Printing method of 3D printer with three-dimensional graphic feedback system

A 3D printer and feedback system technology, applied in the field of 3D printing, can solve the problems of inability to feedback and control the printing effect, waste of debugging man-hours and materials, and semi-finished products that cannot be reused, so as to improve printing efficiency, improve efficiency, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

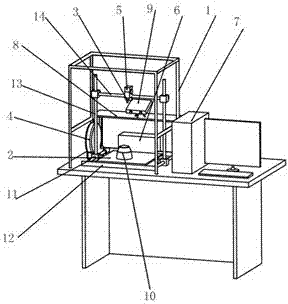

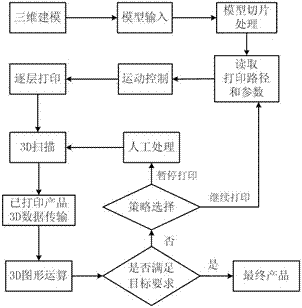

[0065] image 3 For the three-dimensional model A of the target product in Example 1, calculate and slice the three-dimensional model A, set the printing progress corresponding to 3D scanning in the generated slice file to 70%, then the control system reads the slice file, and starts from the first layer Layer-by-layer printing starts. When the printing progress reaches 70%, Figure 4 In order to control the system 6 to read the printed physical map when the scanning command is read, the control drive device remains in place, the temperature of the printing nozzle 3 is lowered, and the printing is suspended; at the same time, the 3D scanner is called to perform 3D scanning of the printed part 10, and the scanned data Synchronously sent to the computer 7, the computer establishes the three-dimensional model B of the printed part through image processing, such as Figure 5 shown.

[0066] The computer compares the 3D model B of the printed part with the 3D model A of the targ...

Embodiment 2

[0068] Figure 7 It is the three-dimensional model A of the target product in Embodiment 2. The difference between Embodiment 2 and Embodiment 1 is that the printing progress corresponding to the 3D scanning is set to 100%, and the 3D scanner is called to Figure 8 The printed object is scanned and created Figure 9 The 3D model B of the computer comparison data is: E1%, indicating that the deviation between the printed product and the target product has exceeded the set value, and the system determines that the product needs to be processed manually. Figure 9 The printed physical 3D model and Figure 7 It can be seen from the 3D model A of the target product that the multi-printed part D mainly comes from the top of the model, and then the top is manually processed to obtain Figure 10 real thing, yes Figure 10 The real object is 3D scanned again to get Figure 11 In the 3D model B’, the computer continues to Figure 11 The 3D model B' of Figure 7 Compared with the 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com