Mounting construction method for joining truss of pipe truss structure system

A construction method and pipe truss technology, which can be applied in building construction and construction, etc., can solve the problems of poor installation quality and the interference of the installation of supplementary rods, and achieve good construction quality, improve docking quality, and promote development. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

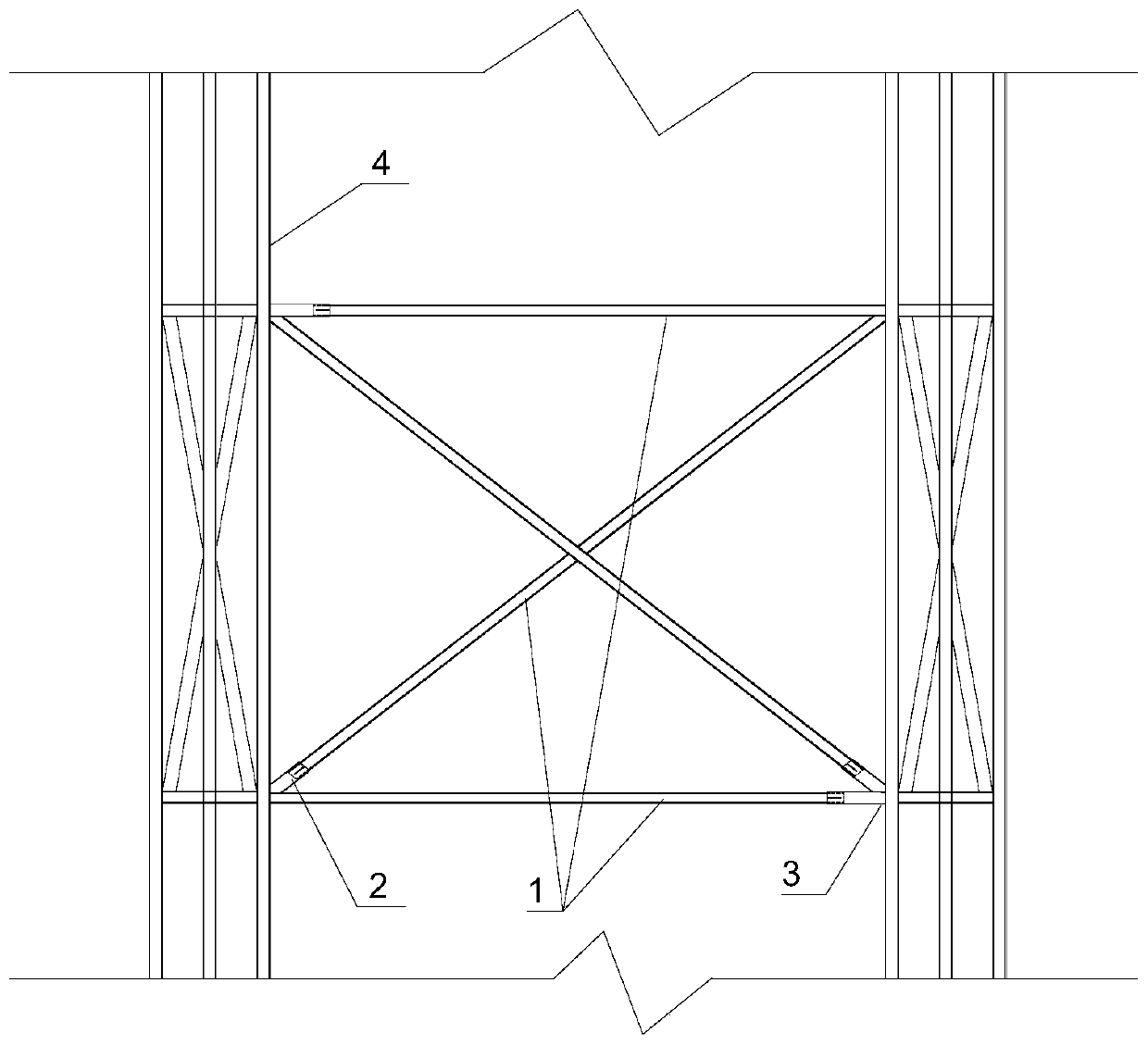

[0014] The specific embodiment of the present invention adopts following steps construction:

[0015] Specific steps are as follows:

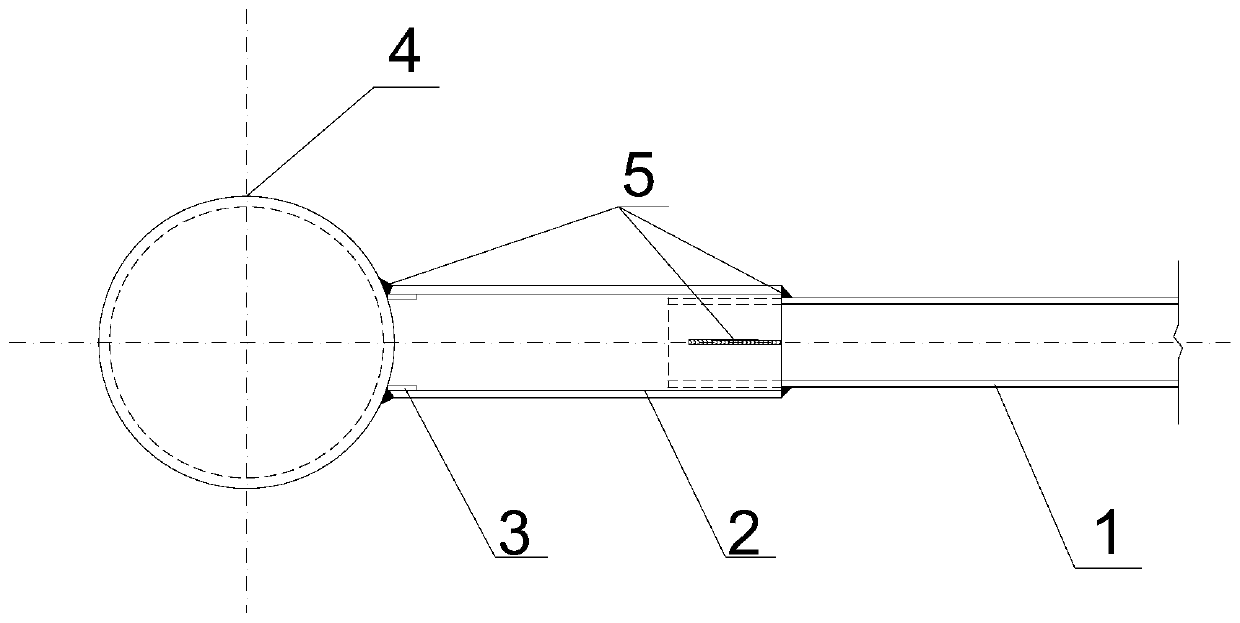

[0016] 2. Process the supplementary rod part 1, one end of the supplementary rod part 1 is processed into an intersecting opening, the other end is a straight opening, and a liner 3 is added on the side of the intersecting opening.

[0017] 2. Processing connecting sleeve 2: one end of the connecting sleeve 2 is processed into a joint and a gasket 3 is added on the side of the joint, and the other end is processed into a straight joint and four plug welding holes are symmetrically arranged on this side.

[0018] 3. Assemble the supplementary rod 1 and the connecting sleeve 2. The end of the supplementary rod 1 is provided with a plug-in connection form of the connecting sleeve 2, and the length of the supplementary rod 1 is adjusted through the expansion and contraction of the connection sleeve 2, so as to solve the problem of interference bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com