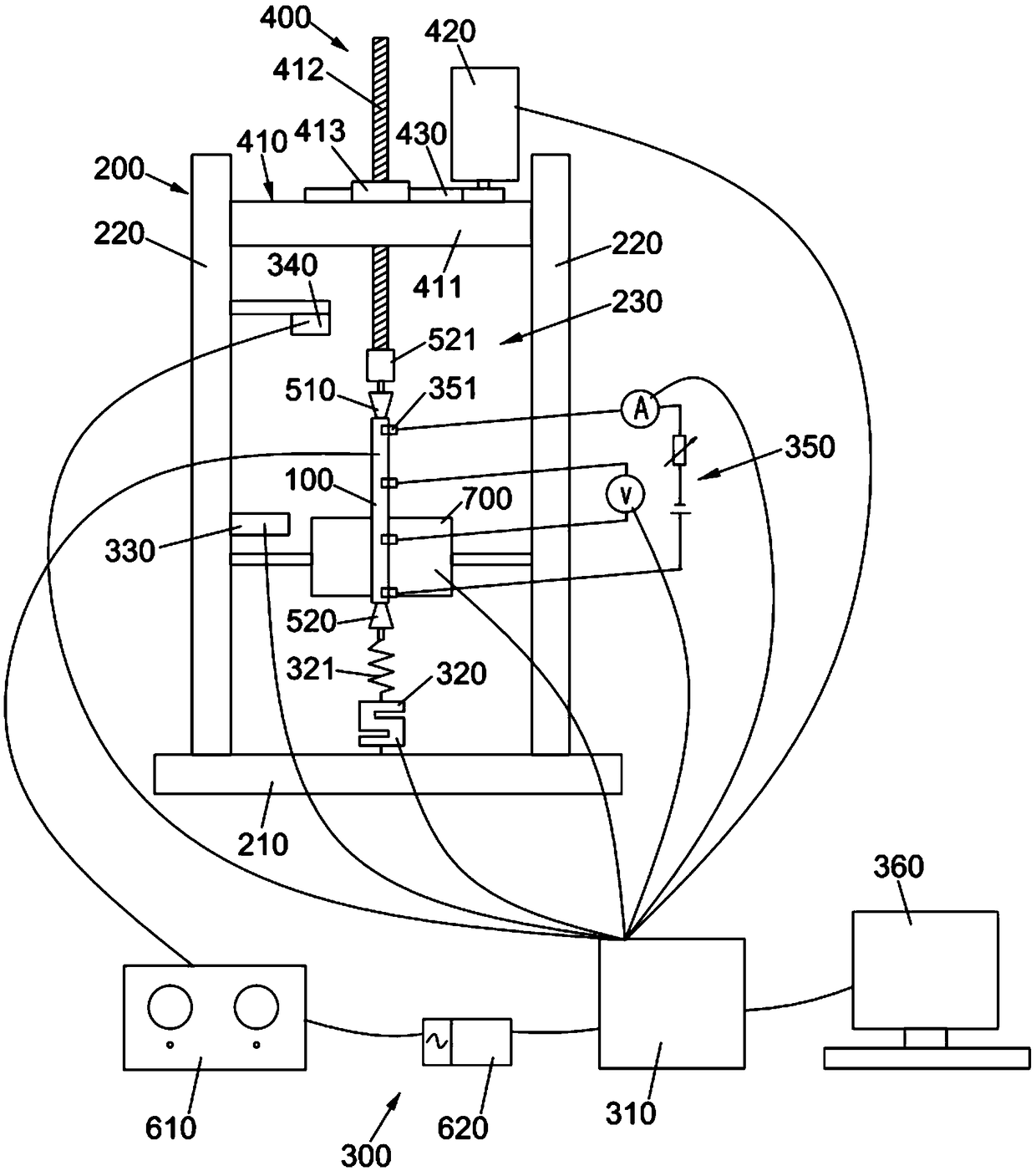

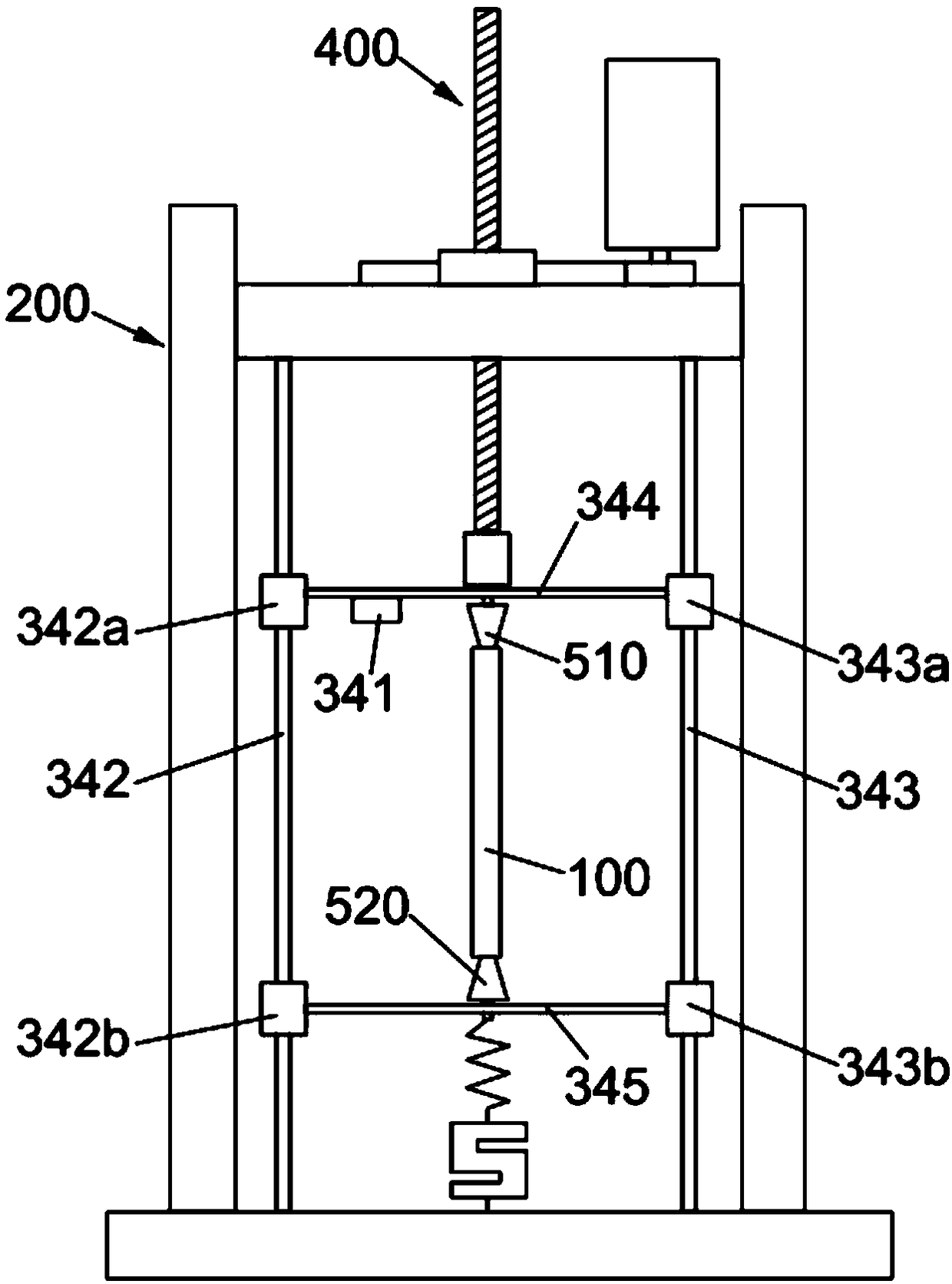

Two-pass shape memory alloy thermal-mechanical functional fatigue test device

InactiveCN108717025AImplement storageRealize acquisitionProgramme controlComputer controlMicrocontrollerPower control system

The invention relates to the field of memory alloy test devices and discloses a two-pass shape memory alloy thermal-mechanical functional fatigue test device. The two-pass shape memory alloy thermal-mechanical functional fatigue test device comprises a data acquisition and control system, a mechanical loading component, a clamping component and a power supply control system; the mechanical loadingcomponent comprises a lead screw sliding table and a stepping motor used for driving a lead screw; the clamping component comprises a first clamping block and a second clamping block, and the first clamping block is connected with the lead screw; the data acquisition and control system comprises a single chip microcomputer, a tension sensor, a temperature sensor, a displacement sensor and a resistivity test module, wherein the tension sensor, the temperature sensor, the displacement sensor and the resistivity test module are electrically connected with the single chip microcomputer; the second clamping block is connected with the tension sensor; the resistivity test module is electrically connected with a tested piece; the power supply control system comprises a constant-current power supply and a relay connected with the constant-current power supply; the constant-current power supply is electrically connected with the tested piece; the relay, the stepping motor and the single chip microcomputer are electrically connected with one another. The two-pass shape memory alloy thermal-mechanical functional fatigue test device disclosed by the invention can quantificationally evaluate the thermal-mechanical functional fatigue characteristics of a two-pass shape memory alloy test piece under cyclic loading.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

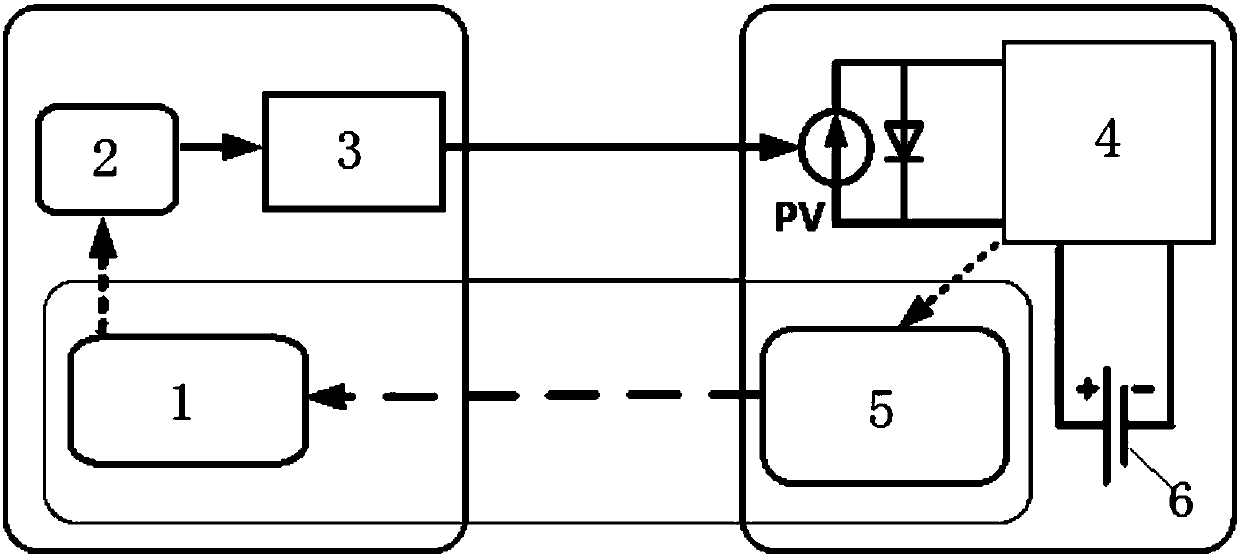

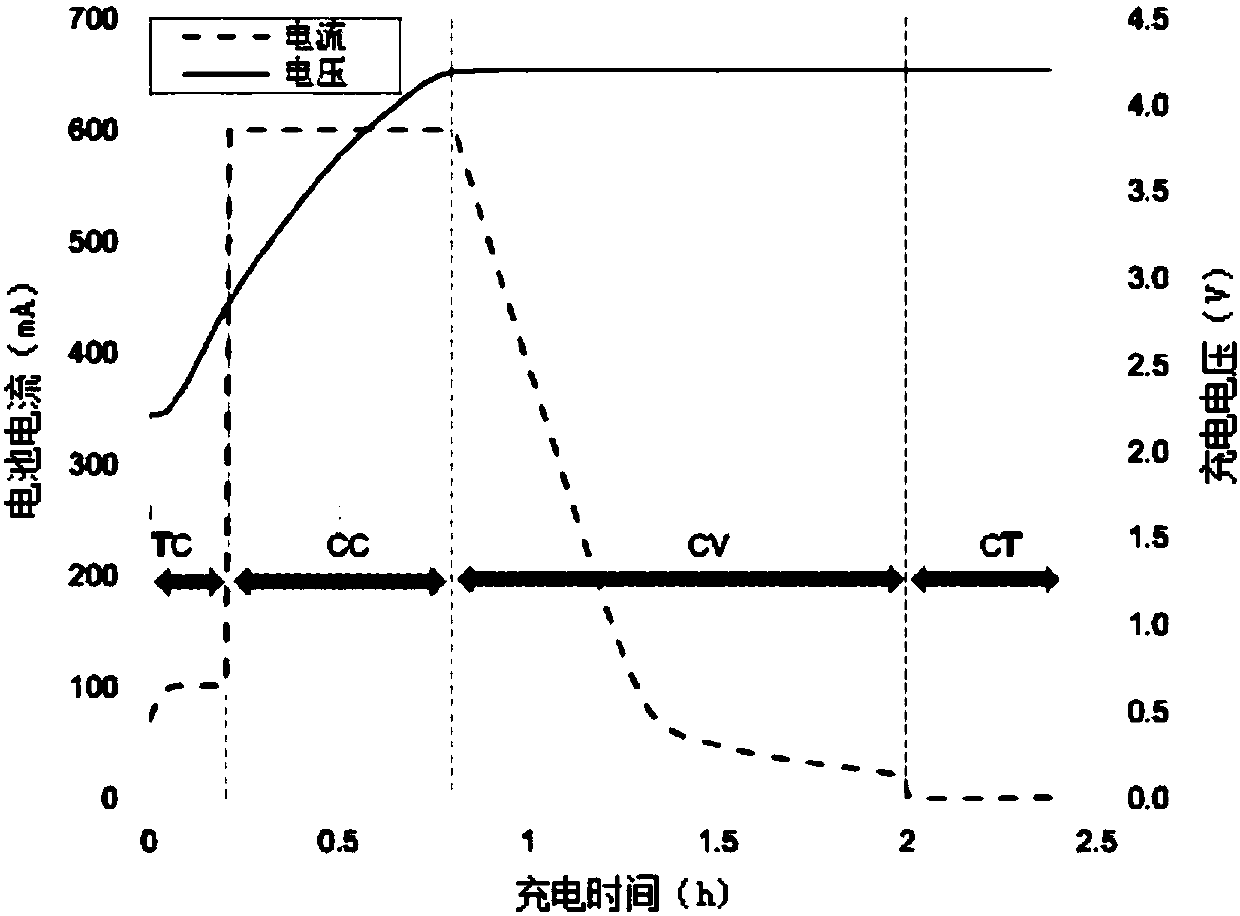

Adaptive mobile optical charging system based on feedback signaling

InactiveCN107658927AMeet charging needsEnable wireless chargingBatteries circuit arrangementsElectric powerFeedback controllerEngineering

The invention relates to an adaptive mobile optical charging system based on feedback signaling. The adaptive mobile optical charging system comprises a transmitting terminal and a receiving terminalwhich are separated, and is characterized in that the transmitting terminal comprises a feedback controller, a power supply and an optical charge transmitter which are sequentially connected, the receiving terminal comprises an optical charge receiver, an electric energy converter and a feedback monitor which are sequentially connected, and the electric energy converter is connected with a charging target; and the optical charge transmitter transmits optical beam transmission power energy to the optical charge receiver, and the feedback monitor is used for feeding back required information tothe feedback controller. Compared with the prior art, the adaptive mobile optical charging system achieves mobile optical charging within a scope of 0-50m; and the adaptive mobile optical charging system further achieves an information feedback mechanism between the transmitting terminal and the receiving terminal, and the transmitting terminal can respond according to the feedback information ofthe receiving terminal.

Owner:TONGJI UNIV

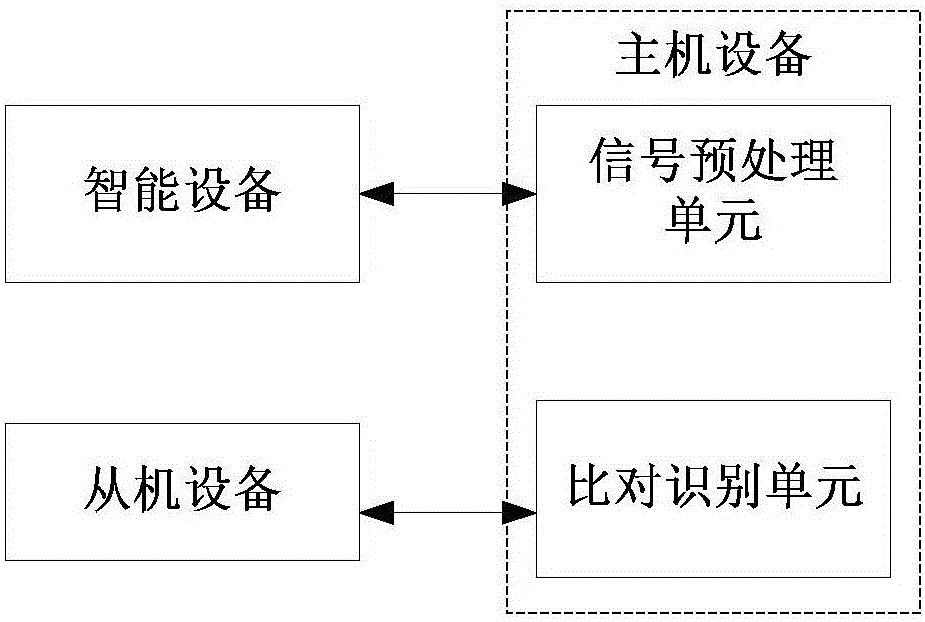

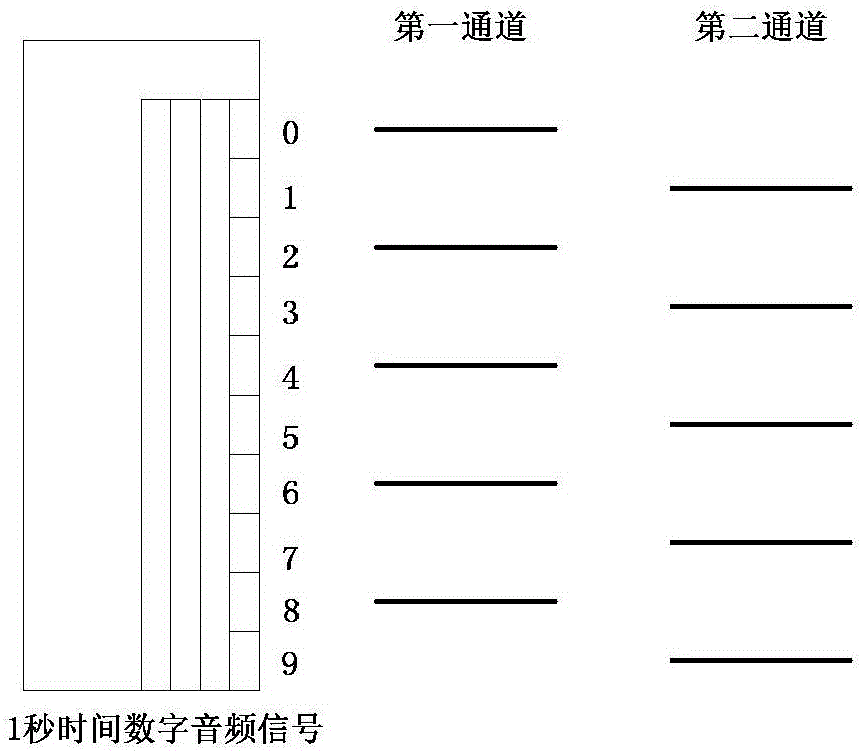

Intelligent device interacting system and method based on audio identification technology based

ActiveCN106028217AImprove experienceRealize non-stopSignal processingTransducer circuitsSocial benefitsAudio recognition

The invention discloses an intelligent device interacting system and method based on an audio identification technology. The system comprises an intelligent device, a host machine device and a slave machine device. The method comprises the steps of S1, acquiring and audio signal in the intelligent device by a host machine device; S2, carrying out pre-processing for the audio signal by the host machine device; and S3, carrying out contrastive identification for the pre-processed audio signal by the host machine device, judging a scene or content corresponding to the audio signal and outputting a control instruction to the slave machine device based on the scene or the content. As the host machine device is used for acquiring and intelligently analyzing the audio signal and controlling the slave machine device to carry out a responding action, the problems of multimedia playing tediousness and single function in the prior art are overcome, interactive connection among intelligent terminals based on a multimedia audio signal is realized, the user experience is improved efficiently, and good economic and social benefits are achieved. The intelligent device interacting method based on the audio identification technology can be widely applied to various intelligent device interacting systems.

Owner:XIUXIU TECH SHENZHEN CO LTD

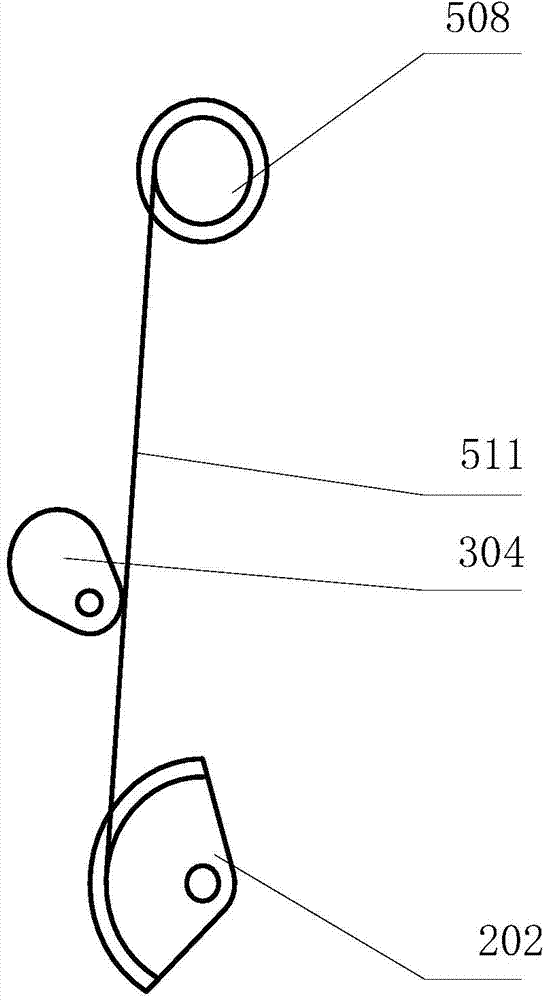

Intelligent man-machine interaction type vehicle accelerator pedal device

InactiveCN103895511ARealize the intention of manipulationWith human-computer information two-way interactionPropulsion unit arrangementsGear wheelOptical axis

The invention discloses an intelligent man-machine interaction type vehicle accelerator pedal device. The device comprises a pedal rotary shaft system, a control shaft system, a sliding polished shaft system and a clutch shaft system. The pedal rotary shaft system, the control shaft system, the sliding polished shaft system and the clutch shaft system are arranged on a pedal support. The pedal rotary shaft system is used for achieving work states of a common accelerator pedal, the control shaft system transmits power to the clutch shaft system through the sliding polished shaft system, a cylindrical cam, idler wheels and a transmission rod in the clutch shaft system drive a pressing plate to move axially so that the plate-type cam of the control shaft system can achieve feedback control of pedal force after the pressing plate and a friction plate are combined and locked, and an adjusting mechanism in the sliding polished shaft system can adjust the axial position of a sliding gear so that the common accelerator pedal can work when a control motor fails. Besides, control of rotation speed and power of an engine and running speed can be achieved through the common accelerator pedal, running states and road condition information can be fed back to drivers through an accelerator pedal in a tactile feedback mode, man-machine interaction is achieved, and the drivers are assisted in improving driving behaviors.

Owner:BEIHANG UNIV +1

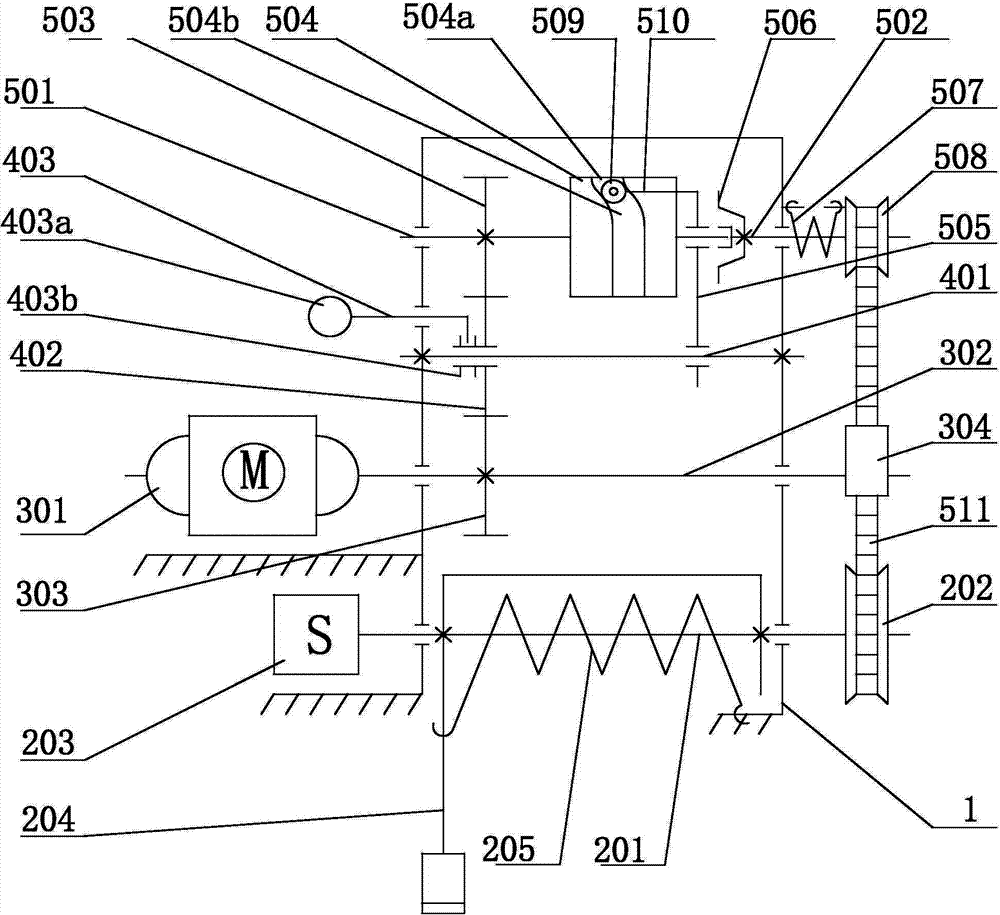

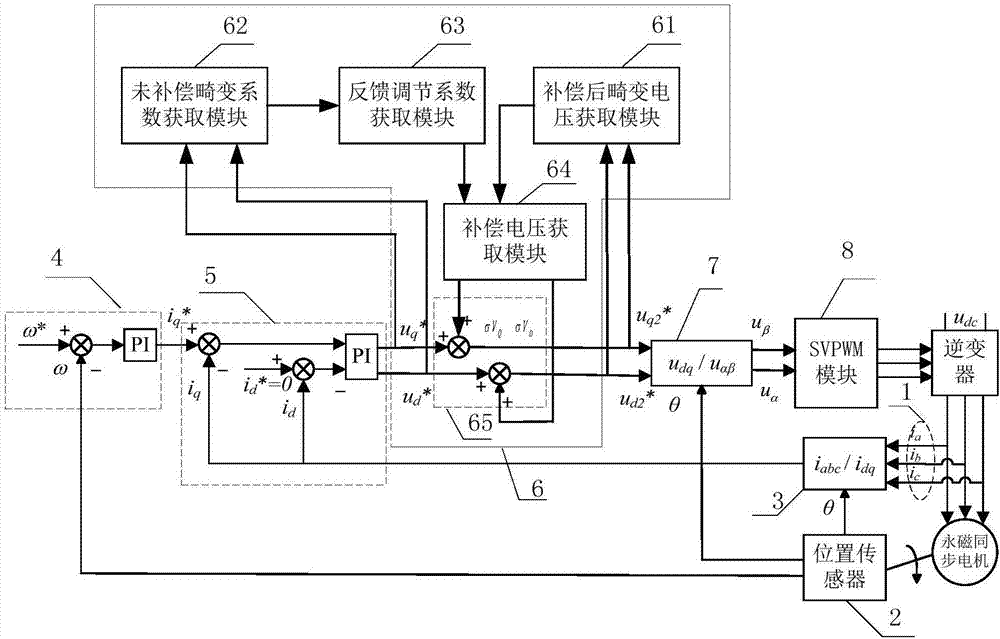

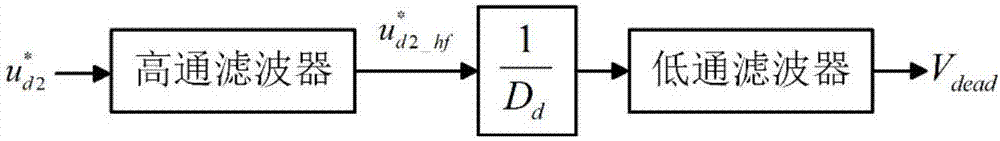

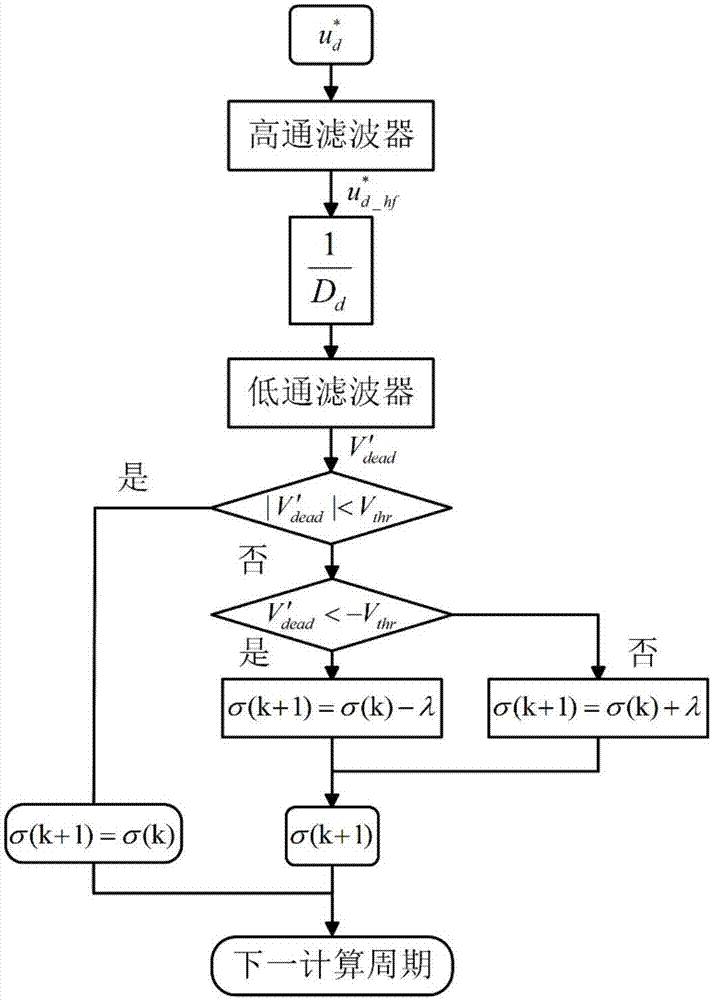

Non-linear compensation device and system for inverter, and control method

InactiveCN107276440AImplement Feedback ControlImprove dynamic output stabilityAC motor controlDc-ac conversion without reversalWave shapeClosed loop

The invention discloses a non-linear compensation device and system for an inverter, and a control method. The method comprises the steps: obtaining a compensated distortion voltage according to a d-axis component of a compensated voltage instruction and the voltage waveform data; obtaining a non-compensated distortion coefficient according to the d-axis component of the compensated voltage instruction and the d-axis component of the voltage waveform data; comparing the non-compensated distortion coefficient with a non-compensated distortion coefficient threshold range, and outputting a judgment result; obtaining a current feedback adjustment coefficient according to the judgment result and a former feedback adjustment coefficient; obtaining a compensation voltage through the current distortion voltage component and the feedback adjustment coefficient, and injecting the compensation voltage component into the non-compensated voltage instruction value, i.e., compensating for the nonlinearity of the inverter. According to the invention, the method achieves the nonlinear closed-loop compensation of the inverter, reduces the distortion degree of a voltage, and improves the control performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com