Continuous laser device spectral line width measurement device based on optical frequency comb

An optical frequency comb and laser technology, applied in spectrum investigation and other directions, can solve problems such as the detection of short-term stability and long-term stability of continuous laser linewidth, the reduction of fiber laser output power, and enhanced stimulated Brillouin scattering. , achieve the effect of suppressing the stimulated Brillouin scattering effect, simple structure, and avoiding complex adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

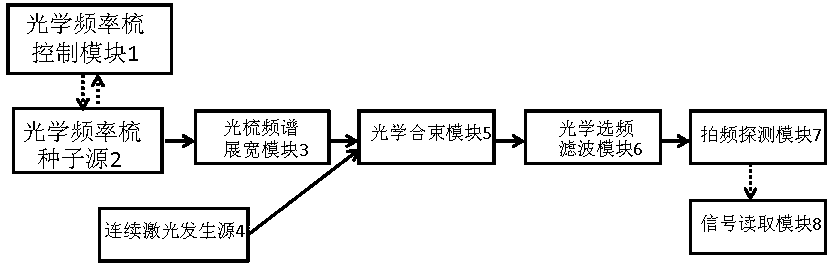

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

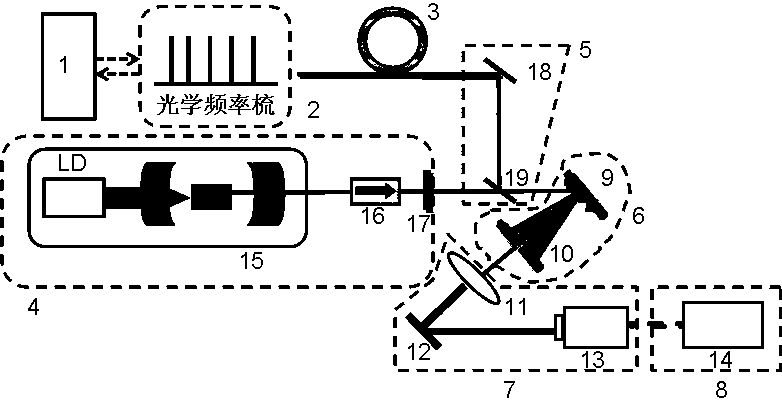

[0041] refer to figure 2 , is a schematic diagram of using a 1064nm solid-state laser as the laser to be tested to measure its output spectral width with an optical frequency comb. In the figure: 1-optical frequency comb control module; 2-optical frequency comb seed source; 3-optical frequency comb spectrum broadening module That is, photonic crystal fiber; 4-continuous laser source (composed of 1064nm continuous laser module 15, 1064nm polarization isolator 16, 1064nm space half-wave plate 17); 6-optical frequency-selective filtering module (consisting of 1 μm band reflective grating 9 and aperture diaphragm 10); 7-beat frequency detection module (consisting of converging lens 11, 1064nm high reflection mirror 12, Avalanche photodetector 13); 8-signal reading module (composed of fast Fourier transform analyzer 14).

[0042] Implementation details:

[0043] (1) The optical frequency comb seed source 2 outputs a highly stable mode-locked pulse sequence in the time domain and...

Embodiment 2

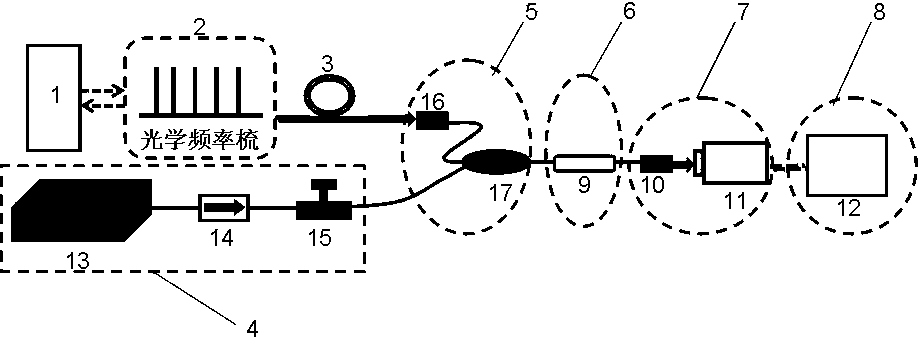

[0052] refer to image 3 , is a schematic diagram of using a 1550nm fiber laser as the laser to be tested to measure its output spectrum width with an optical frequency comb. In the figure: 1-optical frequency comb control module; 2-optical frequency comb seed source; 3-optical comb spectrum broadening module That is, photonic crystal fiber; 4-continuous laser source (composed of 1550nm continuous laser module 13, 1550nm fiber isolator 14 and fiber polarization controller 15); 5-optical beam combination module (composed of fiber collimator 16, 1550nm band optical fiber coupler 17); 6-optical frequency selection filter module (composed of 1550nm band fiber narrowband filter 9); 7-beat frequency detection module (composed of fiber collimator 10, avalanche photodetector 11); 8-signal A reading module (consisting of an electrical filter and a data acquisition card 12).

[0053] Implementation details:

[0054] (1) The optical frequency comb seed source 2 outputs a highly stable ...

Embodiment 3

[0065] refer to Figure 4 , is a schematic diagram of simultaneously measuring the output linewidth of two CW lasers at 657nm and 423nm with an optical frequency comb. In the laser frequency standard module based on calcium atoms, it is necessary to excite calcium ions with a beam of 423nm laser first to make it achieve the laser transition at the energy level of 657nm, so real-time measurement and control of the linewidth of 423nm and 657nm laser is very important. In the figure: 1-optical frequency comb control module; 2-optical frequency comb seed source; 3-optical comb spectrum broadening module is photonic crystal fiber; 4-continuous laser generation source (consisting of 423nm continuous laser module 20, visible light band polarization isolator 22. Visible light band half-space wave plate 24 and lens group 10); 4 , - Continuous laser source (composed of 657nm continuous laser module 21, visible light band polarization isolator 23, visible light band space half-wave plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com