Two-pass shape memory alloy thermal-mechanical functional fatigue test device

A technology of memory alloy and fatigue characteristics, which is applied in the direction of measuring devices, strength characteristics, and the use of repeated force/pulsation force to test the strength of materials, etc., can solve the problems of alloy microstructure changes, structural damage, and reduce service life, etc. High performance, easy control and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

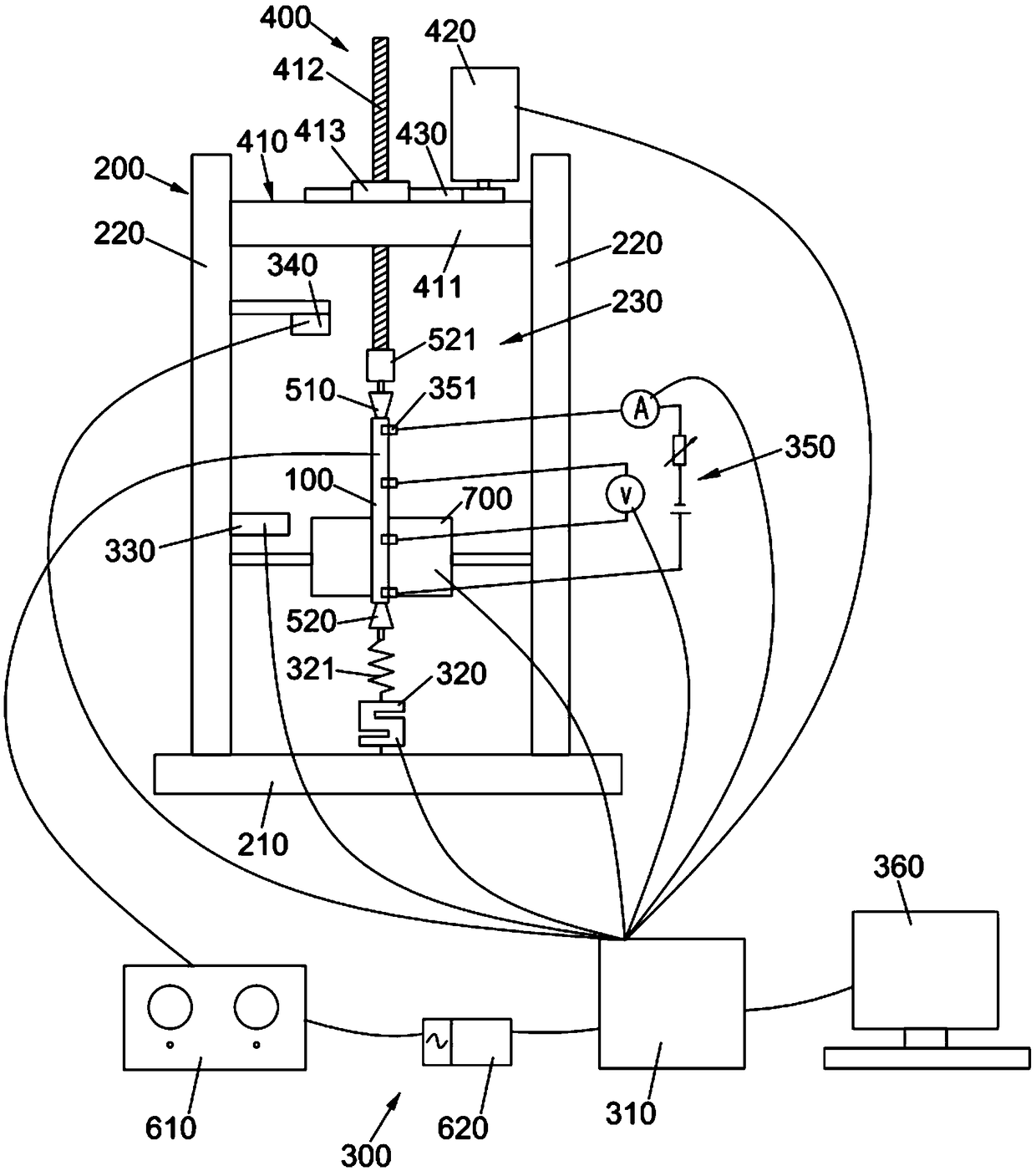

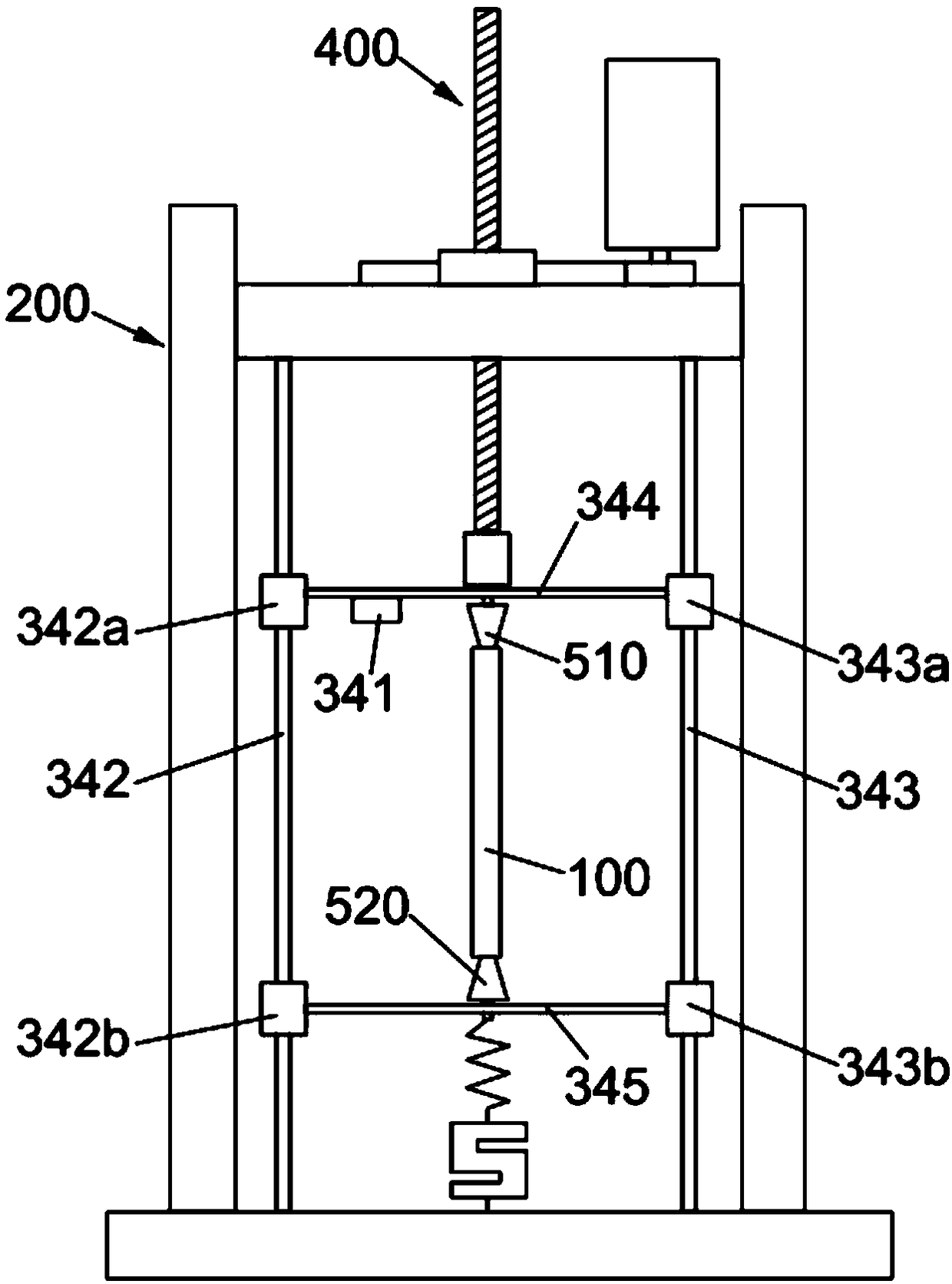

[0031] Please refer to figure 1, the present embodiment provides a dual-pass shape memory alloy thermo-mechanical functional fatigue performance testing device, including a frame 200, a data acquisition control system 300, a mechanical loading assembly 400, a clamping assembly and a power control system. The frame 200 includes a bottom plate 210 and two side plates 220 opposite to one side of the bottom plate 210 . The mechanical loading assembly 400 includes a lead screw slide 410 and a stepping motor 420, the lead screw slide 410 is arranged between two side plates 220, the bottom plate 210, the side plates 220 and the lead screw slide 410 enclose a synthetic test space 230, and the screw The lead screw 412 of the bar slide 410 extends to the testing space 230 , and the stepper motor 420 is connected with the lead screw slide 410 for driving the lead screw 412 . The clamping assembly is arranged in the test space 230, and the clamping assembly includes a first clamping bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com