Tunnel steel arch frame butt joint fine adjusting device

A technology of fine-tuning device and steel arch frame, which is applied in tunnels, tunnel linings, shaft equipment and other directions, can solve the problems of hidden quality problems of I-beam butt joints, difficult butt joints of end faces and I-beam jointing difficulties, etc., so as to improve the fine-tuning of jointing. Efficiency, light weight, the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structure of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but it is not intended as a limitation of the present invention.

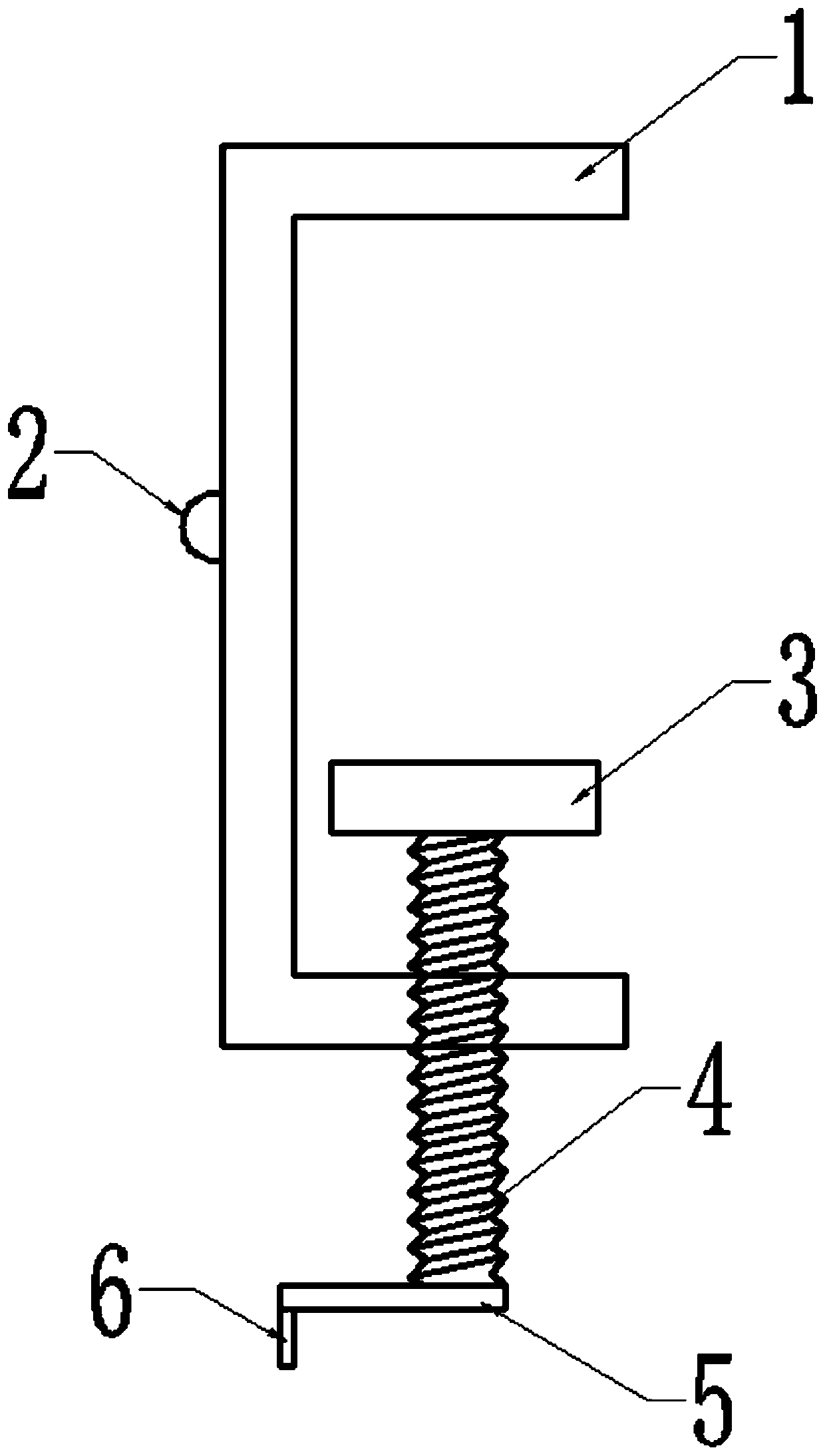

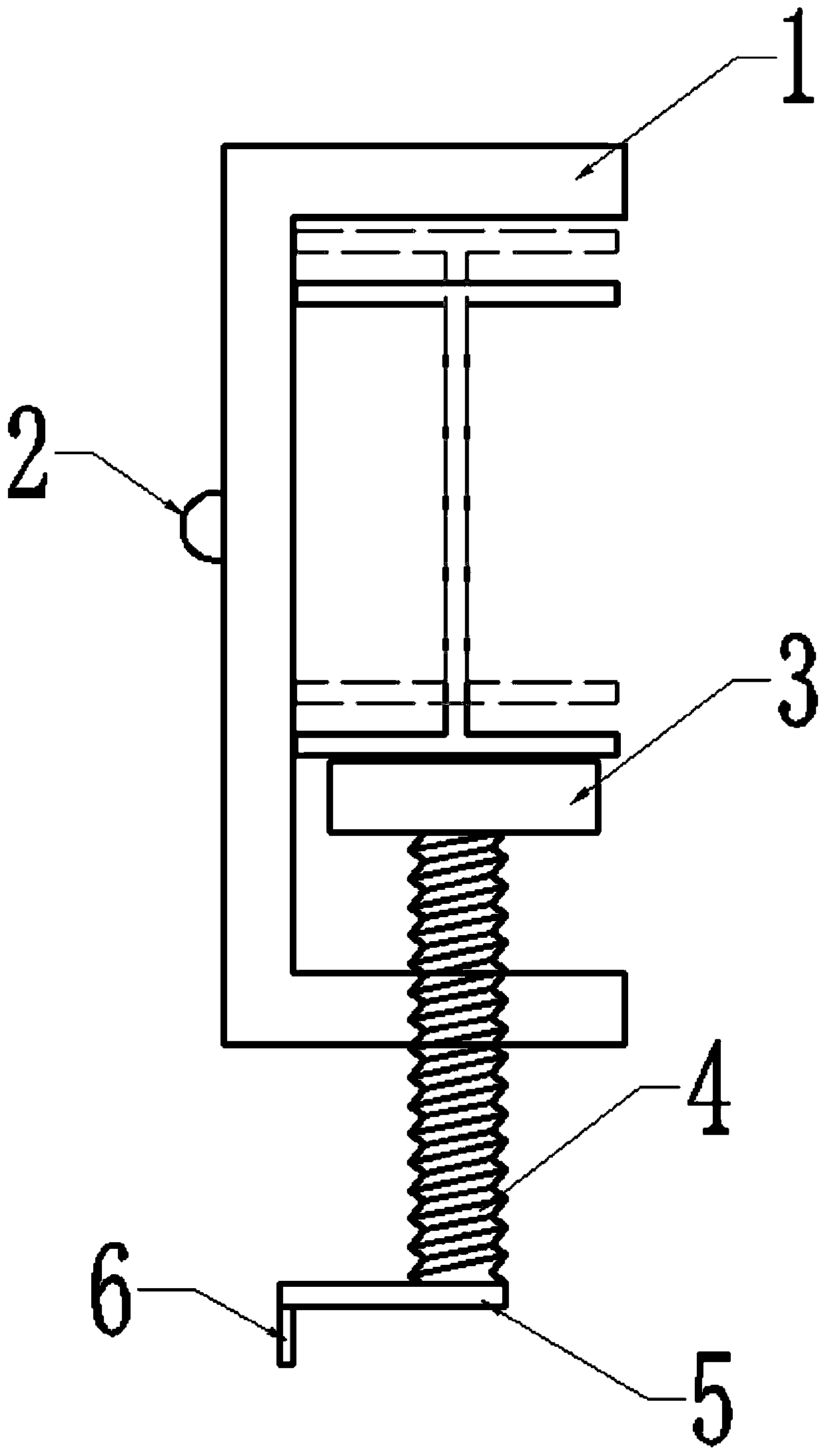

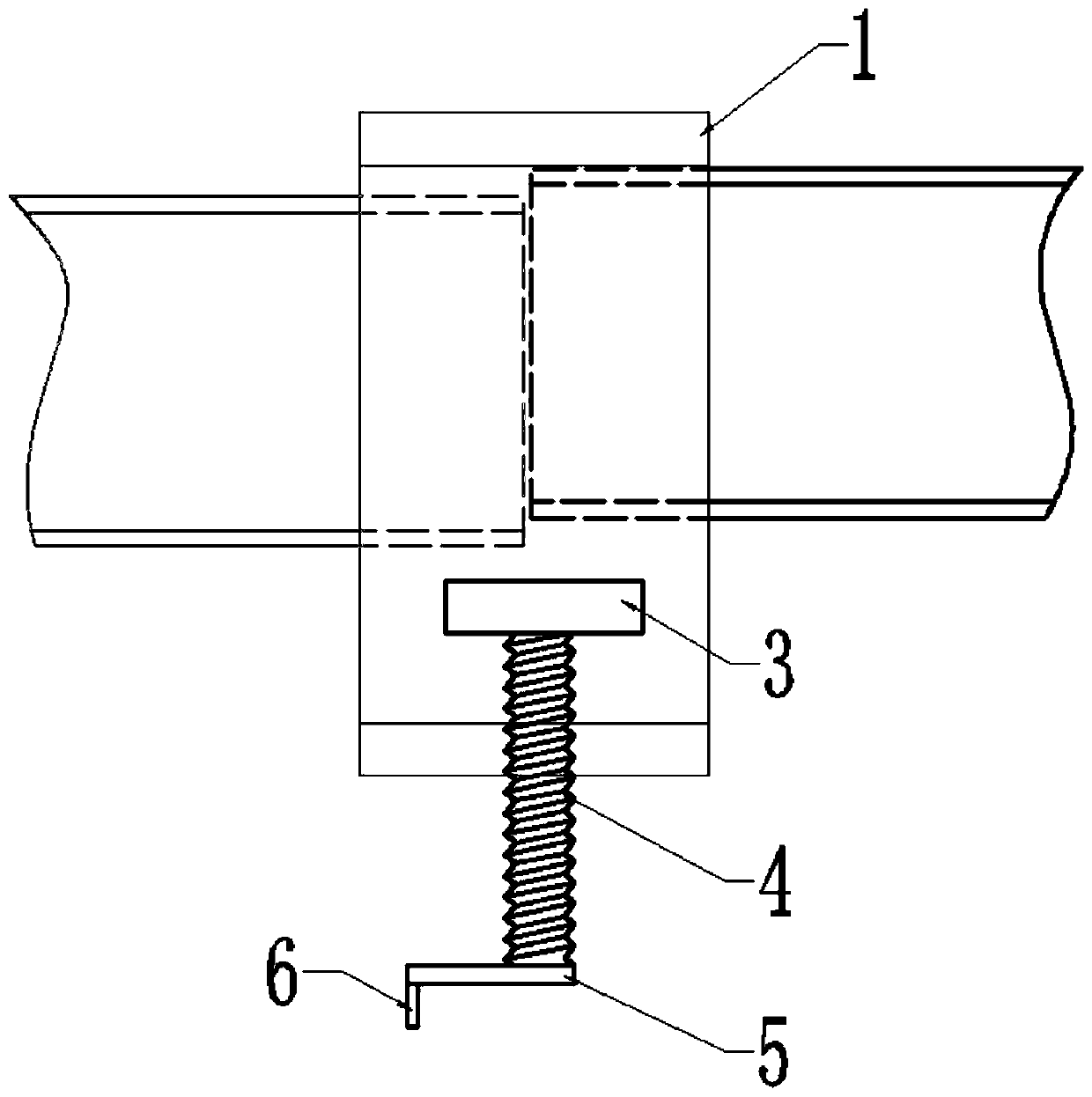

[0020] Such as Figure 1~3 As shown, the present invention discloses a docking fine-tuning device for tunnel steel arches. Specifically, the docking fine-tuning device includes: a U-shaped card slot 1, a clamping steel plate 3, a fine-tuning screw 4, and a handle; the U-shaped card slot 1 includes Top plate, bottom plate and the side plate that top plate and bottom plate are connected together, and the central position of this bottom plate is provided with the threaded hole that matches with fine-tuning screw rod 4; The internal thread of the external thread and the threaded hole is matched and positioned), and the end of the fine-tuning screw 4 positioned above the base plate is fixed with a top tight steel plate 3, and the end of the fine-tuning screw 4 position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com