Patents

Literature

49results about How to "Improve docking quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

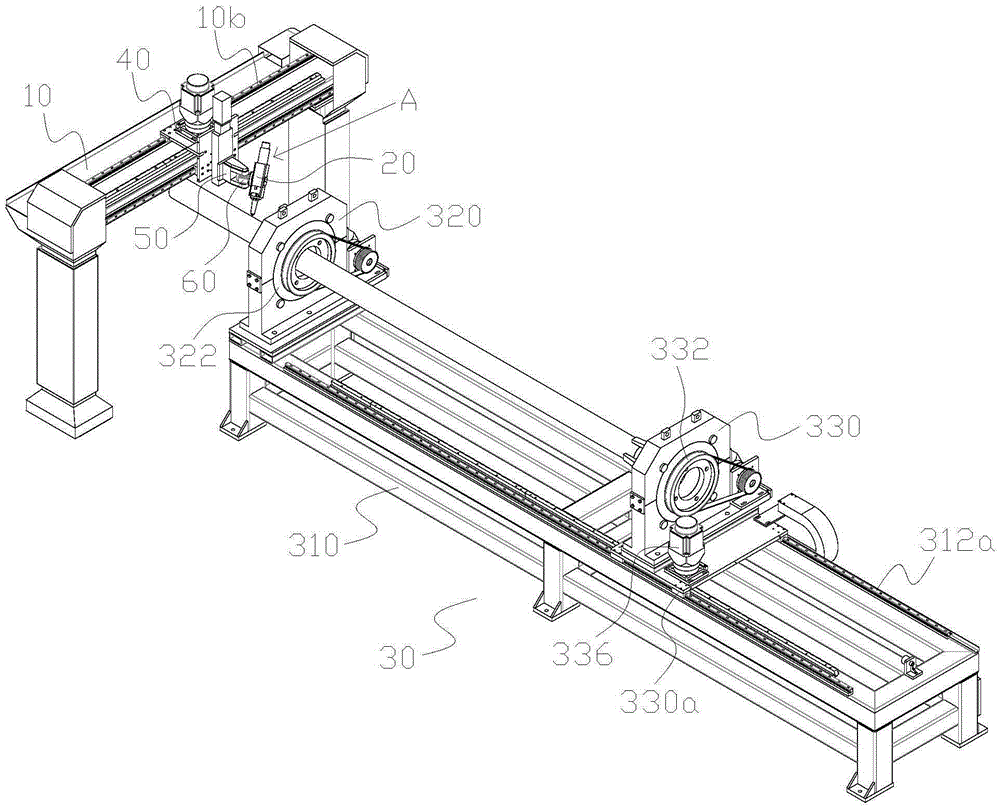

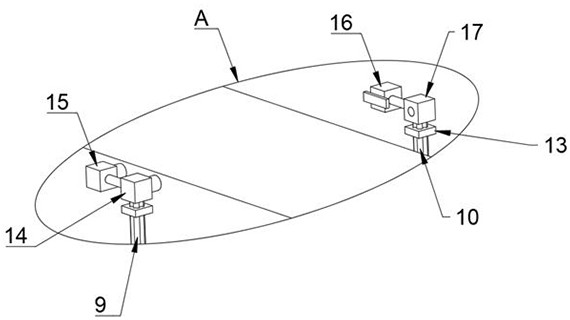

Laser pipe cutting machine and pipe cutting method thereof

InactiveCN105397306AFor precise cuttingAchieve multi-angle effectMetal working apparatusLaser beam welding apparatusVertical planeProgrammable logic controller

The invention discloses a laser pipe cutting machine and a pipe cutting method thereof. The laser pipe cutting machine comprises a portal frame, a laser cutting head, a fixing device and a PLC (programmable logic controller), wherein a first driving frame capable of moving on the horizontal X axis along the portal frame is arranged on the portal frame; a second driving frame capable of moving on the vertical Z axis along the first driving frame is arranged on the first driving frame; a rotating frame capable of horizontally rotating on the horizontal plane around the second driving frame is arranged on the second driving frame; and the laser cutting head is mounted on the rotating frame, and can vertically rotate on the vertical plane around the rotating frame. The laser pipe cutting machine can be used for rotationally cutting pipes from different angles, so that the pipes are cut precisely, the pipe abutting is smooth, and the abutting quality is high. According to the pipe cutting method of the laser pipe cutting machine, the pipes are cut precisely.

Owner:GUANGZHOU TONRY LASER EQUIP CO LTD

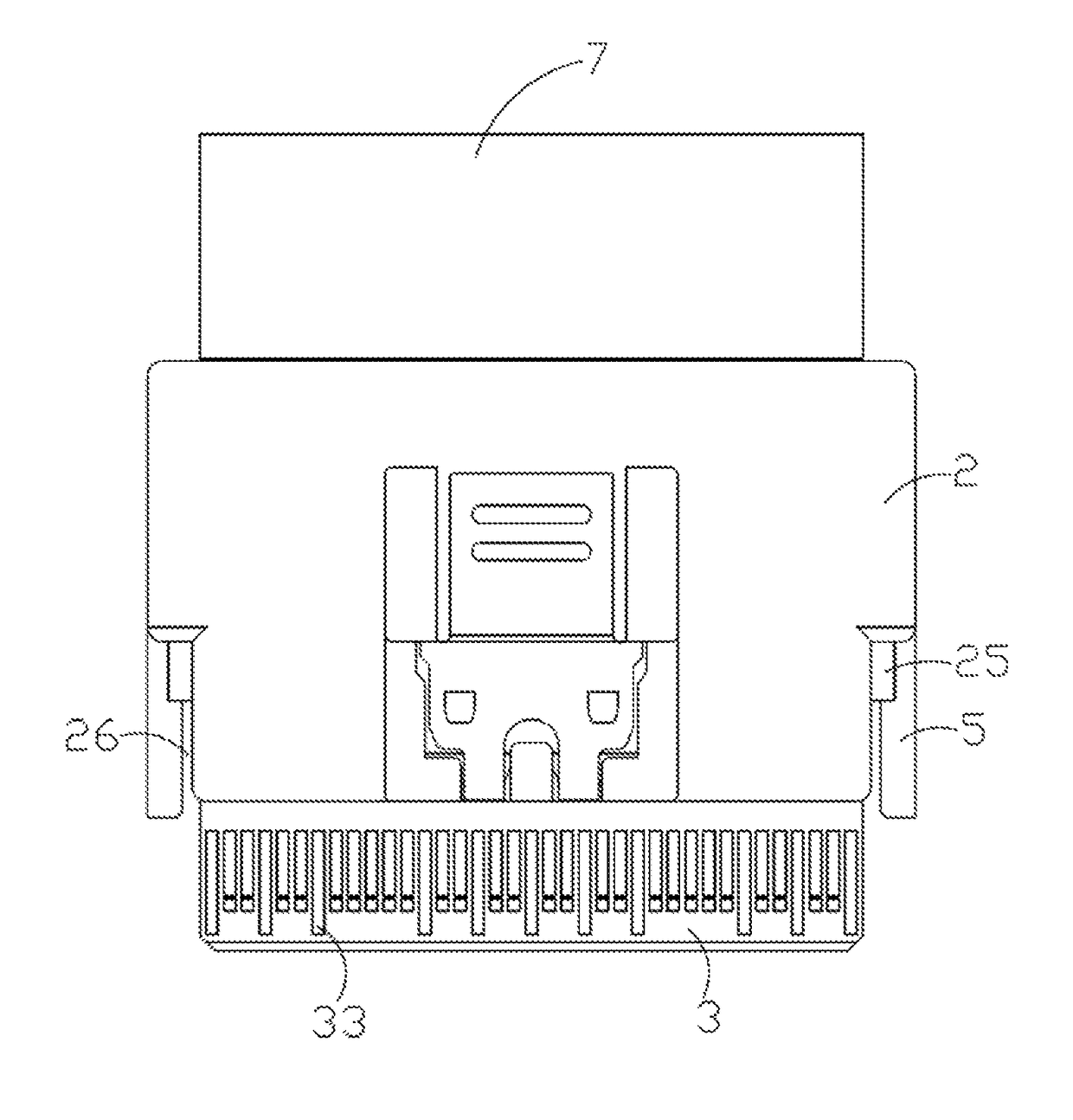

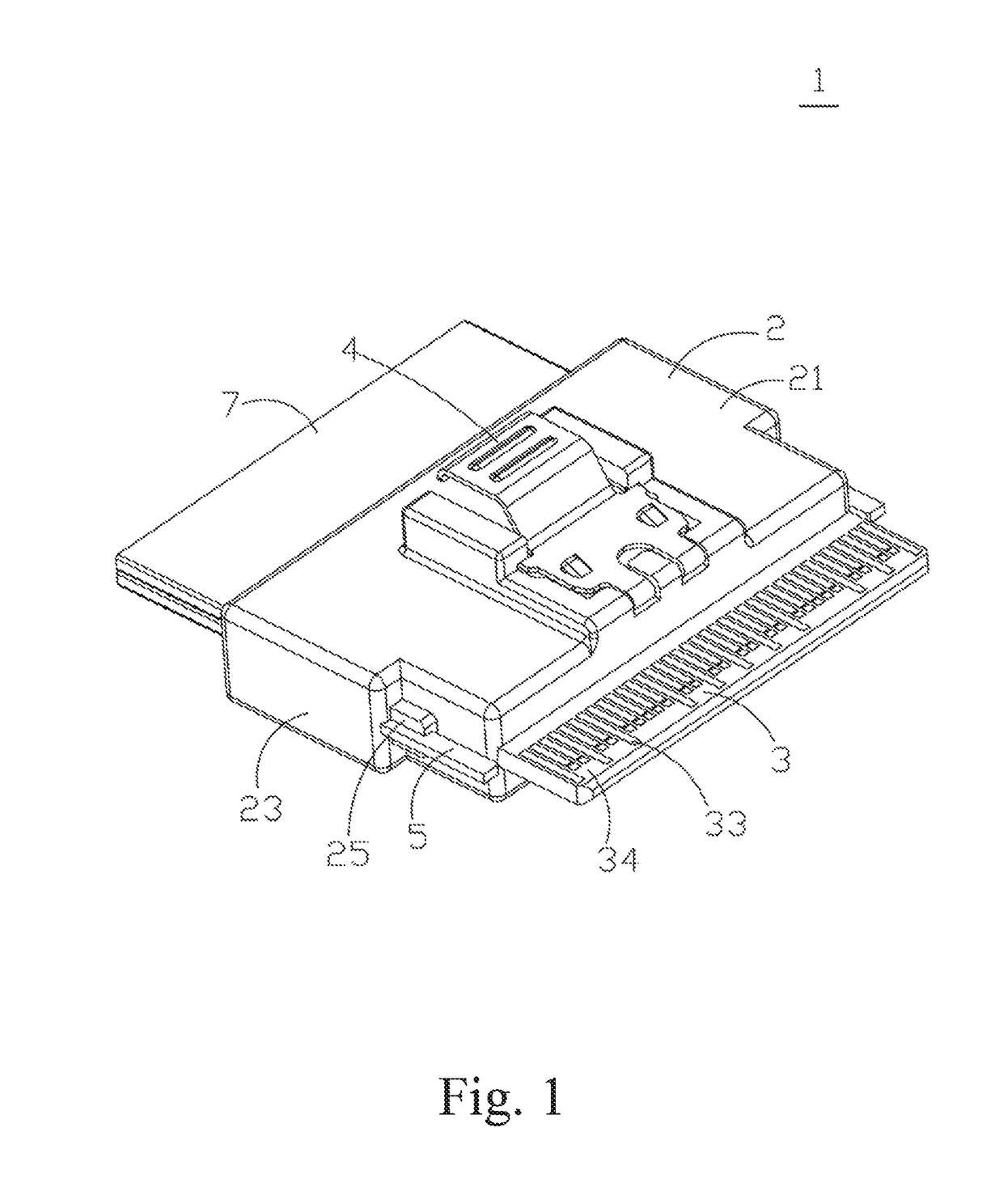

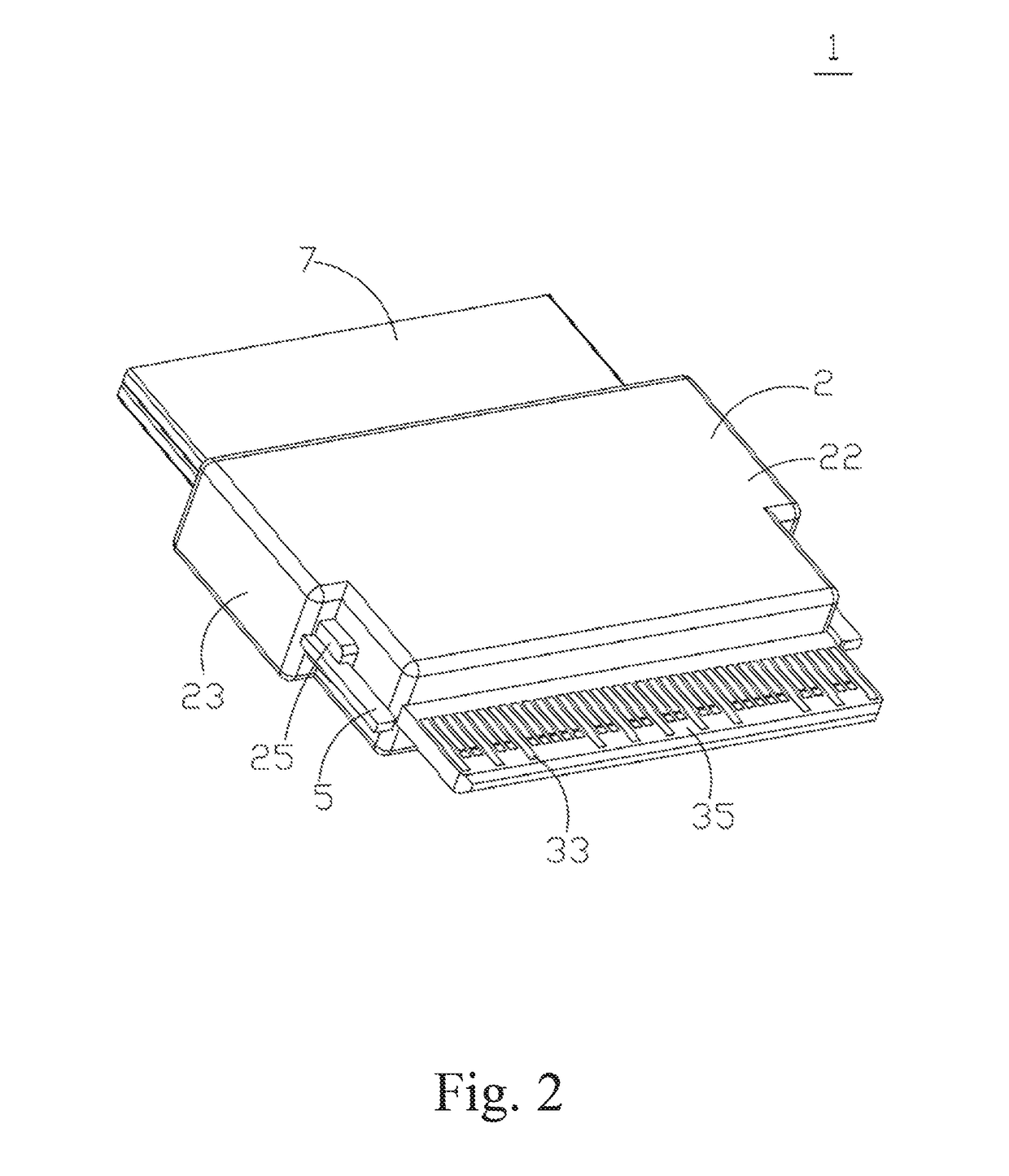

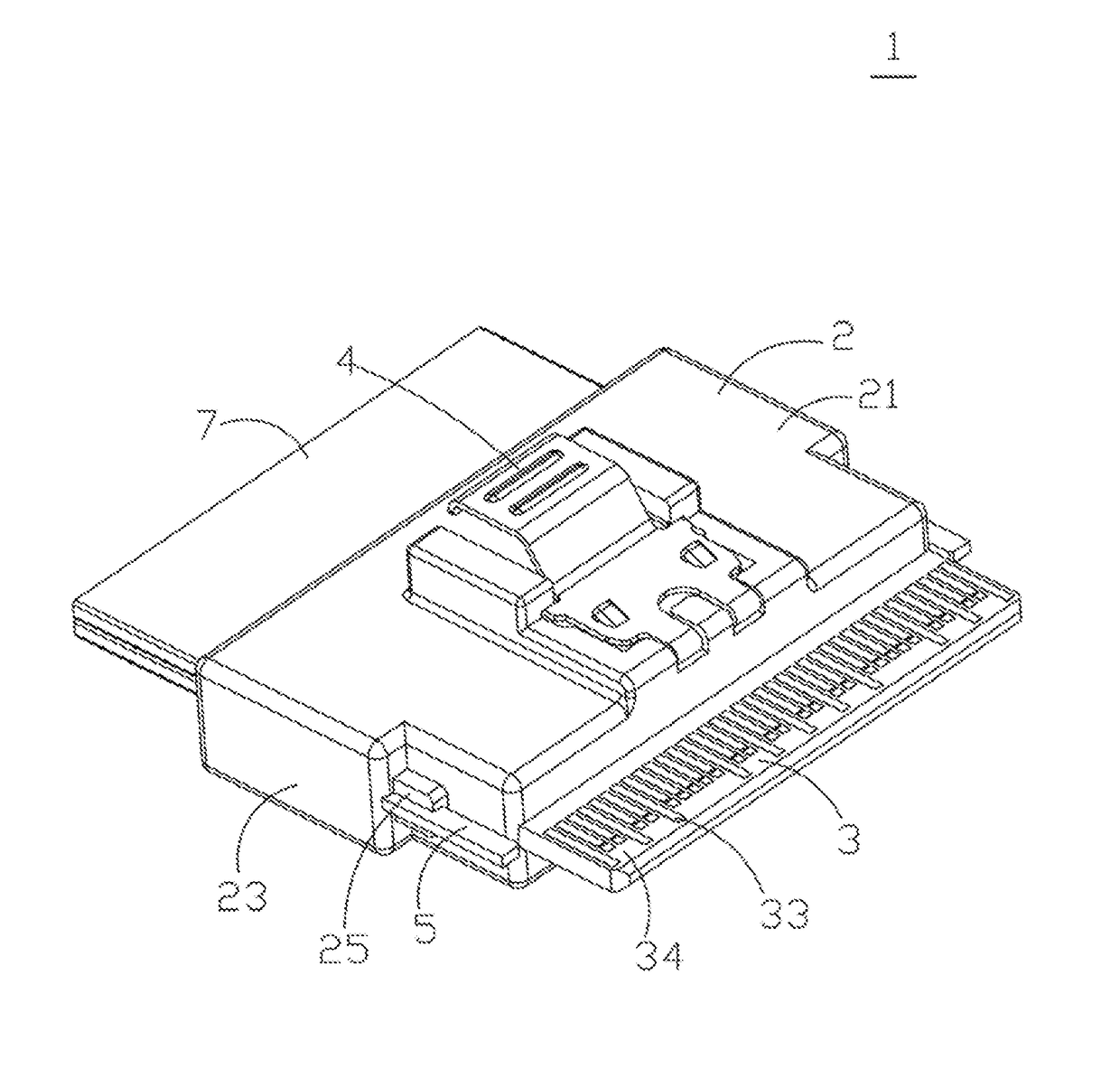

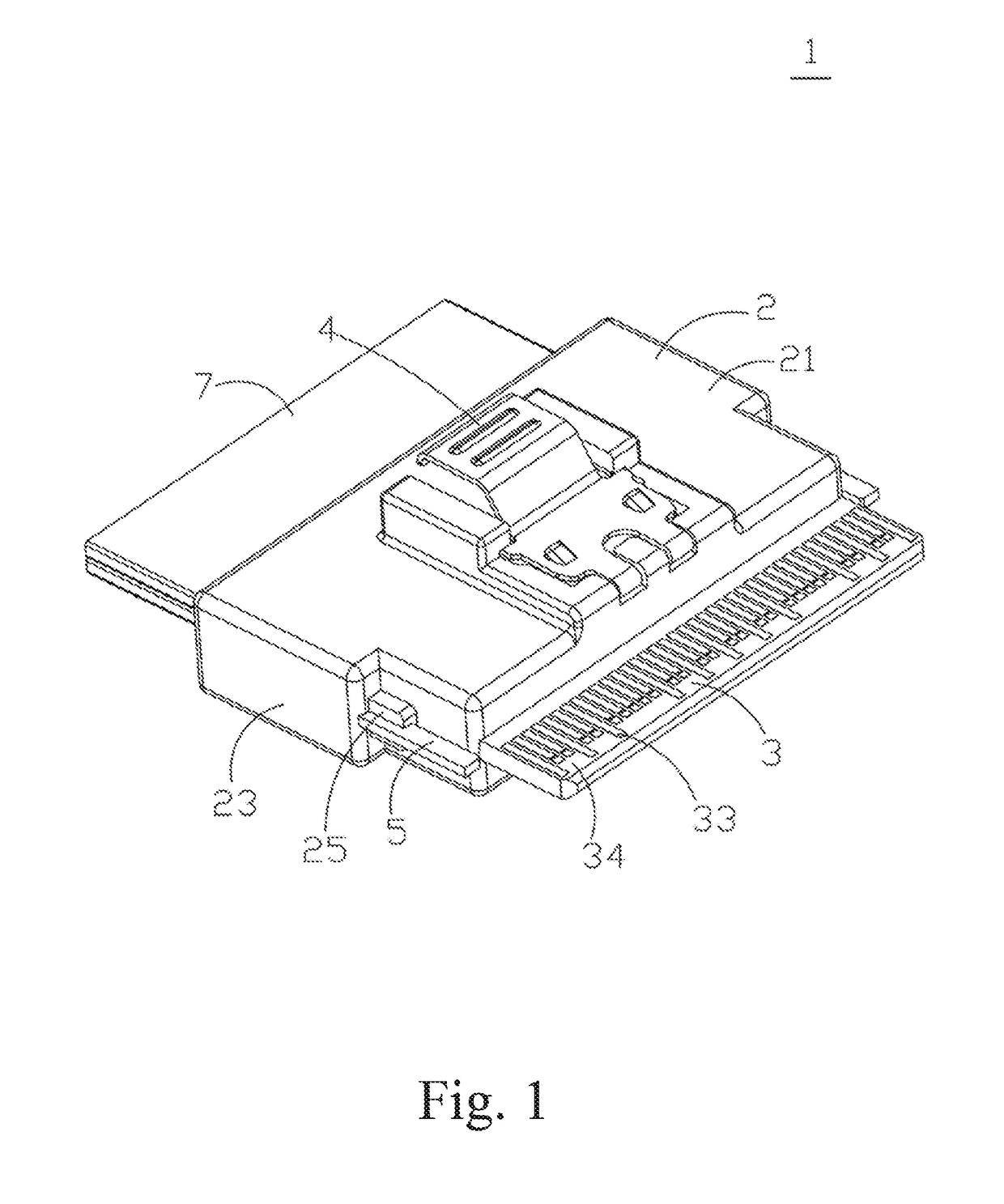

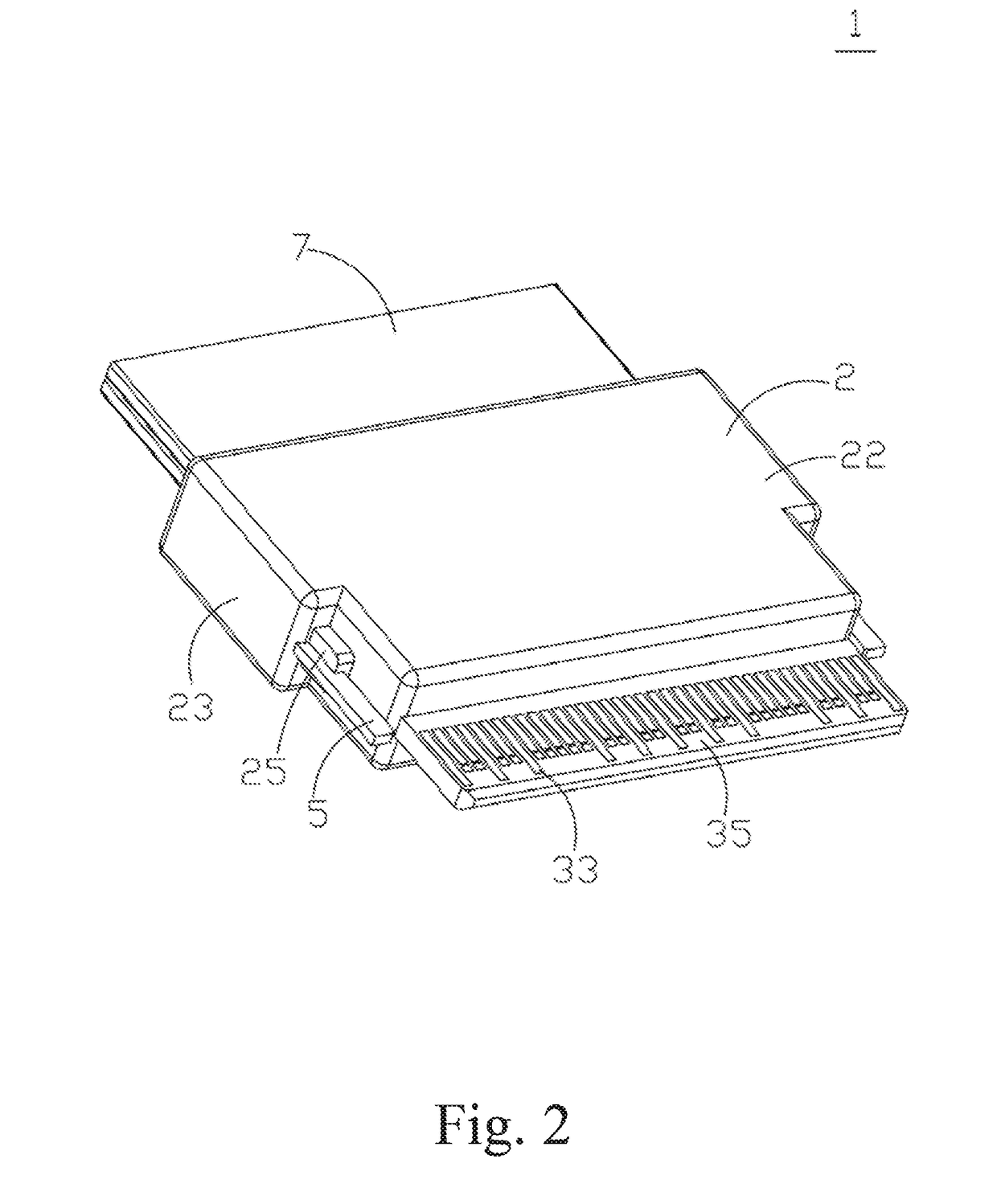

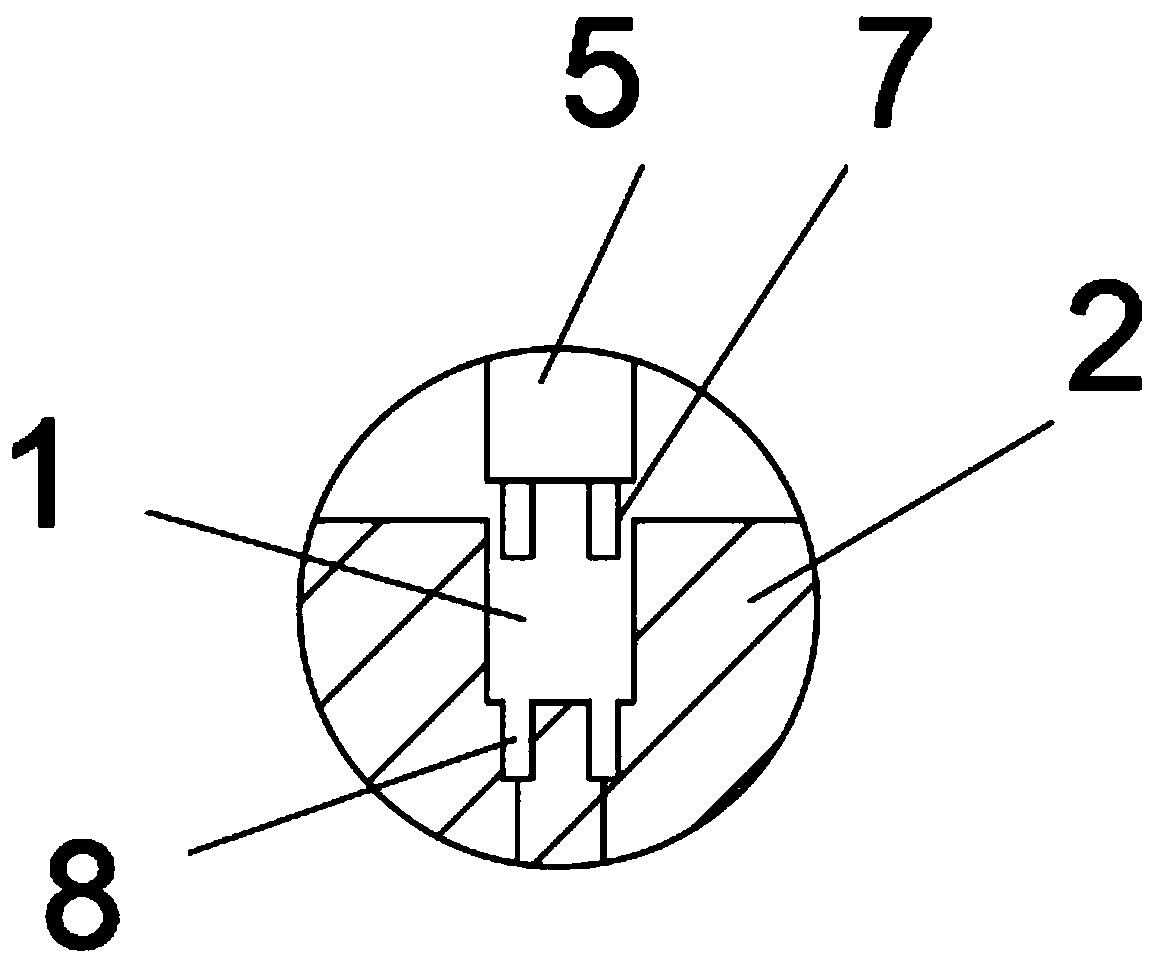

Connector

ActiveUS10096944B2Avoid damageImprove docking qualityIncorrect coupling preventionCoupling contact membersEngineeringElectrical and Electronics engineering

Owner:LUXSHARE PRECISION IND SHENZHEN

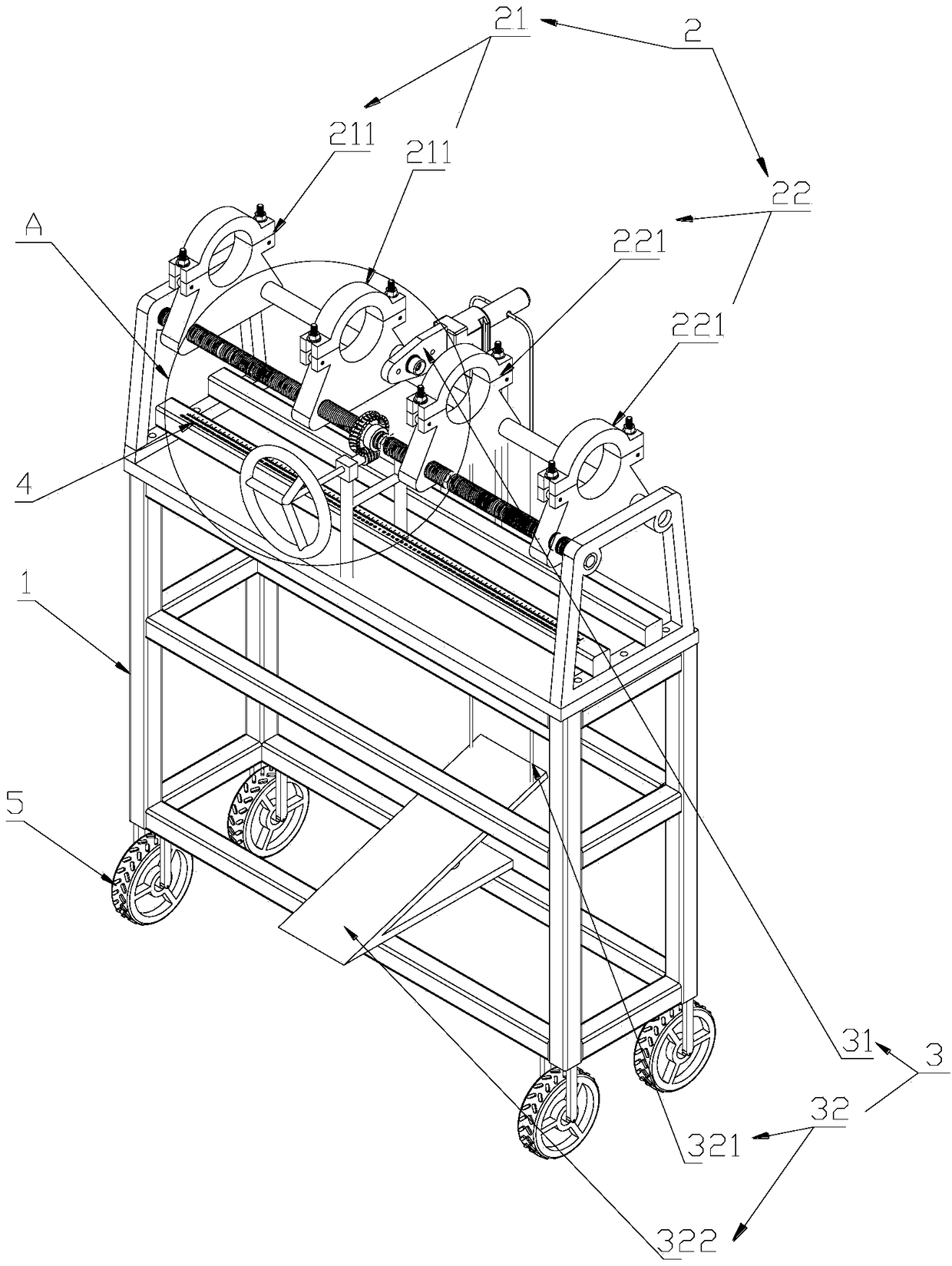

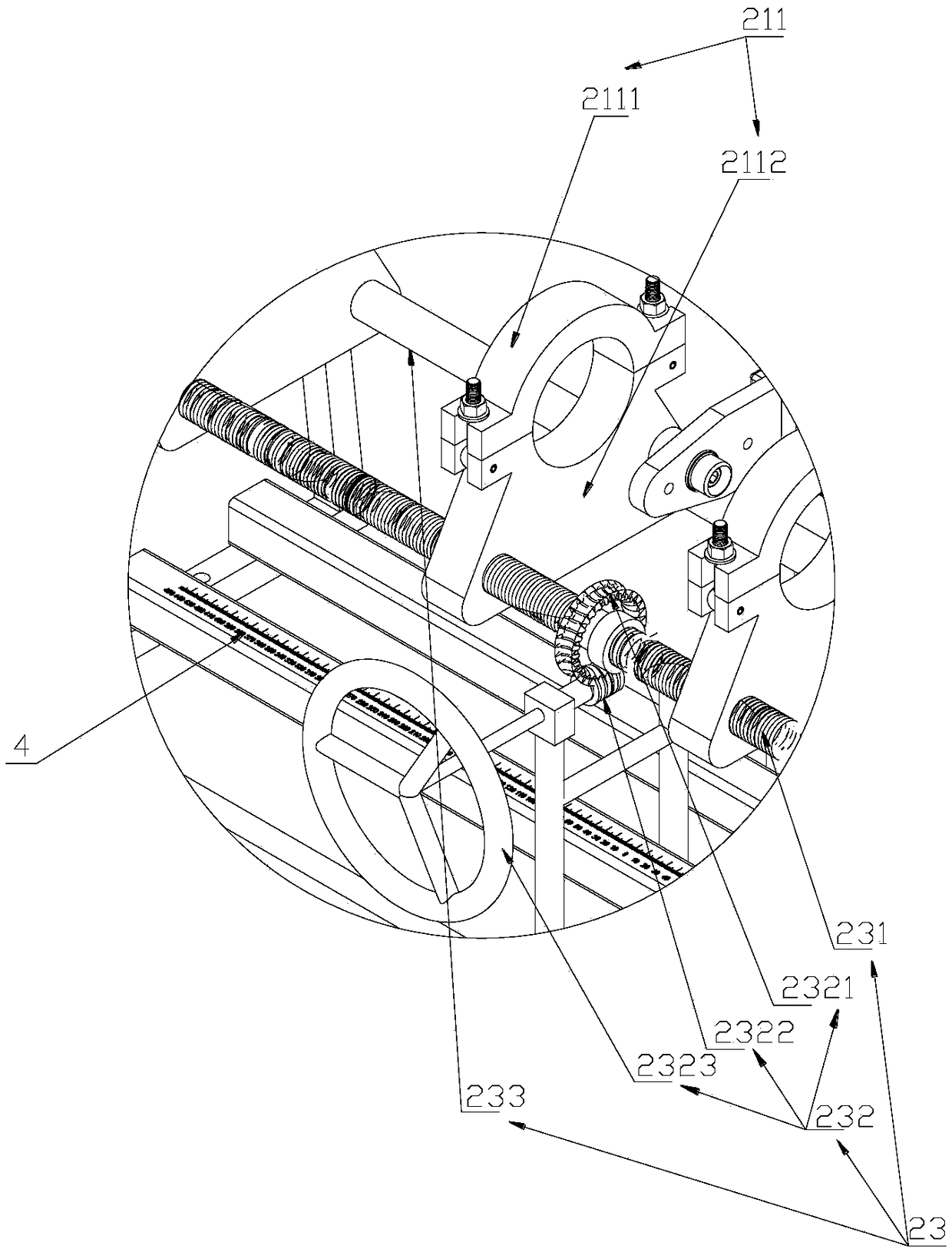

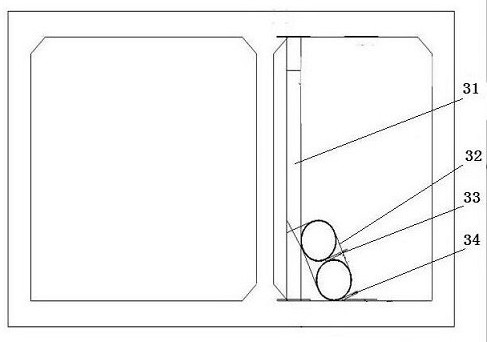

Pipe fitting hot melting butting device

The invention relates to the technical field of hot melting, in particular to a pipe fitting hot melting butting device. The butting device comprises a bracket, a pipe fitting clamping device and a hot melting device mounted on the bracket; the pipe fitting clamping device is used for clamping two pipe fittings to be handled, and the two pipe fittings are close to each other through the pipe fitting clamping device; and the hot melting device is used for heating the two ends, adjacent to each other, of the two pipe fittings to be handled. By means of the pipe fitting clamping device, the two pipe fittings to be handled are close to each other, the hand-held operation is improved, the device is convenient to operation, the safety is high, and the butting strength can be ensured, and the quantity production can be realized; the two pipe fittings to be handled are driven to be close to each other by rotating a hand wheel, and a hot melting machine is turned over driven by a pedal, so thatthe hands and feet are used together, so that the efficiency is improved; and as the two pipe fittings to be handled are close to each other, the butting distance is observed through a ruler, so thatthe butting quality is improved.

Owner:鸿翌科技有限公司

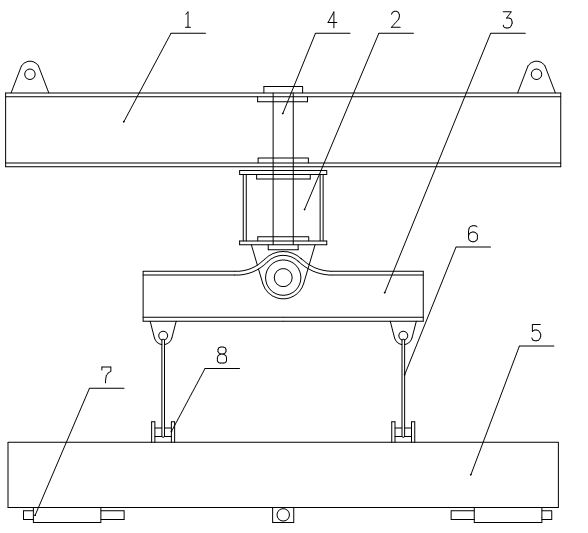

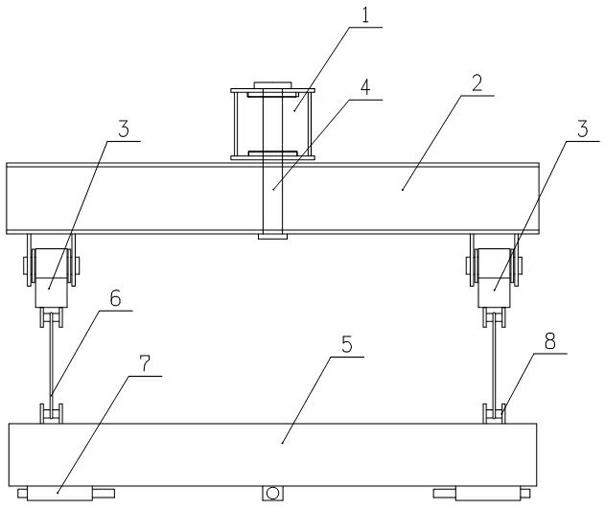

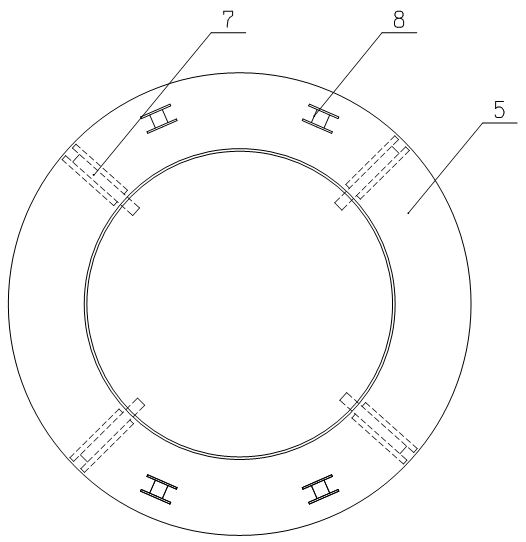

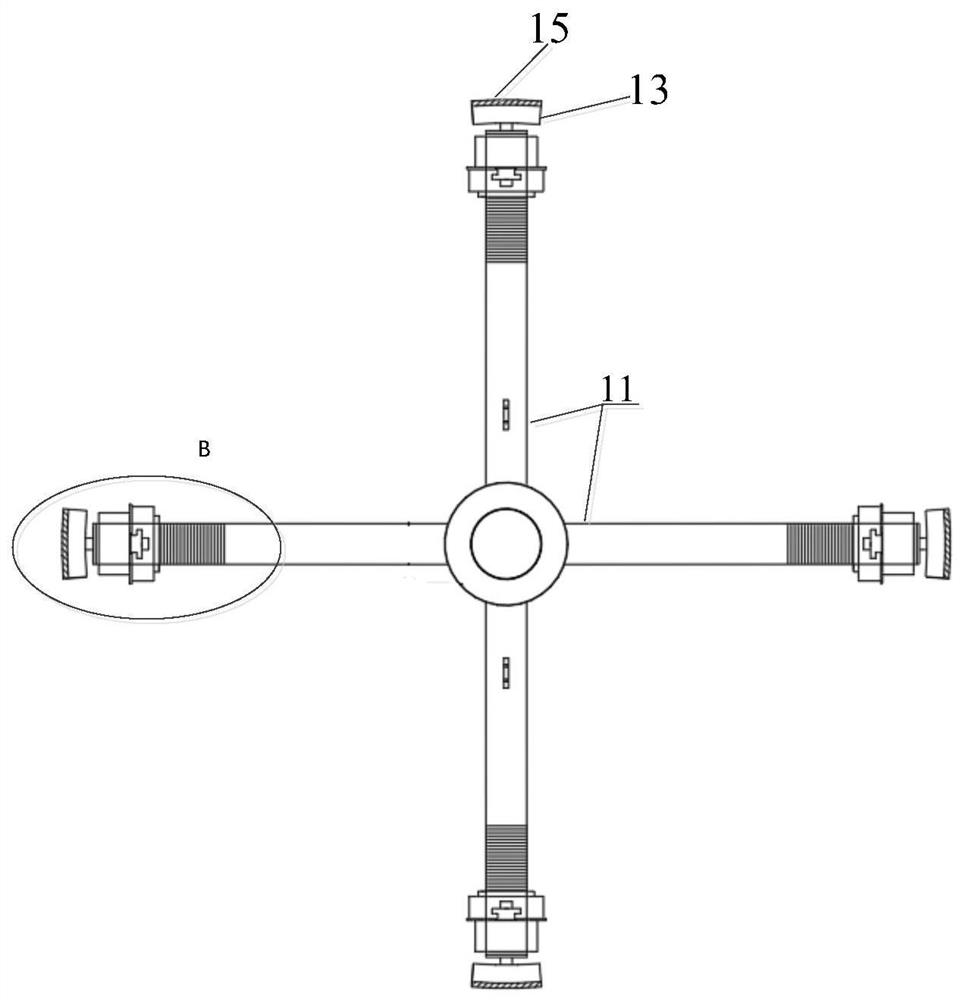

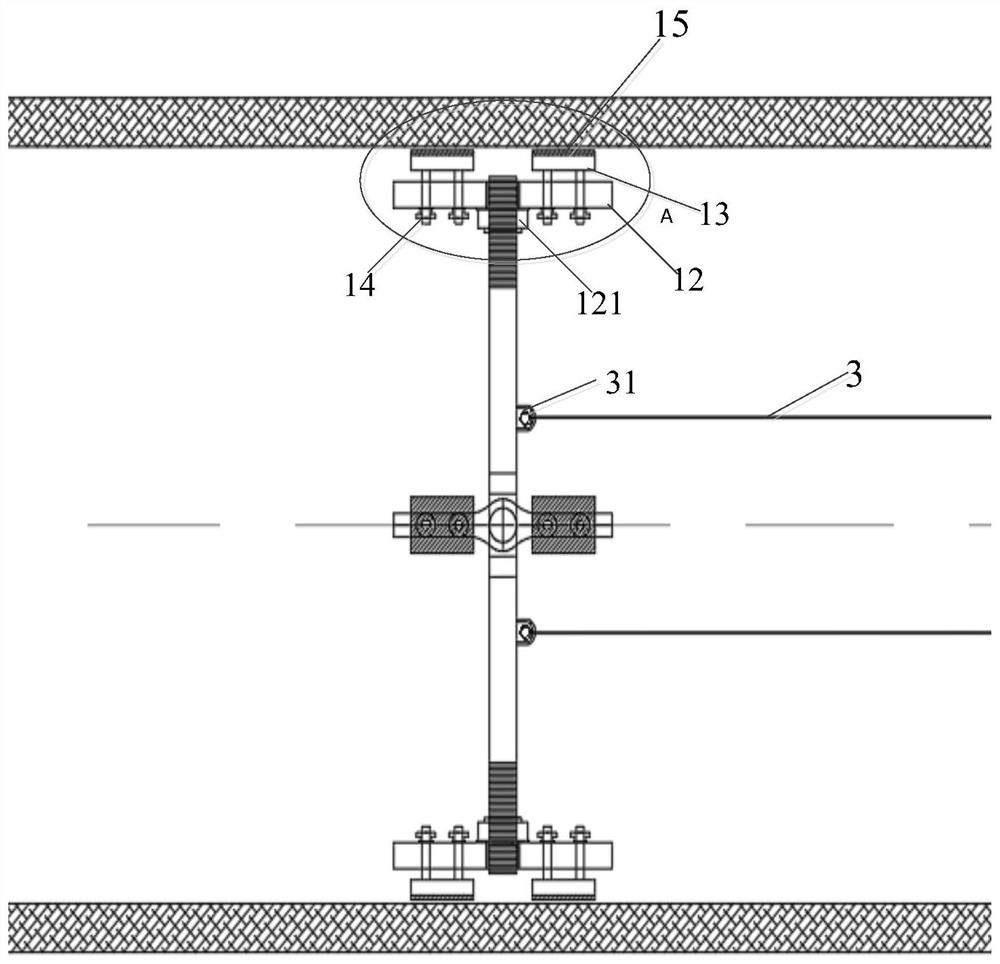

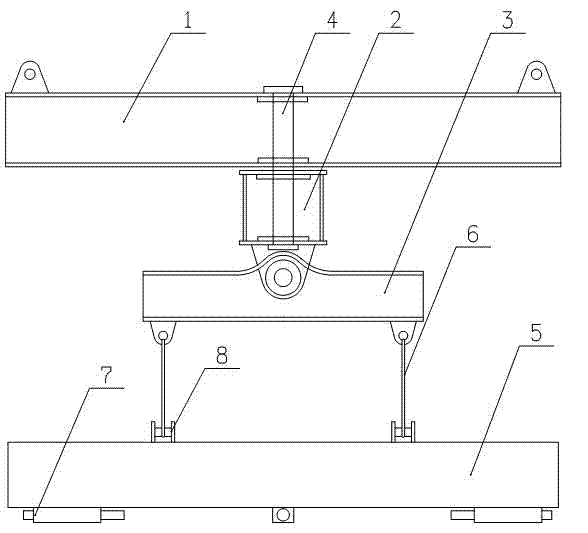

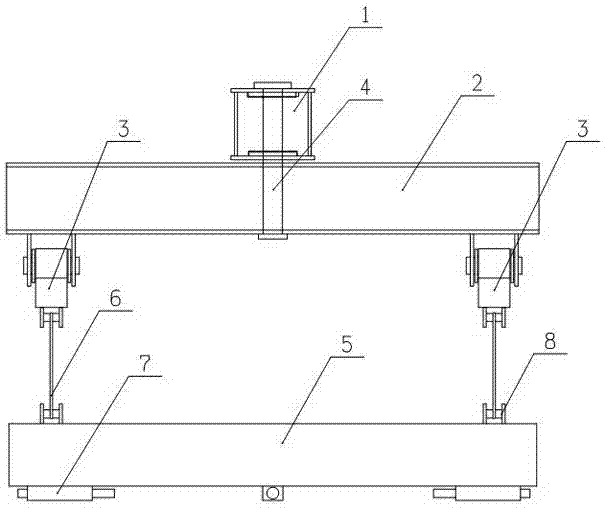

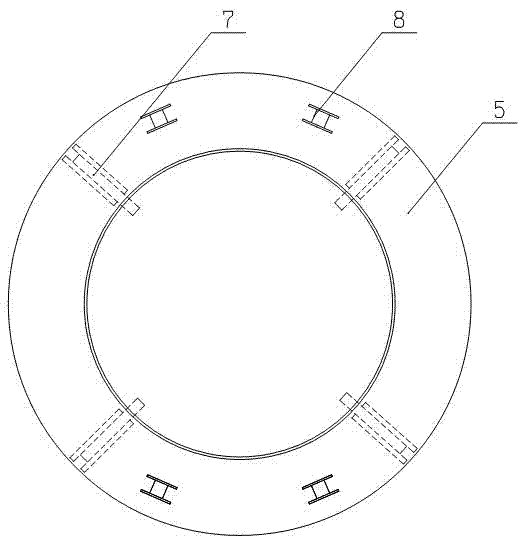

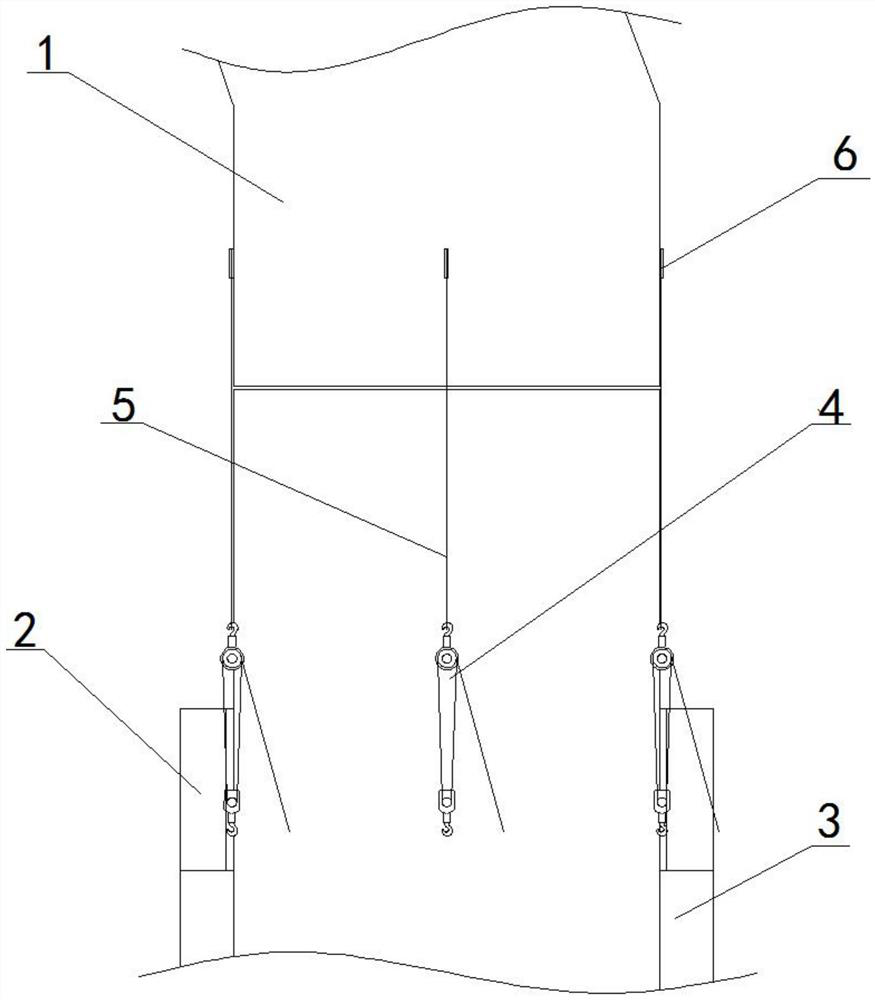

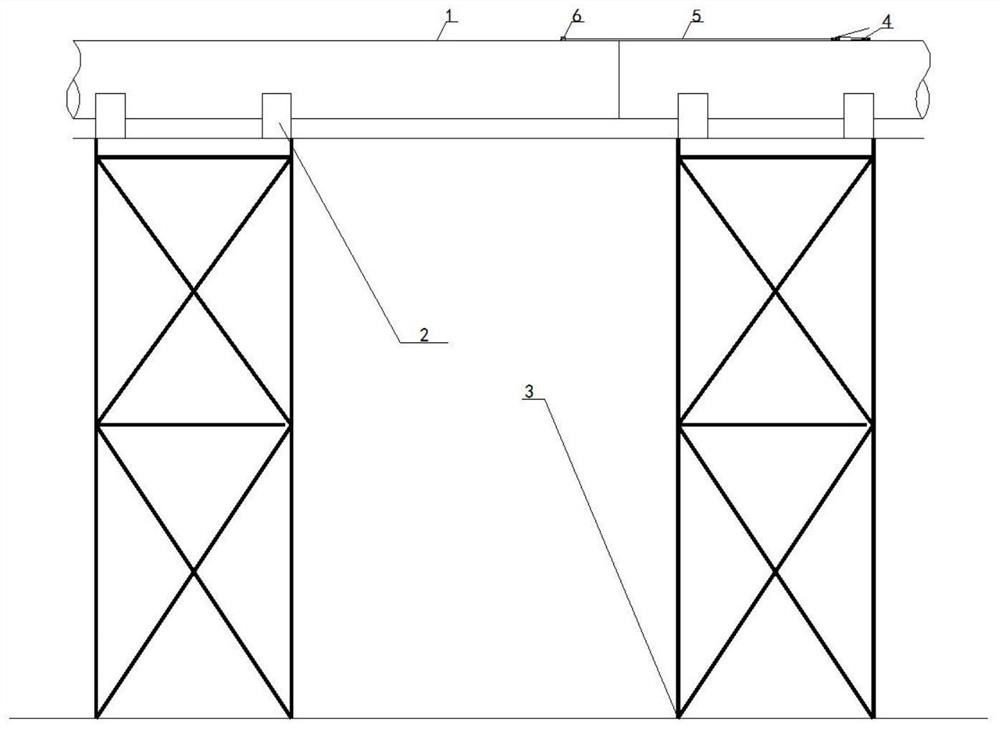

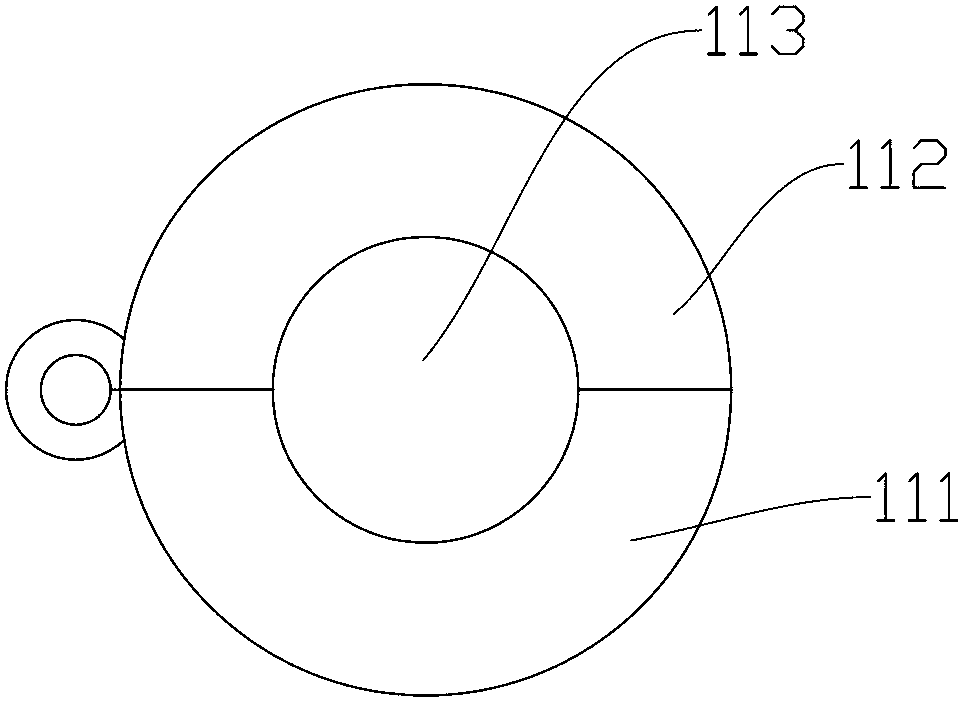

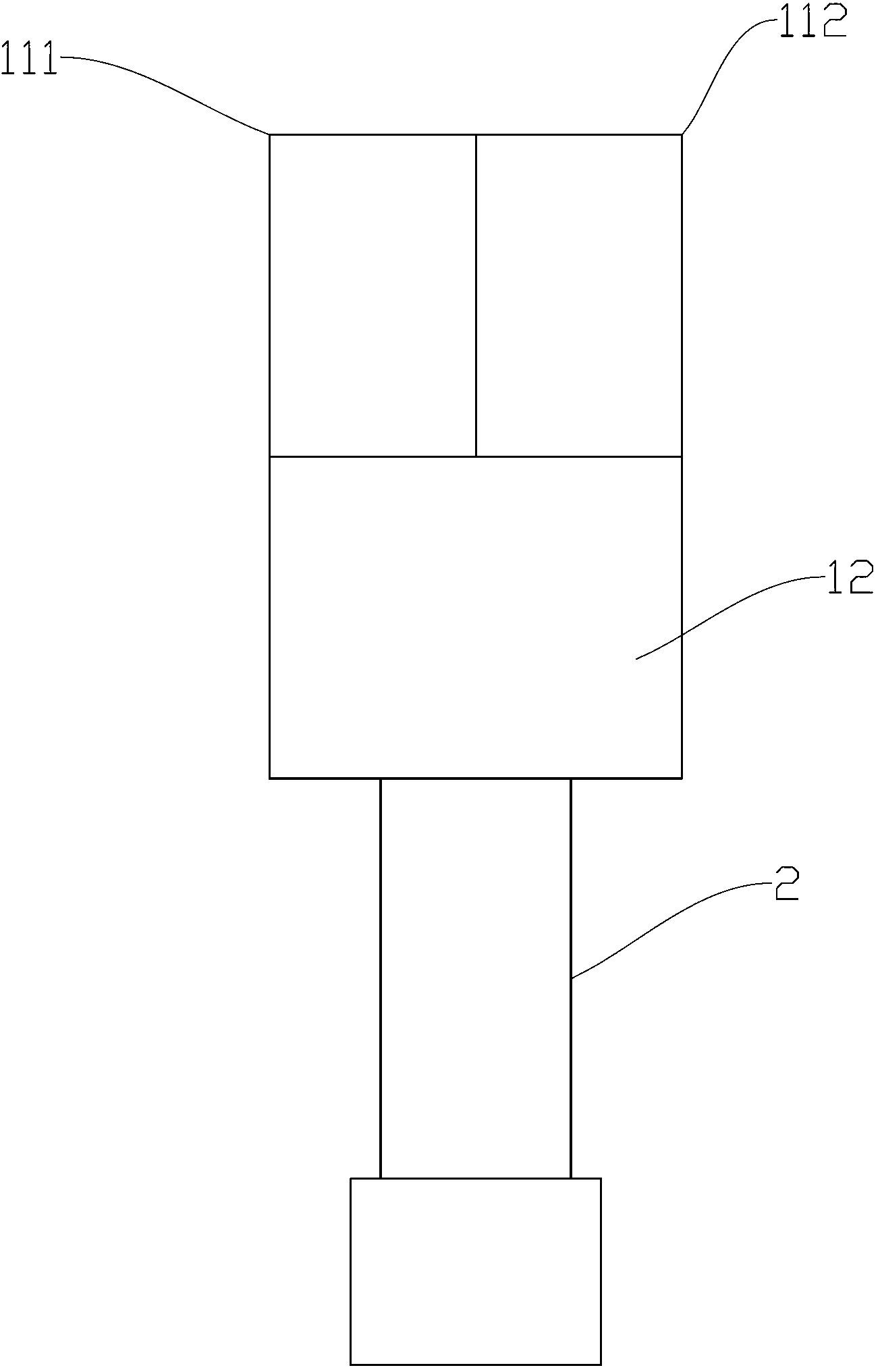

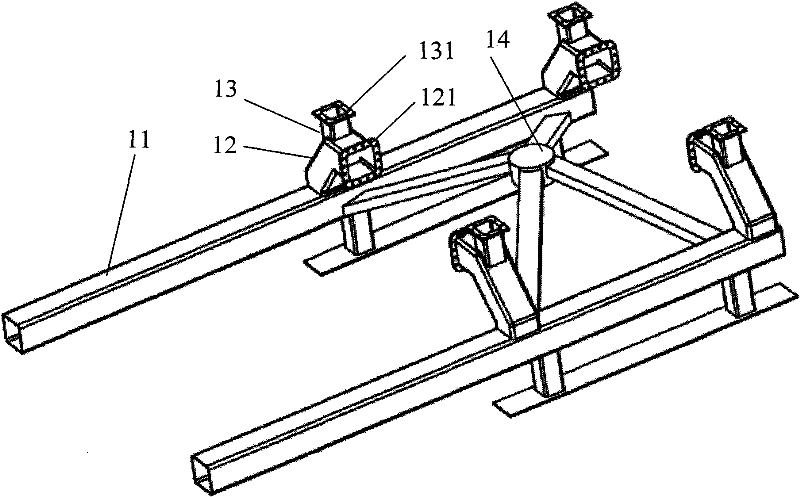

Reinforcement cage lifting device

The invention discloses a reinforcement cage lifting device, which comprises an upper beam, a middle beam, lower beams and an annular beam for connecting a reinforcement cage, wherein the two ends of the upper beam are fixed with a lifting lug for connecting a crane respectively; the middle beam is hinged to the center of the upper beam through a connecting shaft vertically inserted into the middle beam; the lower beams are hinged to the two ends of the middle beam through pin shafts horizontally inserted into the centers of the lower beams respectively; and the annular beam is horizontally suspended on the lower beams by corresponding suspenders. When in use, the reinforcement cage lifting device connects the reinforcement cage to the annular beam in a suspension way, and when the reinforcement cage is jointed, can conveniently drive the reinforcement cage to horizontally rotate, flexibly regulate the vertical angel of the reinforcement cage and ensure the verticality of the reinforcement cage in a jointing process to easily and rapidly finish the jointing of the reinforcement cage, increase the jointing speed of the reinforcement cage and improve the jointing quality of the reinforcement cage by hinging fit among the upper, middle and lower beams, thereby ensuring the progress and quality of pile foundation construction.

Owner:HENAN MINE CRANE

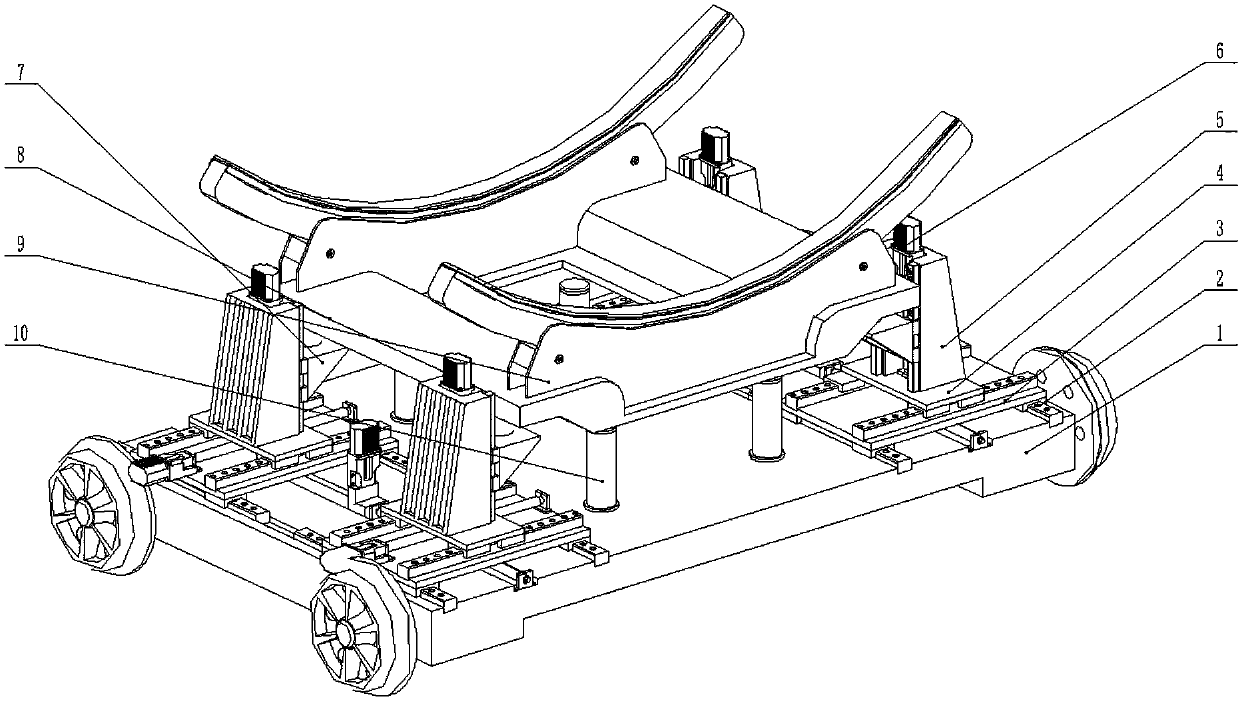

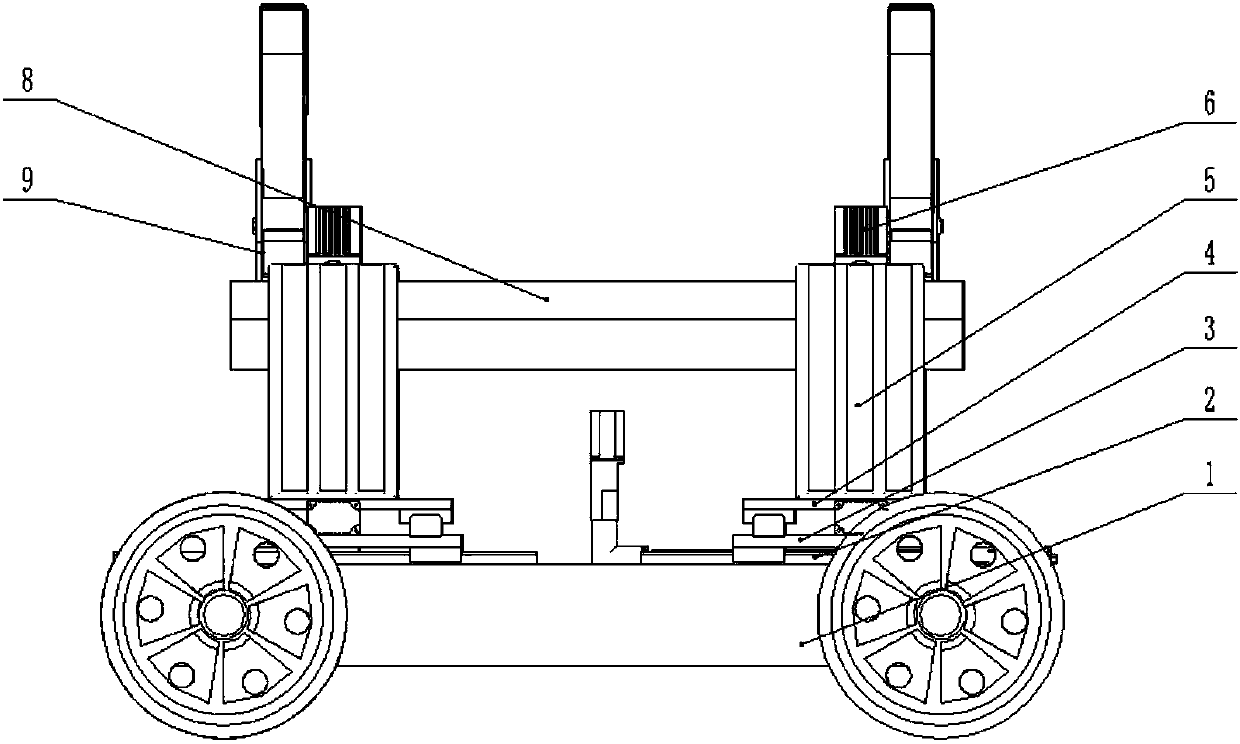

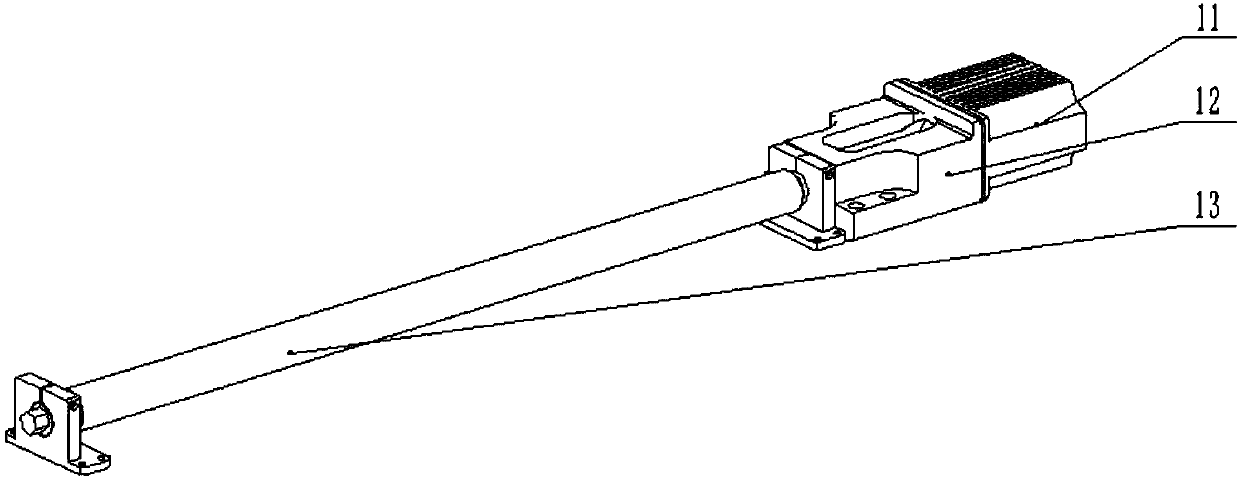

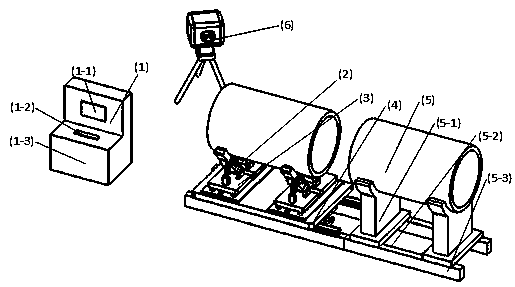

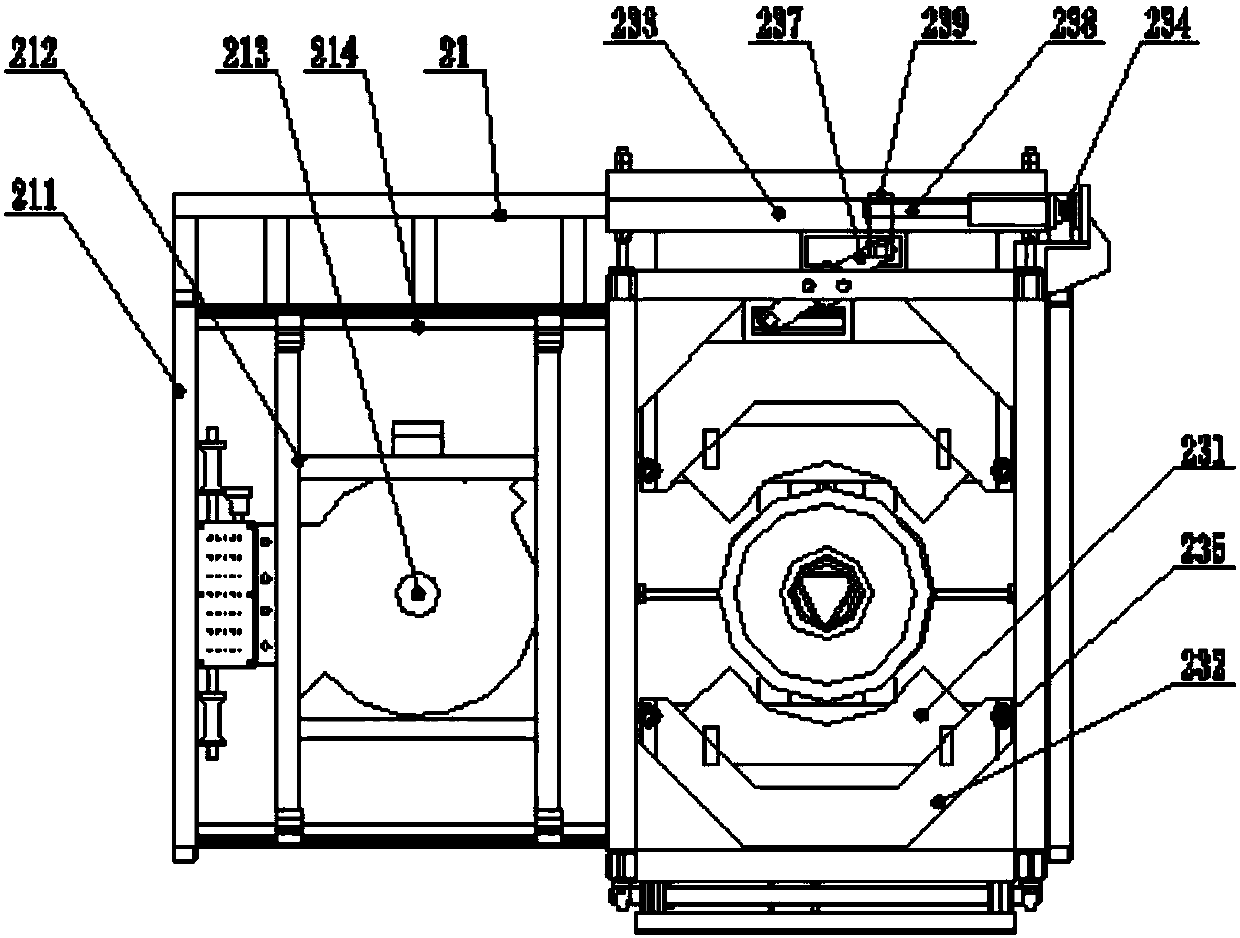

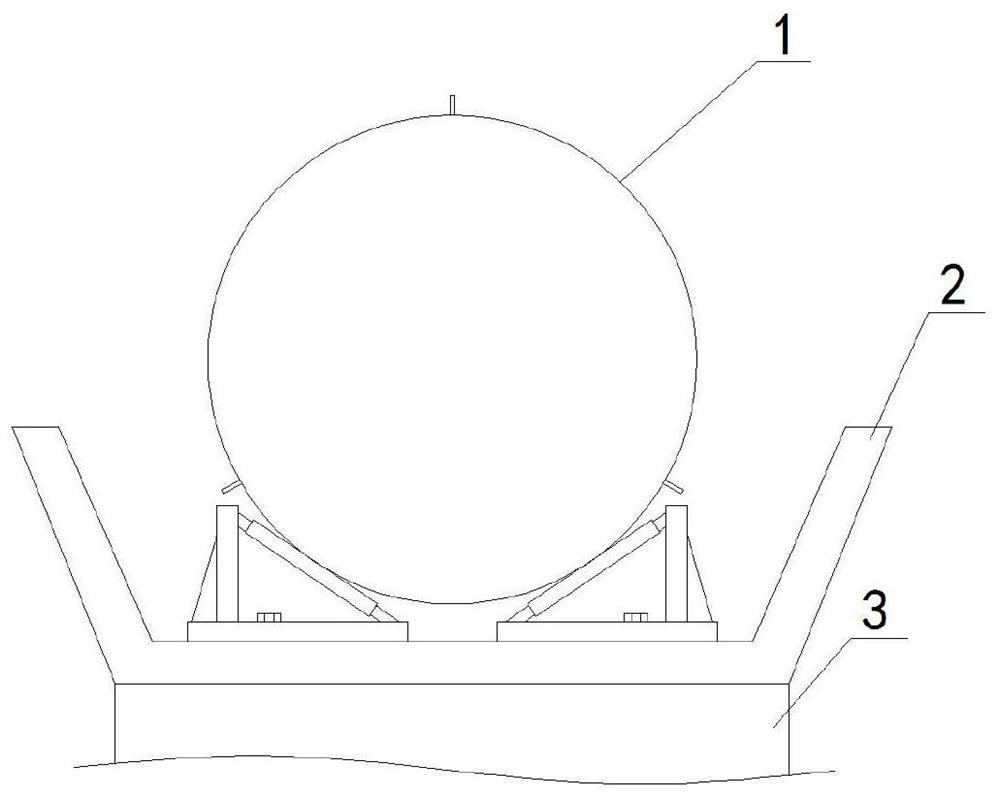

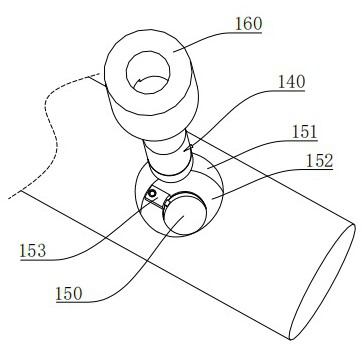

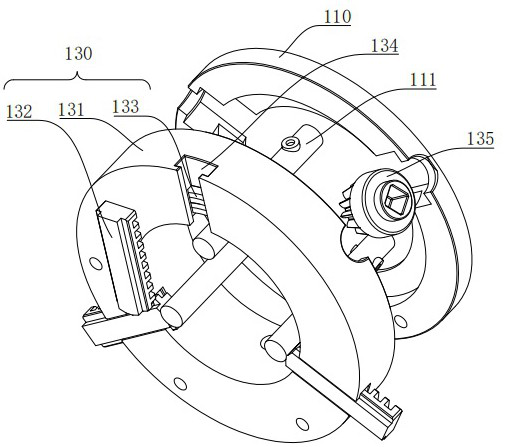

Large thin-wall cylindrical component automatic abut-joint assembling flexible positioning device

InactiveCN108032049ALarge range of motionImprove flexibilityWork holdersMetal working apparatusIndependent motionJoint component

A large thin-wall cylindrical component automatic abut-joint assembling flexible positioning device comprises a chassis, at least two pairs of vertical supporting mechanisms arranged on the chassis movably, a movable platform located on the vertical supporting mechanisms and a flexible bracket; each vertical supporting mechanism and the chassis are connected through a two-dimensional sliding railto achieve plane independent motion, the vertical supporting mechanisms and the movable platform are connected in a ball socket manner so as to achieve six-freedom-degree gesture adjusting of the movable platform and the flexible bracket. The device has the beneficial effects of being high in smoothness, high in moving capacity, high in operation precision, high in automation degree, large in motion range and the like; weighing and mass center measuring functions are achieved, precision abut-joint assembling of large thin-wall components is achieved, the large component abut-joint difficulty and potential safety hazards are greatly reduced, abut-joint efficiency and abut-joint precision are improved, abut-joint components are effectively protected, and the assembling quality needs are met.

Owner:SHANGHAI JIAO TONG UNIV

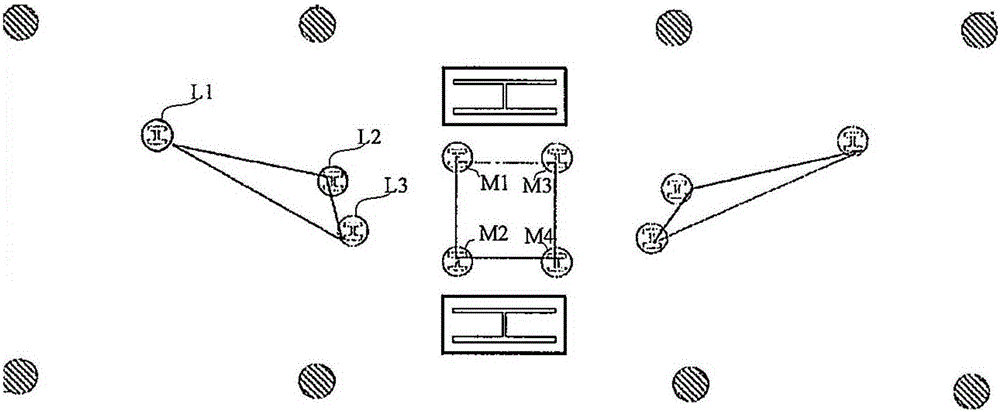

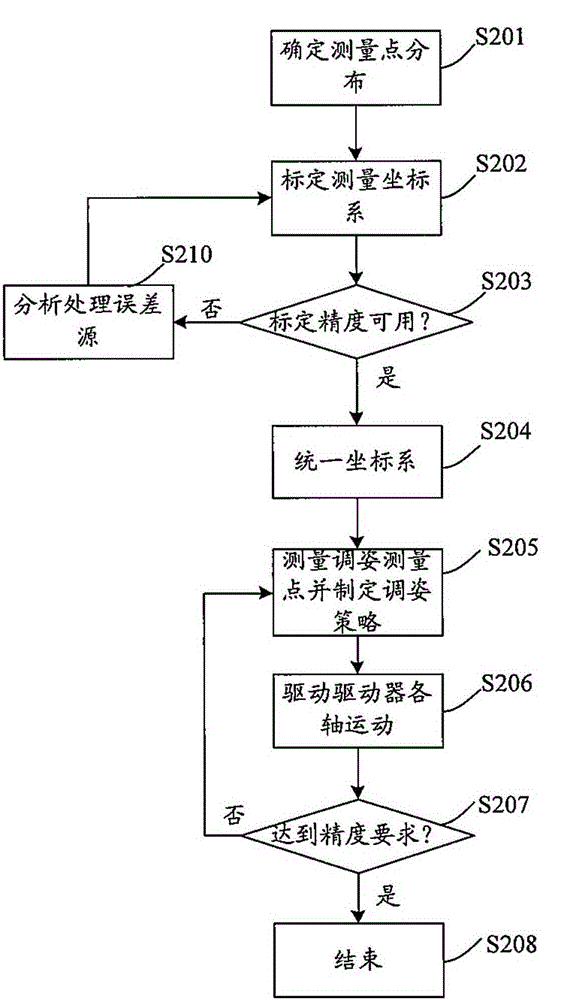

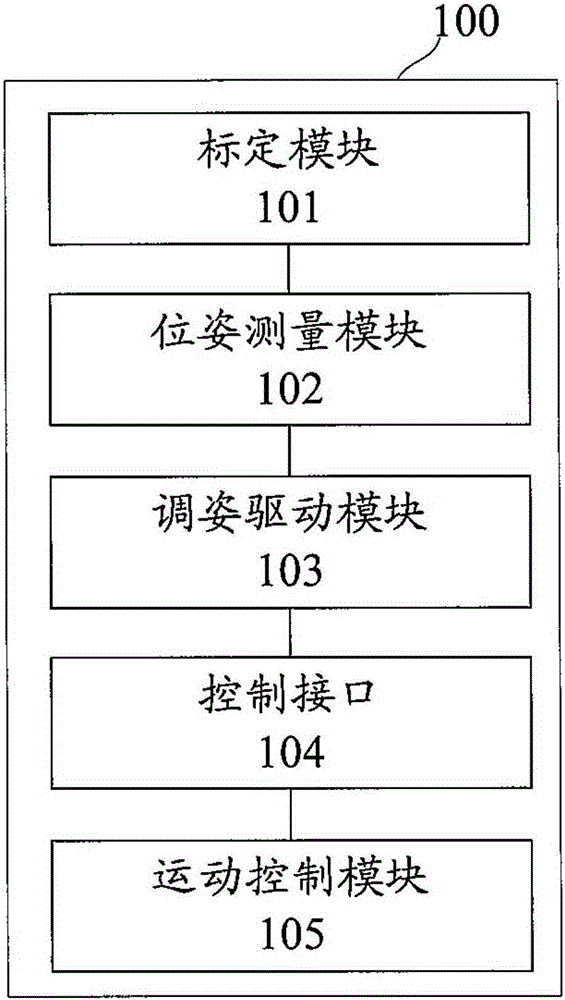

Docking measurement pose-adjusting method based on indoor GPS (iGPS)

InactiveCN105215669AImprove digitizationImprove flexibilityAircraft componentsMetal working apparatusMeasurement pointActuator

The invention provides a method for docking an object to be measured. The method comprises the steps that i, distribution of measurement points on the object to be measured is determined, and a measuring coordinate system related to a measuring spot is constructed based on the actual measurement positional values and the theoretical positional values of the measurement points; ii, the transformational relation between the measuring coordinate system and the design coordinate system of the object to be measured is constructed; iii, the position information of a pose measuring point and the position information of a drive measurement point are acquired, and the target coordinates to which an actuator corresponding to the drive measurement point is to move is determined based on the transformational relation; and iv, the actuator is driven based on the target coordinates. According to the method, measurement data and the theoretical data of a design model are comprehensively processed, and the digitization, flexibility and automation level of plane docking is improved. According to the technical scheme, the automation level of plane docking can be improved.

Owner:COMAC +1

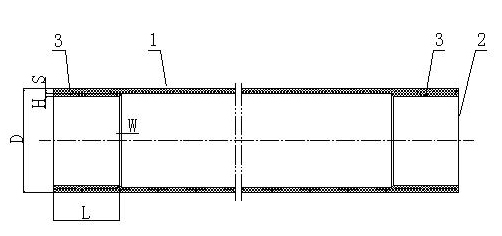

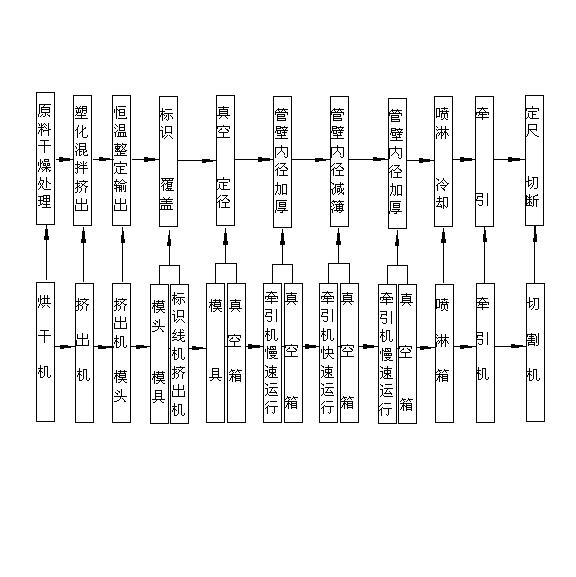

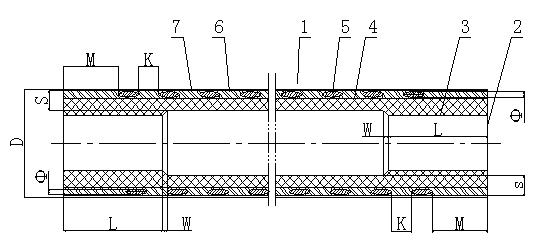

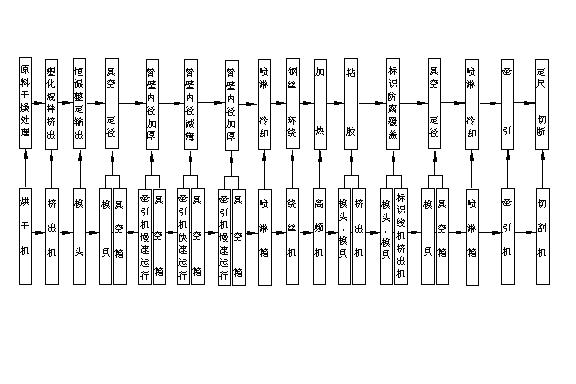

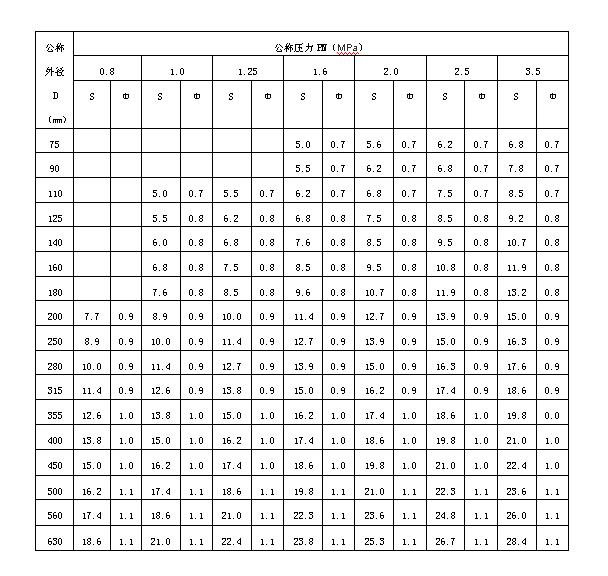

Socket reinforced composite plastic pipe and manufacturing process thereof

ActiveCN101788084ASimple structureSimple manufacturing processRigid pipesProcess engineeringWater leak

The invention relates to a socket reinforced composite plastic pipe and a manufacturing process thereof, and the socket reinforced composite plastic pipe comprises a pipe wall and a socket, wherein a convex ring is arranged at the pipe wall with the inner diameter of L at the end part of the socket, plastics and resin are mixed for being taken as raw materials, and the technical scheme simultaneously produces a product under the synchronous control of a drying machine, an extrusion machine, a mold head, a mold, a vacuum box, a spraying box, a traction machine, a cutting machine and other equipment. The socket reinforced composite plastic pipe can overcome the defects that the strength and the rigidity of the cross section at the butt joint between the pipe and the socket can not bear the internal pressure in the pipe for the existing polyethylene resin composite pipe-PE pipe, thereby causing expansion, deformation and cracking of the pipe wall of a pipe, further resulting in water leakage and gas leakage of a pipeline and causing difficult maintenance of a water supply system, a gas supply system and a liquid supply system, serious loss of resources, environmental pollution caused by gas leakage and the like; and the socket reinforced composite plastic pipe is applicable to being used as connecting pipe for various water transportation projects and gas transportation projects, in particular to socket thickening and reinforcing of PE, PVC-U, PVC-M and other plastic pipes.

Owner:HUNAN ZHENHUI PIPE IND

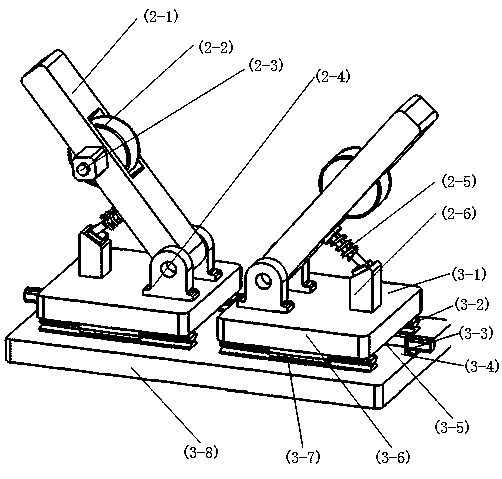

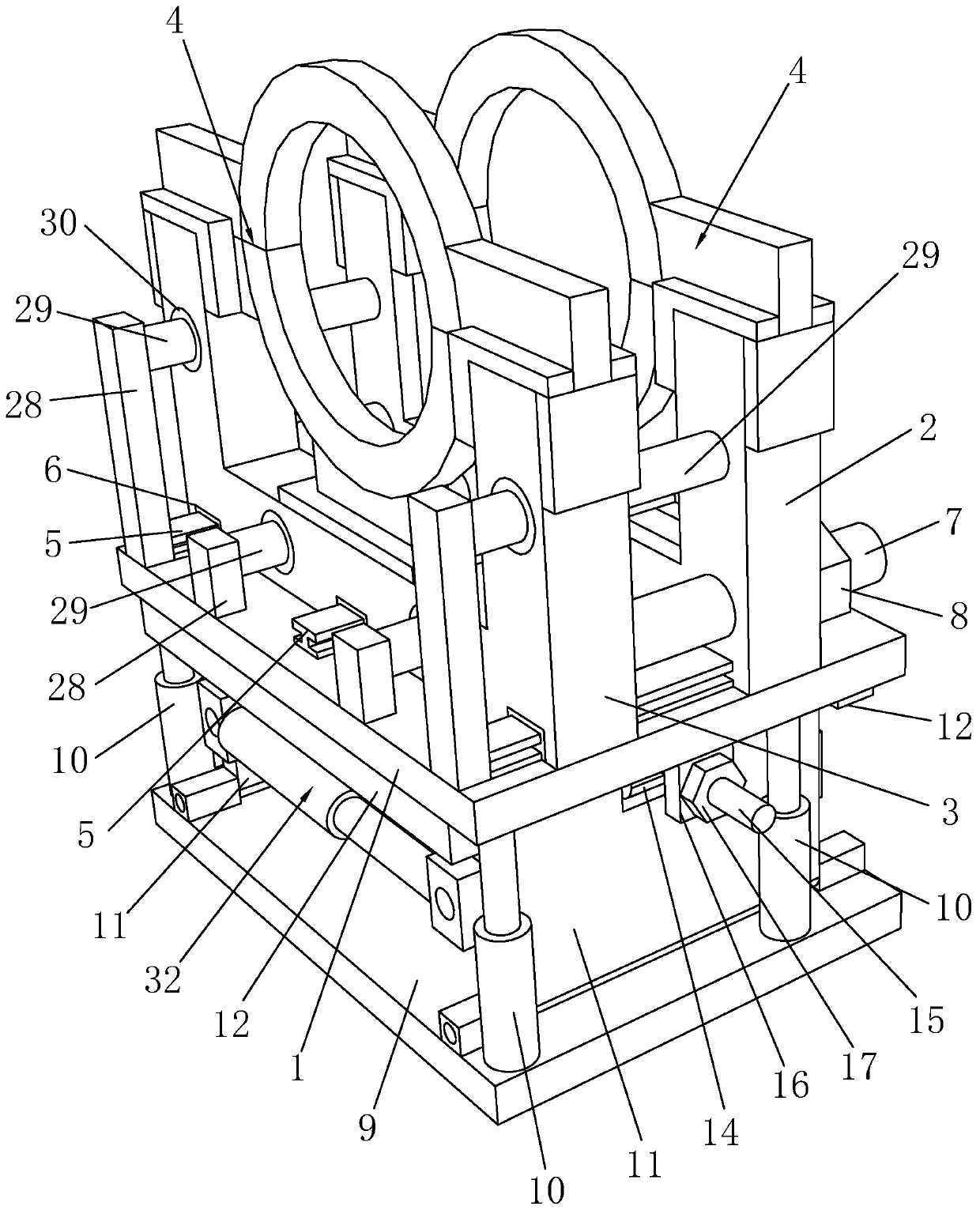

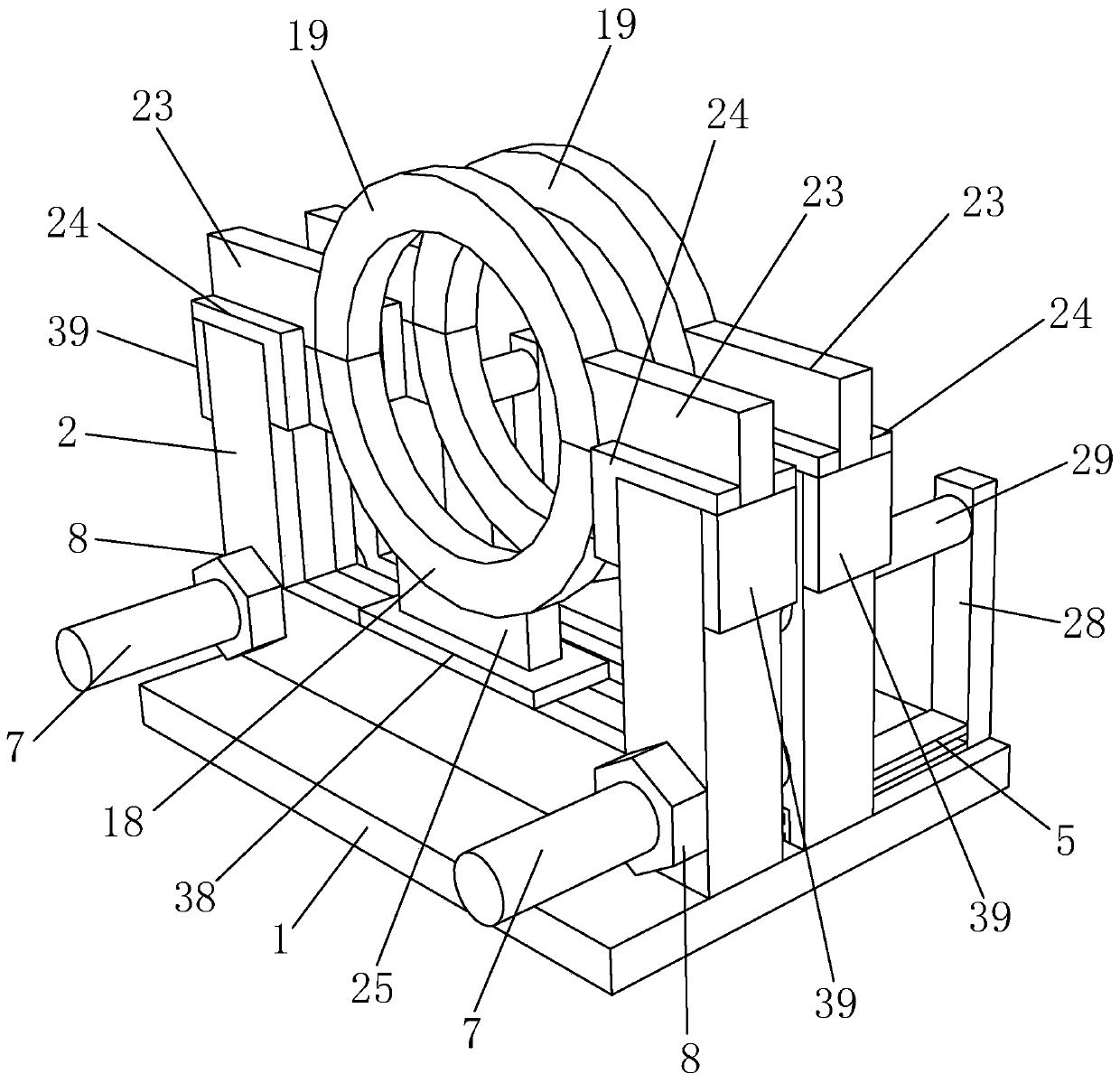

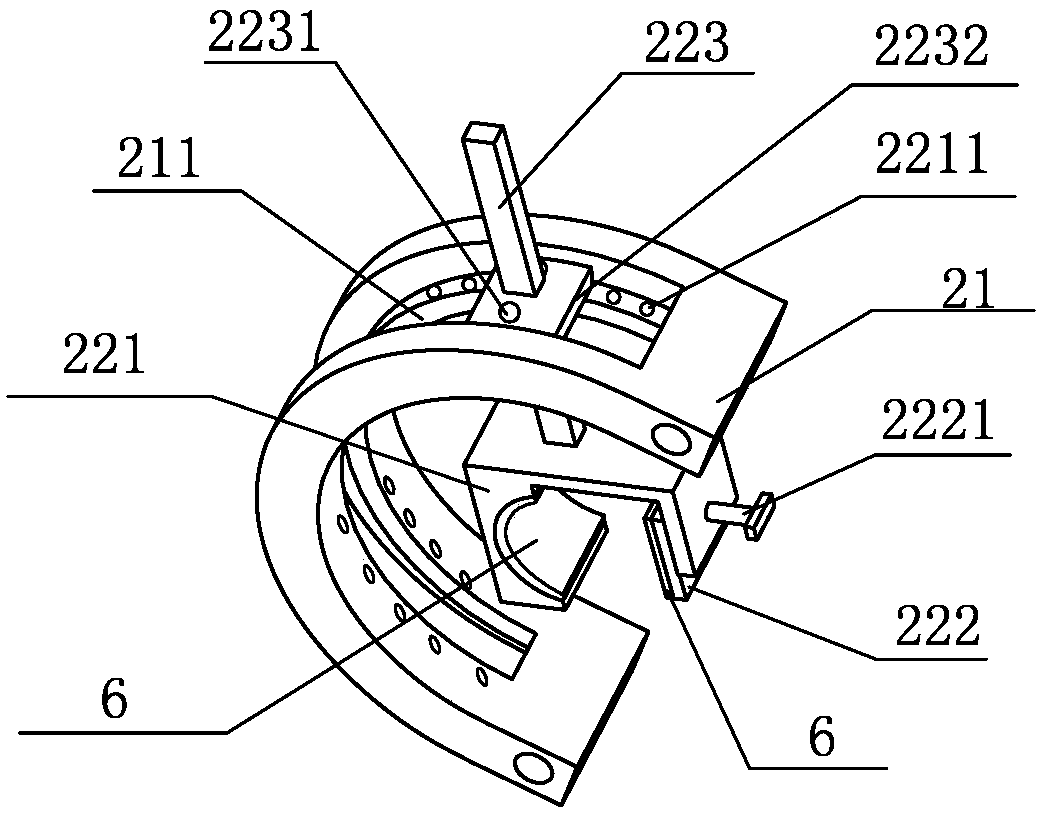

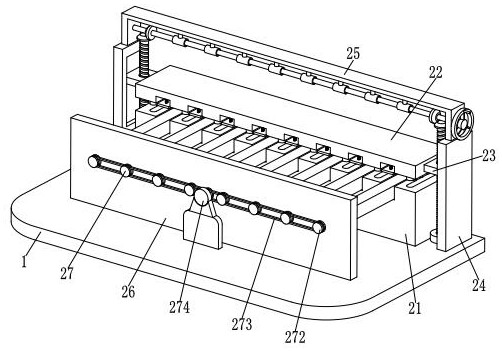

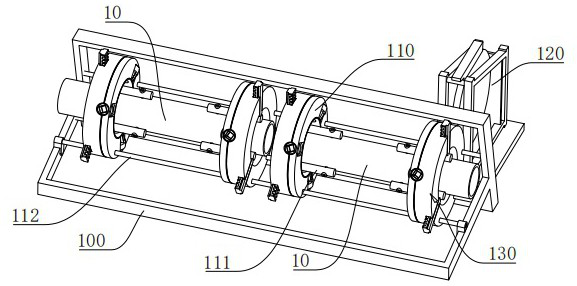

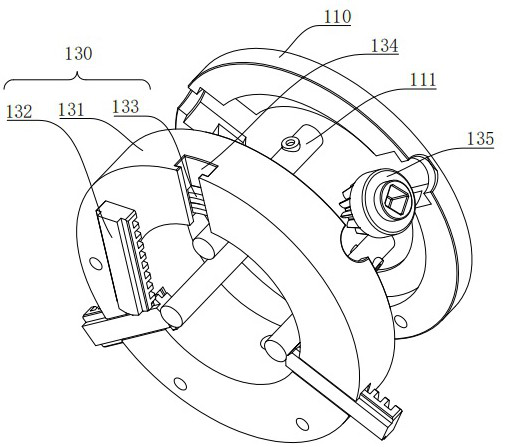

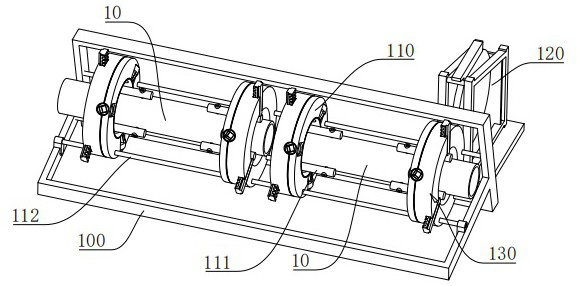

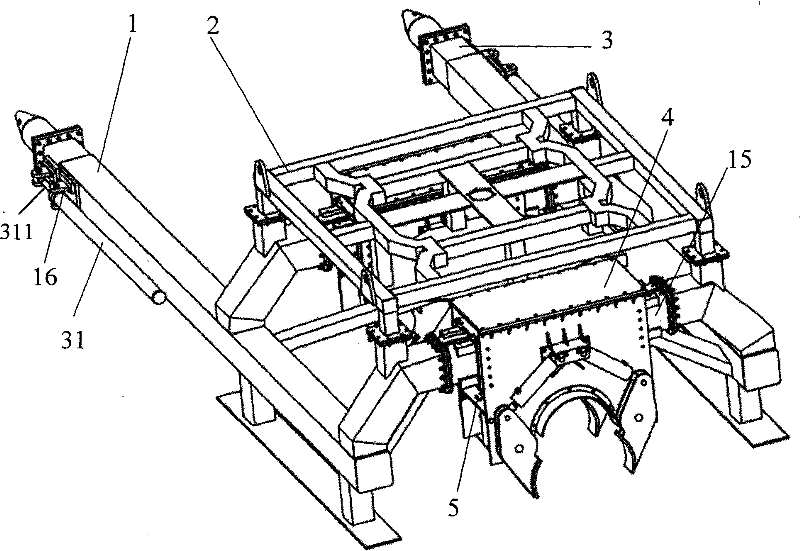

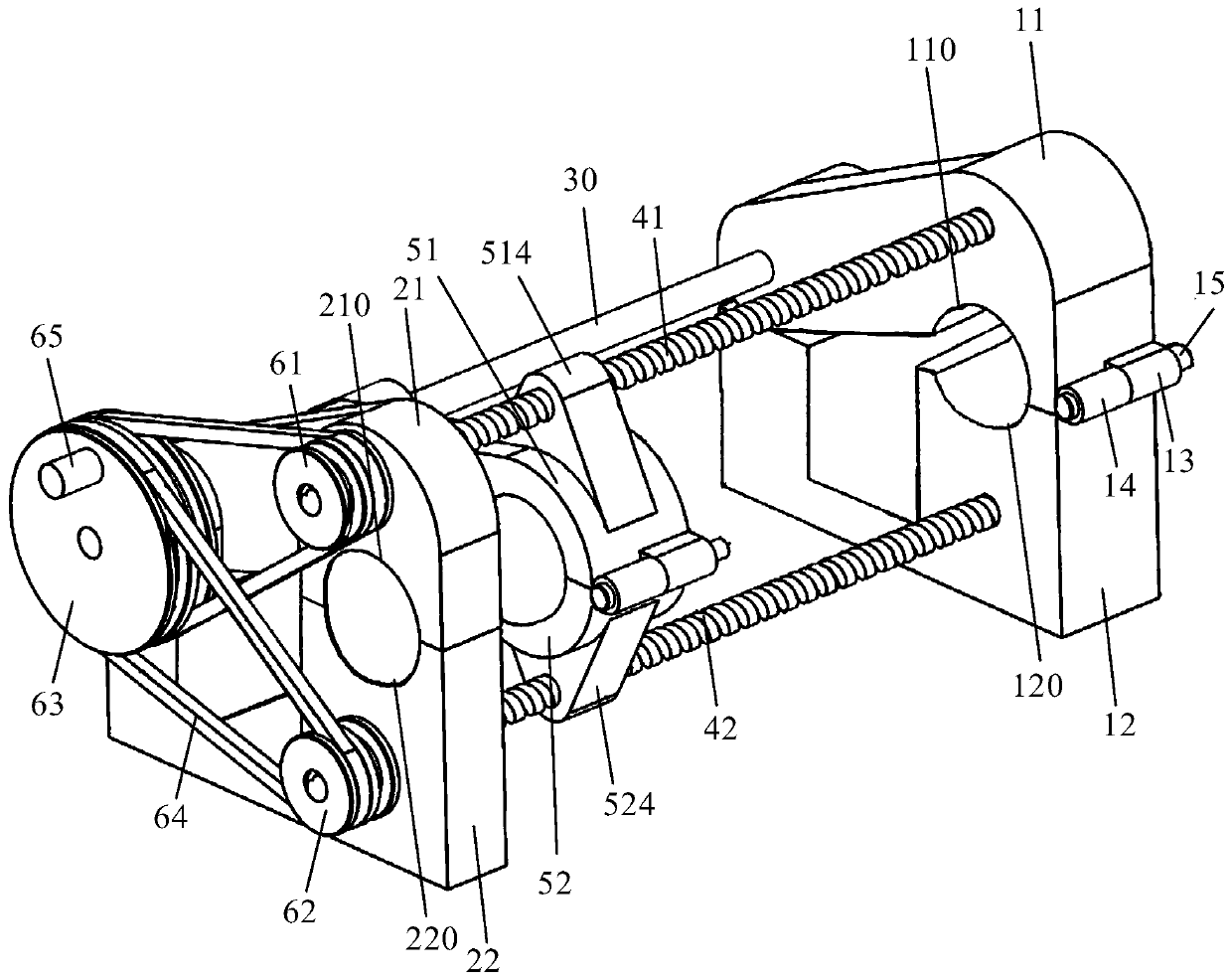

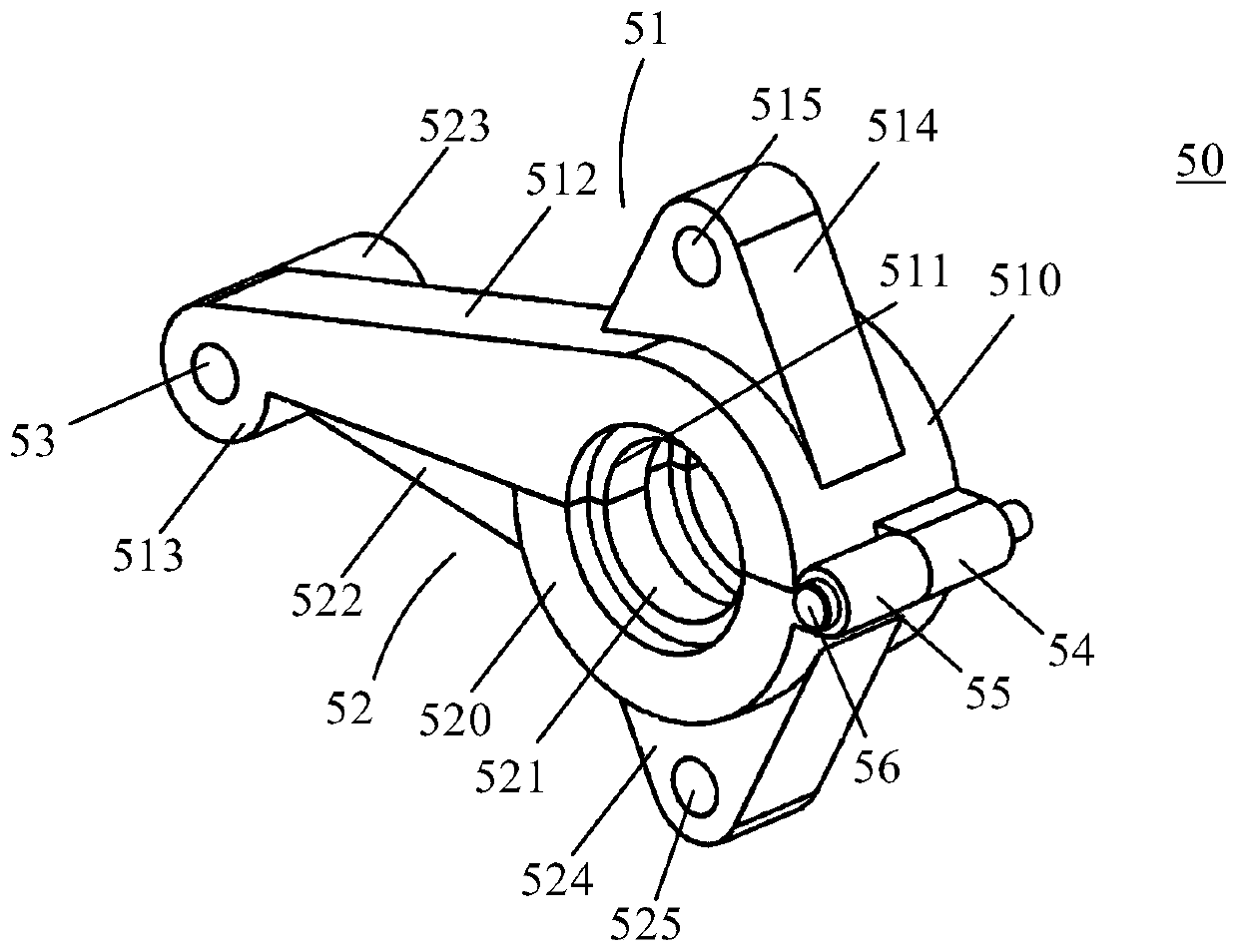

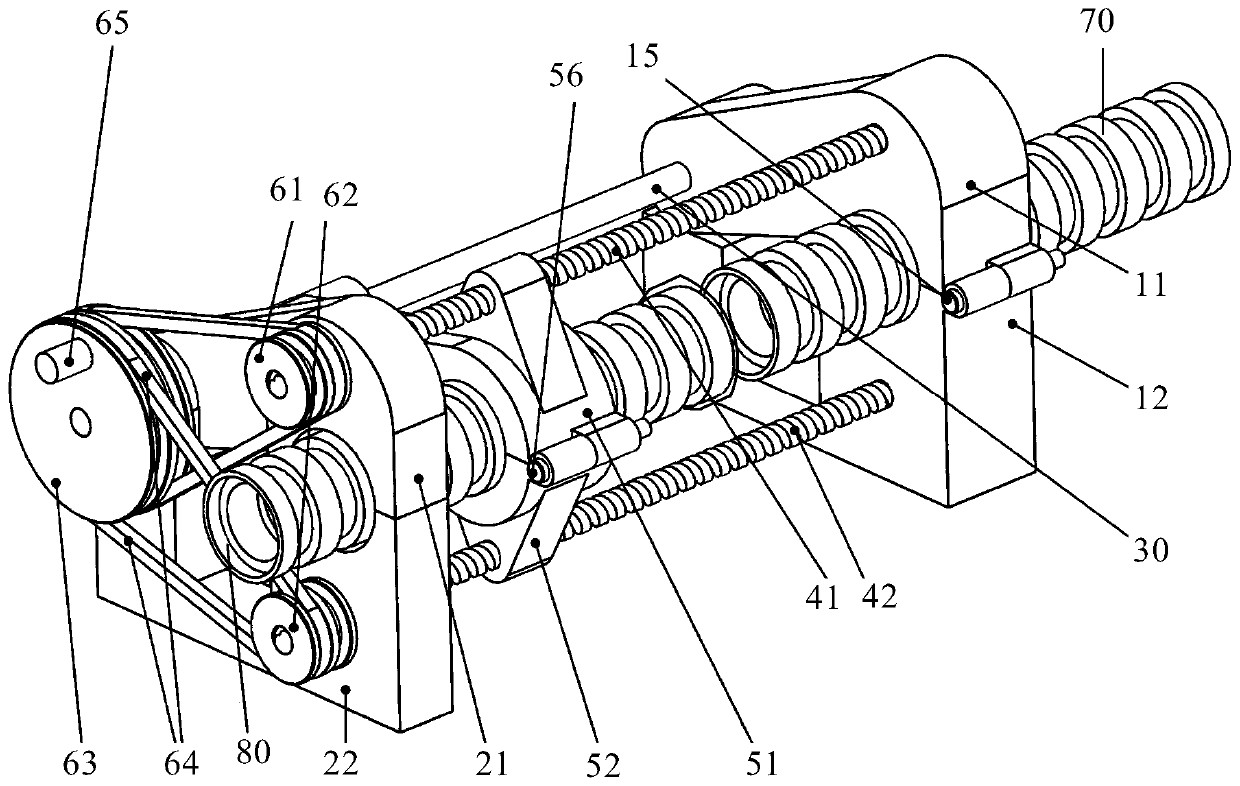

Automatic flexible assembling device and method for drum cabins

InactiveCN111571171AImprove work efficiencyImprove docking qualityMetal working apparatusClassical mechanicsShock absorber

The invention provides an automatic flexible assembling device and method for drum cabins. The method comprises the following steps of placing the drum cabins on a spring damping supporting arm first,wherein the drum cabins are in a force balance state to achieve a floating effect by self-adaptive adjustment of a spring damping shock absorber; then measuring relative poses of the two cabins by alaser contourgraph; then carrying out adjustment by a transverse moving mechanism according to the measured relative poses, wherein axes of the two cabins are superposed; and finally, driving an axialfeeding mechanism to assemble the drum cabins flexibly. A collision phenomenon of the drum cabins in an abutting process is avoided.

Owner:HARBIN UNIV OF SCI & TECH

Connector

ActiveUS20180212364A1Avoid internal structure damageAvoid damageIncorrect coupling preventionCoupling contact membersElectrical and Electronics engineering

Owner:LUXSHARE PRECISION IND SHENZHEN

Ecological pipe network connecting port supporting device and construction method thereof

ActiveCN111503369APlay a supporting rolePlay a guiding rolePipe supportsPipe laying and repairButt jointScrew thread

The invention discloses an ecological pipe network connecting port supporting device and a construction method thereof. The ecological pipe network connecting port supporting device comprises a bottomplate, a first fixing frame and a second fixing frame, the first fixing frame and the second fixing frame are each provided with a fixing assembly, the bottom plate is provided with a sliding rail, the second fixing frame is provided with a sliding block, the sliding block is arranged on the sliding rail and slidably connected with the sliding rail, the second fixing frame is provided with a threaded rod, the first fixing frame is provided with a nut, the nut is rotationally connected with the first fixing frame, and the threaded rod penetrates through the first fixing frame to be in threadedconnection with the nut. The method comprises the steps of a, foundation pit excavation; b, fixing a supporting device; c, adjusting the supporting device; d, pipeline preparation; e, pipeline welding; and f, backfilling. The pipeline connecting port can be supported, the strength of the connecting port is improved, the connecting port is not prone to breakage, meanwhile, butt joint between pipelines can be facilitated through the supporting device, the butt joint effect of the connecting port is improved, the method is easy, convenient and rapid to construct, and the construction efficiencyand construction quality can be effectively improved.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

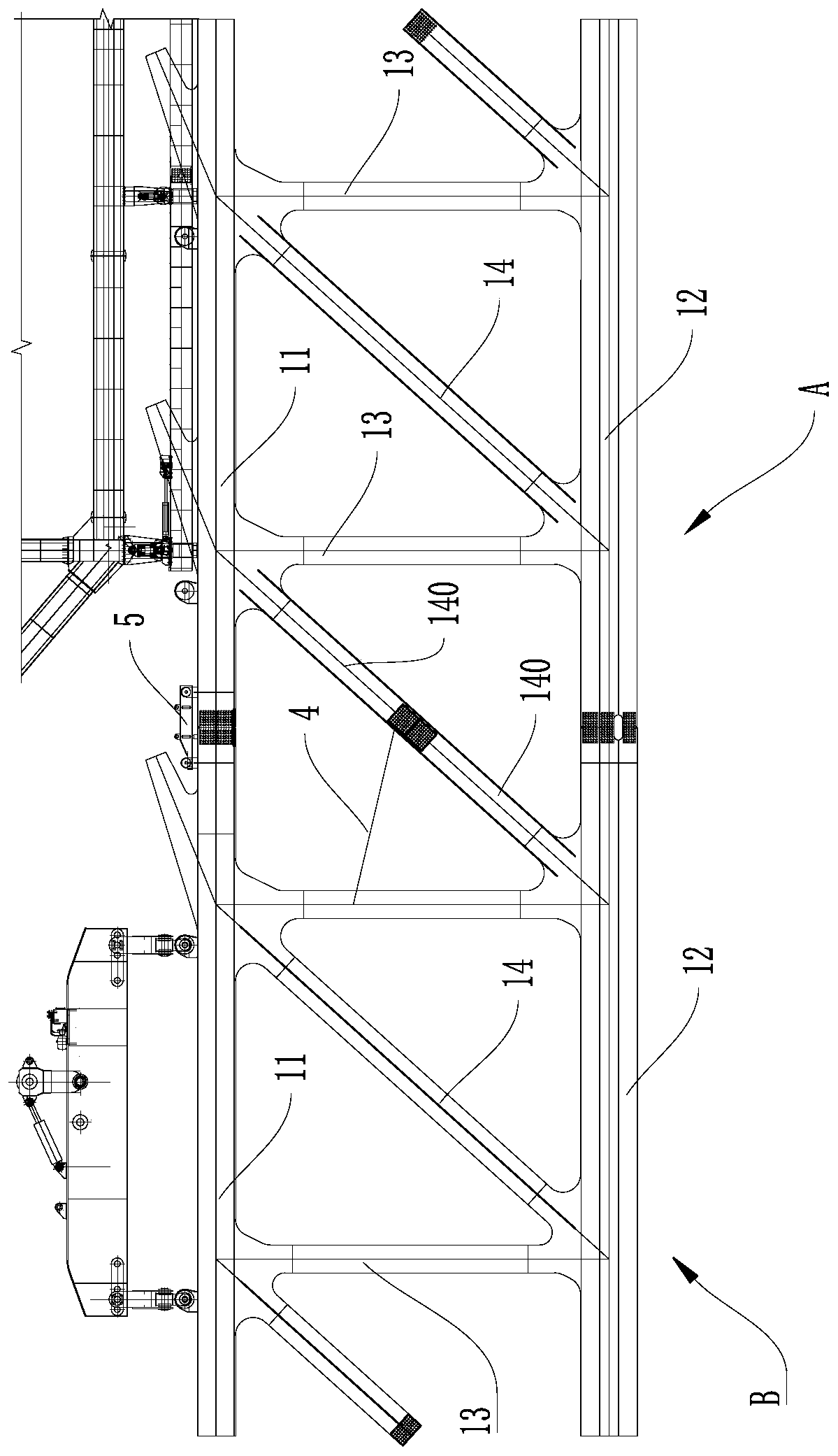

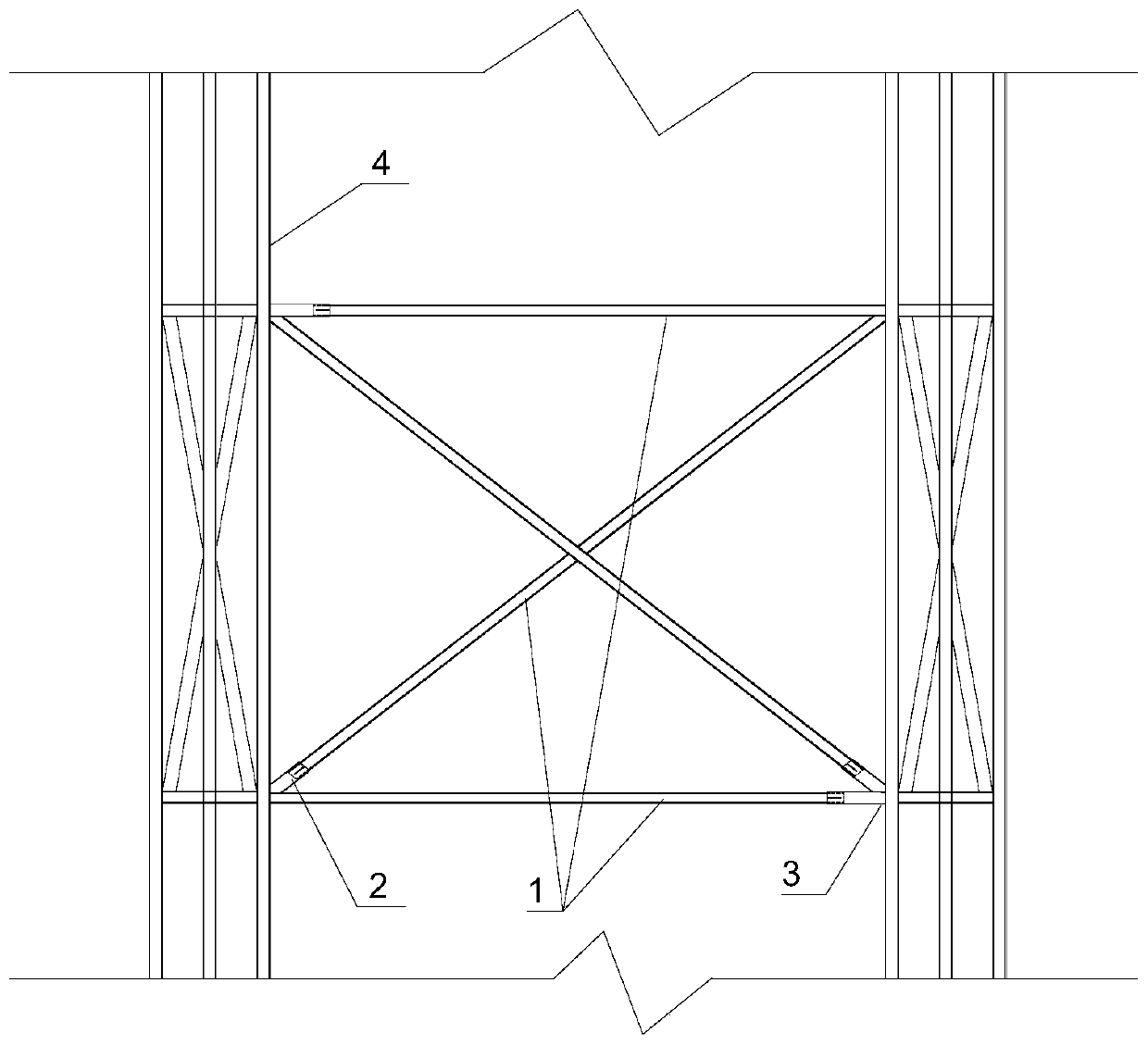

Connection device and method for large-section steel truss girders

The invention discloses a connection device for large-section steel truss girders to connect a mounted girder section and a to-be-mounted girder section. The large-section steel truss girder includesan upper chord, a lower chord, a vertical bar, a connection bar, and a large cross girder. The connection device includes a first pulling mechanism, one end of which is connected to a large cross girder of the to-be-mounted girder section, and the other end of which is connected to the corresponding large cross girder in the mounted girder section, wherein when the first pulling mechanism pulls the mounted girder section and the to-be-mounted girder toward each other, the large cross girder in the to-be-mounted girder section approaches the corresponding large cross girder in the mounted girder section; a second pulling mechanisms the two ends of which are located in the middles of the mounted girder section and the to-be-mounted girder section respectively, wherein when the second pullingmechanism pulls the mounted girder section and the to-be-mounted girder toward each other, a connection bar in the to-be-mounted girder section approaches the corresponding connection bar in the mounted girder section; and a jacking mechanism including a jack disposed on the upper chord in the to-be-mounted girder section and having a fixed top, wherein when the jack is raised upward, the to-be-mounted girder section is pressed down. The connection device effectively adjusts the relative deformation between the mounted girder section and the to-be-mounted girder section, and realizes the connection of large-section steel truss girders.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

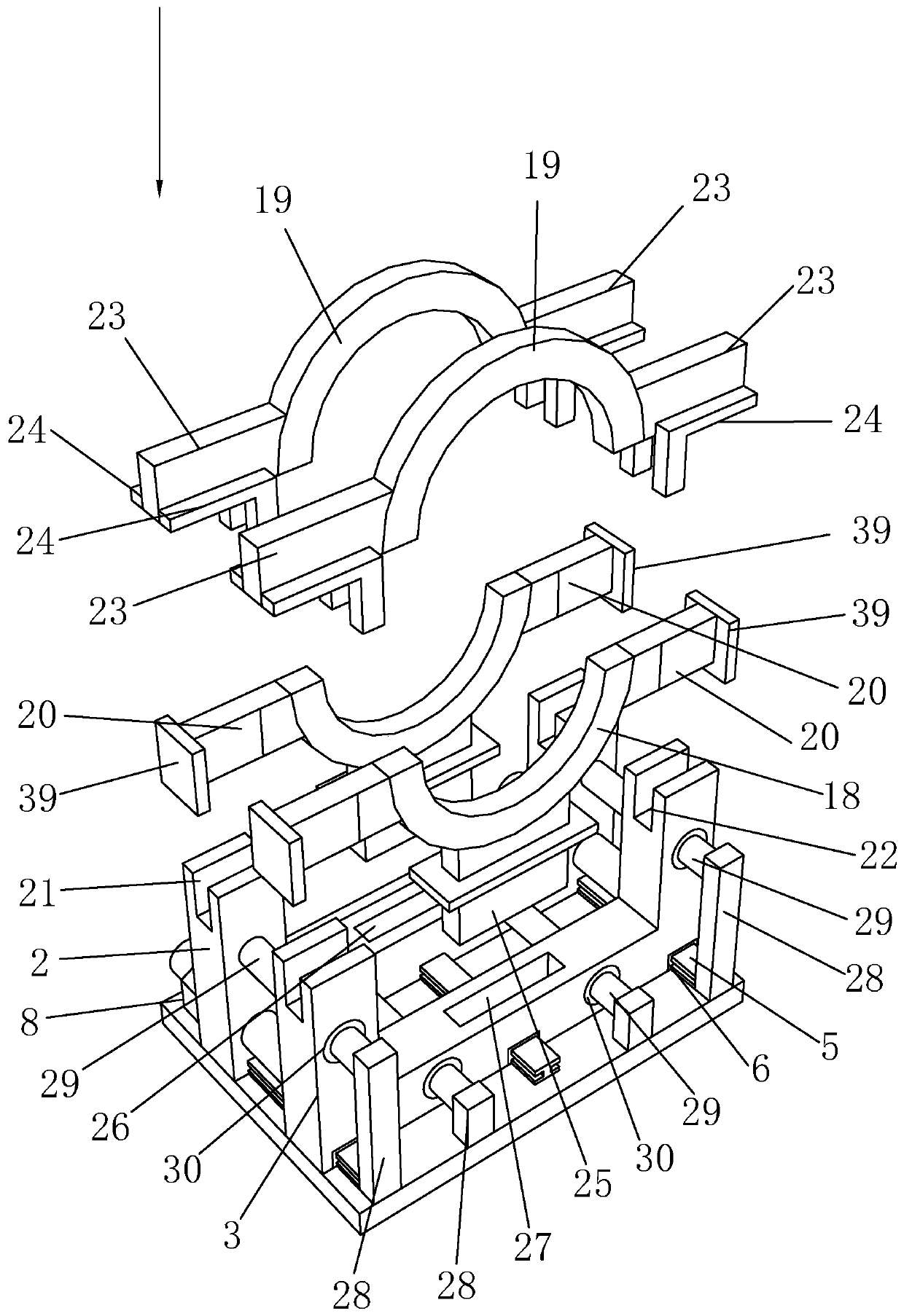

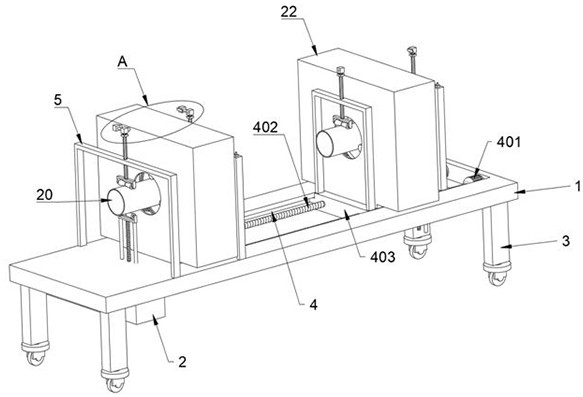

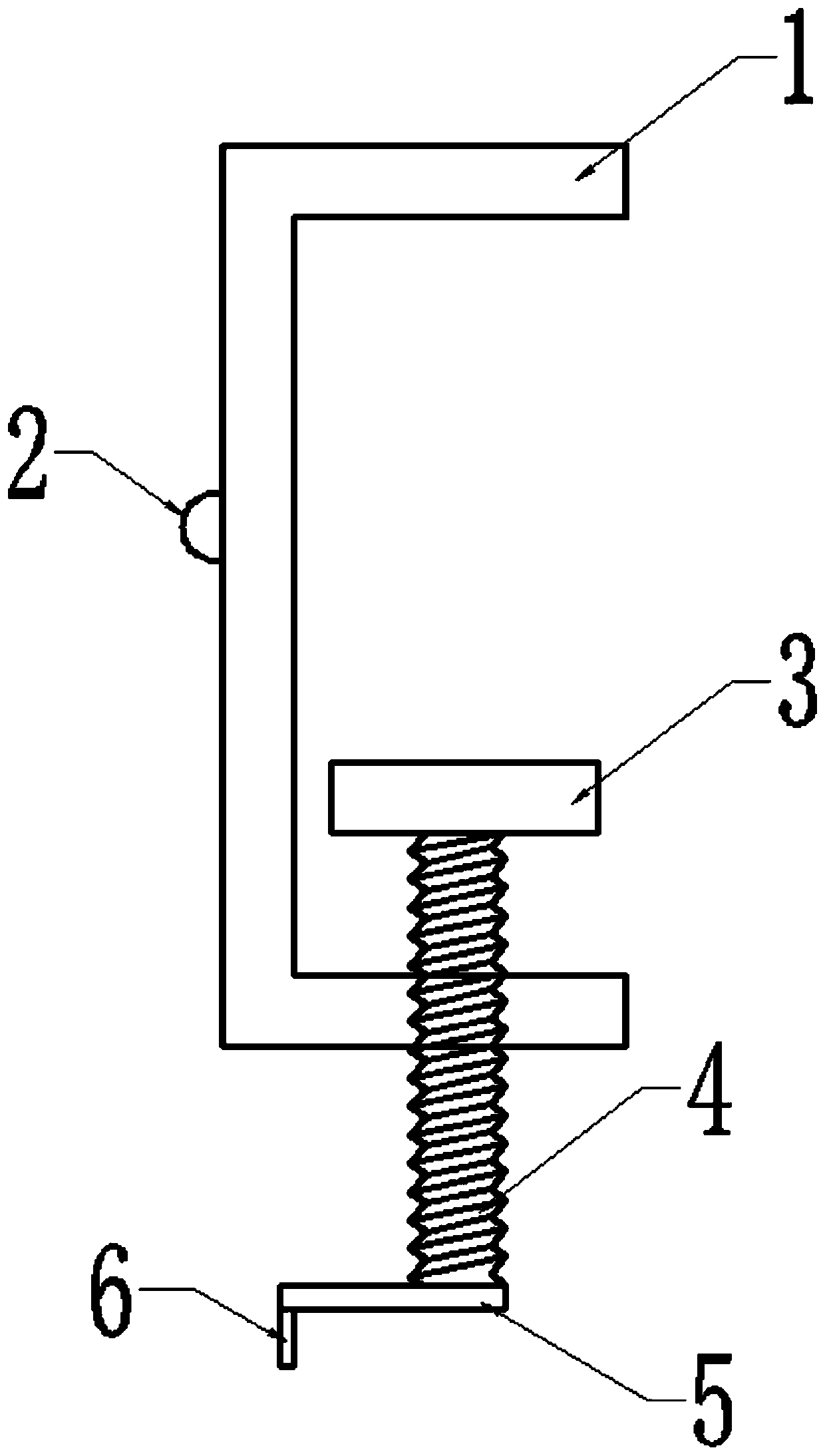

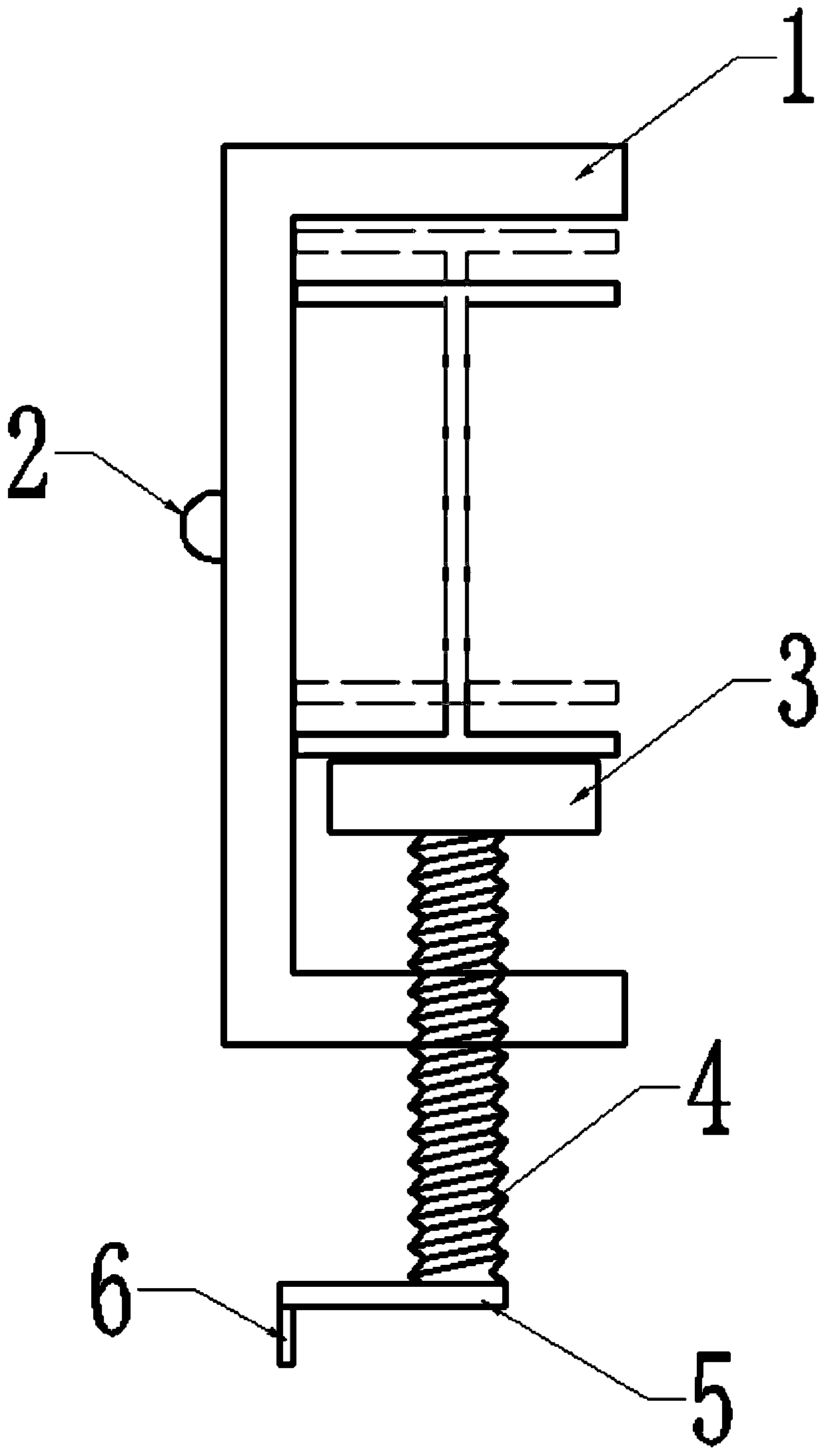

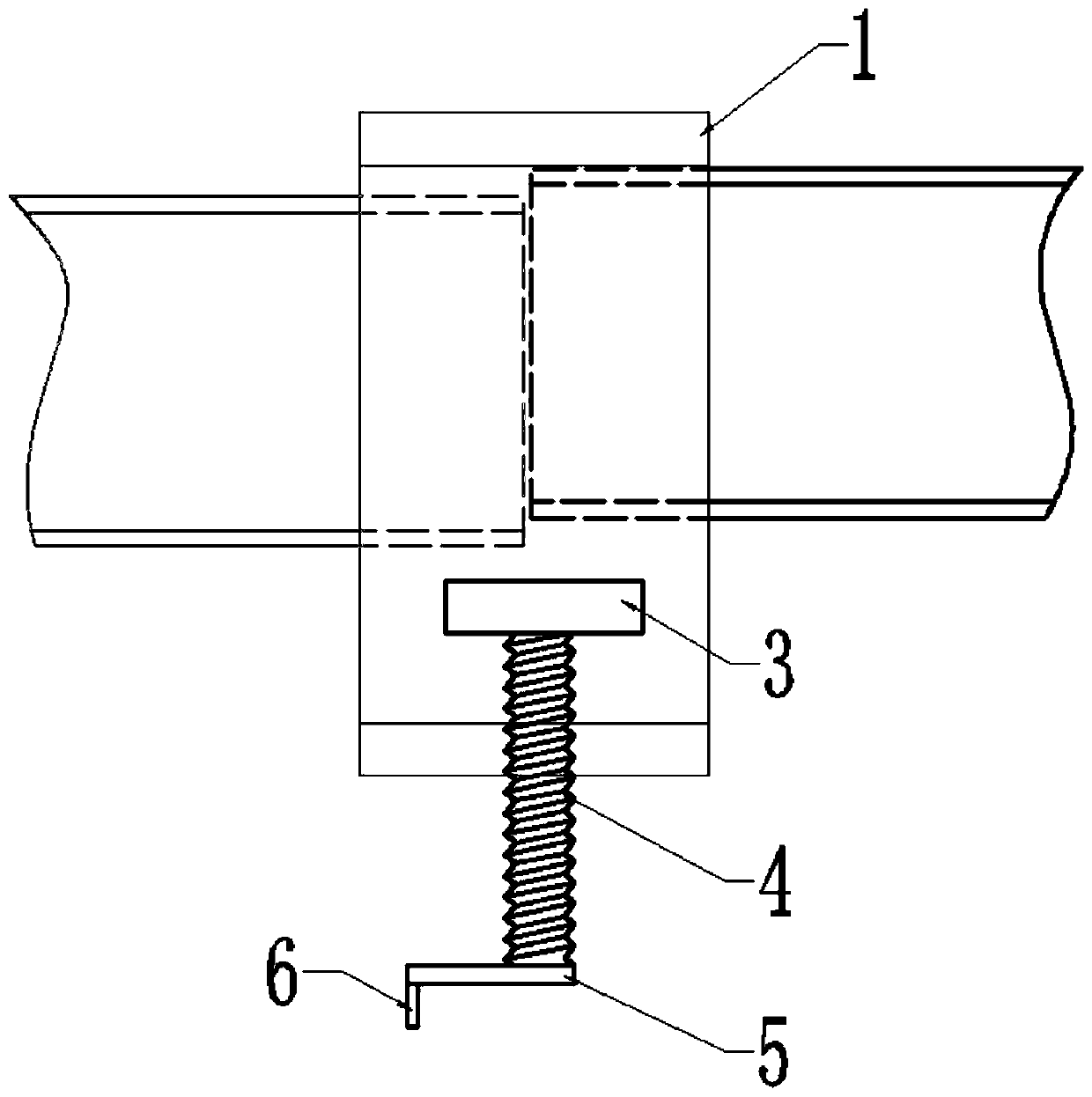

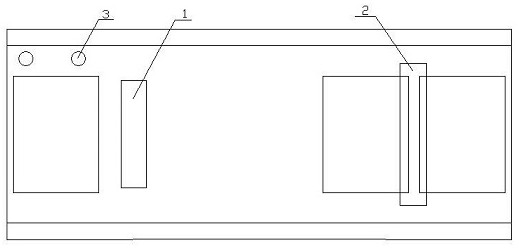

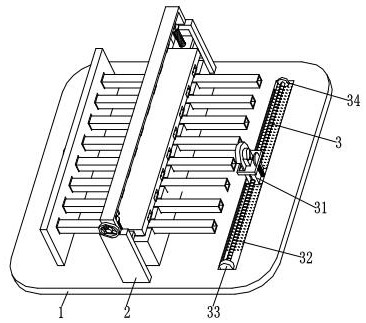

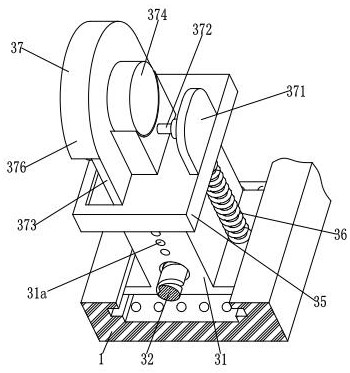

Heating and ventilation pipe fitting butt joint installation auxiliary device

ActiveCN114043119APrevent pipe from skewingImprove docking qualityWelding/cutting auxillary devicesAuxillary welding devicesWorkbenchAssistive device

The invention discloses a heating and ventilation pipe fitting butt joint installation auxiliary device, and relates to the technical field of pipe fitting installation. The heating and ventilation pipe fitting butt joint installation auxiliary device comprises a workbench, a storage battery and supporting legs are installed on the outer wall of the bottom of the workbench, a butt joint mechanism is arranged on the inner wall of a sliding groove, a pipeline clamping mechanism is installed on the inner wall of an equipment box, and a driving mechanism is arranged on one side of a threaded sleeve. And a leveling mechanism is inserted into the inner wall of the insertion hole. According to the invention, the angles of the two butt joint pipelines to be in butt joint are adjusted, the two butt joint pipelines are kept in the horizontal zero-degree posture, butt joint of the pipelines in the non-horizontal zero-degree state is avoided, the butt joint pipelines are prevented from inclining, the butt joint quality of the pipelines is further improved, the first warning lamp and the second warning lamp can timely remind a worker whether the butt joint pipeline is kept in the horizontal zero-degree posture or not, the operation difficulty of the worker is reduced, control is convenient, repeated adjustment is not needed, and the butt joint effect and the butt joint efficiency are further improved.

Owner:山东君鼎汇智科创有限公司

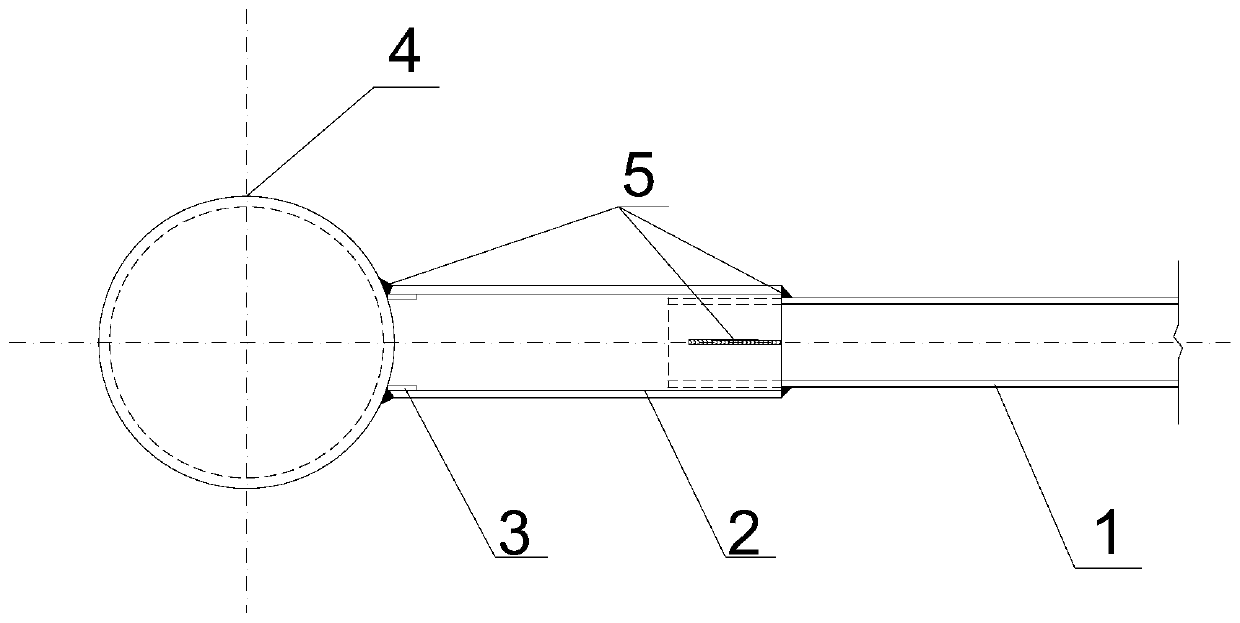

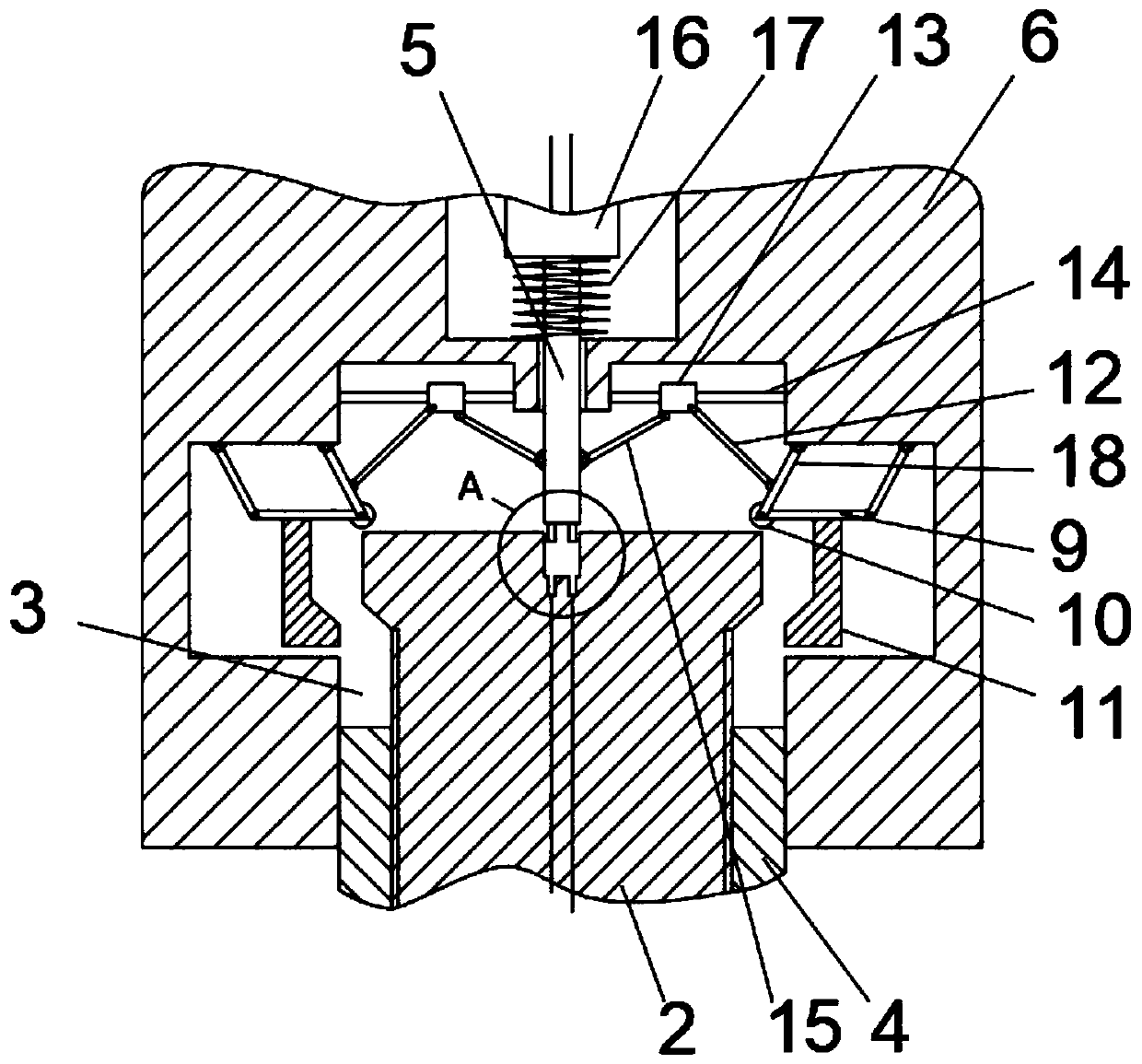

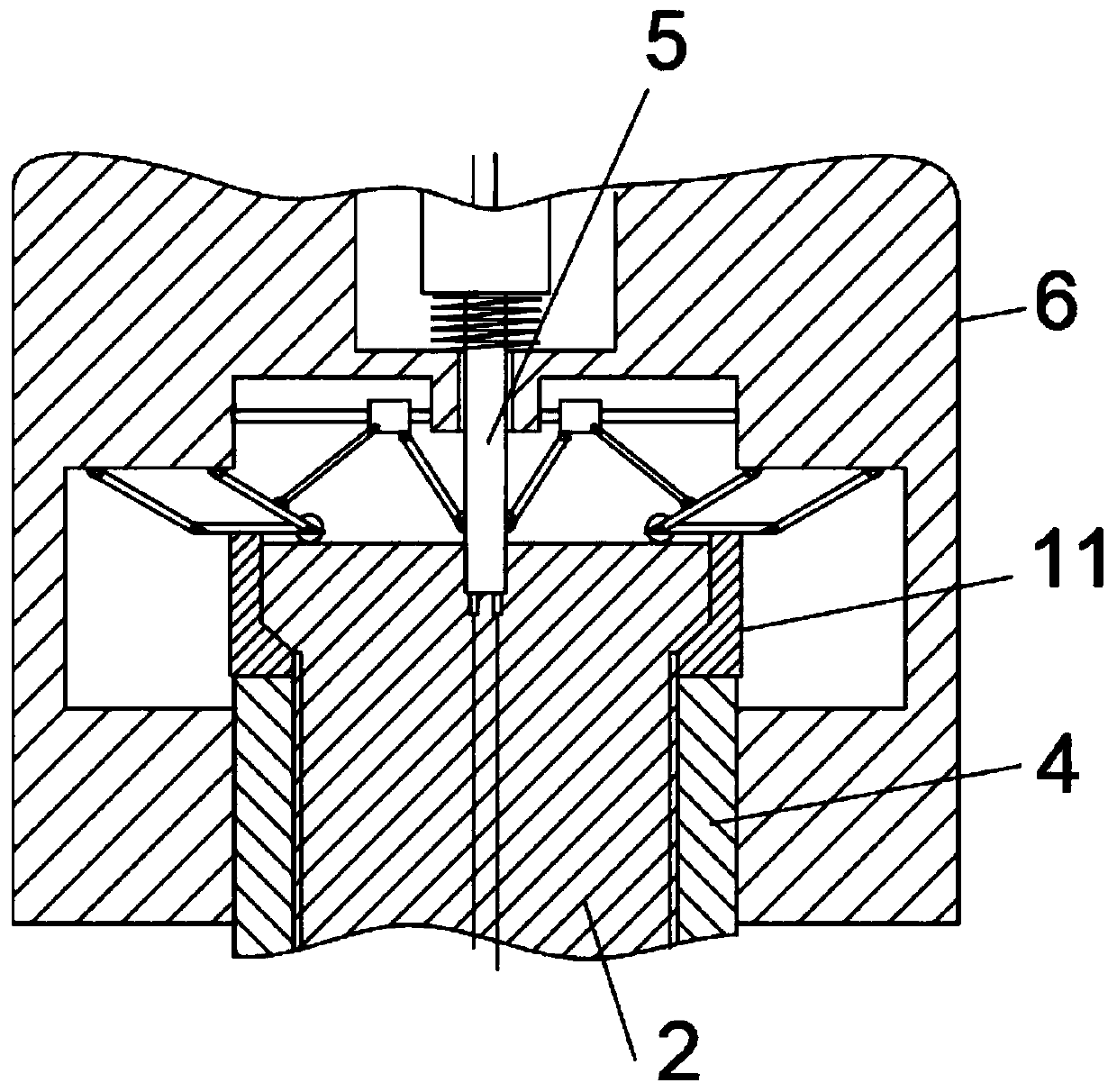

Pipeline socket butt joint device

ActiveCN113251211AThe docking process is simpleImprove docking qualityPipe laying and repairPipe connection arrangementsStructural engineering

The invention provides a pipeline socket butt joint device. The pipeline socket butt joint device comprises an inner support fixing device, an opposite-pulling device and a plurality of sets of traction cables. The inner support fixing device is used for being arranged in the first pipe joint. The opposite-pulling device is arranged at an opening of the second pipe joint, one end of each group of traction cables is fixed on the inner support fixing device, and the other end of each group of traction cables is wound on the opposite-pulling device; A transmission mechanism is arranged on the opposite-pulling device and used for transmitting external acting force to the traction cables so that the traction cables can be tightened, then the opposite-pulling device is pulled so that the opposite-pulling device can push the second pipe joint to move towards the first pipe joint, and butt joint of the first pipe joint and the second pipe joint is achieved. According to the pipeline socket butt joint device, the transmission mechanism is arranged on the opposite-pulling device, the plurality of groups of traction cables are arranged between the inner support fixing device and the opposite-pulling device, the acting force is transmitted to the traction cables through the transmission mechanism, butt joint of two pipe joints is achieved, the pipeline butt joint procedure is simplified, and the pipeline butt joint quality and efficiency are improved.

Owner:CHINA FIRST METALLURGICAL GROUP

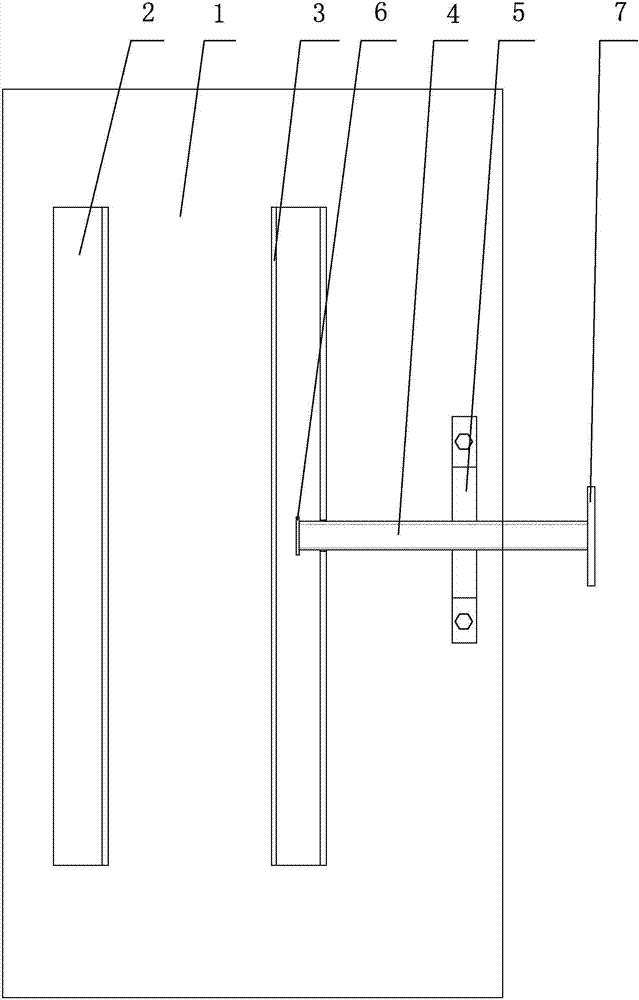

An auxiliary device for quick connection of cables

ActiveCN106384975BReduce docking labor intensityImprove docking qualityApparatus for joining/termination cablesButt jointJackscrew

The invention provides a cable fast butt-joint assisting device comprising a bracket, a crimping mechanism, and cable adjusting mechanisms. The crimping mechanism is disposed between the two cable adjusting mechanisms. The crimping mechanism comprises a fixed crimping block, a movable crimping block and a jack, wherein the fixed crimping block is fixed on the bracket, the movable crimping block is fixedly arranged at the telescopic end of the jack and disposed right under the fixed crimping block, and the bottom of the jack is fixed on the bracket. Each cable adjusting mechanism comprises a half-circular track and a compressing mechanism. Each compressing mechanism comprises a rotating rod, a U-shaped clamping slot and a compressing plate, wherein the U-shaped clamping slot is arranged at the bottom end of the rotating rod. With the cable adjusting mechanisms, there is no need to rotate a cable manually, one-to-one correspondence between the phase sequences of butt-joint cables at the two ends is realized, and the labor intensity is reduced. Though the crimping mechanism, a cable butt-joint pipe can be molded through one crimping process, and there is no need for workers to crimp a cable butt-joint pipe section by section with a pair of hydraulic crimping pliers. Therefore, the work efficiency is improved.

Owner:JINAN CITY CHANGQING DISTRICT POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

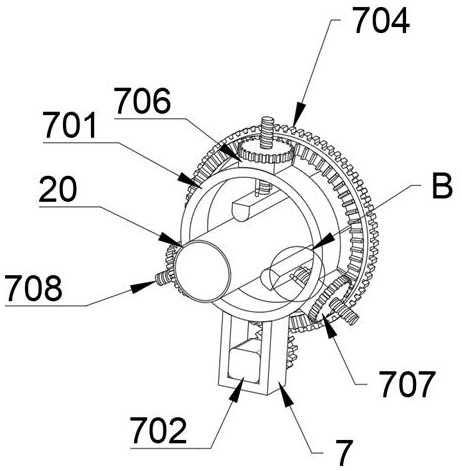

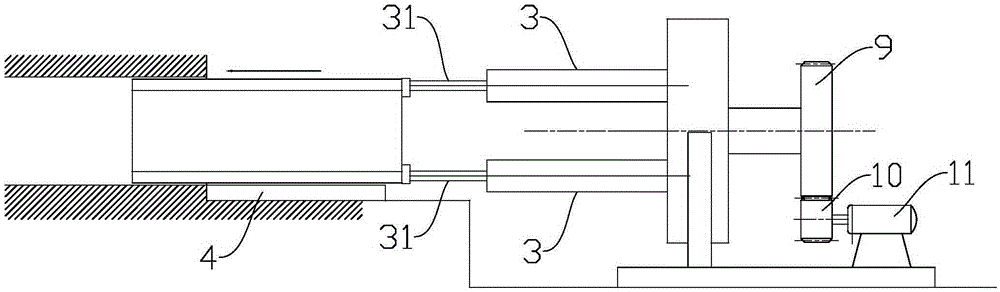

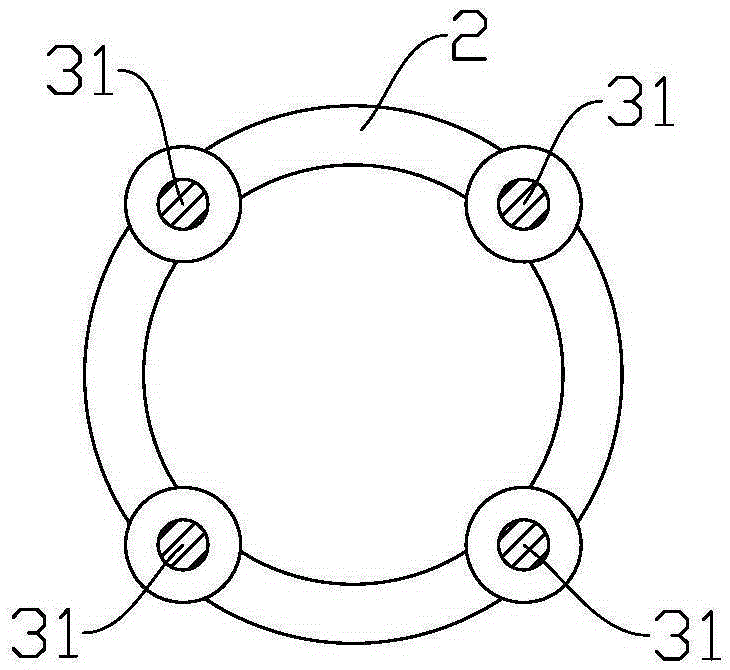

power unit for pipe jacking

ActiveCN104006215BPrevent deviationImprove docking coaxialityPipe laying and repairGear wheelDrive motor

A power device for jacking pipes comprises four jacks and a support for supporting the jacks and is characterized in that the rear end of each jack is coaxially provided with a small gear, parameters of the four small gears are identical and meshed with a center large gear, and the axes of the four small gears around the center large gear are evenly distributed. The four small gears are located in an outer gear ring and meshed with the outer gear ring. The outer gear ring is fixed on the support. A driving gear is coaxially installed on the center large gear, and the driving gear is connected with a driving motor through a transmission mechanism. The driving motor is fixedly installed on the support. The device can prevent pipes from moving off course in the advancing process, prevent blocking of the pipes, improve pipe abutting connection coaxility and improve the abutting connection quality.

Owner:JINAN KAIFENG MUNICIPAL ENG

Tunnel steel arch frame butt joint fine adjusting device

InactiveCN110195605APrecise dockingImprove docking fine-tuning efficiencyUnderground chambersMine roof capsSheet steelButt joint

The invention relates to the technical field of tunnel construction, in particular to a tunnel steel arch frame butt joint fine adjusting device. A threaded hole matched with a fine adjusting screw isformed in a bottom plate of a U-shaped clamping groove, the fine adjusting screw penetrates through the bottom plate of the U-shaped clamping groove through the threaded hole, a jacking steel plate is fixed to the end, located above the bottom plate, of the fine adjusting screw, a handle is fixed to the end, located below the bottom plate, of the fine adjusting screw, thus, in the butt joint process of tunnel I steel, the two pieces of butt joint I steel are finely adjusted and aligned by clamping the I steel by the fine adjusting screw through the jacking steel plate and the U-shaped clamping groove, thus, an I steel butt joint opening can be finely adjusted rapidly, the butt joint fine adjusting efficiency of steel arch frames is improved, the phenomenon of butt joint dislocation of theI steel is avoided, the butt joint quality of the steel arch frames is improved, precise butt joint of the steel arch frames is achieved, then the construction efficiency is improved, the labor costis reduced, and the device is low in weight, convenient to move and high in practicality.

Owner:CHINA MCC5 GROUP CORP

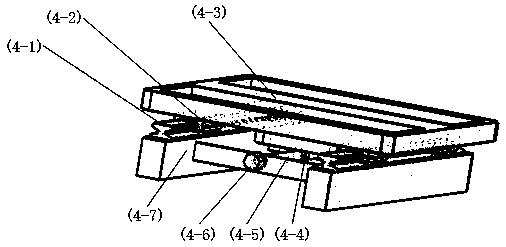

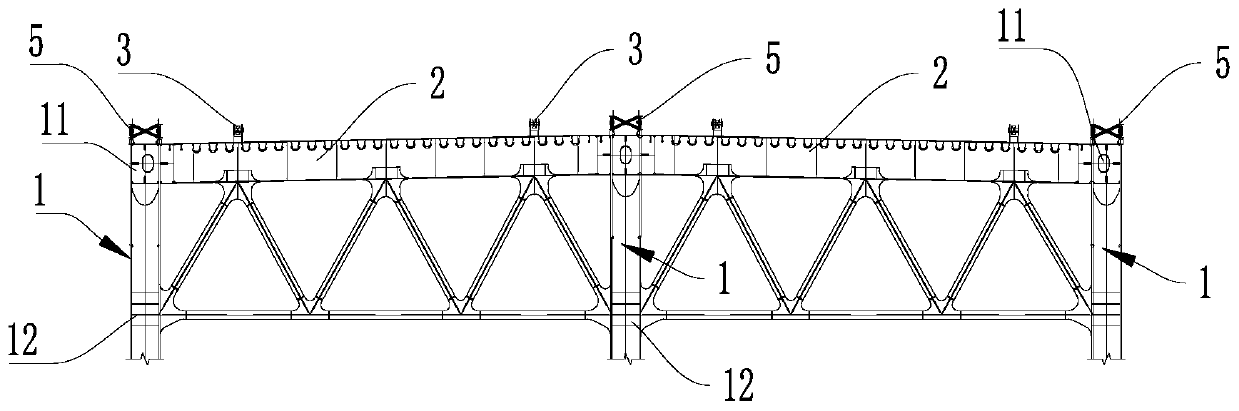

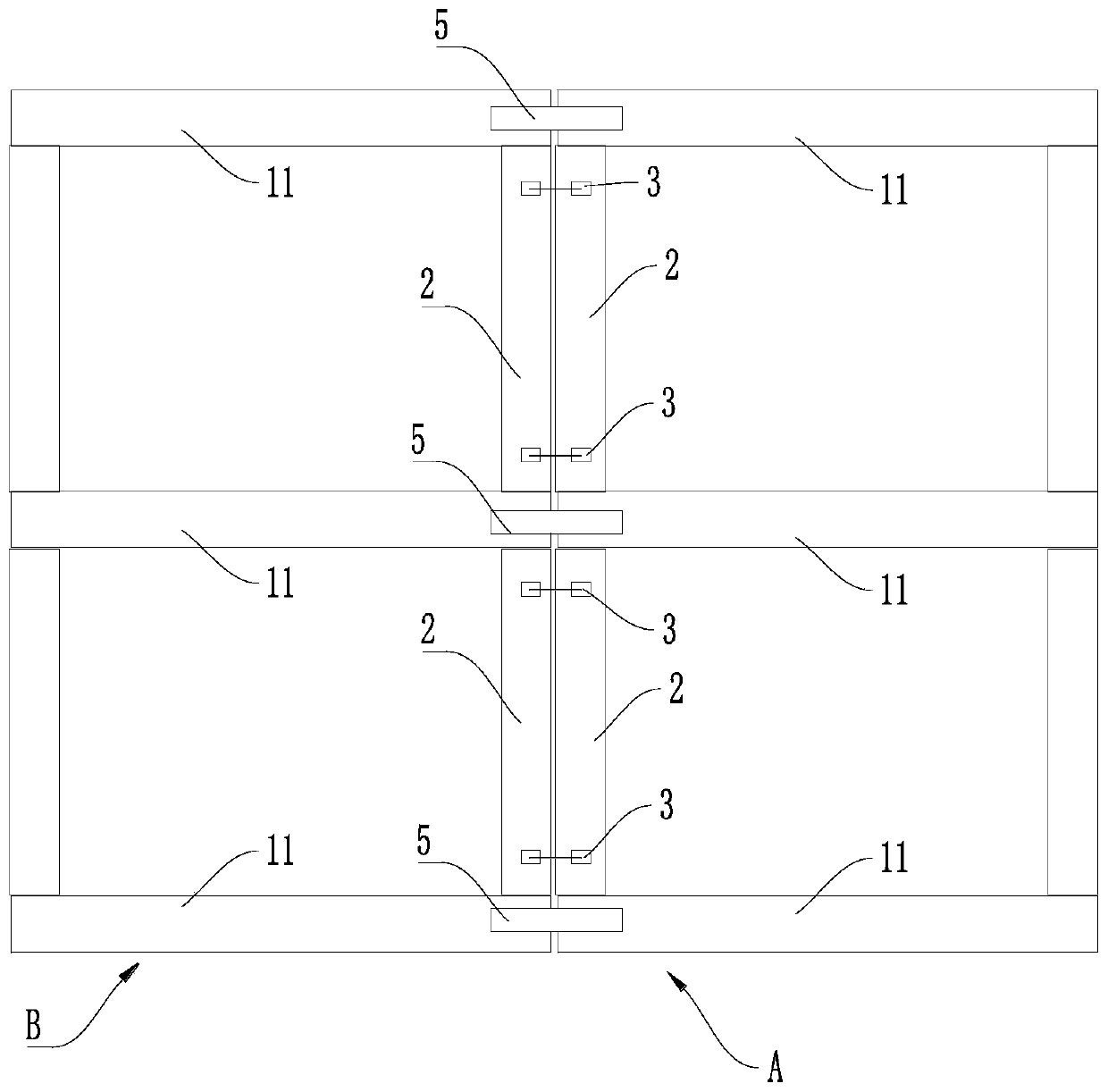

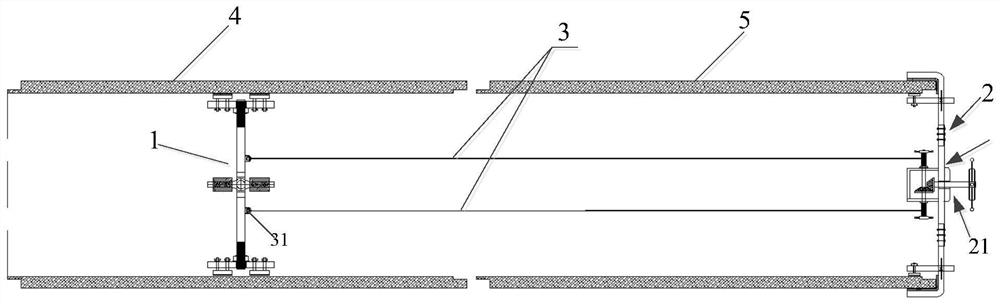

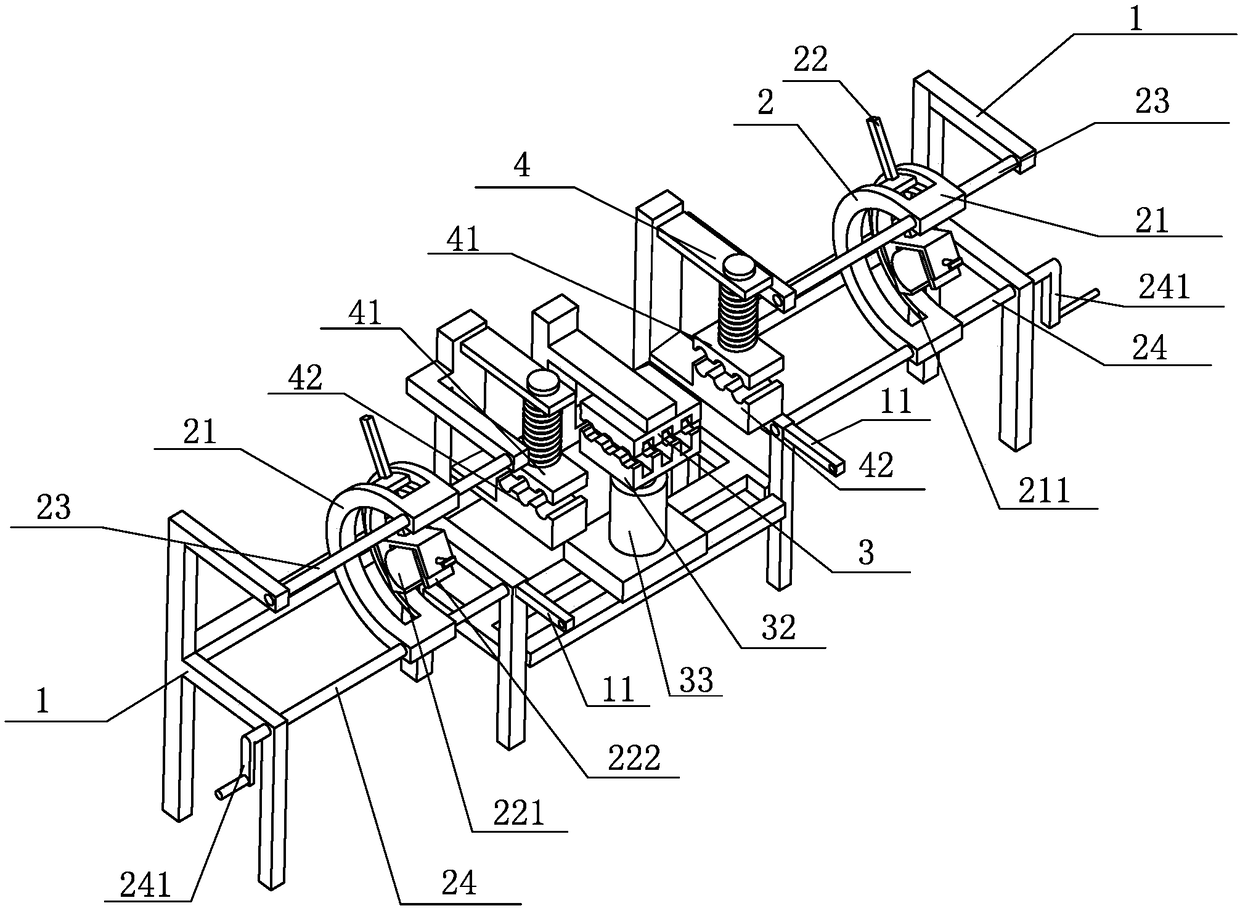

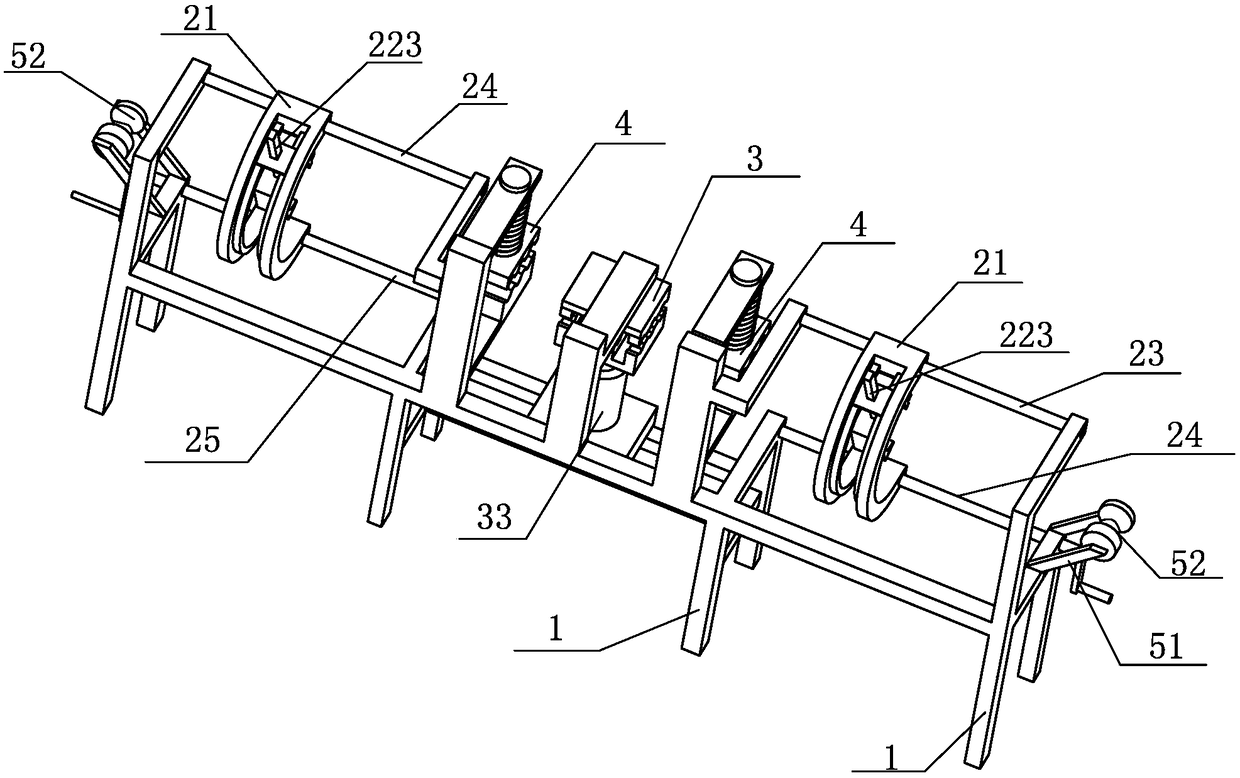

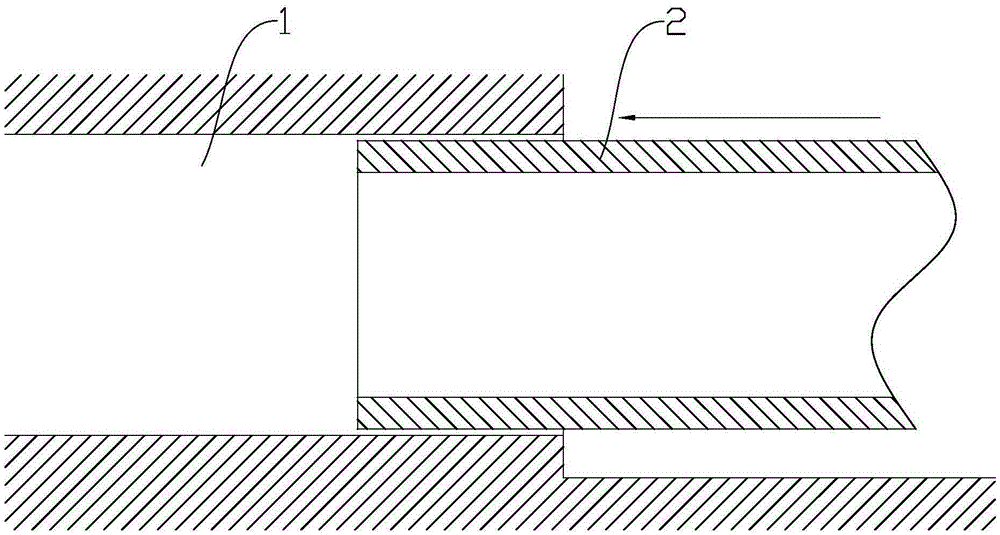

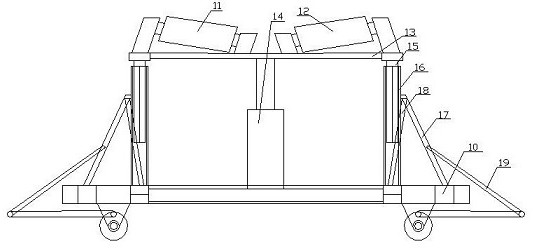

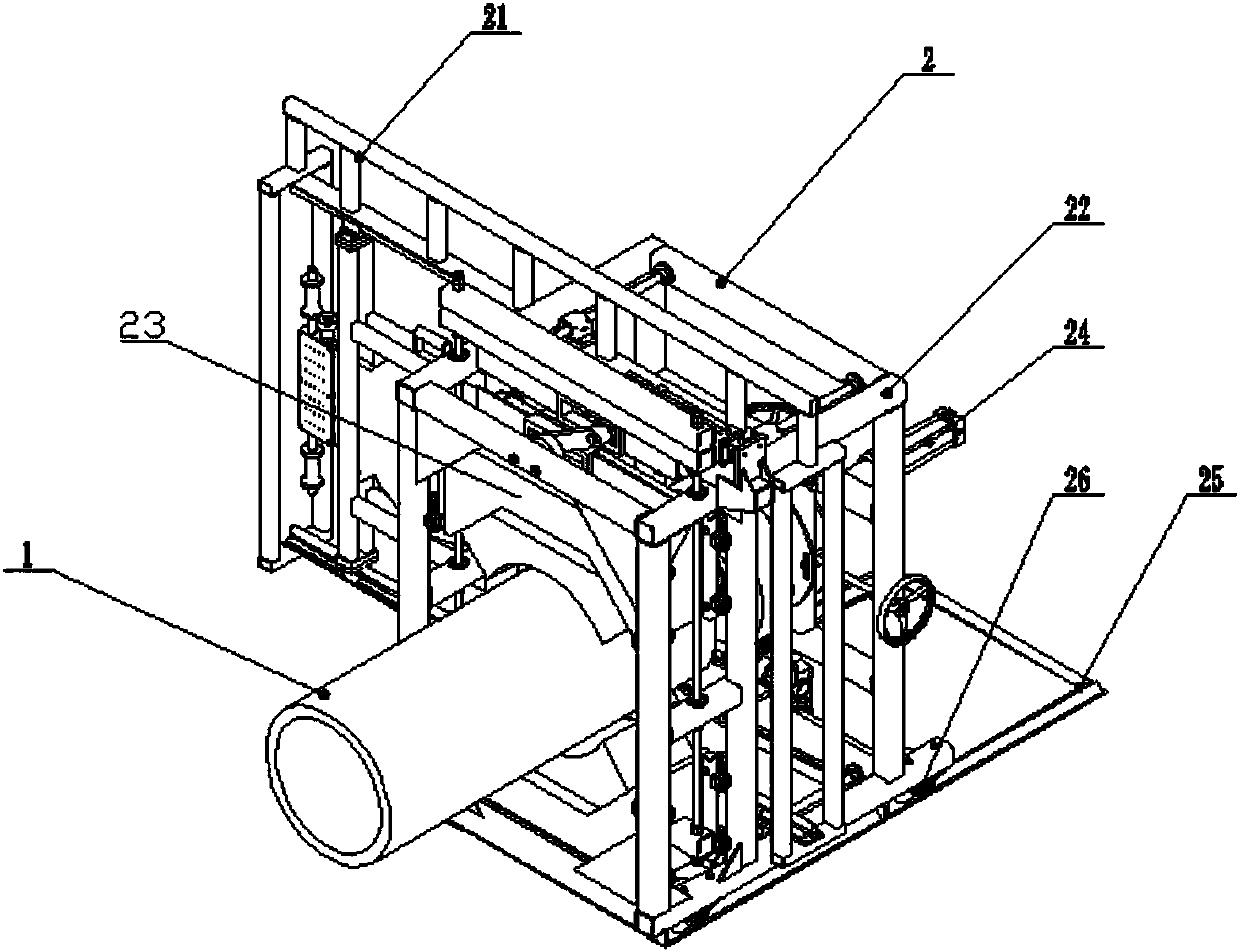

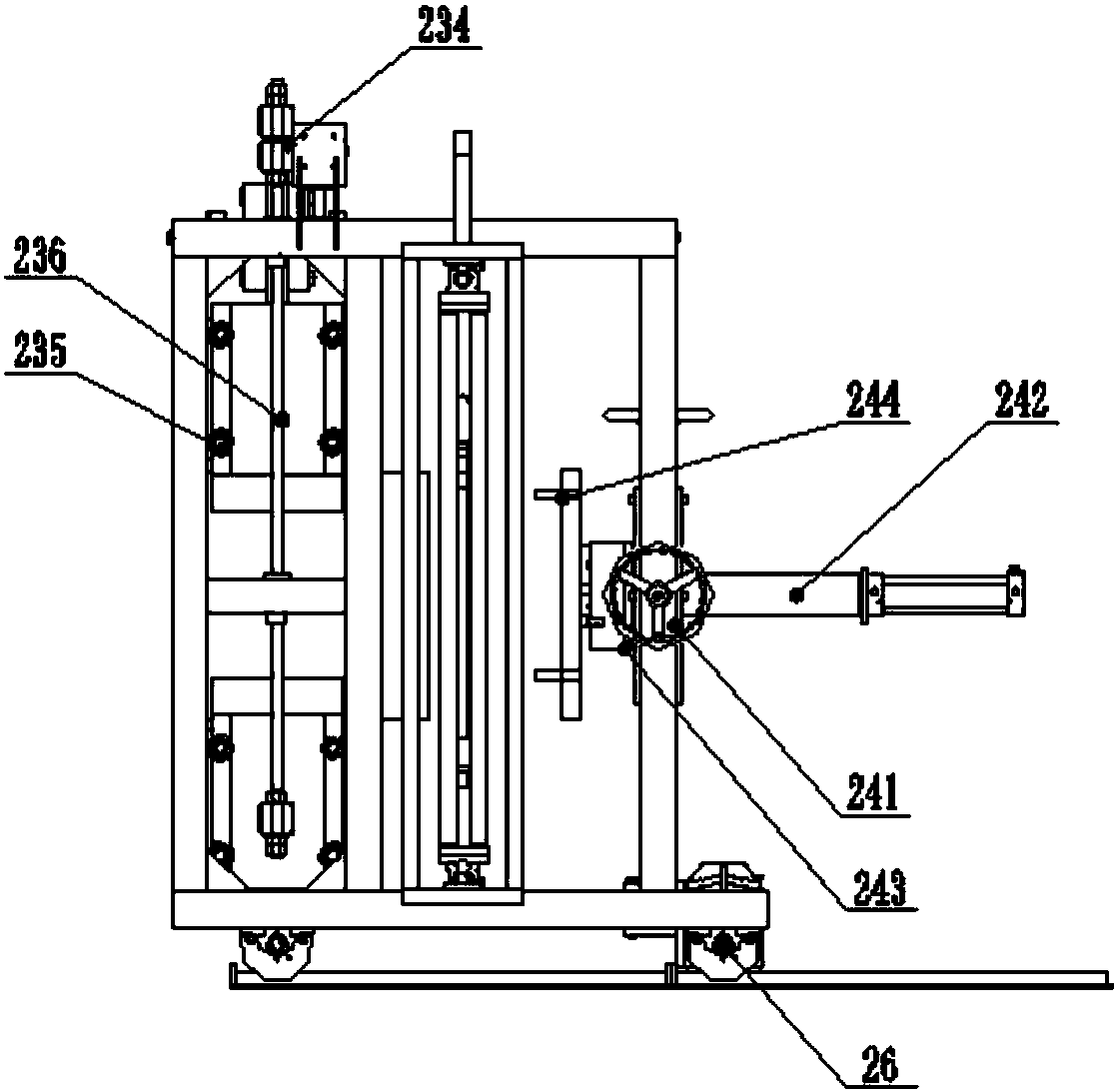

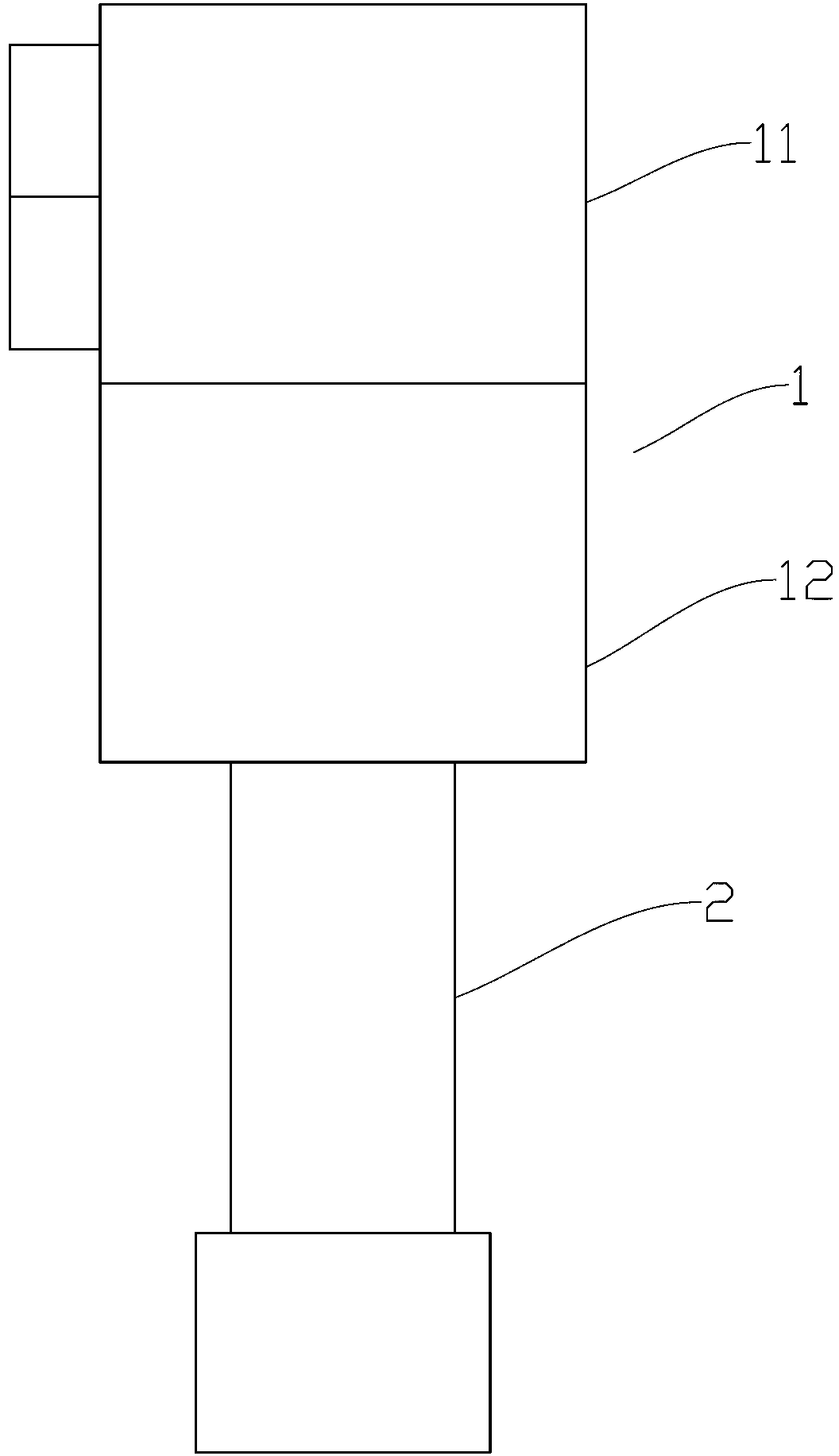

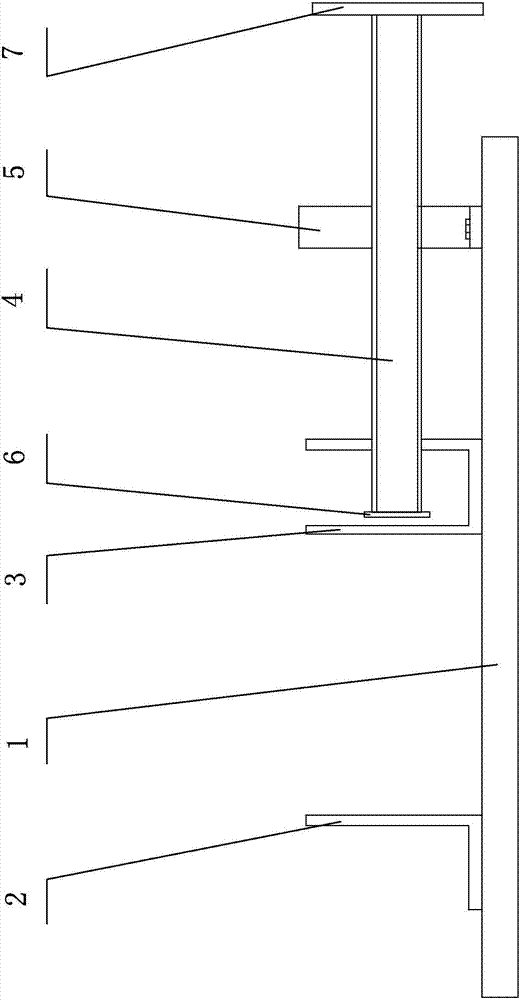

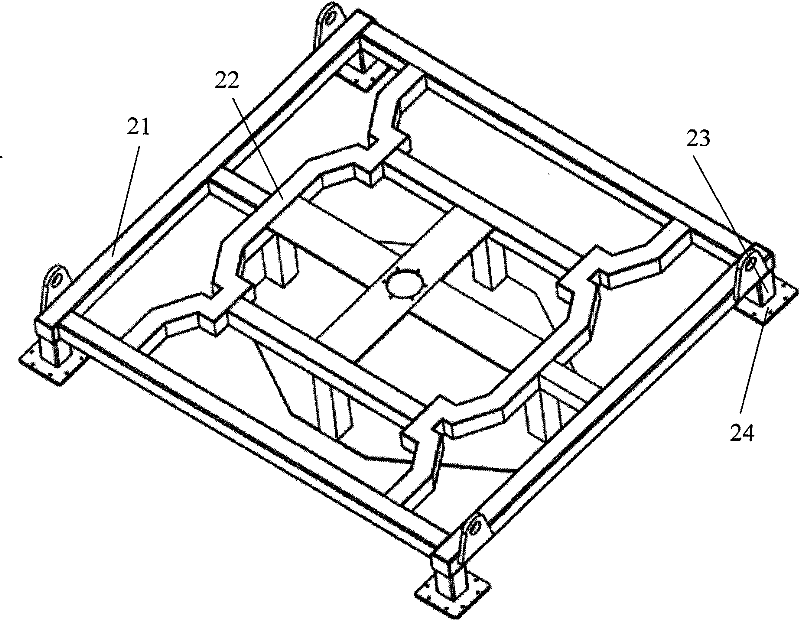

Pipeline construction device and method for pipe gallery

ActiveCN112303332AAchieve a stable connectionImprove docking qualityPipe laying and repairWelding/cutting auxillary devicesEngineeringStructural engineering

The invention relates to a pipeline construction device and method for a pipe gallery. The device comprises a down-passing device (3) for passing a pipe joint in the pipe gallery, a transfer device (1) for moving the pipe joint in the pipe gallery and an abut device (2) for clamping and positioning a welding port of the pipe joint. Through the down-passing device (3), a pipe joint track is passeddown. Through the transfer device (1), the pipe joint is transported. Through the abut device (2), stable connection of the welding port of the pipe joint is achieved, and therefore, the abutting quality of the pipeline is improved.

Owner:中铁十局集团第八工程有限公司

Welding device and welding method for socket and spigot joint of winding pipe

The invention discloses a welding device and welding method for a socket and spigot joint of a winding pipe. The device comprises a movable base and a welding device body arranged on the movable base;the welding device body comprises a heating plate device, a welding device main frame, a pipe material clamping device and a pipe fitting installing device; the heating plate device is arranged on the middle portion of the welding device main frame; the pipe material clamping device and the pipe fitting installing device are installed on the two sides of the heating plate device correspondingly;the movable base comprises sliding wheels arranged at the bottom of the welding device main frame and main frame moving guide rails in sliding connection with the sliding wheels; the main frame movingguide rails are arranged on the two side edges of the base in parallel; and the welding device body can move as a whole. According to the welding method, application is convenient, the product performance is reliable, and the welding connection quality between the winding pipe and an injection molding socket and spigot joint pipe fitting is guaranteed. The problems that during operation of a traditional welding device, frequent disassembling is needed, the center alignment difficulty is large, human power consumption for heating plate taking and assembling is large, and a large-caliber pipe material cannot be moved easily are solved.

Owner:GUANGDONG YONGGAO PLASTIC INDUSTRY DEVELOPMENT CO LTD

Reinforcement cage lifting device

The invention discloses a reinforcement cage lifting device, which comprises an upper beam, a middle beam, lower beams and an annular beam for connecting a reinforcement cage, wherein the two ends of the upper beam are fixed with a lifting lug for connecting a crane respectively; the middle beam is hinged to the center of the upper beam through a connecting shaft vertically inserted into the middle beam; the lower beams are hinged to the two ends of the middle beam through pin shafts horizontally inserted into the centers of the lower beams respectively; and the annular beam is horizontally suspended on the lower beams by corresponding suspenders. When in use, the reinforcement cage lifting device connects the reinforcement cage to the annular beam in a suspension way, and when the reinforcement cage is jointed, can conveniently drive the reinforcement cage to horizontally rotate, flexibly regulate the vertical angel of the reinforcement cage and ensure the verticality of the reinforcement cage in a jointing process to easily and rapidly finish the jointing of the reinforcement cage, increase the jointing speed of the reinforcement cage and improve the jointing quality of the reinforcement cage by hinging fit among the upper, middle and lower beams, thereby ensuring the progress and quality of pile foundation construction.

Owner:HENAN MINE CRANE

Method for butting straight bent pipe and straight pipe of long transmission line pipeline with small and medium pipe diameters in air

PendingCN113102923AConvenient docking constructionLow construction requirementsWelding/cutting auxillary devicesAuxillary welding devicesLine tubingButt joint

The invention discloses a method for butting a straight bent pipe and a straight pipe of a long transmission line pipeline with small and medium pipe diameters in air, relates to the technical field of pipeline construction, and aims to improve the construction quality and the construction efficiency and reduce the construction cost and unsafe factors at the same time. The method comprises the steps that 1, straight bent pipe sections are assembled on the ground, and welding is completed; 2, traction positioning blocks are welded to the outer sides of the bent pipe parts of the straight bent pipe sections; 3, supports are arranged, and pipe brackets are arranged on the supports; 4, the straight bent pipe sections and straight pipe sections are hoisted to the pipe brackets; and 5, chain blocks and traction steel wire ropes are used for pulling the traction positioning blocks to move pipe fittings, an operation platform is erected at the upper ends of the supports, and welding construction is conducted on the to-be-butt-jointed positions of the straight bent pipe sections and the straight pipe sections to complete air butt joint. The method is convenient to operate, safe and reliable to use and high in applicability, the construction cost and unsafe factors are reduced, and the construction quality and the construction efficiency are improved.

Owner:CHINA MCC17 GRP

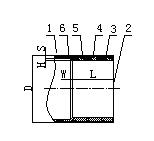

Composite type plastic pipe with wound netting wire and strengthened bell mouth and manufacturing process thereof

ActiveCN101788085AImprove performanceSave pipe wall materialsRigid pipesTubular articlesAdditive ingredientEngineering

The invention relates to a composite type plastic pipe with wound netting wires and strengthened bell mouths, and a manufacturing process thereof. The invention adopts the following technical scheme: the tube ball with a distance of the inner diameter length L to the end part of the bell mouth is a reinforced and thickened wall; the tube wall with a distance of the outer diameter length M to the end part of the bell mouth is a netting wire reinforced wall; and a viscose glue layer, a mark and a protection layer, the wall thickness S, diameter phi and outer diameter D are set according to corresponding ratios; plastic resin mulling-ingredient is utilized as the raw material; and simultaneously, products are manufactured under the synchronous control of a dryer, an extruder, a die head, a die, a vacuum box, a spraying box, a take-up winder, a high-frequency machine, a tractor, a cutter and the like. The technical scheme of the invention overcomes the defect that the axial rigidity of the existing pipe workpiece influences the axial flexibility, geology sinking resistance and tension resistance at the welding part of the bell mouth, as well as the defect that the non-roundness at the joint of the bell mouth leads the strength and rigidity at the cross section of the joint of the bell mouth of the pipe workpiece to be unable to load tubing pressure when the electrofusion pipe fittings are welded, and the like, thus being suitable for serving as connection pipe workpieces for various water delivery and gas transmission projects, and especially suitable for strengthening pipe walls and thickening the bell mouths of PE, PVC-U, PVC-M and the like.

Owner:HUNAN ZHENHUI PIPE IND

Automatic cutting and grinding integrated device for galvanized pipes

ActiveCN113352169ARealize the function of batch grindingImprove docking qualityEdge grinding machinesGrinding carriagesElectric machineSlide plate

The invention relates to an automatic cutting and grinding integrated device for galvanized pipes. The automatic cutting and grinding integrated device comprises a bottom plate, a supporting and locking mechanism and a notch grinding mechanism, and is characterized in that the supporting and locking mechanism comprises a placing table, a pressing unit, a sliding plate, a supporting frame, an adjusting and locking unit, a limiting baffle and an inner supporting unit; and the notch grinding mechanism comprises a sliding base, a lead screw, a rotating motor, a limiting disc, a grinding table, a supporting spring and a grinding unit. The problems that in the prior art, when automatic cutting treatment is conducted on galvanized pipes, a worker holds a grinding machine to grind notches mostly, batched grinding cannot be conducted on the notches, the grinding efficiency is low, end opening grinding is uneven, the smooth degree of the surfaces of the notches is affected, the notches cannot be fixed before being ground, the stability of the galvanized pipe is poor during grinding, the notch grinding precision is affected, the galvanized pipe cannot be stably supported from the inside, and the notch is prone to deformation due to heat generated by grinding are solved.

Owner:徐州市瑞泰钢管有限公司

Flattening tool for end part of corrugated pipe

A flattening tool for the end part of a corrugated pipe is characterized by comprising a first cylindrical component and a second rod-shaped component, wherein a stepped hole, formed by buckling of semi-circular grooves of a first half-cylinder and a second half-cylinder which are hinged together, is formed in the upper section of the first component; a small round through hole is positioned at the upper part of a big round through hole; the diameter of a first round hole in the lower section of the first component is equal to that of the big round through hole, and the first round hole is communicated with the big round through hole coaxially, and the lower part of the first round hole is coaxially communicated with a second round hole with small diameter; the second component comprises an internal section positioned in the first round hole, an external section positioned outside the first component, and a middle section positioned between the internal section and the external section; the diameter of the internal section is greater than that of the small round through hole in the middle upper section of the first component, and is less than that of the big round through hole in the upper section of the first component; the middle section penetrates through the second round hole of the first component and is in clearance fit with the second round hole. The flattening tool can effectively solve the out-of-flatness problem of the port of the corrugated pipe, and improve butting quality of the device, and is high in efficiency and good in flatness.

Owner:STATE GRID CORP OF CHINA +1

Mounting construction method for joining truss of pipe truss structure system

InactiveCN110629876AImprove docking qualityImprove the level of construction technologyBuilding constructionsEconomic benefitsArchitectural engineering

The invention provides a mounting construction method for a joining truss of a pipe truss structure system, and belongs to the technical field of pipe truss mounting construction. Through the form ofarranging a connecting sleeve at the end of a reinforcing rod piece, the length of the reinforcing rod piece is adjusted through extending and retracting of the connecting sleeve, and thus the problemof interference of the reinforcing rod piece and a main rod is solved; an intersecting opening is formed in one end of the connecting sleeve to be in welded connection with the main rod, the other end of the connecting sleeve and the reinforcing rod piece are subjected to girth welding, four plug welding holes are symmetrically formed in the connecting sleeve, and the plug welding holes and the reinforcing rod piece are subjected to plug welding to form welding seams. The mounting construction method has the advantages that the problem of intersecting opening interference of reinforcing rod piece mounting in a limited space is solved in the form of the fabricated connecting sleeve, and the butting quality of the reinforcing rod piece and the truss main rod is effectively improved; and inpipe truss mounting construction, the construction quality is good, the efficiency is high, economic benefits are obvious, the construction technical level of a pipe truss structure is increased, anddevelopment of the steel structure industry is promoted.

Owner:BEIJING SHOUGANG CONSTR GROUP

Drainage pipeline butt joint device and method

ActiveCN113733576AGood effectImprove docking qualityTubular articlesStructural engineeringMechanical engineering

The invention discloses a drainage pipeline butt joint device and method. According to the main technical scheme, the drainage pipeline butt joint device comprises a base, at least two sliding frames arranged on the base and a hot melting structure arranged on the base; the sliding frames are provided with positioning round rods used for limiting a pipeline in the circumferential direction and the axial direction at the same time, positioning pieces used for being fixedly connected to the pipeline are inserted into the positioning round rods in the radial direction of the pipeline, and at least one of the sliding frames is connected to the base in a sliding mode; the hot melting structure is detachably connected to the base and used for heating the end of the pipeline. The drainage pipeline butt joint device and method have the following effects that the positioning round rods are matched and connected with the positioning pieces in the inserted mode, the positioning round rods are mainly used for achieving the positioning function, the positioning pieces can limit the pipeline in the circumferential direction and the axial direction, the acting force of the positioning pieces is not in the radial direction, the possibility of pipeline deformation in the hot melting butt joint process is reduced, and the quality is improved.

Owner:CCCC FOURTH HIGHWAY ENG +1

Technology method for section steel butting and centering clamp

The invention discloses a technology method for a section steel butting and centering clamp. The manufacturing technology for the section steel butting and centering clamp includes the steps that 1, a front clamping plate and a back clamping plate are arranged on an operation platform, and the front clamping plate and the back clamping plate are a fixed plate and a movable plate respectively; 2, the fixed plate is fixedly arranged on the operation platform and the movable plate is put on the operation platform or is arranged on the operation platform by forward and rearward left and right sliding mechanisms; and 3, a transmission mechanism consisting of a screw and a nut which are combined with each other in a rotating mode is arranged on the rear part of the movable plate, and drives the movable plate to move forward and backward. The centering technology includes the steps that 1, the transmission mechanism pulls the movable plate to move backward to increase distance; 2, the section steel which needs to be butt are put between the fixed plate and the movable plate; 3, the transmission mechanism pushes the movable plate to move forward to compress and align the front part of the section steel. The technology method for the section steel butting and centering clamp can be implemented on a common operation platform, can solve problems of staggering, bending and the like during the butting process of the section steel, is suitable for various kinds of section steel, can be used repeatedly so that the cost can be reduced, and has simple and practical characteristics.

Owner:CHINA 19TH METALLURGICAL FANGCHENGGANG DEVICE STRUCTURES

Drainage pipe docking device and docking method

Owner:CCCC FOURTH HIGHWAY ENG +1

Plug connector for detection of high voltage system of electric vehicle and method of use thereof

ActiveCN108539494BIngenious and reasonable structureRealize linkageCoupling device detailsElectric carsElectric vehicle

The invention discloses an electric vehicle high-voltage system detection-used connector and a using method thereof. The electric vehicle high-voltage system detection-used connector comprises a plugging rod in plugged connection with a high-voltage power plug, a clamping block for clamping the high-voltage power plug and a linkage mechanism for enabling the plugging rod and the clamping block tobe linked, wherein the clamping block is located at the circumferential position of the plugging rod; the linkage mechanism is connected with the plugging rod and the clamping block; and the bottom end of the plugging rod is provided with a conductive plugging piece or a jack for enabling the high-voltage power plug to be plugged. Butt joint and clamping of the high-voltage power plug can be realized reliable, and the structure is reasonable and delicate.

Owner:WM MOTOR TECH GRP CO LTD

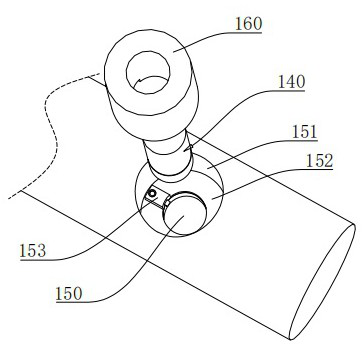

Deep water submarine pipeline axial aiming machine

InactiveCN101929583BImprove docking qualityFulfil requirementsPipe laying and repairOcean bottomEngineering

The invention provides a deep water submarine pipeline axial aiming machine, comprising a main body frame, an underwater robot connecting frame, a jointing device, clamping devices and adjusting devices; wherein the two sides of the bottom of the main body frame are provided with a foundation beam, the jointing device is respectively arranged on the foundation beams at the two sides, two cross beams opposite at the upper part of the main body frame are respectively provided with a clamping device and an adjusting device; and the upper part of the main body frame is connected with the underwater robot connecting frame. The machine clamps a new pipeline on a working mother boat, the machine and the new pipeline are dragged onto a designated H-shaped frame by an ROV, or the machine is directly dragged onto a new pipeline placed on the H-shaped frame by an ROV and then the pipeline is clamped by the clamping device, adjusting on the distance between the new pipeline and a butt pipeline and jointing operation are carried out with the coordination of a jointing tool, and meanwhile longitudinal position and transverse position of the new pipeline can be adjusted, so that the aiming accuracy of new and old pipelines can satisfy the requirement of bolt flange connection machine and deep water submarine pipeline butt quality is effectively improved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Corrugated pipe butt joint device

The invention discloses a corrugated pipe butt joint device, which comprises an upper permanent seat, a lower permanent seat, an upper supporting seat, a lower supporting seat and a butt joint buckling mechanism, wherein the butt joint buckling mechanism comprises an upper buckle and a lower buckle; the lower permanent seat, the lower supporting seat and the lower buckle are rotatably provided with the upper permanent seat, the upper supporting seat and the upper buckle through the same smooth bar; one end of an upper lead screw is rotatably connected with the upper permanent seat, and the other end rotatably penetrates through the upper buckle and the upper supporting seat to be fixedly connected with an upper driven belt pulley; one end of a lower lead screw is rotatably connected with the lower permanent seat, and the other end rotatably penetrates through the lower buckle and the lower supporting seat to be fixedly connected with a lower driven belt pulley; the upper driven belt pulley and the lower driven belt pulley are connected with the same driving belt pulley through one belt; the upper permanent seat, the upper supporting seat and the upper buckle are simultaneously opened and buckled independently relative to the lower permanent seat, the lower supporting seat and the lower buckle; the upper permanent seat and the lower permanent seat form a fixed groove; the uppersupporting seat and the lower supporting seat form a supporting groove; and the upper buckle and the lower buckle form a clamping groove. According to the corrugated pipe butt joint device, a corrugated pipe is evenly stressed to prevent from being damaged, and butt joint quality is high.

Owner:CHINA RAILWAY CONSTR ENG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com