Device and method for detecting friction force of continuous casting crystallizer on line

A technology of continuous casting mold and detection device, which is applied to the configuration of indicating equipment/measuring equipment, casting equipment, manufacturing tools, etc., can solve the problems of difficult determination of vibration system parameters, cumbersome work of acceleration sensor, poor practicability and reliability, etc. , to achieve the effect of small workload, strong practicability and small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

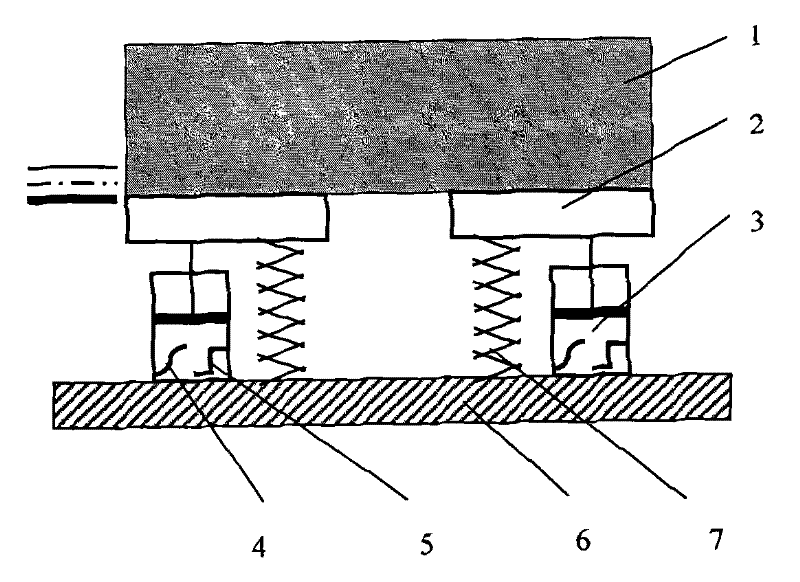

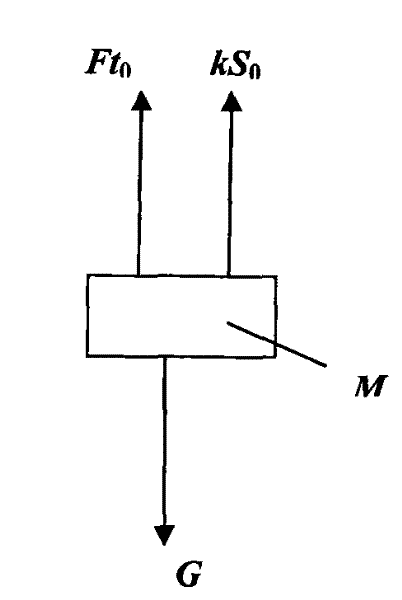

[0058] figure 1 It is a structural schematic diagram of the vibration system. As shown in the figure, the crystallizer 1 is installed on the vibration table 2, and two symmetrical hydraulic cylinders 3 are arranged on both sides below the vibration table. The two hydraulic cylinders are rigidly connected directly with the vibration table. A pressure sensor 4 and a displacement sensor 5 are installed on the cylinder to detect the working pressure and displacement of the hydraulic cylinder. The lower ends of the two hydraulic cylinders are connected with the vibrating table base 6, and a buffer spring 7 is installed between the vibrating table and the vibrating table base. The thick solid line on the left side of the figure represents the lower limit of vibration, the dotted line represents the vibration balance position, and the thin solid line represents the upper limit of vibration. The vibration system vibrates up and down around the preset vibration balance position, which c...

Embodiment 2

[0119] The casting machine used in this example is the same slab test casting machine as in Example 1, the difference is that the inclination of the crystallizer vibration curve is 20°, that is, in the non-sinusoidal vibration mode, the amplitude is 5.0mm, and the air vibration process The vibration frequency is gradually increased from 50cpm to 150cpm, and the casting speed is controlled at 0.8~2.2m / min. The implementation steps and test results are as follows:

[0120] The first step is to detect the average value Ft of the output force of the hydraulic cylinder when it is still at the vibration balance position 0

[0121] Detect the output force of the hydraulic cylinder within 8 minutes, and calculate the average value of the output force Ft 0 =18.80kN;

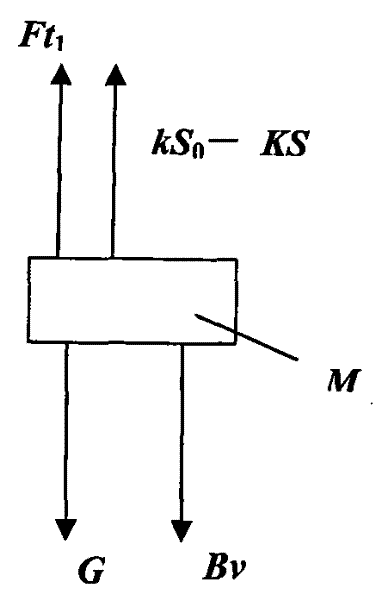

[0122] The second step is the determination of the comprehensive stiffness K and equivalent damping B in the air vibration state

[0123] The approximate linear relationship between the comprehensive stiffness K and t...

Embodiment 3

[0130] The casting machine used in this example is a thin slab test casting machine, which produces a thin slab with an end face of 1000mm×80mm, and the total mass of the crystallizer and the vibrating table is 25.8t. The crystallizer vibration mode is non-sinusoidal vibration with a deflection of 40°, the amplitude is 2.2mm, the vibration frequency gradually increases from 90cpm to 195cpm during the empty vibration process, and the casting speed is controlled at 1.0~3.0m / min. The implementation steps and test results are as follows :

[0131] The first step is to detect the average value Ft of the output force of the hydraulic cylinder when it is still at the vibration balance position 0

[0132] Detect the output force of the hydraulic cylinder within 10 minutes, and calculate the average value of the output force Ft 0 =14.22kN;

[0133] The second step is the determination of the comprehensive stiffness K and equivalent damping B in the air vibration state

[0134] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com