Omnidirectional wheel and rubber wheel composite type three-wheel robot chassis

An omnidirectional wheel and compound technology, applied in the field of robots, can solve the problems of limited carrying capacity, shaking of robots, difficult control, etc., and achieve the effects of low manufacturing cost, stable motion and wide usable range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The object of the present invention will be further described in detail through specific examples below.

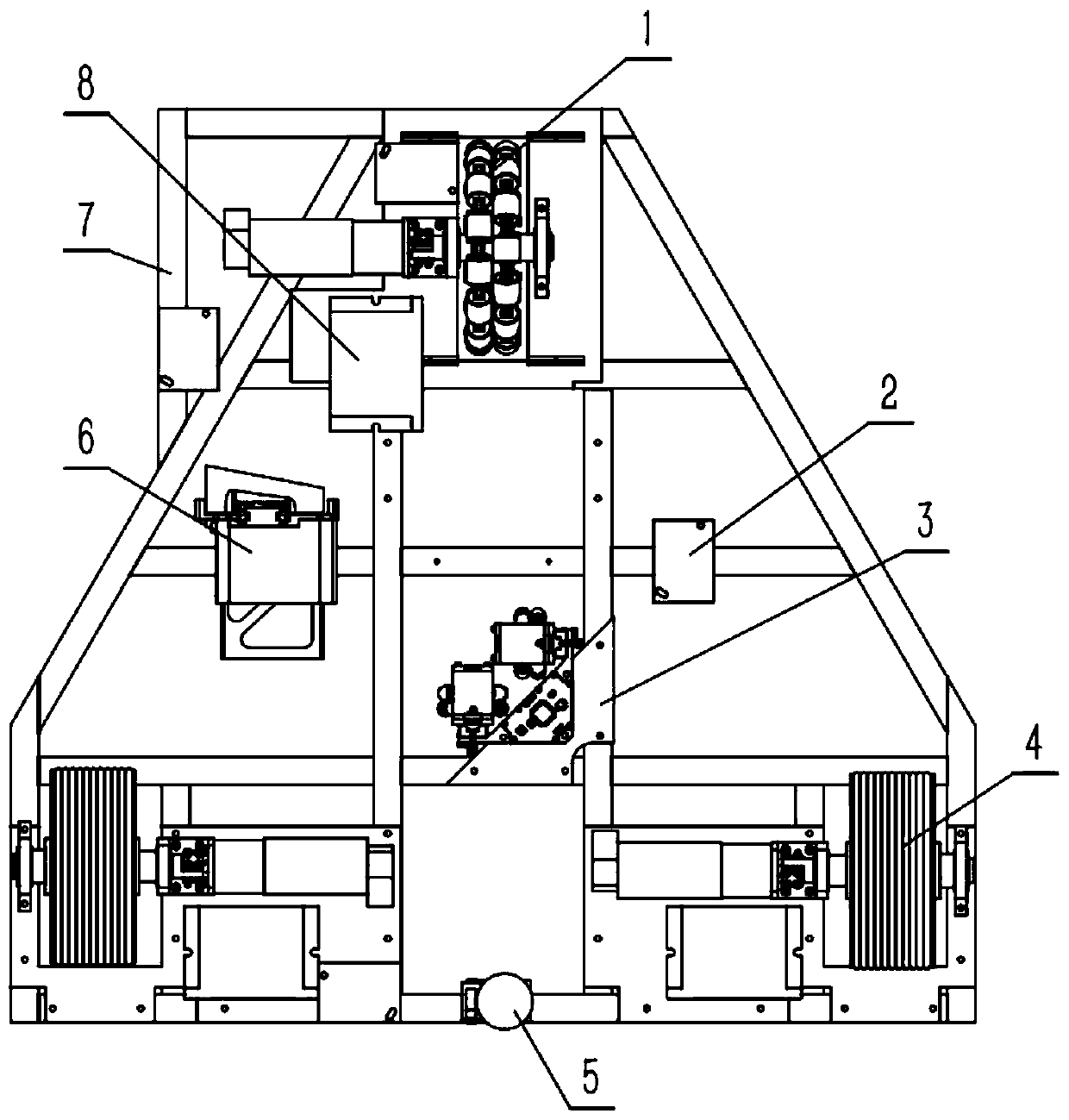

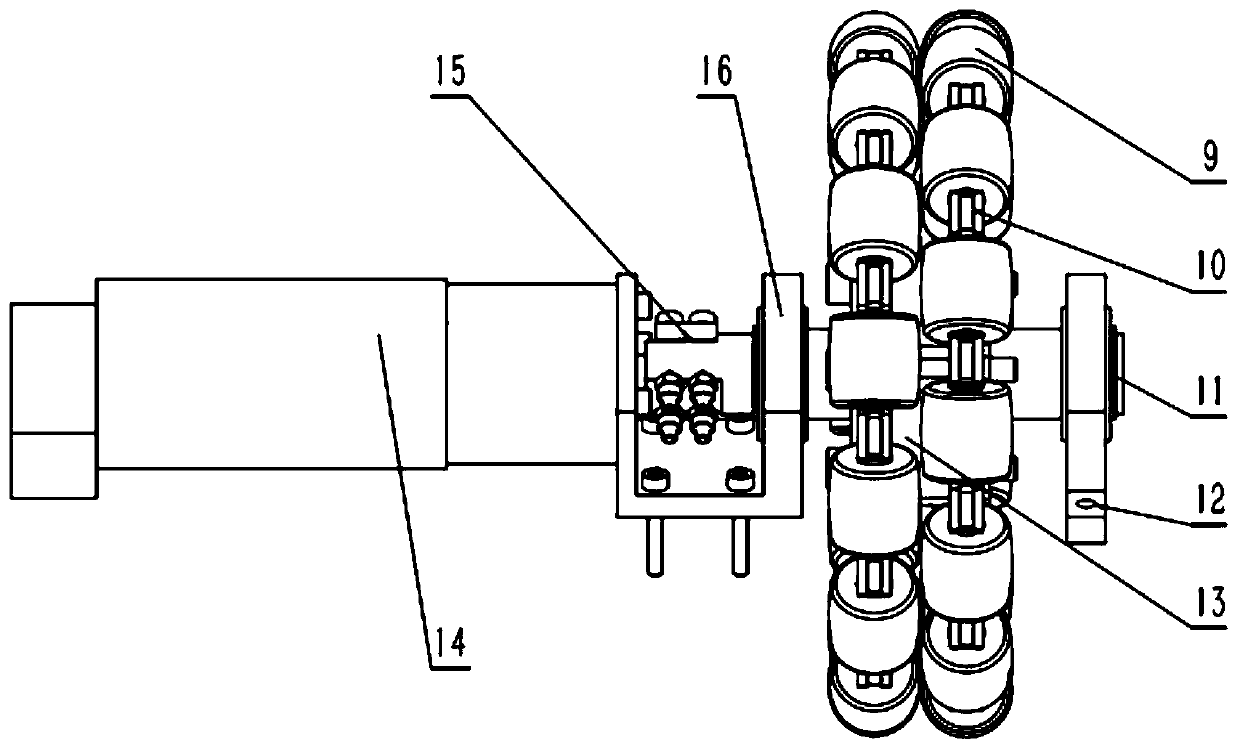

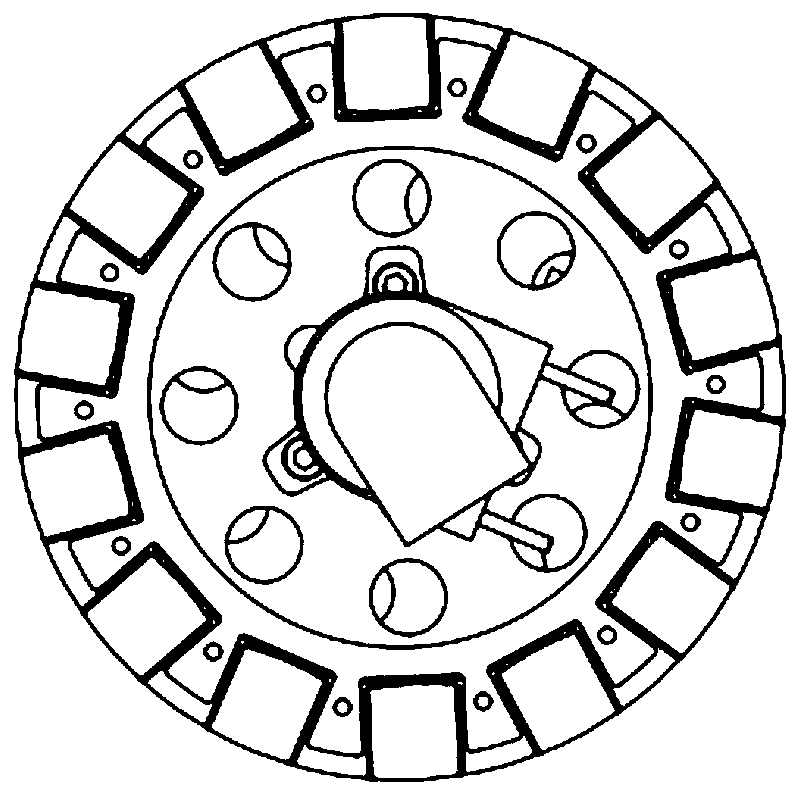

[0041] Such as figure 1 As shown, a composite three-wheel robot chassis with omnidirectional wheels and rubber wheels includes:

[0042] The chassis frame, the chassis frame includes an aluminum tube bottom frame 7, the aluminum tube bottom frame 7 is mainly welded by several square aluminum tubes, and is arranged at the bottom of the chassis frame;

[0043] An omnidirectional wheel mechanism 1, installed on the front end of the chassis frame;

[0044] Two groups of silicone wheel mechanisms 4 are symmetrically installed on the rear end of the chassis frame and are distributed in an isosceles triangle with the omnidirectional wheel mechanism 1;

[0045] The wheel set gyroscope 3 is fixedly installed in the middle of the chassis frame, and is used for real-time feedback of the position and the distance traveled;

[0046] A laser sensor 2, the laser sensor 2 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com